Preparation method for aluminum oxide and carbon composite coated sodium vanadium fluorophosphate positive electrode material

A technology of fluorine-coated sodium vanadium phosphate and positive electrode material is applied in the field of electrochemical power supply, which can solve the problems of side reaction between active material and electrolyte, low electronic conductivity, decrease of material cycle performance, etc. improve the structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

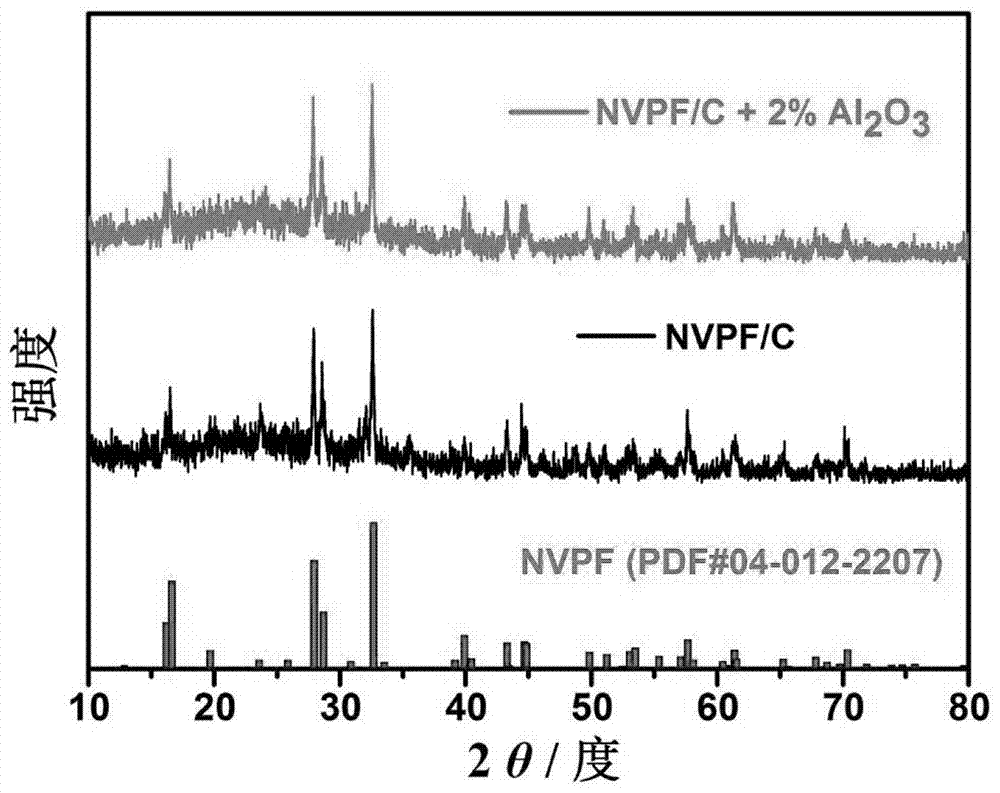

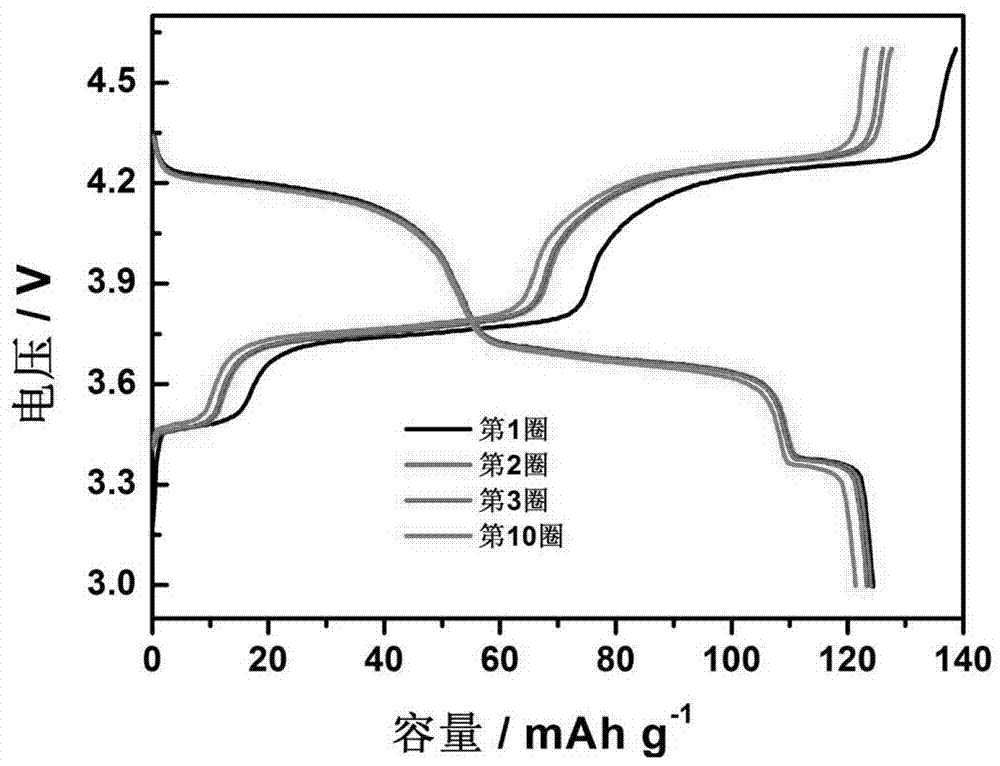

Embodiment 1

[0026] Dissolve oxalic acid (11.3459 g), sodium fluoride (2.5193 g), vanadium pentoxide (4.6010 g) and ammonium dihydrogen phosphate (3.6376 g) in deionized water and stir at 60 °C to form a gel. After drying The precursor was obtained by pre-calcining at 350 °C for 6 hours under nitrogen atmosphere; 0.45 g glucose was added to 5 g precursor, ball milled for 2 hours and then dried in an oven at 50 °C; the obtained powder was dried in a tube furnace at 700 °C under nitrogen atmosphere Sintering for 10 hours; after cooling, grind and sieve to obtain NVPF / C cathode material. Take 1 g NVPF / C and add it into 50 ml deionized water for 40 minutes, stir to form a black suspension, then add 0.01 g aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2O, sonicate for 20 minutes and then stir for 30 minutes, then add ammonia NH 3 ·H 2 O, continue to stir at 60°C for 1.5 hours, then filter with suction, wash with deionized water several times and dry, sinter the resulting powder in a tube furn...

Embodiment 2

[0028] Dissolve oxalic acid (11.3459 g), sodium fluoride (2.5193 g), vanadium pentoxide (4.6010 g) and ammonium dihydrogen phosphate (3.6376 g) in deionized water and stir at 60 °C to form a gel. After drying The precursor was obtained by pre-calcining at 350 °C for 6 hours under nitrogen atmosphere; 0.45 g glucose was added to 5 g precursor, ball milled for 2 hours and then dried in an oven at 50 °C; the obtained powder was dried in a tube furnace at 700 °C under nitrogen atmosphere Sintering for 10 hours; after cooling, grind and sieve to obtain NVPF / C cathode material. Take 1 g NVPF / C and add it into 50 ml deionized water for 40 minutes, stir to form a black suspension, then add 0.02 g aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O, sonicate for 20 minutes and then stir for 30 minutes, then add ammonia NH 3 ·H 2 O, continue to stir at 60°C for 1.5 hours, then filter with suction, wash with deionized water several times and dry, sinter the resulting powder in a tube fur...

Embodiment 3

[0030] Dissolve oxalic acid (11.3459 g), sodium fluoride (2.5193 g), vanadium pentoxide (4.6010 g) and ammonium dihydrogen phosphate (3.6376 g) in deionized water and stir at 60 °C to form a gel. After drying The precursor was obtained by pre-calcining at 350 °C for 6 hours under nitrogen atmosphere; 0.45 g glucose was added to 5 g precursor, ball milled for 2 hours and then dried in an oven at 50 °C; the obtained powder was dried in a tube furnace at 700 °C under nitrogen atmosphere Sintering for 10 hours; after cooling, grind and sieve to obtain NVPF / C cathode material. Take 1 g of NVPF / C and add it to 50 ml of deionized water for 40 minutes, stir to form a black suspension, then add 0.03 g of aluminum nitrate nonahydrate Al(NO 3 ) 3 9H 2 O, sonicate for 20 minutes and then stir for 30 minutes, then add ammonia NH 3 ·H 2 O, continue to stir at 60°C for 1.5 hours, then filter with suction, wash with deionized water several times and dry, sinter the resulting powder in a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com