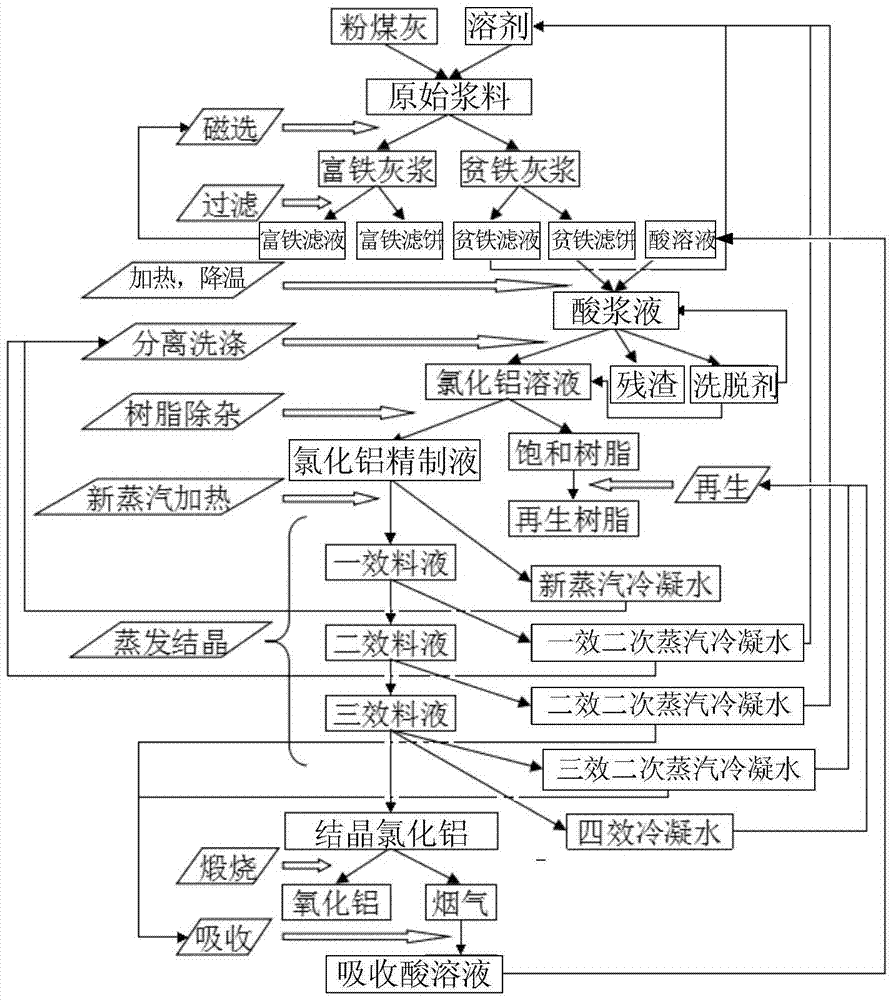

Method for producing aluminum oxide from coal ash through acid process

A technology of fly ash and alumina, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of waste of water resources and achieve the effects of relieving pressure, reducing water consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Into the fly ash according to 2.5m 3 / t fly ash ratio plus water to prepare the original slurry, enter the magnetic separation system with 0.3m 3 / t Fly ash flushing water washes down the iron-rich mortar, and the iron-rich mortar is filtered to obtain an iron-rich filter cake and an iron-rich filtrate, of which the iron-rich filtrate is 0.3m 3 / t Fly ash is returned to continue to be used as flushing water, and the iron-poor mortar after magnetic separation is also filtered to obtain iron-poor filter cake and iron-poor filtrate, wherein the iron-poor filtrate is 3 The amount of / t fly ash is returned to the original slurry, and the first-effect secondary steam condensate is 0.95m 3 The amount of fly ash per ton and the condensed water of the second-effect secondary steam are respectively set at 0.05m 3 The amount of / t fly ash is used to supplement the preparation of the original slurry.

[0053] Put the iron-poor filter cake in an acid-resistant reaction kettle, ad...

Embodiment 2

[0058] Into the fly ash according to 2.83m 3 / t fly ash ratio plus water to prepare the original slurry, enter the magnetic separation system with 0.5m 3 / t Fly ash flushing water washes down the iron-rich mortar, and the iron-rich mortar is filtered to obtain iron-rich filter cake and iron-rich filtrate, of which the iron-rich filtrate is 0.5m 3 / t Fly ash returns to continue to be used as flushing water, and the iron-poor mortar after magnetic separation is also filtered to obtain iron-poor filter cake and iron-poor filtrate, in which the iron-poor filtrate is 2.16m 3 The amount of / t fly ash is returned to the original slurry, and the condensate of the first effect and the second steam is 0.16m 3 The amount of fly ash per ton and the condensed water of the secondary steam of the second effect are respectively set at 0.51m 3 The amount of / t fly ash is used to supplement the preparation of the original slurry.

[0059] Put the iron-poor filter cake in an acid-resistant re...

Embodiment 3

[0064] Into the fly ash according to 3.0m 3 The proportion of / t fly ash is added with water to prepare the original slurry, and the dosage for entering the magnetic separation system is 0.7m 3 / t Fly ash flushing water washes down the iron-rich mortar, and the iron-rich mortar is filtered to obtain iron-rich filter cake and iron-rich filtrate, of which the iron-rich filtrate is 0.7m 3 / t Fly ash is returned to continue to be used as flushing water, and the iron-poor mortar after magnetic separation is also filtered to obtain iron-poor filter cake and iron-poor filtrate, of which the iron-poor filtrate is 2.36m 3 The amount of / t fly ash is returned to the original slurry, and the first-effect secondary steam condensate is 0.02m 3 The amount of fly ash per ton and the condensed water of the second-effect secondary steam are respectively set at 0.62m 3 The amount of / t fly ash is used to supplement the preparation of the original slurry.

[0065] Put the iron-poor filter cak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com