Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

A high-alumina fly ash and activated calcium silicate technology, applied in chemical instruments and methods, alumina/hydroxide preparation, silicate, etc., can solve problems such as difficult technology control, small market share, complex equipment, etc. , to achieve the effects of increasing economic and social value, reducing the amount of slag, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

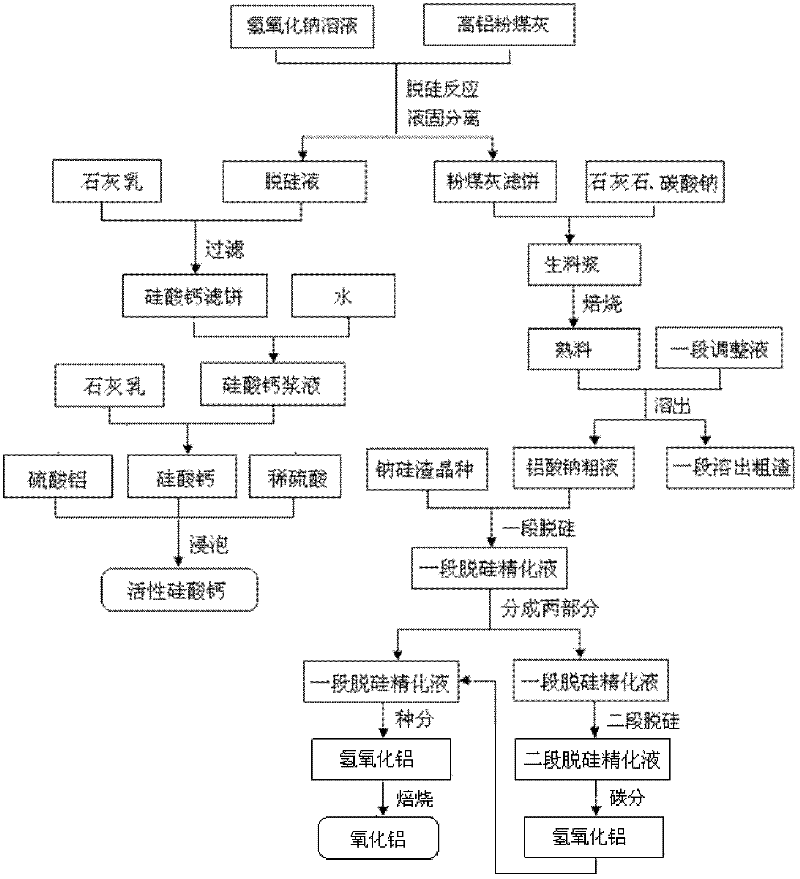

[0037] figure 1 The production process flowchart that provides for the embodiment of the present invention one, as figure 1 It can be seen that the method for producing alumina and co-producing active calcium silicate with high-alumina fly ash provided in this embodiment comprises the following steps:

[0038] 1), pre-desilication, after heating the mixed solution composed of high-alumina fly ash and 20% sodium hydroxide solution (the mass ratio of sodium hydroxide to high-alumina fly ash is 0.5:1) to 110°C , introduced into a pressure-resistant container for desiliconization reaction for 2 hours, and then liquid-solid separation to obtain liquid-phase desiliconization liquid and solid-phase fly ash filter cake. The ratio of aluminum to silicon in the fly ash filter cake is higher than that before the desilication reaction High aluminum fly ash; the mass content of alumina in high aluminum fly ash is higher than 40%;

[0039] 2), the preparation of active calcium silicate, c...

Embodiment 2

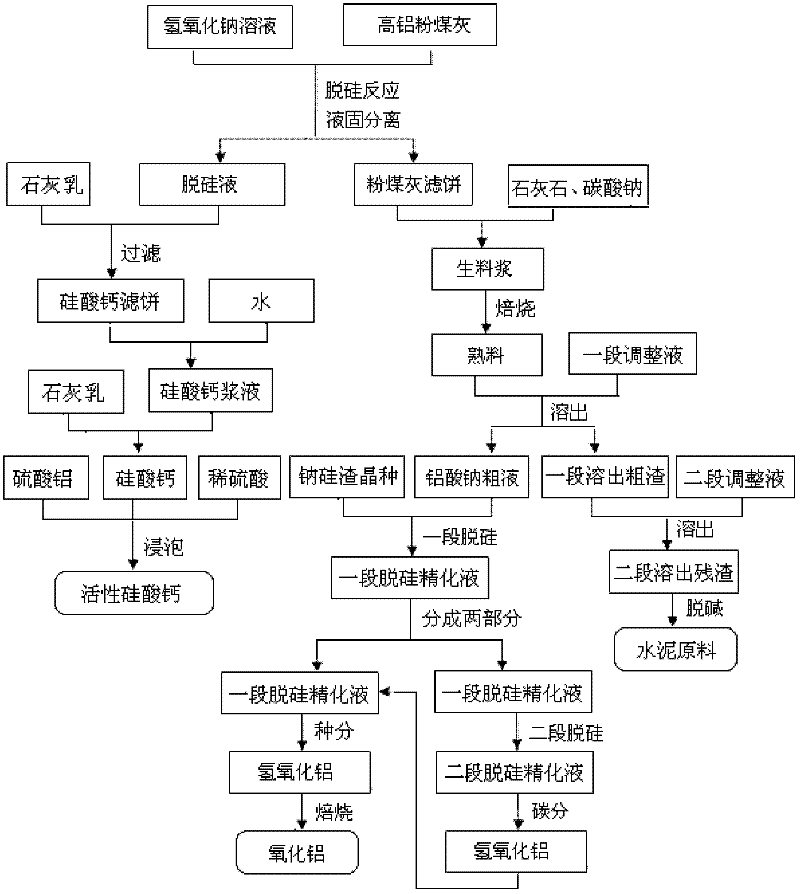

[0046] figure 2 The production process flowchart that provides for the embodiment of the present invention two, as figure 2 As shown, the method for producing alumina and co-producing active calcium silicate with high alumina fly ash provided in this embodiment comprises the following steps:

[0047] 1), pre-desiliconization, the mixed solution (the mass ratio of sodium hydroxide solution and high aluminum fly ash is 0.6:1) of high alumina fly ash and 10% sodium hydroxide solution is heated to 130 °C Afterwards, it is introduced into the insulation retention tank for desiliconization reaction for 2.5 hours, and then liquid-solid separation is carried out after depressurization from the evaporator to obtain the desiliconization liquid of the liquid phase and the desiliconization fly ash filter cake of the solid phase, wherein the former fly ash The aluminum-silicon ratio is 1.15, which rises to 2.12 after desiliconization, and SiO in the desilication solution 2 The concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com