Drying device for bio-organic fertilizer

A bio-organic fertilizer and drying device technology, applied in manure drying, heating device, drying of solid materials, etc., can solve the problems affecting the production quality of organic fertilizer, wound of granular organic fertilizer, damage of granular organic fertilizer, etc. The effect of high efficiency and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

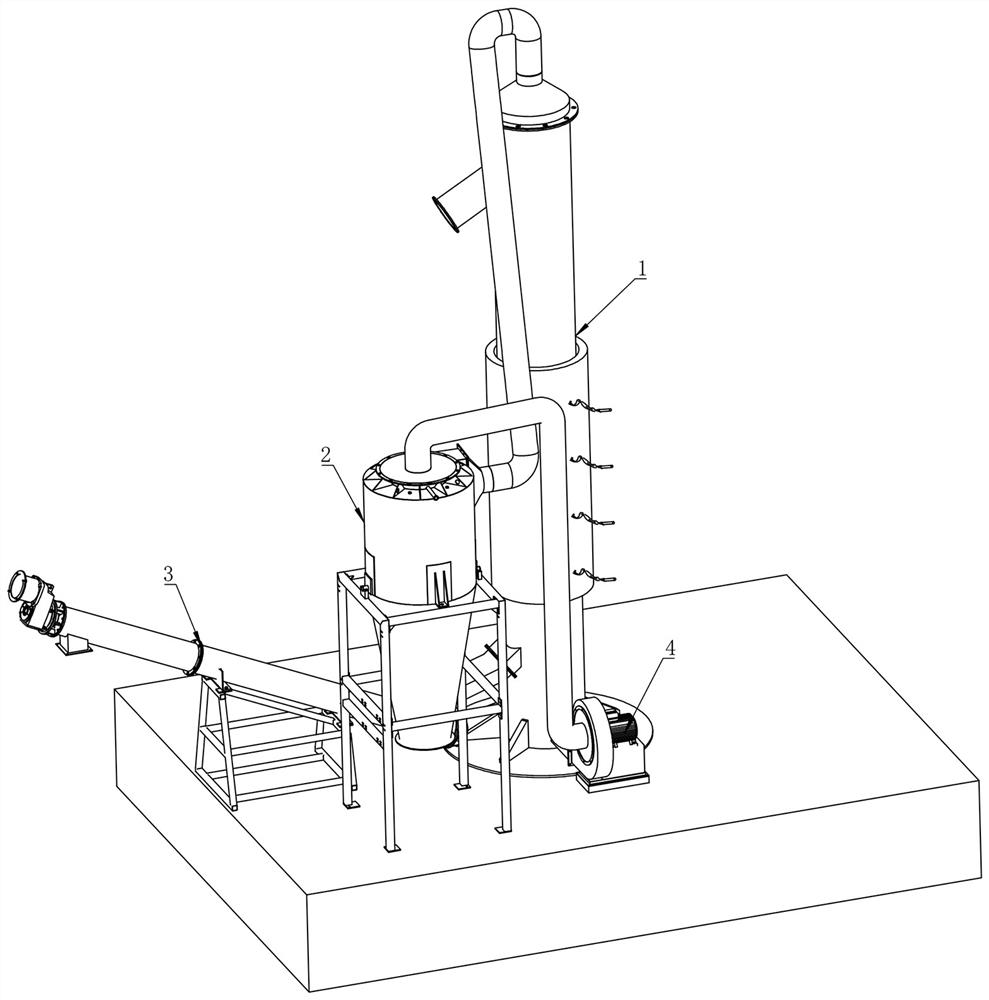

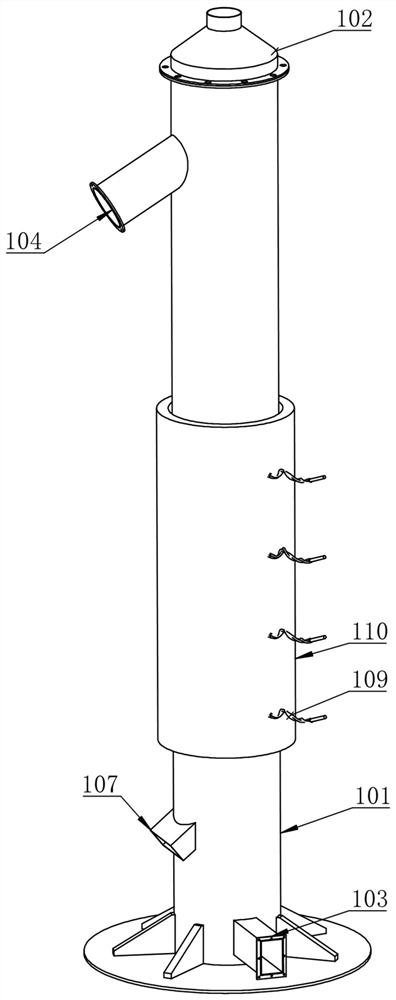

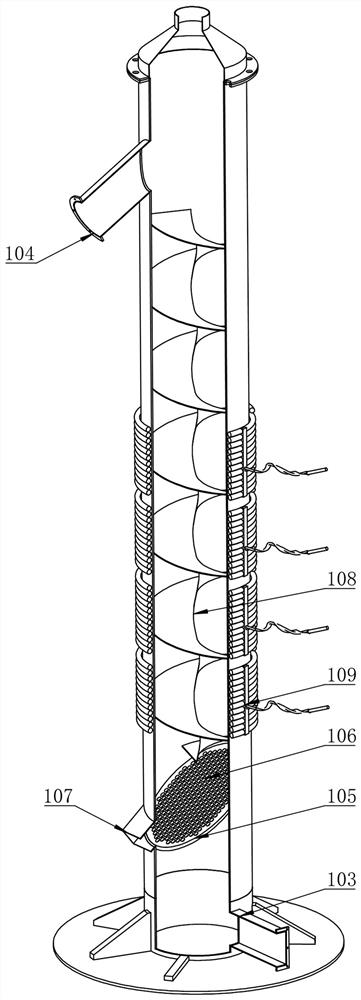

[0028] Specific implementation mode one: combine Figure 1-6 As shown, a biological organic fertilizer drying device is characterized in that it includes a convective falling body drying device 1, a cyclone recovery device 2 and a tubular conveyor 3; the tubular conveyor 3 is arranged on the convective falling body drying device 1 One side; the cyclone recovery device 2 is arranged on one side of the tube conveyor 3; a centrifugal fan 4 is arranged between the convective falling body drying device 1 and the cyclone recovery device 2; the convective falling body drying device 1 It includes a drying cylinder 101 and an outlet reducing diameter 102; the drying cylinder 101 is vertically arranged, and the bottom is sealed; the outlet reducing diameter 102 is arranged above the drying cylinder 101; the cyclone recovery device 2 includes a frame 201 and The cyclone separation cylinder 202; the cyclone separation cylinder 202 is fixedly arranged above the frame 201; the separation ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com