Method for simultaneously extracting aluminum oxide from coal ash and red mud

A technology of fly ash and alumina, which is applied in the field of extracting alumina from fly ash and red mud at the same time, can solve the problems of difficult utilization of fly ash, difficulty of red mud utilization, and high cost, so as to reduce the extraction cost , Improve the ratio of aluminum to silicon, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

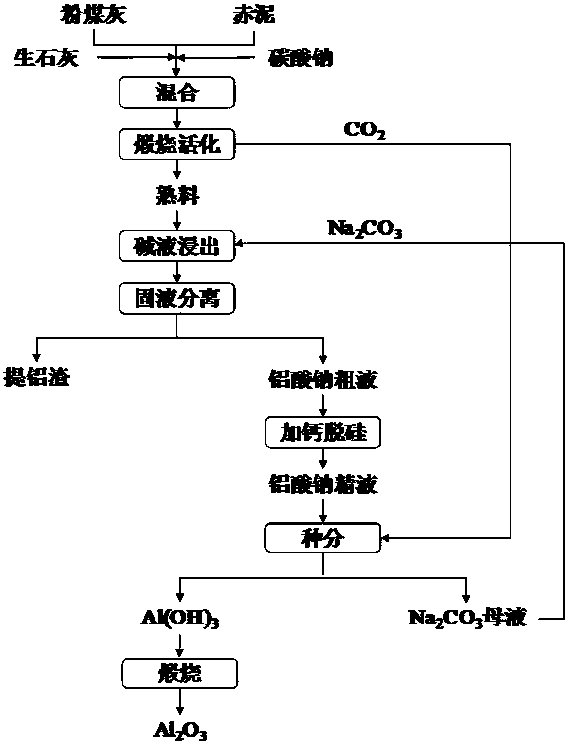

Image

Examples

Embodiment 1

[0032] In this embodiment, the content of alumina in fly ash is 32.94%, the content of silica is 40.91%, the content of alumina in red mud is 24.20%, and the content of silica is 17.60%. The specific process is as follows:

[0033] (1) Ingredients: Mix and grind fly ash, red mud, quicklime and sodium carbonate evenly in a certain proportion, so that the ratio of aluminum to silicon is 1:1, Na 2 O / Al 2 o 3 The ratio is 1:1, CaO / SiO 2 The ratio is 2:1;

[0034] (2) Calcination activation: calcining the mixed material at 1000°C for 120min;

[0035] (3) Alkali leaching: After the calcined clinker is ground, it is leached with 3% sodium carbonate solution, leached for 30 minutes at a temperature of 70°C, and solid-liquid separation is obtained to obtain crude sodium aluminate liquid, and the filter residue is washed three times, and the leaching rate of alumina in the filtrate is collected 90.65%;

[0036] (4) After desiliconization by adding calcium to the crude solution of s...

Embodiment 2

[0039] In this embodiment, the content of alumina in fly ash is 35.69%, the content of silica is 43.09%, the content of alumina in red mud is 21.26%, and the content of silica is 16.60%. The specific process is as follows:

[0040] (1) Ingredients: Mix and grind fly ash, red mud, quicklime and sodium carbonate evenly in a certain proportion, so that the ratio of aluminum to silicon is 0.9:1, Na 2 O / Al 2 o 3 The ratio is 1.2:1, CaO / SiO 2The ratio is 2.2:1;

[0041] (2) Calcination activation: calcining the mixed material at 1200°C for 150min;

[0042] (3) Alkali leaching: After grinding the calcined clinker, leaching with 5% sodium carbonate solution, leaching at 80°C for 60 minutes, separating solid and liquid to obtain crude sodium aluminate liquid, washing the filter residue three times, collecting the leaching rate of alumina in the filtrate 93.64%;

[0043] (4) After desiliconization by adding calcium to the crude solution of sodium aluminate, the CO 2 The gas is pas...

Embodiment 3

[0046] In this embodiment, the content of alumina in fly ash is 38.04%, the content of silica is 42.91%, the content of alumina in red mud is 25.90%, and the content of silica is 19.68%. The specific process is as follows:

[0047] (1) Ingredients: Mix and grind fly ash, red mud, quicklime and sodium carbonate evenly in a certain proportion, so that the ratio of aluminum to silicon is 1.1:1, Na 2 O / Al 2 o 3 The ratio is 0.5:1, CaO / SiO 2 The ratio is 2.5:1;

[0048] (2) Calcination activation: Calcinate the mixed material at 900°C for 100min;

[0049] (3) Alkali leaching: After grinding the calcined clinker, leaching with 6% sodium carbonate solution, leaching at 60°C for 40 minutes, separating solid and liquid to obtain crude sodium aluminate liquid, washing the filter residue three times, collecting the leaching rate of alumina in the filtrate 89.16%;

[0050] (4) After adding calcium to desiliconization of sodium aluminate crude solution, CO 2 The gas is passed into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com