Alumina slurry and preparation method and application thereof

An alumina and slurry technology, applied in the field of metal processing, can solve the problems of burrs, unfavorable dispersion, and small output of particles, achieve good dispersibility and stability, overcome false particle agglomeration, and be difficult to precipitate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a kind of preparation method of aluminum oxide slurry, it comprises the following steps:

[0040] Step S1: ball milling the alumina raw material, solvent and dispersant to prepare the first grinding material, wherein the dispersant is a mixed dispersant containing at least two different components;

[0041] Step S2: sanding the first abrasive at least once until the particle size D50<1 μm and D99<3 μm, to prepare a second abrasive;

[0042] Step S3: The second abrasive is filtered to obtain a finished slurry.

[0043] In a specific example, the alumina raw material is calcined α-Al 2 o 3 , the calcination temperature is above 1600℃, α-Al 2 o 3 Content > 98%, total Al 2 o 3 The content is >99%, the primary grain size is <2 μm, preferably the primary grain size is <0.5 μm. It can be understood that in other embodiments, other raw materials with similar or higher specifications and grades can also be used.

[0044] Optionally, the solvent is ...

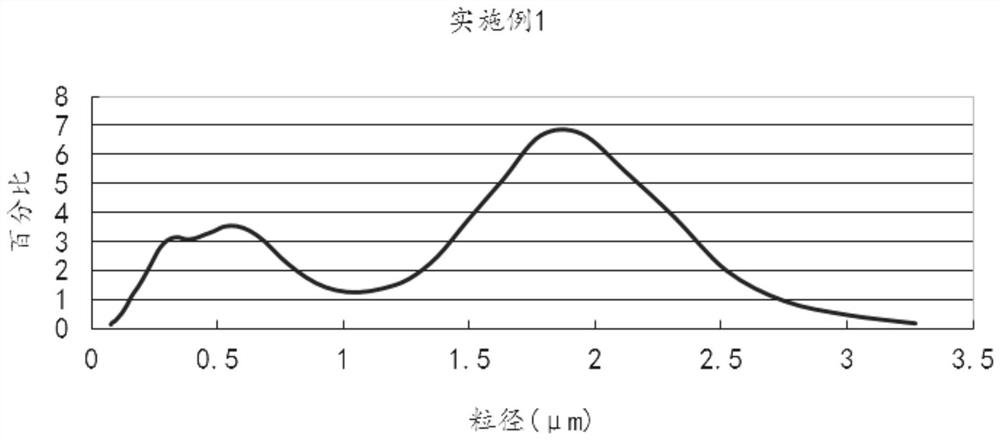

Embodiment 1

[0066] S1: Put 500kg of calcined α-Al into a horizontal ball mill with a diameter of 2200mm and a frequency modulation speed of 26RPM 2 o 3 , put into 3000kg of 99.99% alumina balls (diameter is 8mm) as grinding medium, drop into 2.4kg mixed dispersant (ethylene glycol 0.8kg+nonylphenol polyoxyethylene ether 0.8kg+maleic acid-styrene type modified copolymer 0.8kg), put in 928kg of water, transfer to intermediate storage tank A after grinding for 6 hours, connect hose pump, transfer to 50L sand mill;

[0067] S2: 99.99% alumina balls with a diameter of 0.8 mm are put into the sand mill as a grinding medium, and the amount used is 70% of the total volume. After sanding, if the particle size reaches the standard, filter it directly to obtain the finished product; if the particle size does not reach the standard, then grind the abrasive from the intermediate storage tank B to the intermediate storage tank C again through the sand mill, and filter after the particle size reaches t...

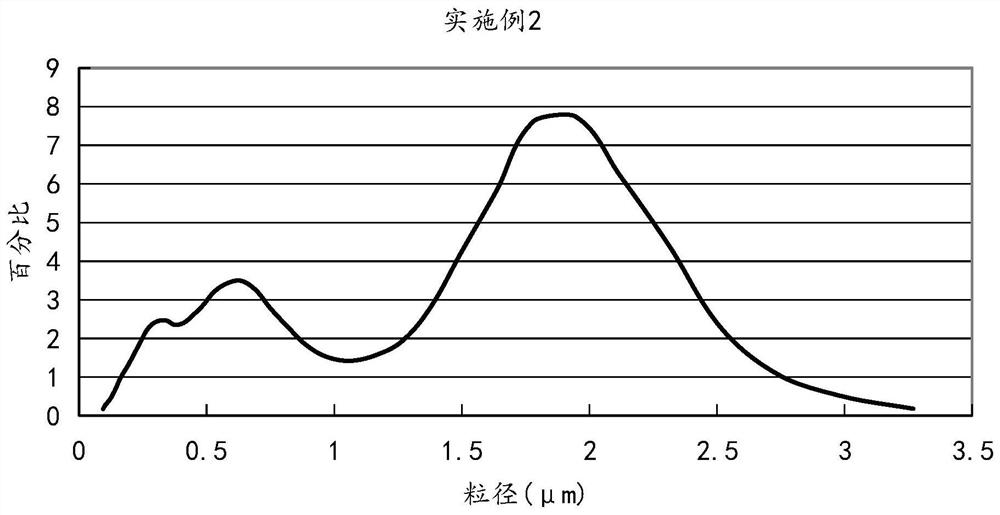

Embodiment 2

[0070] S1: Put 500kg of calcined α-Al into a horizontal ball mill with a diameter of 2200mm and a frequency modulation speed of 26RPM 2 o 3 , put into 4500kg of 99.99% alumina balls (diameter is 8mm) as grinding medium, drop into 2.72kg mixed dispersant (ethylene glycol 0.96kg+nonylphenol polyoxyethylene ether 0.8kg+maleic acid-styrene type modified copolymer 0.96kg), put in 928kg of water, transfer to intermediate storage tank A after grinding for 6 hours, connect hose pump, transfer to 50L sand mill;

[0071] S2: 99.99% alumina balls with a diameter of 0.8 mm are put into the sand mill as a grinding medium, and the amount used is 70% of the total volume. After sanding, if the particle size reaches the standard, filter it directly to obtain the finished product; if the particle size does not reach the standard, then grind the abrasive from the intermediate storage tank B to the intermediate storage tank C again through the sand mill, and filter after the particle size reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com