Preparation method of aluminum oxide coated lithium nickel manganese cobalt cathode material

A technology of nickel-cobalt-lithium-manganese-manganese oxide and positive electrode materials, which can be applied to battery electrodes, electrochemical generators, structural parts, etc., and can solve problems such as difficulty in obtaining materials without impurities, reduction in comprehensive electrical properties, and difficulty in drying and removing water. , to achieve the effect of improving electrochemical cycle performance, high tap density and reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

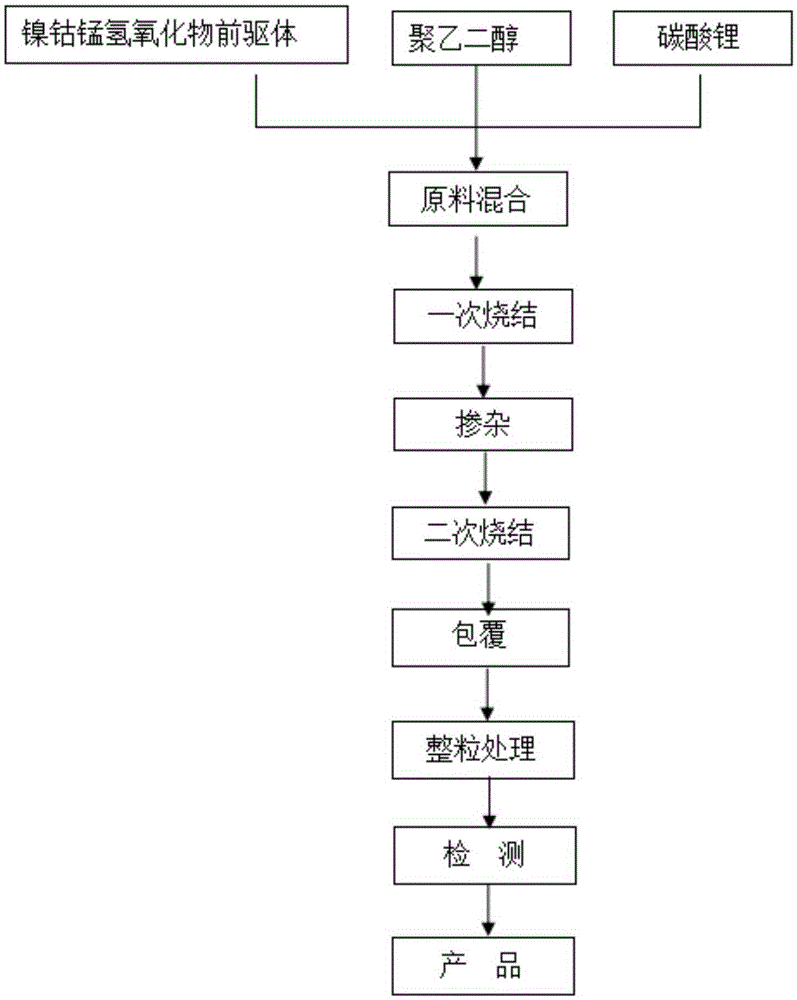

Method used

Image

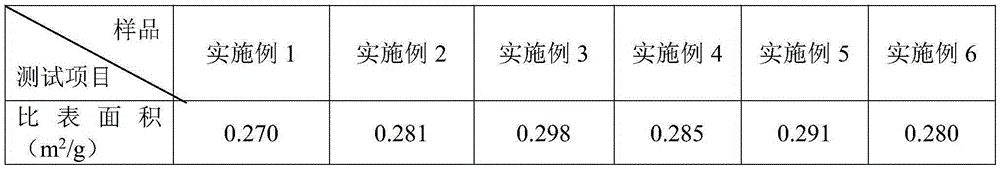

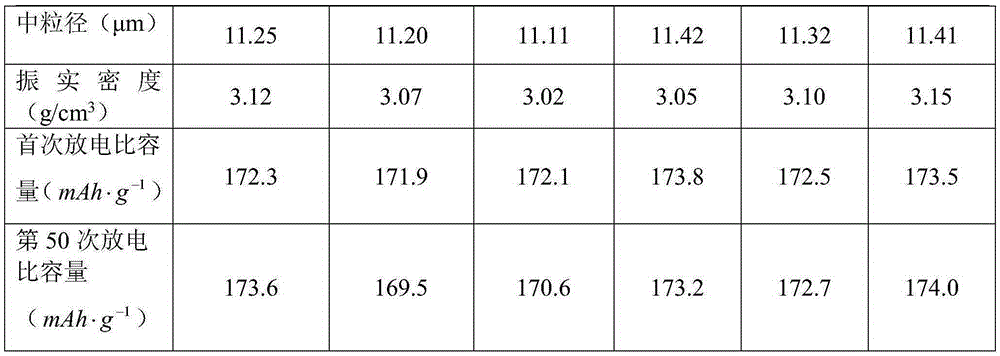

Examples

Embodiment 1

[0030] A method for preparing an alumina-coated nickel-cobalt-manganate-lithium-manganate positive electrode material, comprising the following steps:

[0031] (1) Mixing of raw materials: Using a three-dimensional high-efficiency inclined mixer and using polyurethane balls as the mixing medium, the lithium carbonate and nano-spherical nickel-cobalt-manganese hydroxide precursors were weighed in a molar ratio of 1:0.53, and the mass ratio of the total mixture was weighed. Disperse, mix and pulverize 10% polyethylene glycol to form a uniform intermediate mixture, wherein the specific gravity of polyurethane balls is 1.3, the ratio of balls to material is 3:4:3, and the mixing time is 3h;

[0032] (2) One-time sintering: the intermediate mixture obtained in step (1) is loaded into a sagger, and sent to a push-plate kiln for sintering to produce nickel-cobalt lithium manganate materials. The sintering process is continuously filled with oxygen, and the sintering temperature is 650...

Embodiment 2

[0038] (1) Mixing of raw materials: using a three-dimensional high-efficiency inclined mixer and using polyurethane balls as the mixing medium, weighing lithium carbonate and nano-spherical nickel-cobalt-manganese hydroxide precursors in a molar ratio of 1:0.535, and the mass ratio of the total mixture Disperse, mix and pulverize 20% polyethylene glycol to form a uniform intermediate mixture, wherein the specific gravity of polyurethane balls is 1.5, the ratio of balls to materials is 3:4:3, and the mixing time is 3h;

[0039] (2) One-time sintering: the intermediate mixture obtained in step (1) is loaded into a sagger, and sent to a push-plate kiln for sintering to produce nickel cobalt lithium manganate materials. The sintering process is continuously filled with oxygen, and the sintering temperature is 700 ℃ ℃, the sintering time is 3h;

[0040](3) Doping: Select nano-scale MgO, dope the nickel-cobalt lithium manganate obtained in step (2), and add the nickel-cobalt lithium...

Embodiment 3

[0045] (1) Mixing of raw materials: using a three-dimensional high-efficiency inclined mixer and using polyurethane balls as the mixing medium, weighing lithium carbonate and nano-spherical nickel-cobalt-manganese hydroxide precursors in a molar ratio of 1:0.55, and the mass ratio of the total mixture Disperse, mix and pulverize 30% polyethylene glycol to form a uniform intermediate mixture, wherein the specific gravity of the polyurethane ball is 1.4, the ratio of the ball to the material is 3:4:3, and the mixing time is 4h;

[0046] (2) One-time sintering: the intermediate mixture obtained in step (1) is loaded into a sagger, and sent to a push-plate kiln for sintering to produce nickel cobalt lithium manganate materials. The sintering process is continuously filled with oxygen, and the sintering temperature is 750 ℃ ℃, the sintering time is 5h;

[0047] (3) Doping: select nano-scale Al 2 O 3 performing doping treatment on the nickel-cobalt lithium manganate obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com