Preparation method of anhydrous aluminum chloride

A technology of anhydrous aluminum chloride and aluminum ore, which is applied in the direction of aluminum chloride and aluminum halide, can solve the problems of complex anhydrous aluminum chloride process, etc., and achieve easy industrial large-scale production, easy-to-obtain raw materials, and low-cost raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

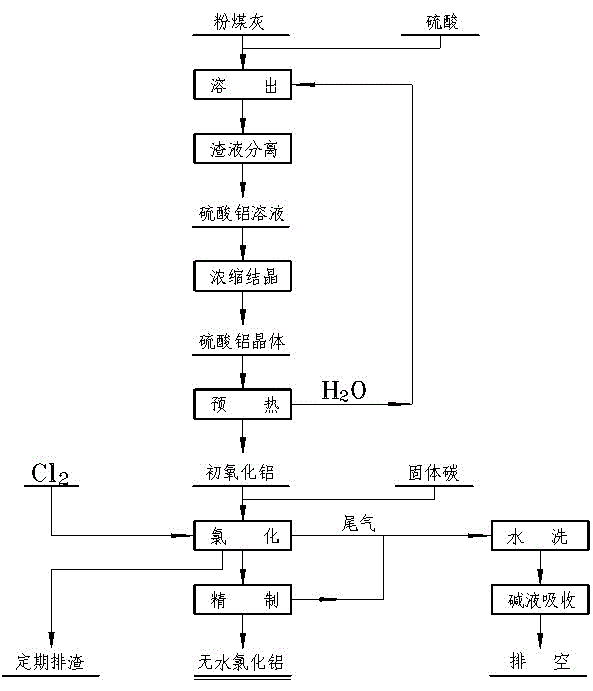

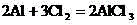

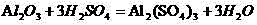

[0034] A method for preparing anhydrous aluminum chloride, using fly ash (containing more than 25% of the mass fraction of alumina) or aluminous ore (such as bauxite, coal gangue, etc. containing more than 25% of the mass fraction of alumina) as raw materials, The aluminum sulfate solution is obtained by leaching with sulfuric acid, and after concentration and crystallization, aluminum sulfate crystals are obtained; the aluminum sulfate crystals are preheated at a temperature higher than 80°C for more than 30 minutes to remove crystal water to obtain aluminum sulfate. Mix aluminum sulfate with solid carbon (petroleum coke, activated carbon, calcined coke, charcoal or coal coke, etc.) and use a quantitative screw feeder to make the molar ratio of solid carbon to aluminum sulfate greater than 3.5 and then add the mixture at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com