Preparation method of aluminum oxide containing phosphorus and silicon

A silica-alumina and alumina technology, applied in chemical instruments and methods, catalyst supports, molecular sieve catalysts, etc., can solve the problems affecting the surface properties and performance of alumina supports, the inhomogeneity of the physical and chemical properties of alumina products, and the fluidity of colloids and poor uniformity, to achieve the effect of improving heavy oil conversion capacity, reducing peptization speed, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

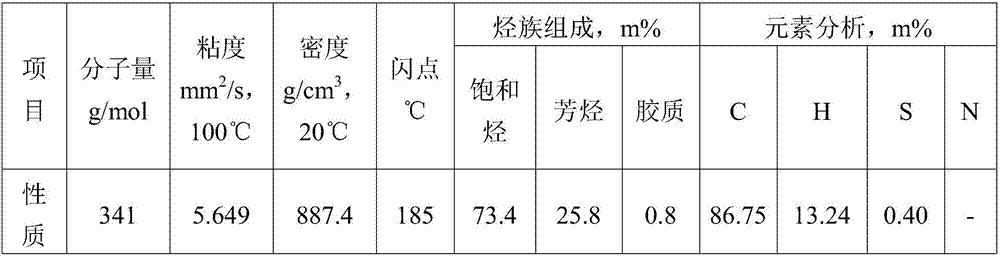

Image

Examples

Embodiment 1

[0030] The preparation method of phosphorus-containing and silicon-containing alumina provided by the invention:

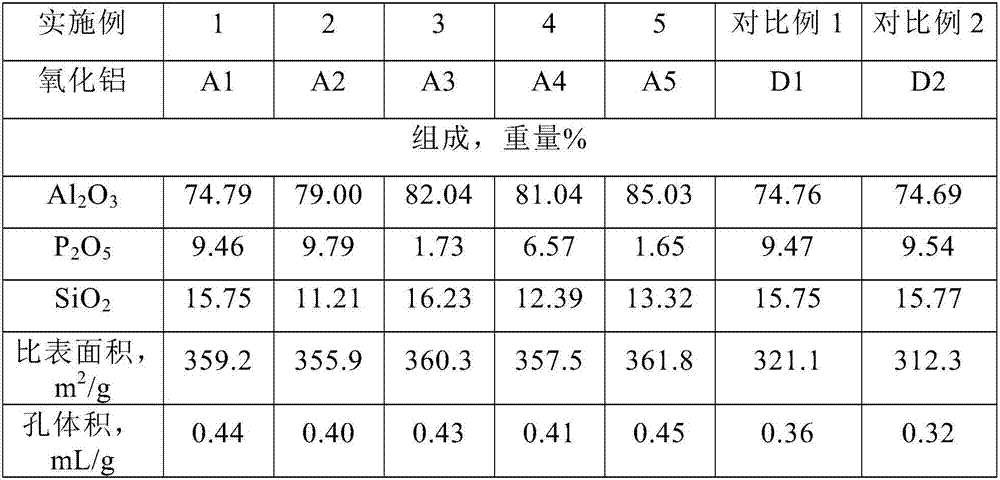

[0031](1) 1038 grams of pseudo-boehmite and 2849 grams of deionized water were mixed and beaten and dispersed; (2) 202 grams of ammonium chloride was added, stirred for 15 minutes, and left to stand for 24 hours; (3) then the slurry in step (2) was stirred After uniformity, add 160 grams of concentrated phosphoric acid at 15 g / min; (4) Finally, add 296 grams of silicic acid to the slurry in step (3), stir for 20 minutes, bake at 100°C for 2 hours, and roast at 500°C for 30 minutes to obtain phosphorous and silicon oxide Aluminum A1, its composition, specific surface area, and pore volume data are shown in Table 2.

Embodiment 2

[0033] Illustrate the preparation method of phosphorus-containing and silicon-alumina provided by the invention:

[0034] (1) Mix 968 grams of pseudo-boehmite with 6726 grams of deionized water, beat and disperse; (2) Add 608 grams of ammonium nitrate, stir for 30 minutes, and let stand for 20 hours; (3) Then stir the slurry in step (2) evenly Finally, add a mixture of 98 grams of concentrated phosphoric acid and 55 grams of diammonium hydrogen phosphate at 30 g / min; (4) finally add 368 grams of acidic silica sol to the slurry in step (3), stir for 25 minutes, bake at 120°C for 1 hour, and Roasting at ℃ for 30 minutes, phosphorus and silicon-containing alumina A2 was obtained, and its composition, specific surface area, and pore volume data are shown in Table 2.

Embodiment 3

[0036] Illustrate the preparation method of phosphorus-containing and silicon-alumina provided by the invention:

[0037] (1) 1168 grams of pseudo-boehmite and 3770 grams of deionized water are mixed and beaten and dispersed; (2) 323 grams of ammonium chlorate are added, stirred for 50 minutes, and left to stand for 12 hours; (3) then the slurry in step (2) is stirred After uniformity, add 30 grams of concentrated phosphoric acid at 60 g / min; (4) Finally, add 619 grams of acidic silica sol to the slurry in step (3), stir for 25 minutes, bake at 150°C for 1 hour, and roast at 550°C for 15 minutes to obtain phosphorus and silicon. Alumina A3, its composition, specific surface area, and pore volume data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com