Aluminum oxide ceramic metallization method used for brazing

A technology of alumina ceramics and metallization, which is applied in the field of metallization of alumina ceramics in the indirect brazing method, can solve the problems of poor metallization effect, high cost, and high equipment requirements, and achieve reduced metallization costs, fewer procedures, and simplified The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the process steps of the alumina ceramic metallization method for brazing are as follows:

[0026] (1) Al 2 o 3 Polycrystalline alumina ceramics with a mass percentage of 95% (commonly known as 95% alumina ceramics) are washed in a detergent obtained by mixing 2.5g NaOH and 100mL hydrogen peroxide for 15 minutes to remove the oil stains adhering to the surface, and then ultrasonically cleaned with deionized water for 20 minutes and then baked. Drying, place the dried 95% alumina ceramics in a box-type resistance furnace, heat-preserve and sinter at 1100°C for 60 minutes to remove volatile organic matter and moisture;

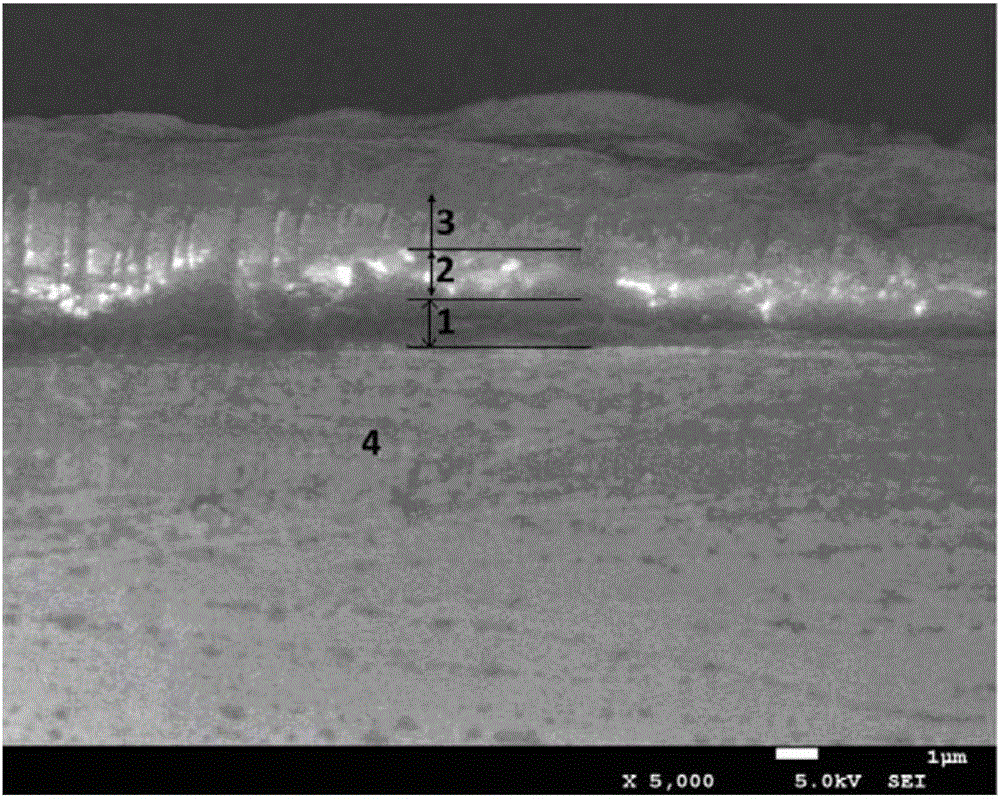

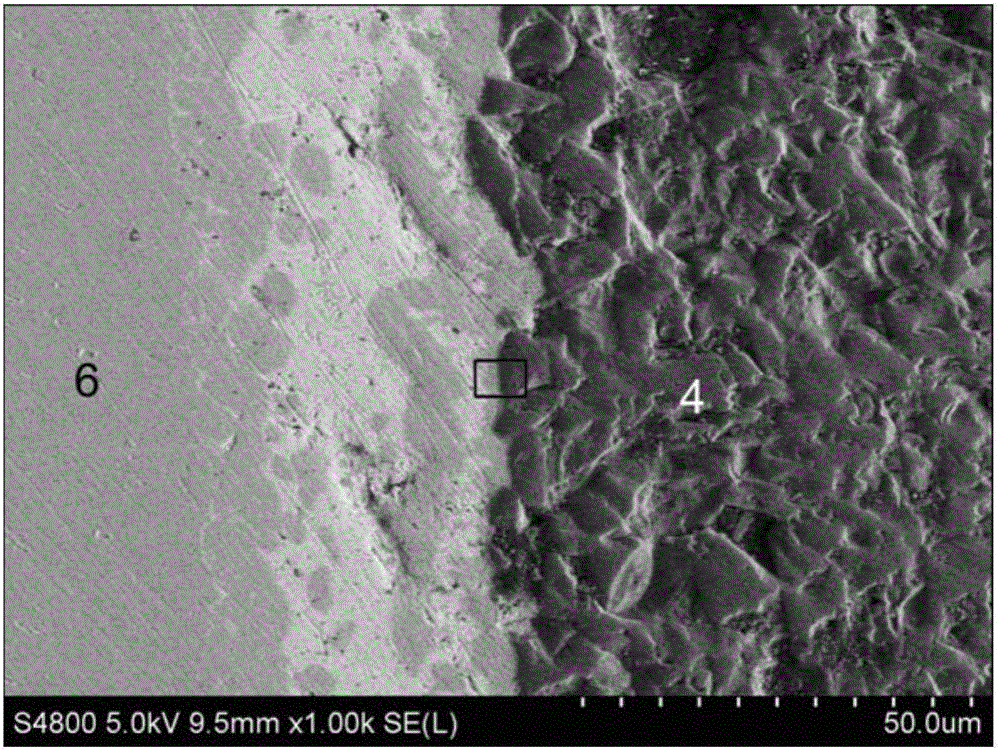

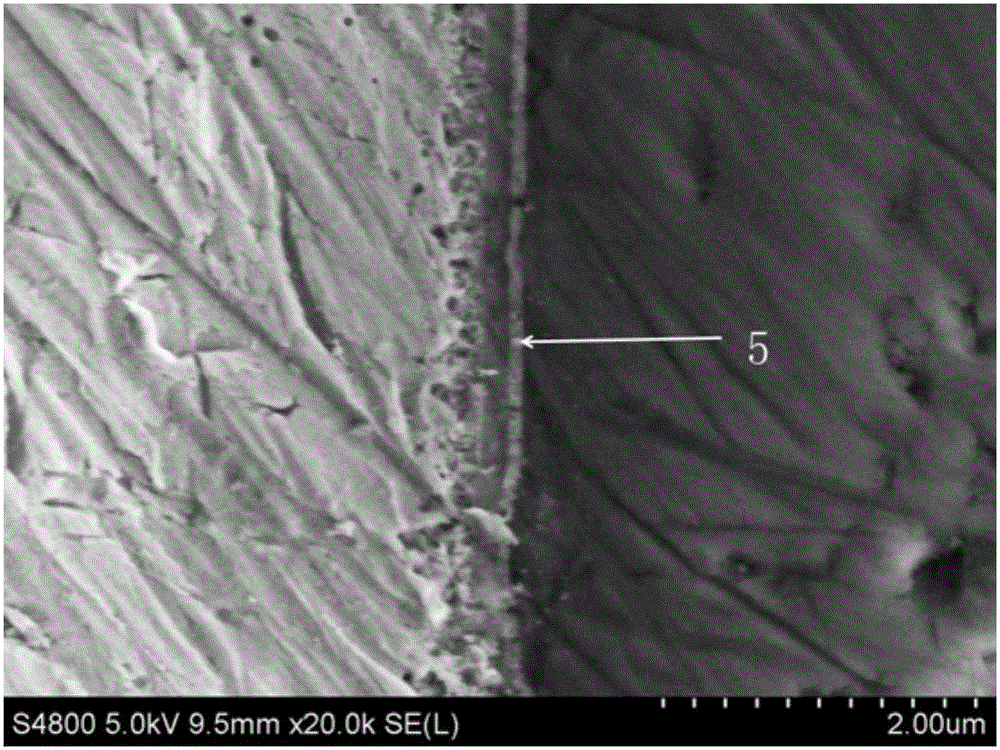

[0027] (2) Place the JTZ-800 type intermediate frequency magnetron sputtering coating with Ti target, Mo target and Ni target after covering the part of the surface that does not need to deposit a metal layer with aluminum foil for the 95% alumina ceramics obtained in step (1) In the vacuum coating chamber of the machine, vacuumize t...

Embodiment 2

[0034] In this embodiment, the process steps of the alumina ceramic metallization method for brazing are as follows:

[0035] (1) Al 2 o 3 Polycrystalline alumina ceramics with a mass percentage of 95% (commonly known as 95% alumina ceramics) are washed in a detergent obtained by mixing 2.5g NaOH and 100mL hydrogen peroxide for 15 minutes to remove the oil stains adhering to the surface, and then ultrasonically cleaned with deionized water for 20 minutes and then baked. Drying, put the dried polycrystalline alumina ceramics in a box-type resistance furnace, heat-preserve and sinter at 1200°C for 50 minutes to remove volatile organic matter and moisture;

[0036] (2) Cover the 95% alumina ceramics sintered in step (1) with aluminum foil to cover the part of the surface that does not need to deposit a metal layer, and then place it in the JTZ-800 type medium frequency magnetron sputtering device with Zr target, Cr target and Ni target In the vacuum coating chamber of the spray...

Embodiment 3

[0043] In this embodiment, the process steps of the alumina ceramic metallization method for brazing are as follows:

[0044] (1) Al 2 o 3 Alumina ceramics with a mass percentage of 97% (commonly known as 97% alumina ceramics) are washed in a detergent obtained by mixing 2.5g NaOH and 100mL hydrogen peroxide for 10 minutes to remove the oil stains adhering to the surface, and then ultrasonically cleaned with deionized water for 20 minutes and then dried. Place the dried 97% alumina ceramics in a box-type resistance furnace, heat-preserve and sinter at 1000°C for 70 minutes to remove volatile organic matter and moisture.

[0045] (2) Cover the 97% alumina ceramics sintered in step (1) with aluminum foil to cover the part of the surface that does not need to deposit a metal layer, and then place it in the vacuum of IGBT type high-frequency induction evaporation coating equipment (produced by Xi'an Taixin Electromechanical Equipment Co., Ltd.) chamber substrate, and place metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com