Method for coating high-nickel ternary material with aluminum oxide and boron oxide

A high-nickel ternary material, coated alumina technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of long sintering equipment, poor cycle performance, cumbersome process, etc., to shorten the production cycle and reduce the return The effect of fire temperature and streamlining process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] 3) Preparation of dry material: separating the solid and liquid of the suspension coated with alumina, and drying the obtained solid material to obtain a dry material;

[0033] 4) Coating of boron oxide: the dry material is mixed with a boron-containing compound, and then sintered to obtain a finished product of high-nickel ternary material coated with alumina and boron oxide;

[0034] The composition of the high-nickel ternary material is LiNi 0.8 co x mn y o 2 , where 0

[0035] Preferably, the content of coated Al per 1 kg of high-nickel ternary material is 0.05-2 g, and the content of coated B is 0.5-2 g; more preferably, the content of coated Al per 1 kg of high-nickel ternary material is 1-1.7 g, the content of coating B is 0.9-1.1 g.

[0036] Preferably, the composition of the high-nickel ternary material is LiNi 0.8 co 0.1 mn 0.1 o 2 , namely NCM811.

[0037] Further, the high-nickel ternary material is a high-nickel base m...

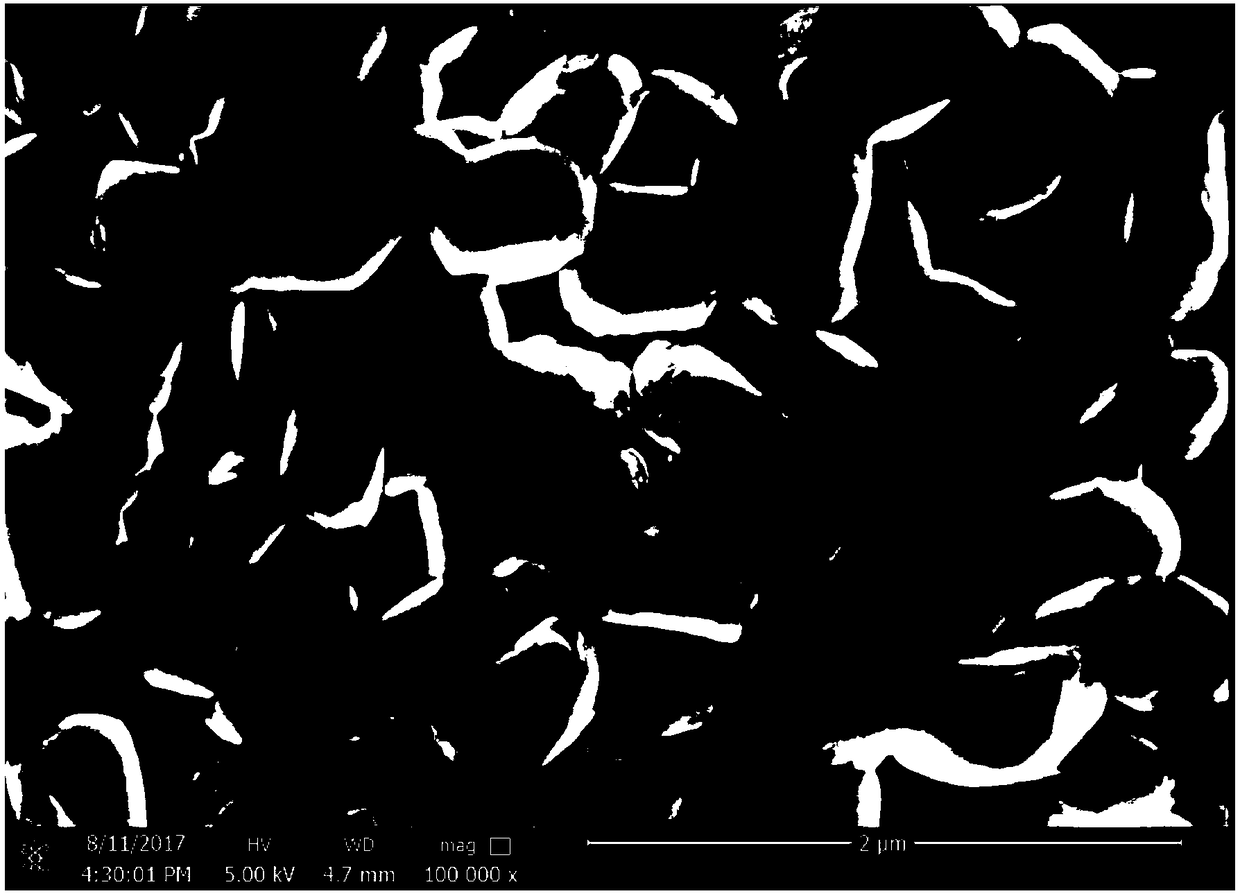

Embodiment 1

[0053] Example 1 The finished product processing method of the high-nickel ternary material coated with alumina and boron oxide is as follows:

[0054] 1. Use conventional NCM811 ternary high-nickel substrate, take 8000g;

[0055] 2. Take 103.623g Al 2 (SO 4 ) 3 18H 2 O and 119.952g H 2 C 2 o 4 2H 2 O was dissolved in 800mL deionized water to obtain a coating solution;

[0056] 3. Pour 8000g of substrate into 5600mL of deionized water, and stir at 1300rpm for 5 minutes to fully disperse the material and fully contact the surface impurities with water to form a suspension;

[0057] 4. Add the coating solution dropwise into the suspension at a rate of 0.8mL / s under stirring at 1300rpm, and continue stirring for 20 minutes after the dropwise addition to obtain an aluminum-coated material;

[0058] 5. Centrifuge the suspension to obtain a wet material;

[0059] 6. Put the wet material into a double-cone vacuum drying oven, control the vacuum degree to ≤0.01MPa, dry it at...

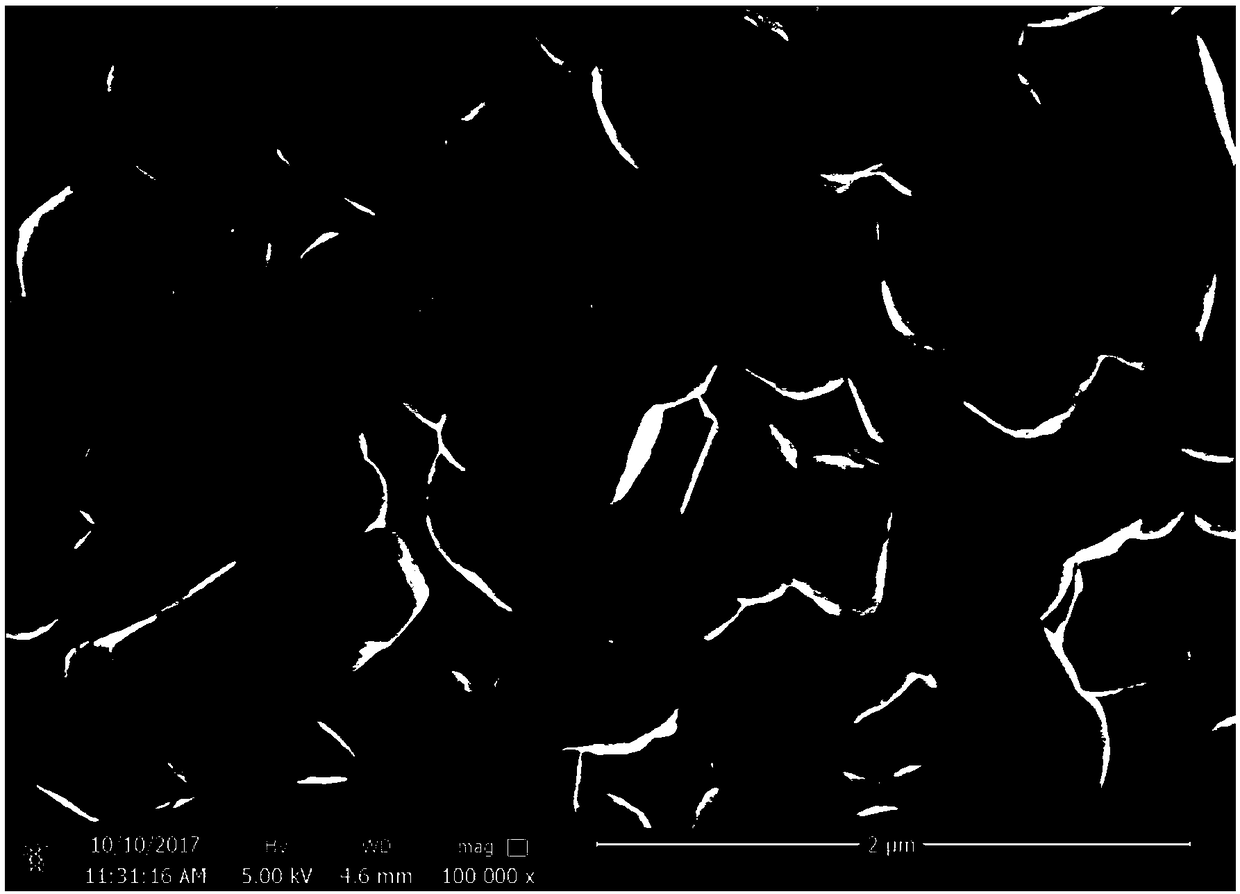

Embodiment 2

[0063] Example 2 The finished product processing method of the high-nickel ternary material coated with alumina and boron oxide is as follows:

[0064] 1. Use conventional NCM811 ternary high-nickel substrate, take 8000g;

[0065] 2. Take Al 2 o 3 122.4g of aluminum sol accounting for 20% by mass, and then dilute it to 900mL with deionized water to obtain a coating solution;

[0066] 3. Pour 8000g of substrate into 5600mL of deionized water, and stir at 1300rpm for 5 minutes to fully disperse the material and fully contact the surface impurities with water to form a suspension;

[0067] 4. Add the coating solution dropwise into the suspension at a rate of 0.8mL / s under stirring at 1300rpm, and continue stirring for 20 minutes after the dropwise addition to obtain an aluminum-coated material;

[0068] 5. Centrifuge the suspension to obtain a wet material;

[0069] 6. Put the wet material into a double-cone vacuum drying oven, control the vacuum degree to ≤0.01MPa, dry it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com