Process of removing silicon from low-grade bauxite by adopting chemical floatation method

A chemical flotation, bauxite technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of high production cost, complex production process, poor comprehensive benefit, etc., achieve simple method, easy operation, and improve the ratio of aluminum to silicon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

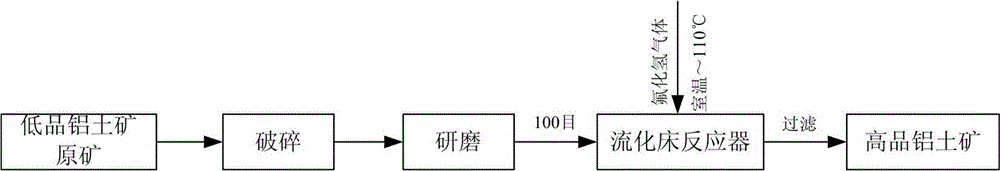

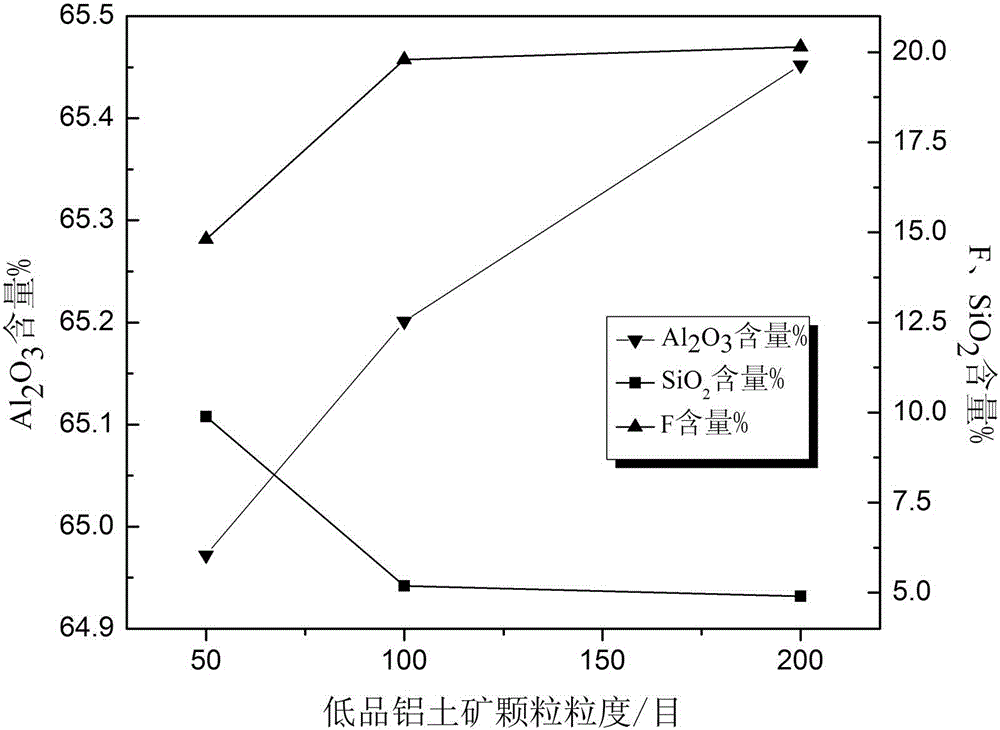

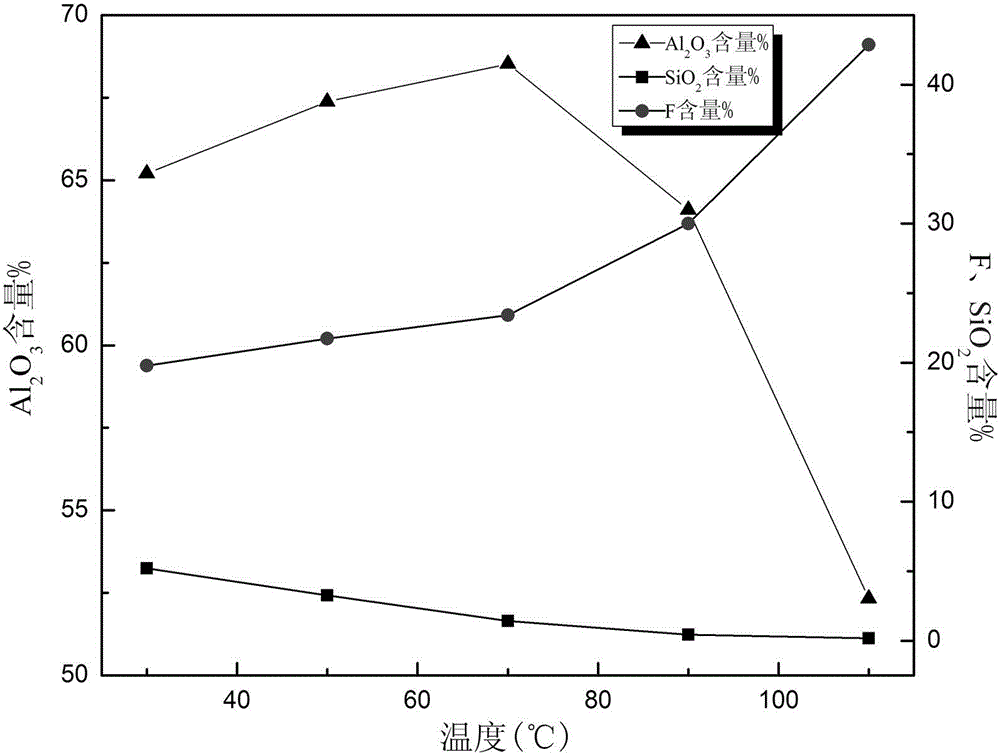

[0019] see figure 1 , the first embodiment of the present invention provides a process for removing silicon from low-grade bauxite by chemical flotation, comprising the following steps: providing low-grade bauxite raw ore as shown in Table 1, and placing it in Crushing in a crusher, and then placing the crushed low-grade bauxite in a grinder for grinding to obtain a particle size of 100 mesh low-grade bauxite particles; take 10.00 g of the 100 mesh low-grade bauxite particles In the fluidized bed reactor, hydrogen fluoride gas was passed into the fluidized bed reactor at 110°C, and reacted for 30 minutes to obtain a desiliconized solid residue; wash and filter the desiliconized solid residue with 80°C water to obtain 6.969 g high-grade bauxite products. X-ray fluorescence analysis method is used to analyze and know: SiO in high-grade bauxite products 2 content of 0.18%, the removal rate of silicon is 99.61%, the content of fluorine is 42.89%, Al 2 o 3 The content is 52.33%...

Embodiment 2

[0023] The second embodiment of the present invention provides a process for removing silicon from low-grade bauxite by chemical flotation, which differs from the first embodiment in that:

[0024] The reaction temperature of the low-grade bauxite particles and hydrogen fluoride gas is 70°C, react for 15 minutes to obtain a desiliconized solid residue, and sequentially wash and dry the desiliconized solid residue with 85°C water to obtain 5.400g of high-grade bauxite product . X-ray fluorescence analysis method is used to analyze and know: SiO in high-grade bauxite products 2 content of 1.41%, the removal rate of silicon is 97.65%, the content of fluorine is 23.41%, Al 2 o 3 The content is 68.53%.

Embodiment 3

[0026] The third embodiment of the present invention provides a process for removing silicon from low-grade bauxite by chemical flotation, which differs from the first embodiment in that:

[0027] The reaction temperature of the low-grade bauxite particles and hydrogen fluoride gas was 20°C, and the desiliconization solid residue was obtained after reacting for 20 minutes. The desiliconization solid residue was successively washed with water at 90°C and dried to obtain 5.410 g of high-grade bauxite product. X-ray fluorescence analysis method is used to analyze and know: SiO in high-grade bauxite products 2 content of 5.19%, the removal rate of silicon is 91.33%, the content of fluorine is 19.80%, Al 2 o 3 The content is 65.20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com