Small-particle-size nickel-cobalt-aluminum oxide and preparation method thereof

A nickel-cobalt-aluminum oxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high sphericity, good monodispersity, and low tap density of nickel-cobalt-aluminum cathode materials, and achieve high sphericity. , good monodispersity, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

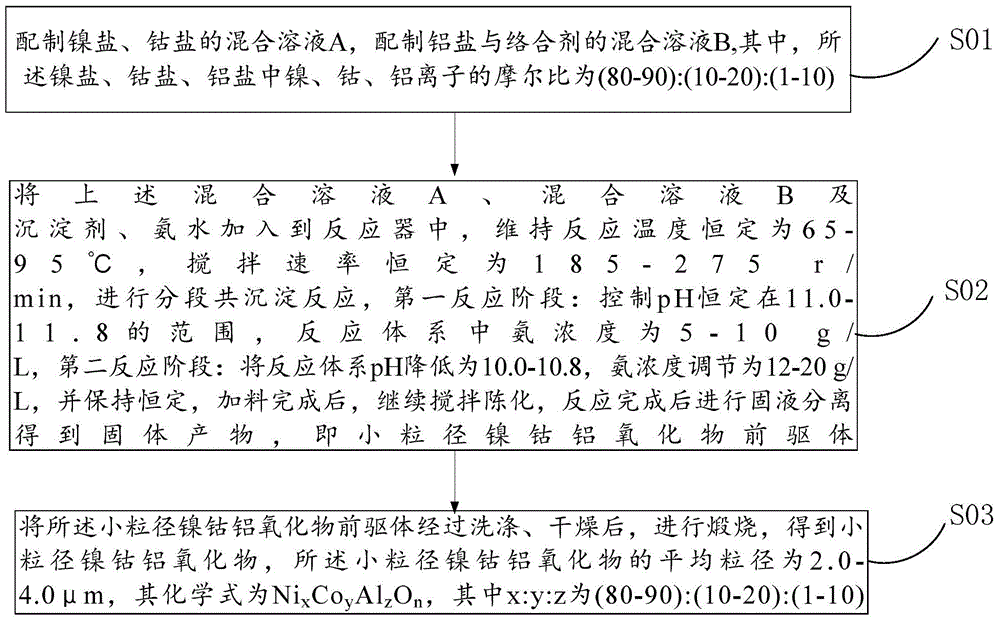

[0054] Please refer to figure 1 , figure 1 It is a flow chart of the preparation method of nickel-cobalt-aluminum oxide with medium and small particle size of the present invention, comprising the following steps:

[0055] S01, prepare the mixed solution A of nickel salt, cobalt salt, prepare the mixed solution B of aluminum salt and complexing agent, wherein, the mol ratio of nickel, cobalt, aluminum ion in described nickel salt, cobalt salt, aluminum salt is (80 -90):(10-20):(1-10);

[0056] S02. Add the above-mentioned mixed solution A, mixed solution B, precipitant, and ammonia water into the reactor, keep the reaction temperature constant at 65-95°C, and keep the stirring rate constant at 185-275r / min, and carry out segmental co-precipitation reaction, the first The first reaction stage: control the pH to be constant in the range of 11.0-11.8, the ammonia concentration in the reaction system is 5-10g / L, the second reaction stage: reduce the pH of the reaction system to ...

Embodiment 1

[0059] A preparation method of small particle size nickel cobalt aluminum oxide, comprising the following steps:

[0060] (1) Take by weighing nickel sulfate, cobalt sulfate, aluminum sulfate crystal in molar ratio 80:10:10, and take by weighing EDTA, wherein the molar ratio of aluminum sulfate crystal, complexing agent EDTA is 1:0.5, after mixing uniformly, respectively Be made into the aluminum-EDTA mixed solution B of the nickel-cobalt mixed solution A of 85g / L, the 8g / L of metal ion concentration;

[0061] (2) Pure water is added in the reactor, ammoniacal liquor is added, and the concentration of ammoniacal liquor in the bottom liquid is 4g / L, under stirring condition, the sodium hydroxide solution of above-mentioned mixed solution A, mixed solution B and mass concentration 30wt%, 18wt% Add % ammonia water into the reaction kettle concurrently, adjust the stirring speed to 185r / min, the temperature to 65°C, maintain a constant reaction temperature and stirring speed, cont...

Embodiment 2

[0066] A preparation method of small particle size nickel cobalt aluminum oxide, comprising the following steps:

[0067] (1) Take by weighing nickel sulfate, cobalt sulfate, aluminum sulfate crystal in molar ratio 80:10:10, and take by weighing EDTA, wherein the molar ratio of aluminum sulfate crystal, complexing agent EDTA is 1:1, after mixing uniformly, respectively Be made into the nickel-cobalt mixed solution A, the aluminum-EDTA mixed solution B of 10g / L that metal ion concentration is 110g / L;

[0068] (2) add pure water in the reactor, add ammoniacal liquor, make the ammoniacal liquor concentration in the bottom liquid of reaction be 6g / L, under stirring condition, be the sodium hydroxide solution of 20wt% with above-mentioned mixed solution A, mixed solution B and mass concentration , 18wt% ammonia water is added into the reaction kettle concurrently, the stirring speed is adjusted to be 220r / min, the temperature is 75°C, the constant reaction temperature and stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com