Method of recovering fluorine resource in process of processing low-grade bauxite by chemical floatation method

A chemical flotation and bauxite technology, applied in the directions of alumina/aluminum hydroxide, ammonium halide, silicon oxide, etc., can solve the problems of resource and energy consumption, improve the recovery rate, reduce the cost, and the treatment process is simple and easy row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

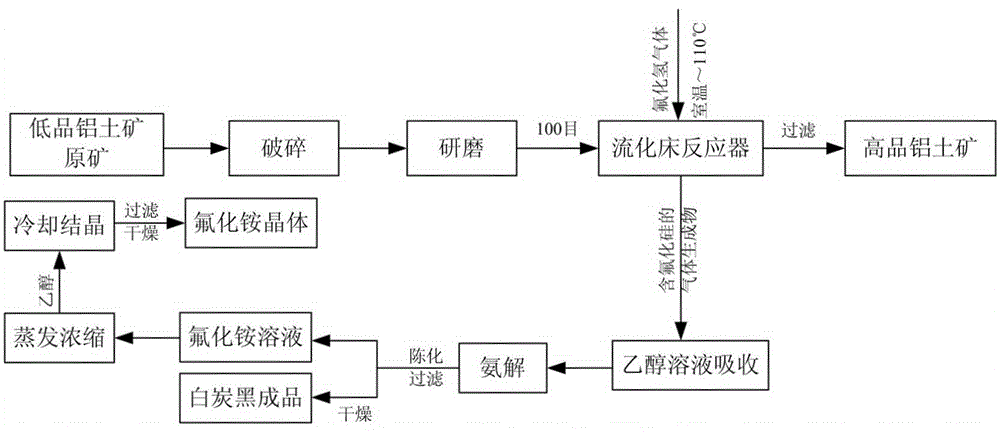

[0031] see figure 1 , the first embodiment of the present invention provides a method for recovering fluorine resources from the chemical flotation process for processing low-grade bauxite, comprising the following steps:

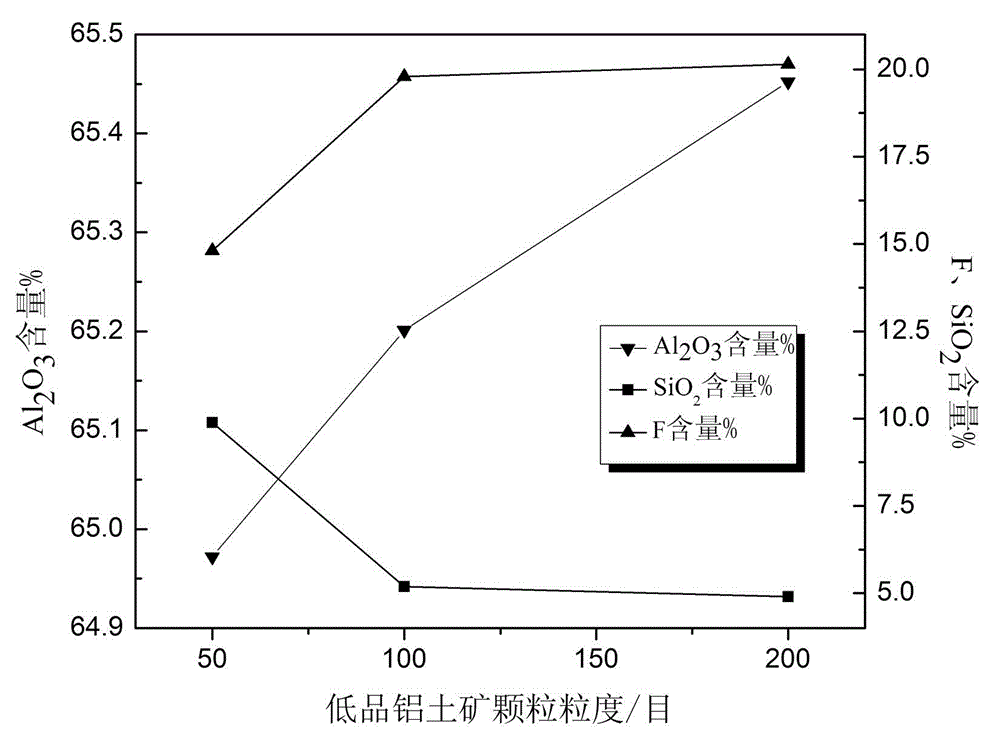

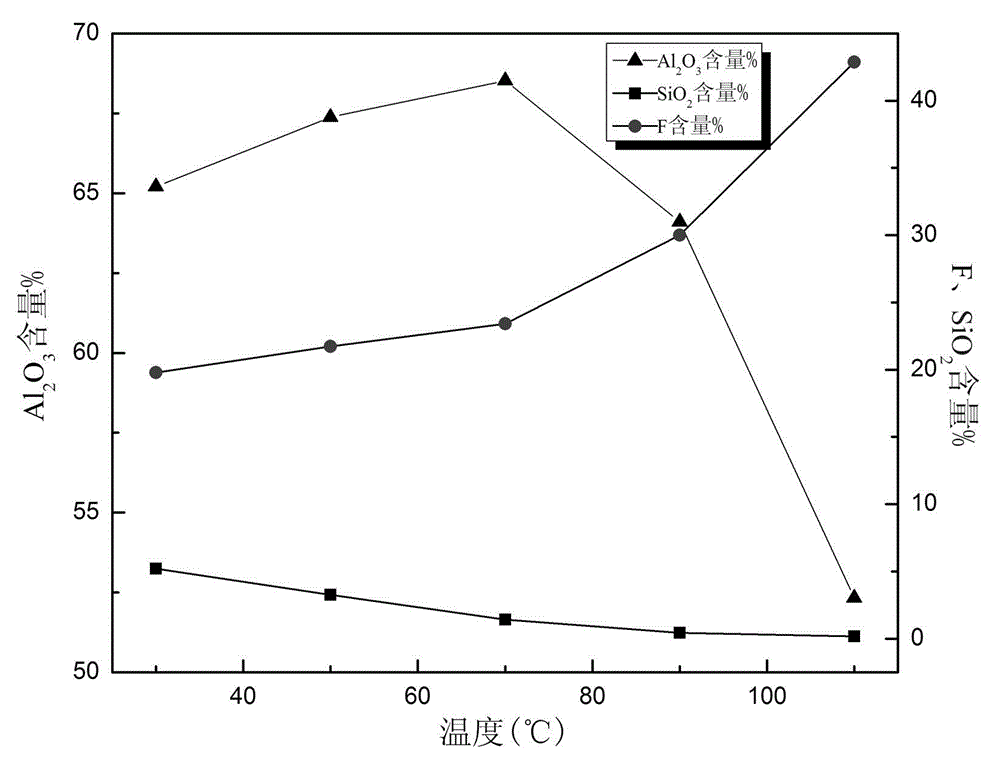

[0032]Chemical flotation silicon removal: provide low-grade bauxite raw ore as shown in Table 1, and place it in a crusher for crushing, then place the crushed low-grade bauxite in a grinder for grinding to obtain The particle size is 100 mesh low-grade bauxite particles; take 10.00 g of the 100 mesh low-grade bauxite particles and place them in a fluidized bed reactor, and pass hydrogen fluoride gas into the fluidized bed reactor at 110 ° C, After reacting for 30 minutes, a desiliconized solid residue and a gas product containing silicon fluoride were obtained; the desiliconized solid residue was washed with water and filtered to obtain 6.969 g of high-grade bauxite product. X-ray fluorescence analysis method is used to analyze and know: SiO in high-grade...

Embodiment 2

[0038] The second embodiment of the present invention provides a process for removing silicon from low-grade bauxite by chemical flotation, which differs from the first embodiment in that:

[0039] In the step of removing silicon by chemical flotation, the reaction temperature of the low-grade bauxite particles and hydrogen fluoride gas is 70° C., and the reaction takes 15 minutes to obtain 5.400 g of high-grade bauxite product. X-ray fluorescence analysis method is used to analyze and know: SiO in high-grade bauxite products 2 content of 1.41%, the removal rate of silicon is 97.65%, the content of fluorine is 23.41%, Al 2 o 3 The content is 68.53%.

[0040] In the step of gas absorption ammonolysis, the gas product is passed into the absorption tower at -4kPa, the gas product is hydrolyzed at 80°C, and the ammonolysis neutralizes the content in the ammonolysis tank The pH was 8 and aged at 80°C for 1.5 hours.

[0041] In the step of recovering fluorine resources, the fluo...

Embodiment 3

[0043] The third embodiment of the present invention provides a process for removing silicon from low-grade bauxite by chemical flotation, which differs from the first embodiment in that:

[0044] In the step of removing silicon by chemical flotation, the reaction temperature of the low-grade bauxite particles and hydrogen fluoride gas is 20° C., and the reaction takes 20 minutes to obtain 5.410 g of high-grade bauxite product. X-ray fluorescence analysis method is used to analyze and know: SiO in high-grade bauxite products 2 content of 5.19%, the removal rate of silicon is 91.33%, the content of fluorine is 19.80%, Al 2 o 3 The content is 65.20%.

[0045] In the step of gas absorption ammonolysis, the gas product is passed into the absorption tower at -5kPa, the gas product is hydrolyzed at 78°C, and the ammonolysis neutralizes the content of the ammonolysis tank The pH was 8 and aged at 78°C for 2 hours.

[0046] In the step of recovering fluorine resources, the fluorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com