Preparation method for aluminum oxide nano-particles

A technology of alumina nano and aluminum hydroxide, which is applied in the direction of alumina/hydroxide preparation, nanotechnology, nanotechnology, etc., can solve the problems of large particle size of alumina nanoparticles, environmental pollution, etc., and reach the particle size distribution range The effect of narrow, environment-friendly and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

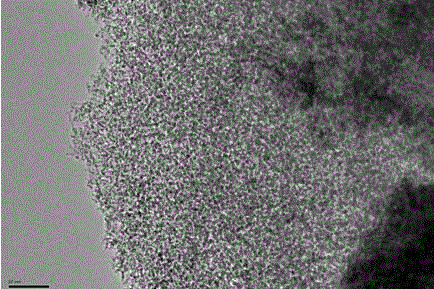

Embodiment 1

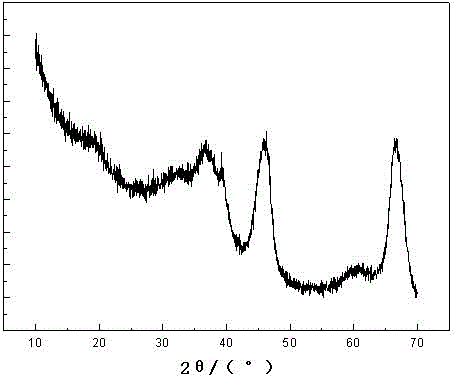

[0022] Measure 100mL of 1M aluminum chloride solution and place it in a beaker, add 1M sodium hydroxide solution drop by drop to the beaker under magnetic stirring to make the pH of the final slurry 7; add 1.8 grams of Sorbitol; then the beaker is placed in ultrasonic equipment for ultrasonic treatment, the ultrasonic frequency is 50KHz, the ultrasonic power is 600W, the ultrasonic power density is 1500W / L, and the treatment time is 0.5 hour; Heat treatment in sealed water at 150°C for 3 days; after natural cooling, filter the precipitate, wash with distilled water until there is no impurity ion, dry at 110°C for 8 hours, and roast at 550°C for 4 hours to obtain the alumina nanoparticles of the present invention. The particle size distribution range of the obtained alumina nanoparticles is 5-8nm, the average particle size is 6nm, and it is characterized by powder X-ray diffraction as γ-Al 2 o 3 .

Embodiment 2

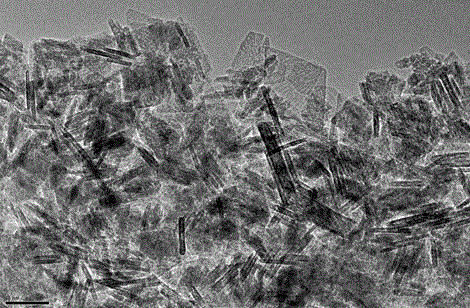

[0024] The same as Example 1, except that the aluminum salt is aluminum nitrate, the precipitating agent is ammonia water, and the pH value of the final slurry is 8 during precipitation; the added polyols are xylitol and arabitol with a mass ratio of 1:1, and the addition of polyols The amount is 6.8 grams; the temperature of the hydrothermal treatment is 200° C., and the treatment time is 1 day to obtain the alumina nanoparticles of the present invention. The particle size distribution range of the obtained alumina nanoparticles is 7-12nm, the average particle size is 10nm, and it is characterized by powder X-ray diffraction as γ-Al 2 o 3 .

Embodiment 3

[0026] Same as Example 1, except that the aluminum salt is aluminum sulfate, the precipitating agent is sodium hydroxide, and the pH value of the final slurry during precipitation is 5; the added polyhydric alcohol is ethylene glycol, glycerol and The addition of mannitol and polyols is 3.36 grams; the frequency of ultrasonic treatment is 80KHz, the ultrasonic power density is 1000W / L, and the treatment time is 1.5 hours; the temperature of hydrothermal treatment is 230°C, and the treatment time is 5 days. Invention of alumina nanoparticles. The particle size distribution range of the obtained alumina nanoparticles is 5-11nm, the average particle size is 7nm, and it is characterized by powder X-ray diffraction as γ-Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com