Patents

Literature

34results about How to "Increase the number of hits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

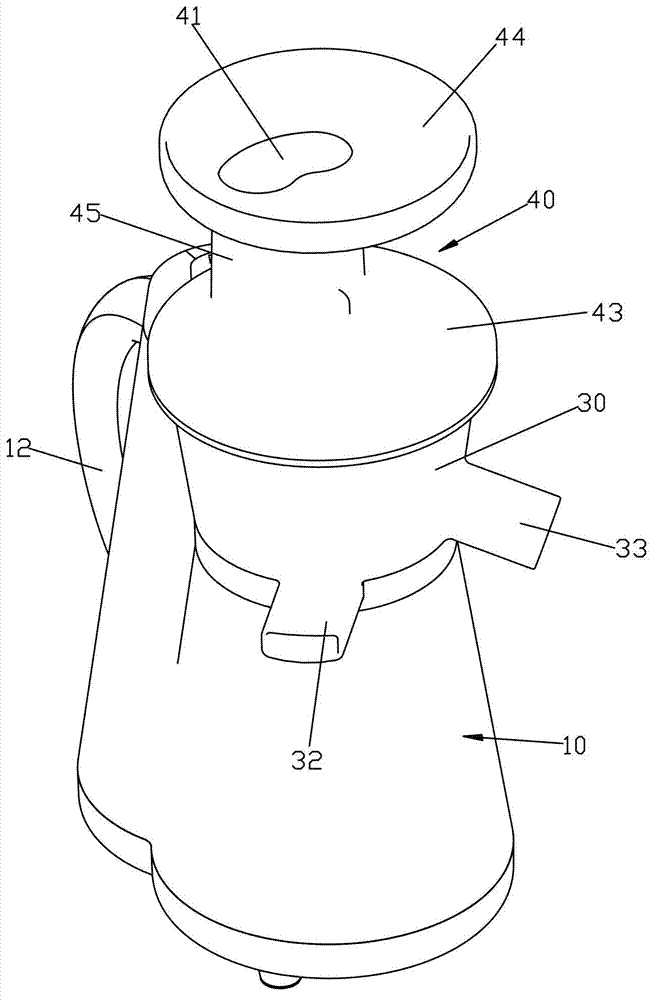

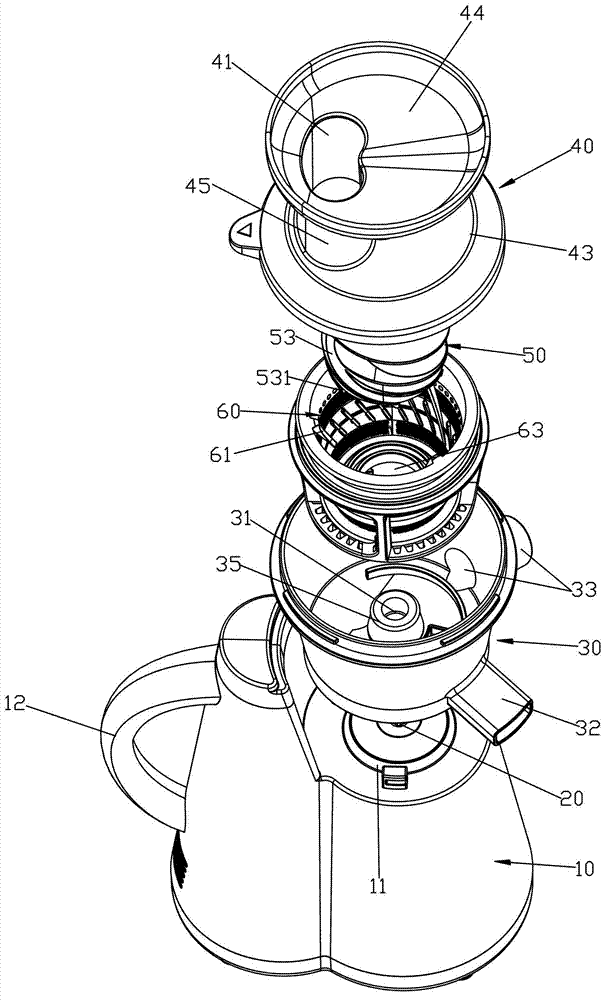

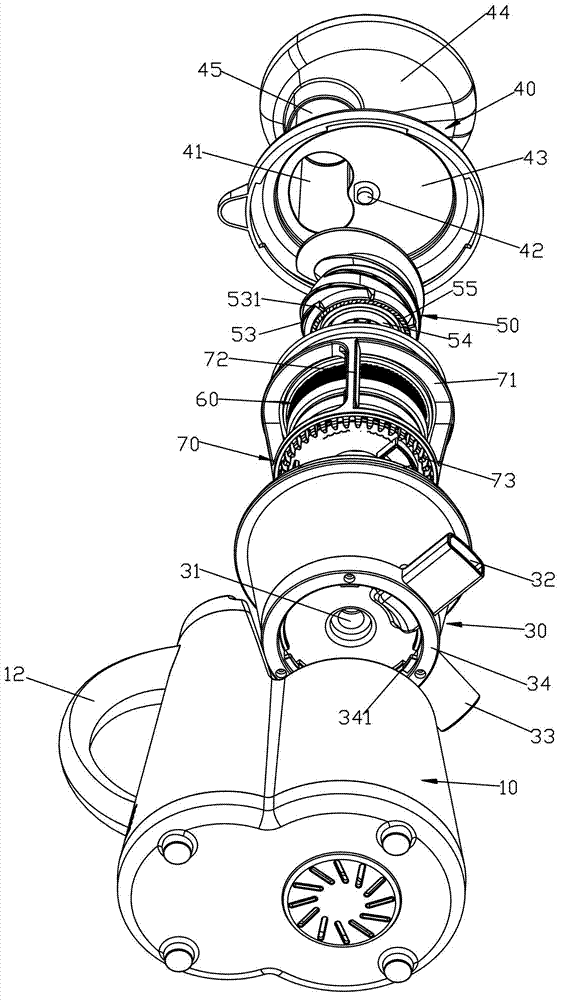

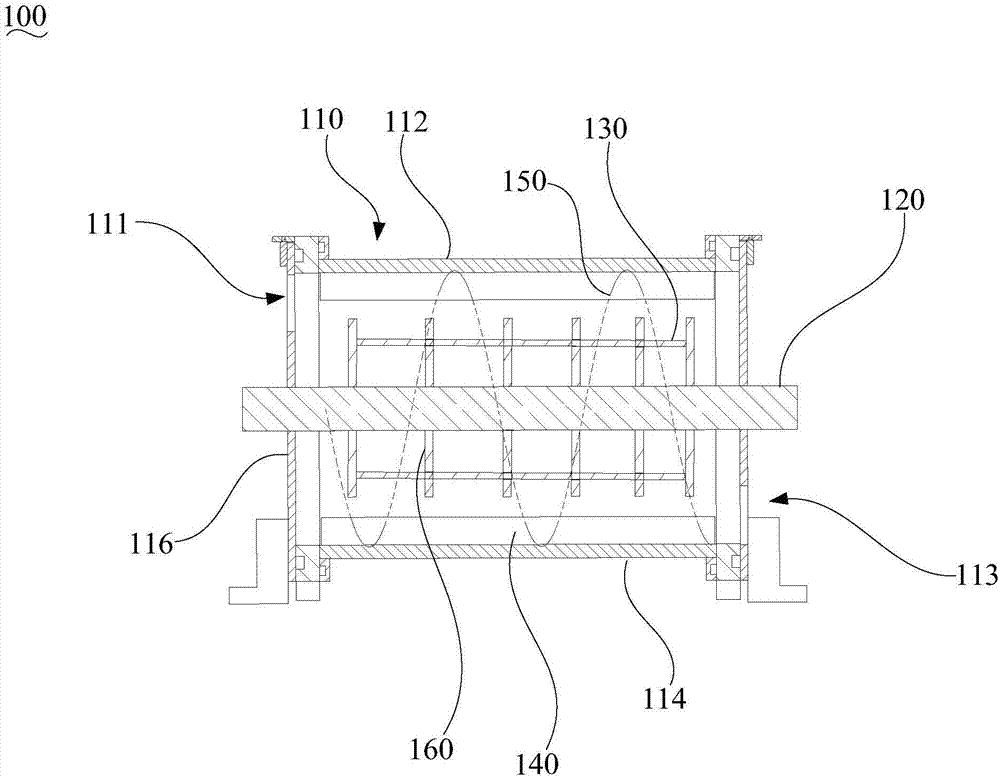

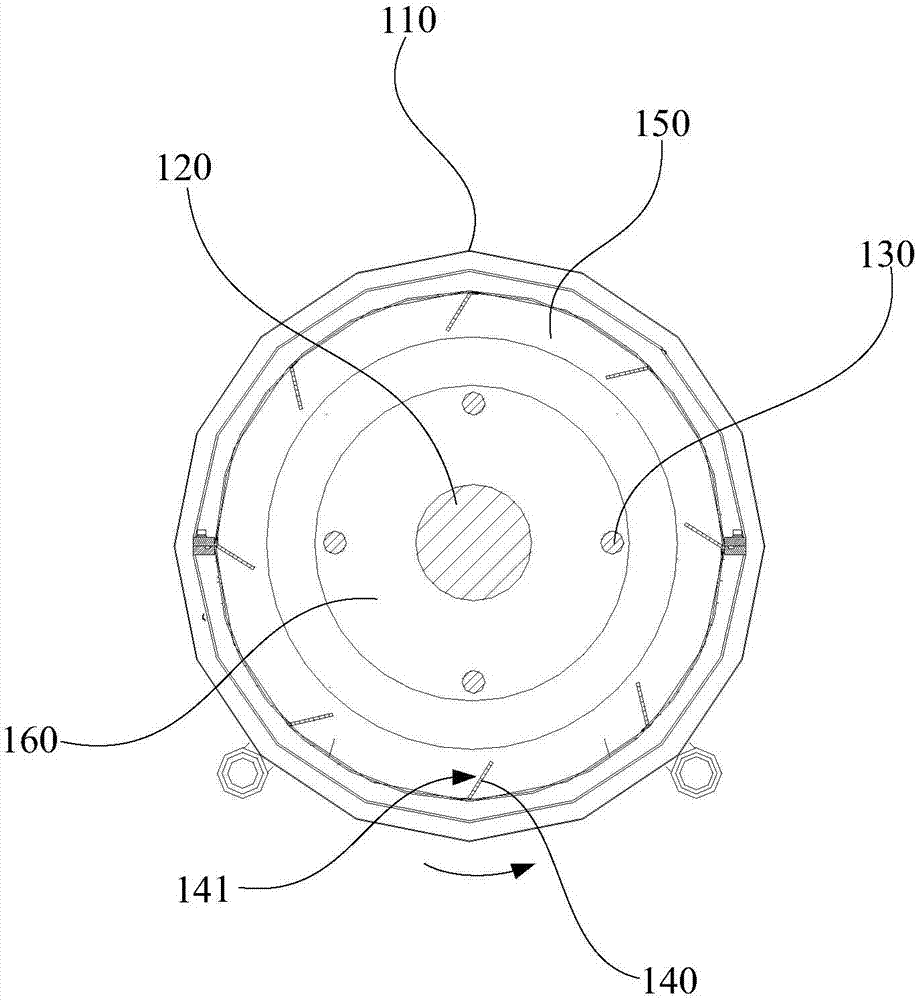

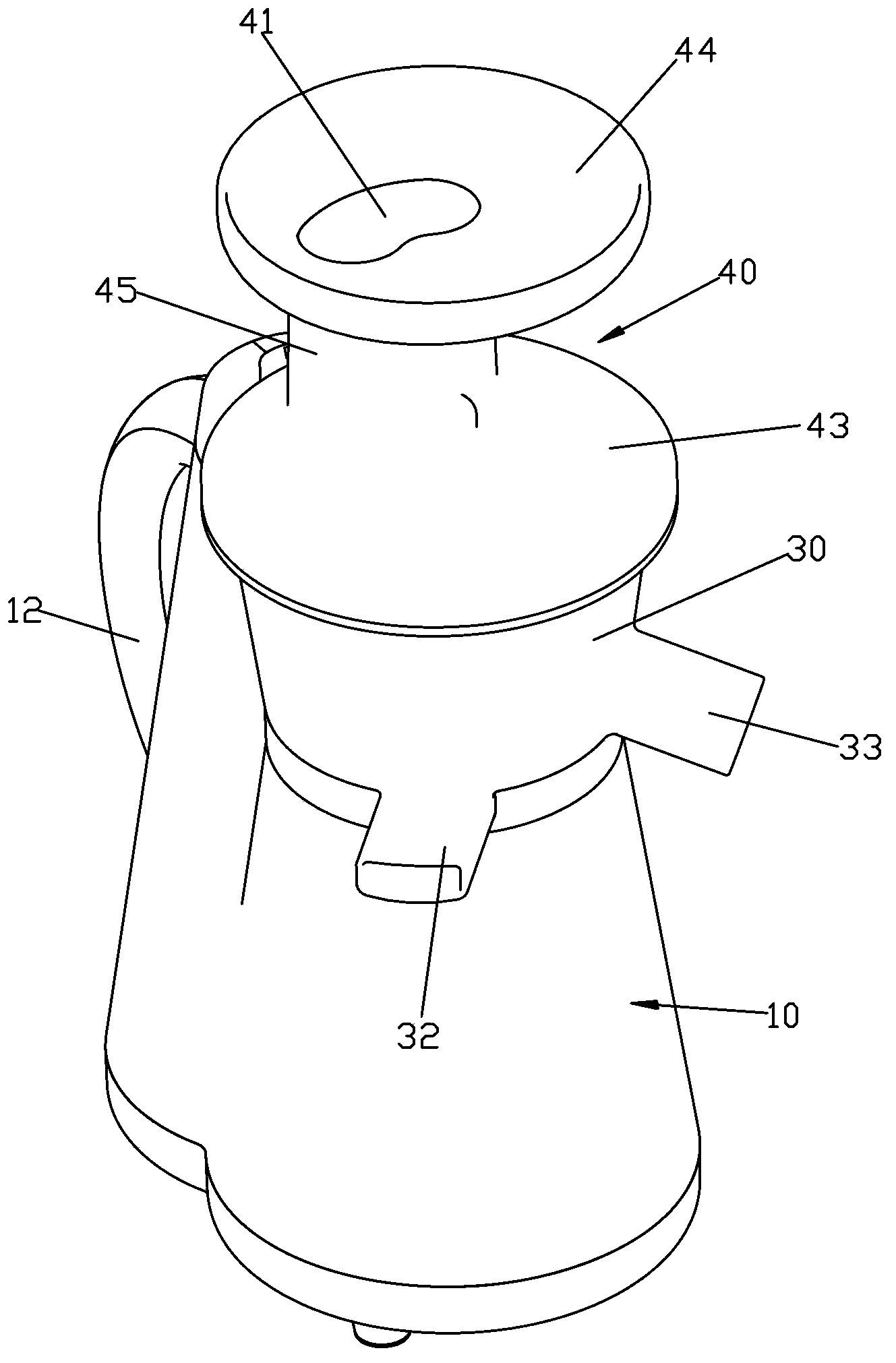

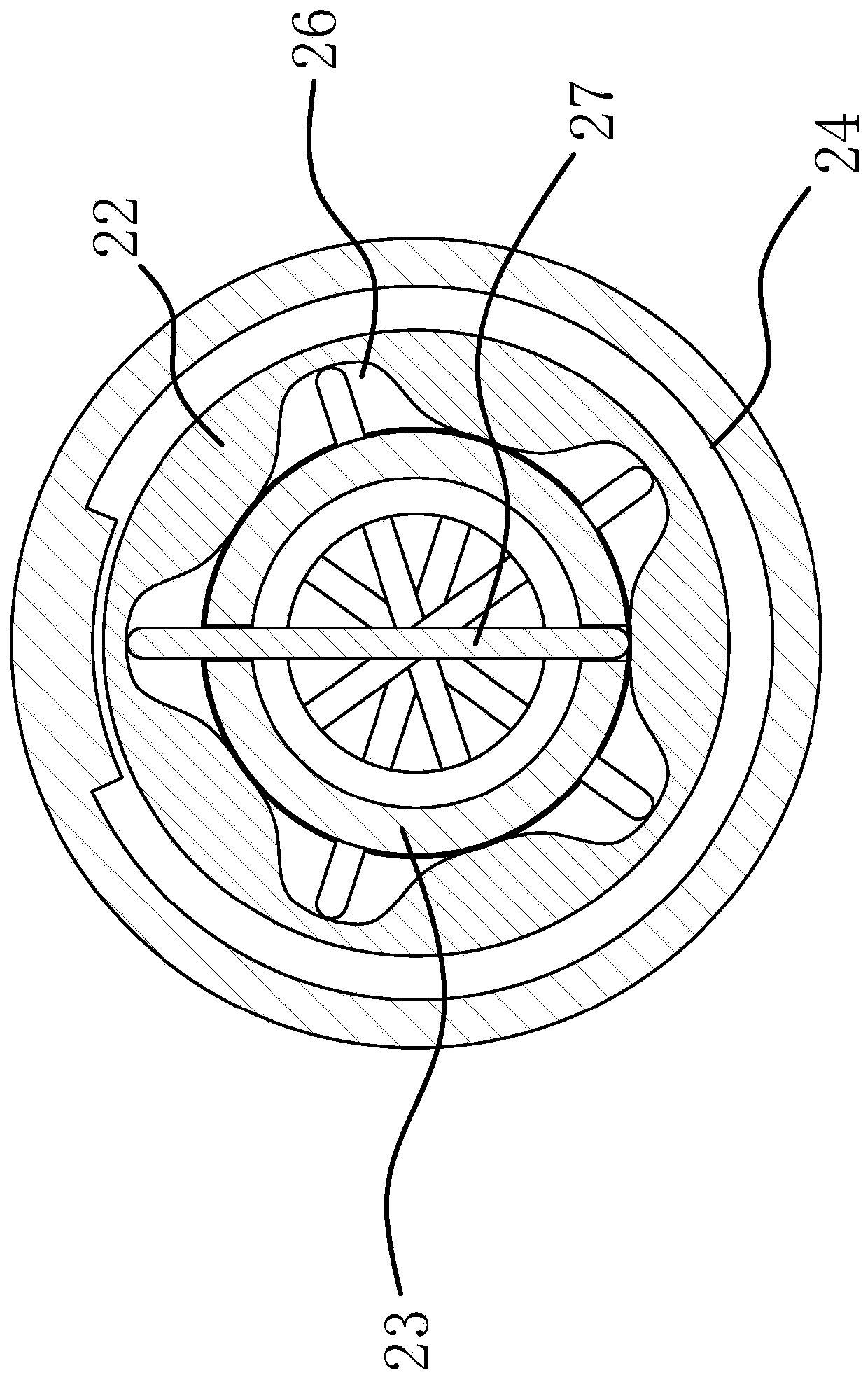

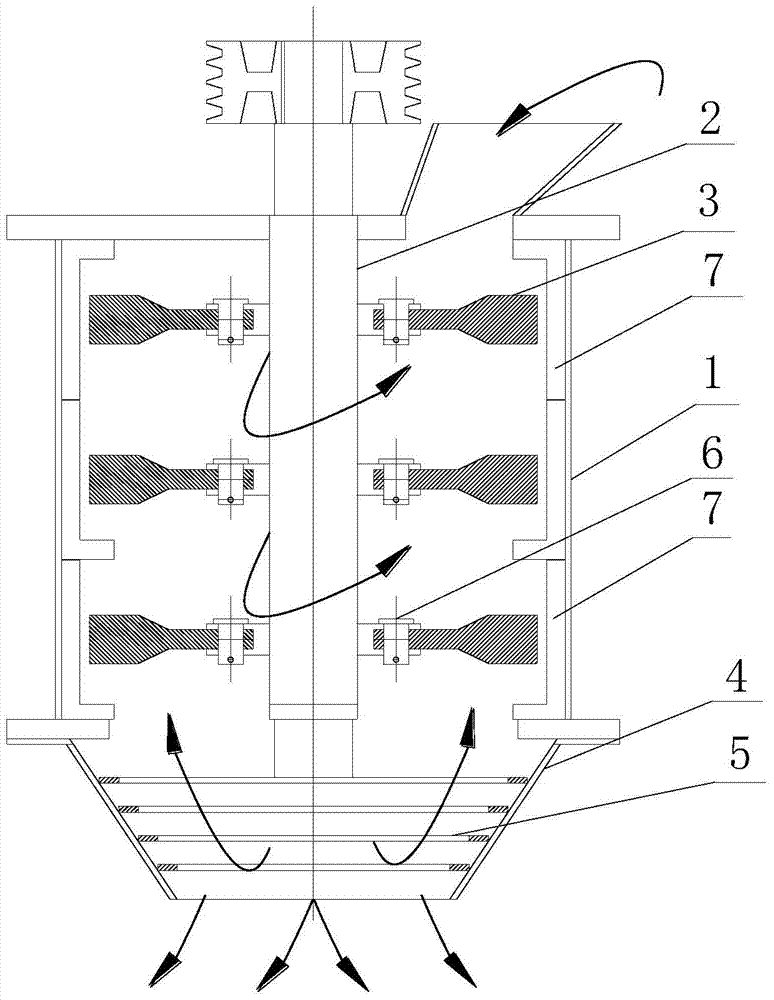

Juice extraction machine

InactiveCN102813442AEnhance swirl effectIncrease the number of hitsStrainersEngineeringMechanical engineering

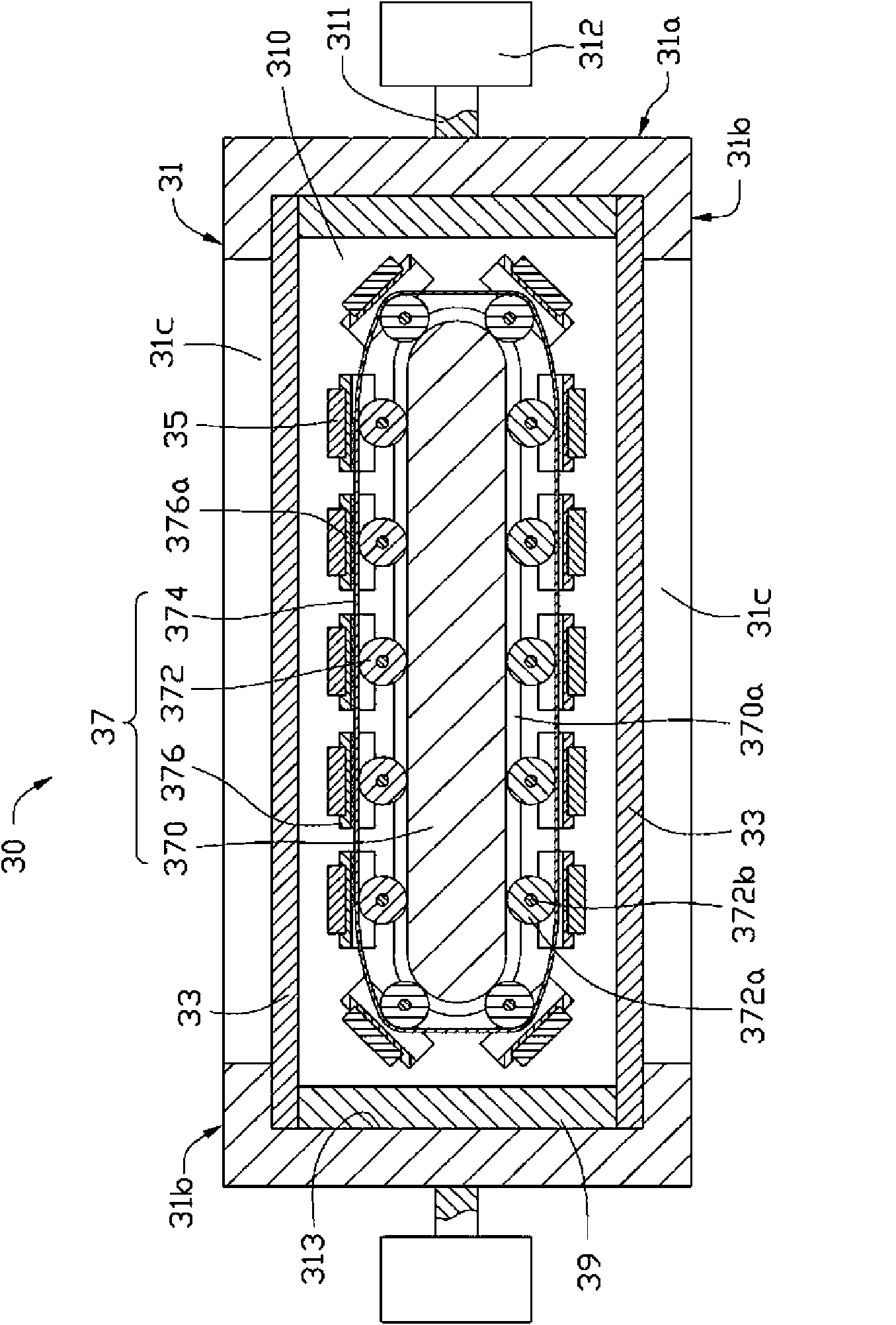

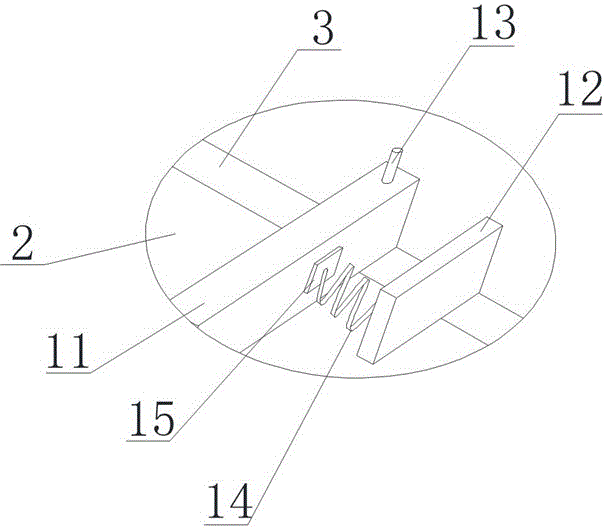

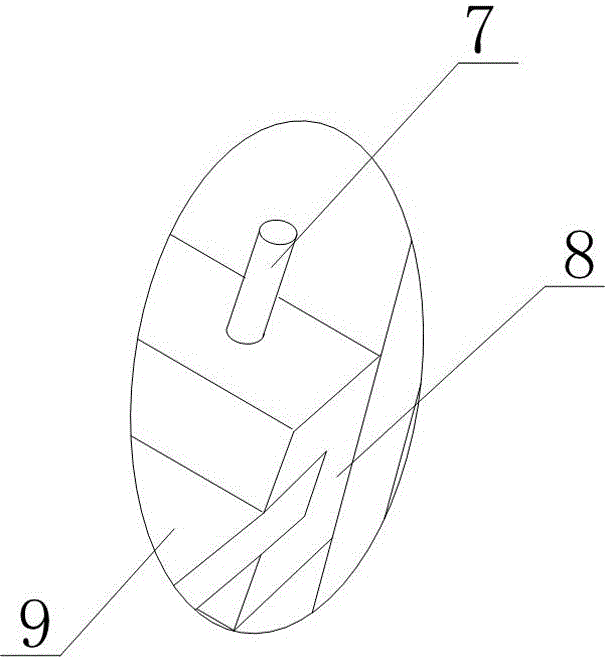

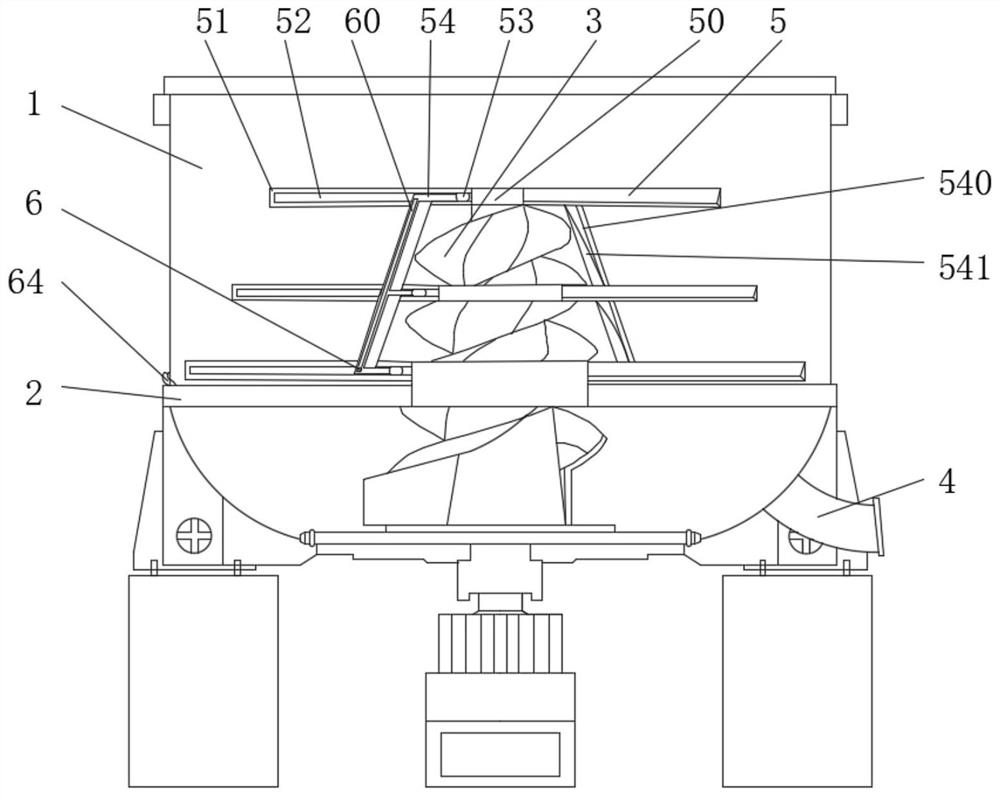

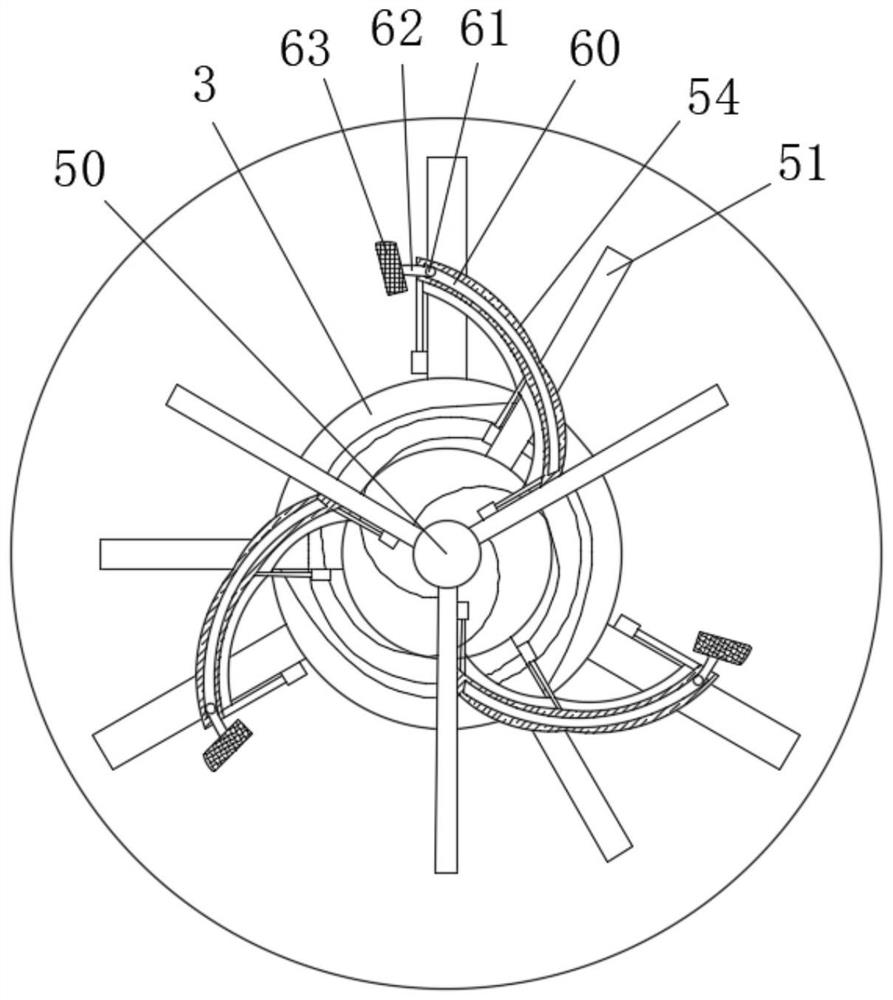

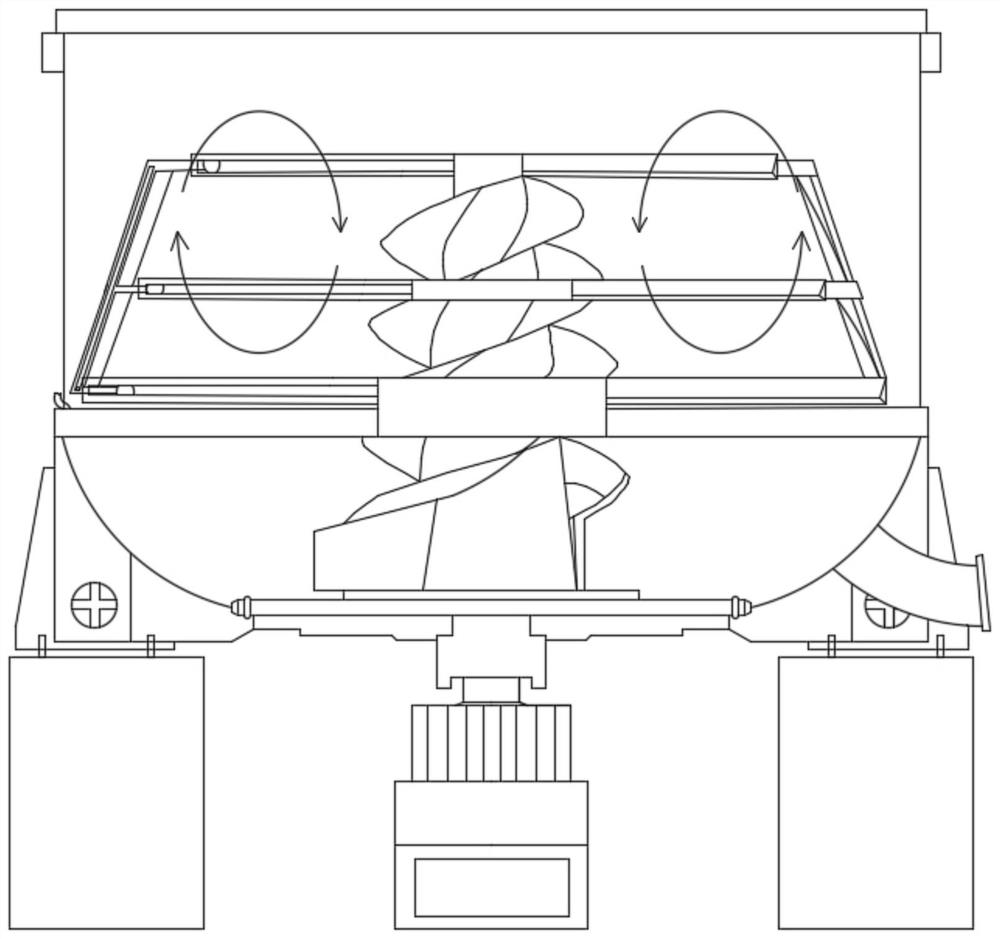

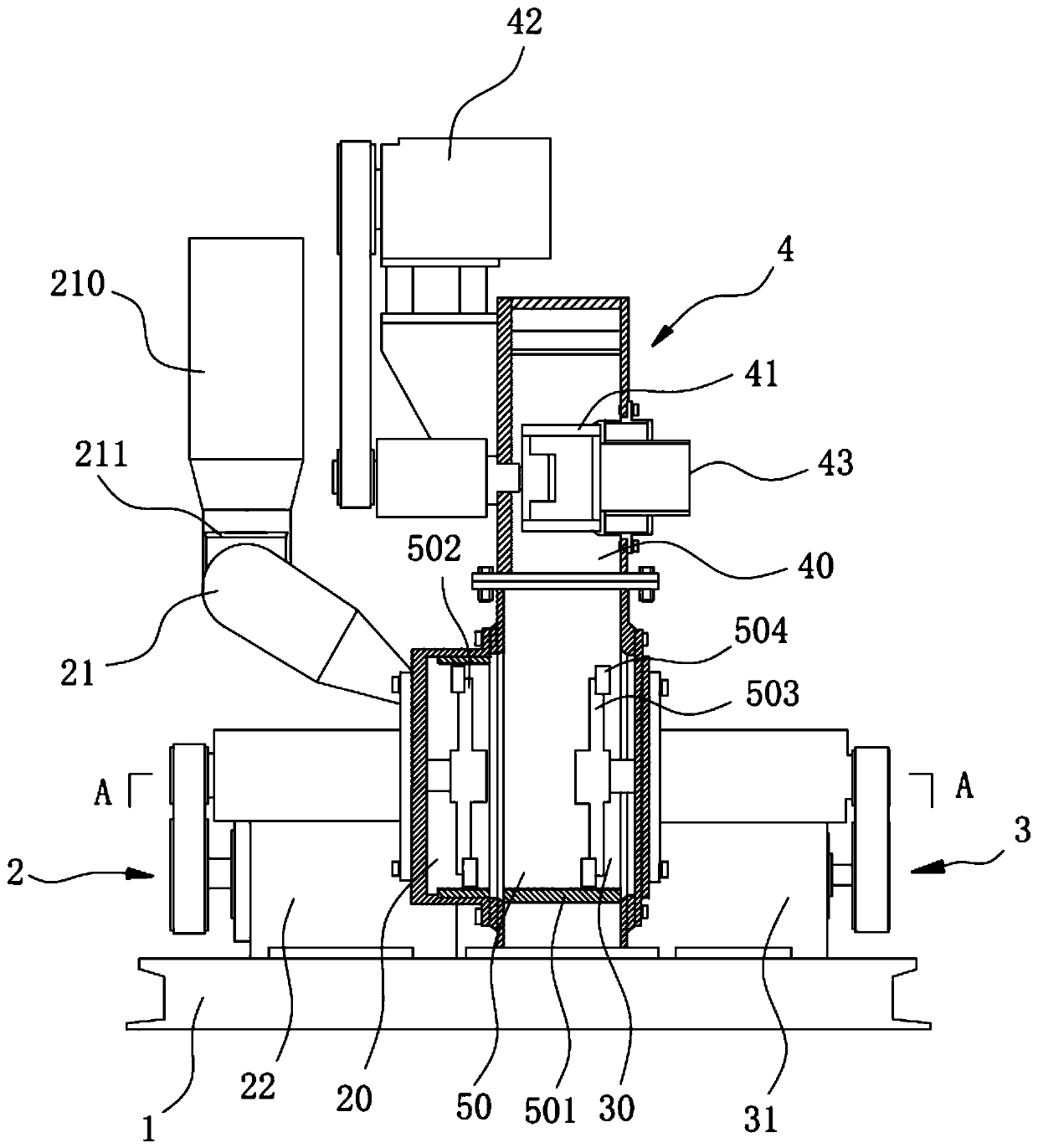

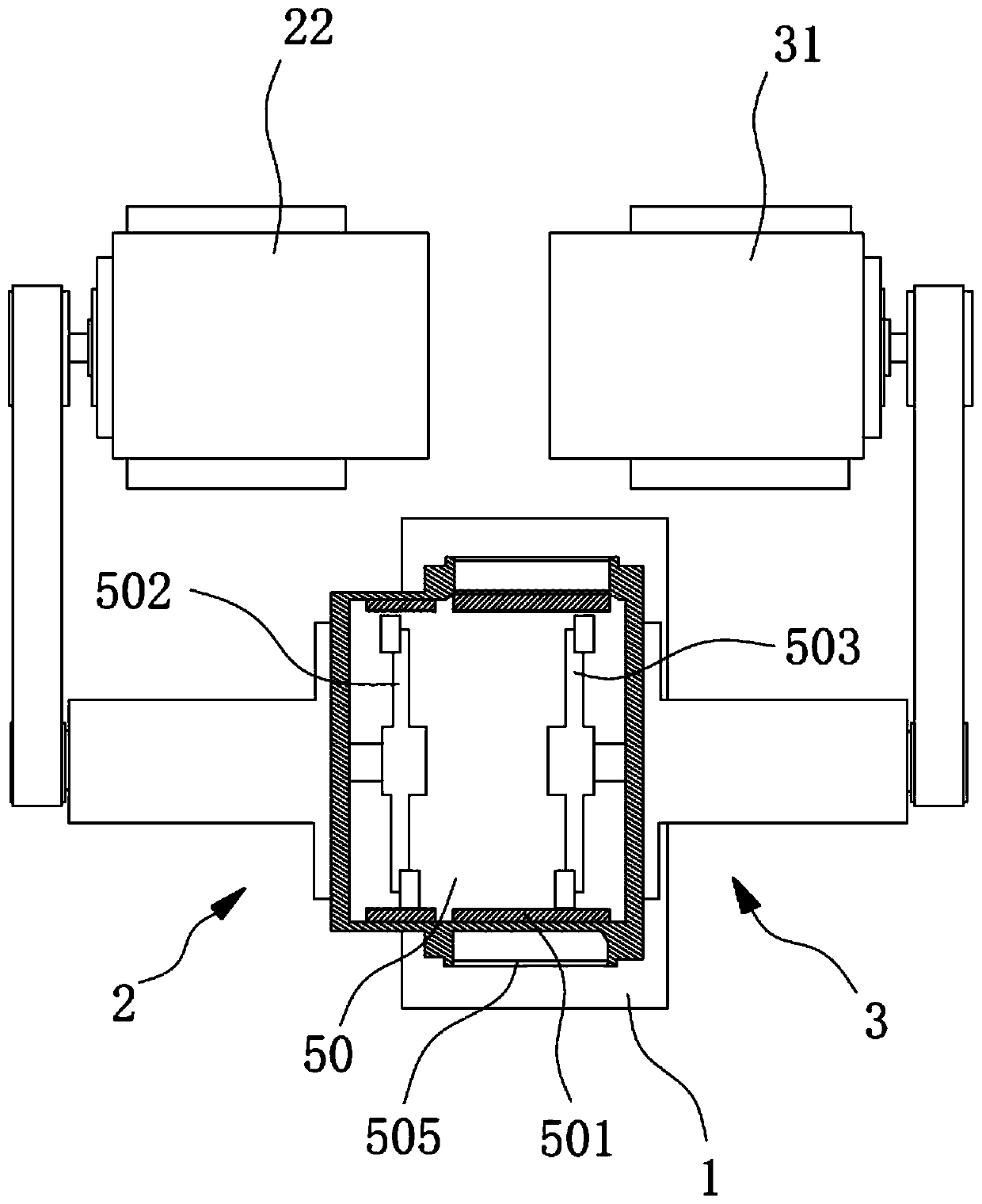

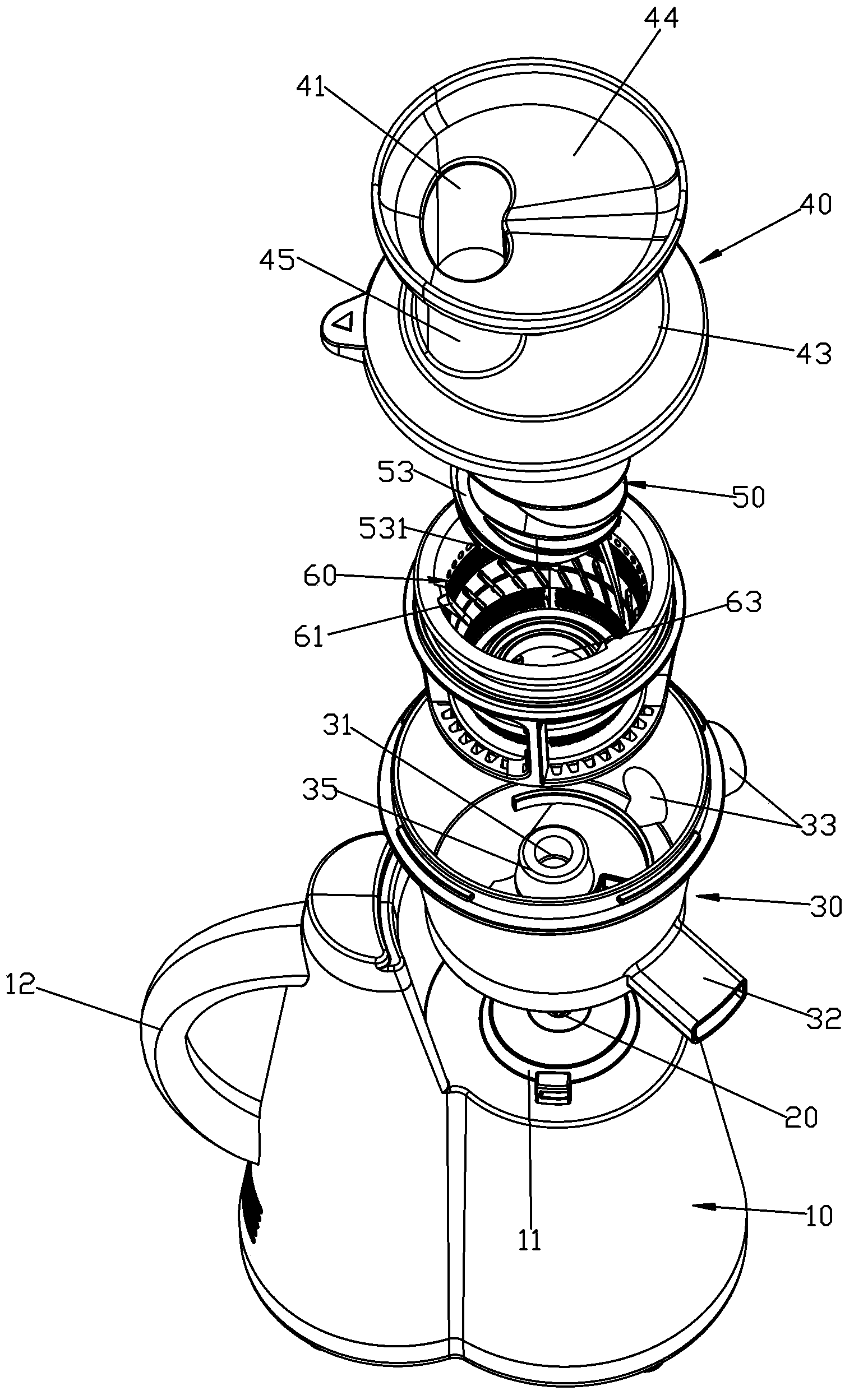

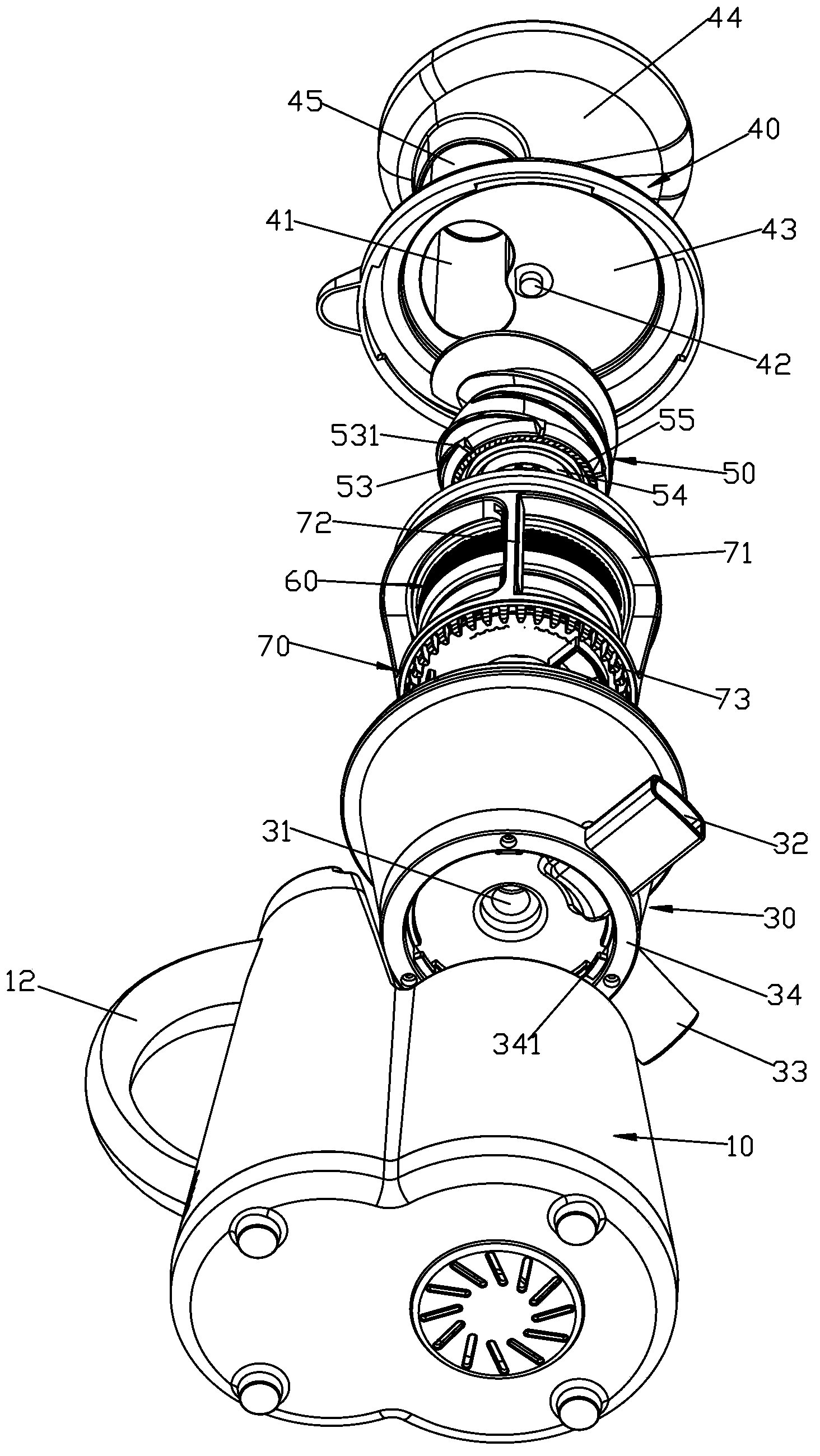

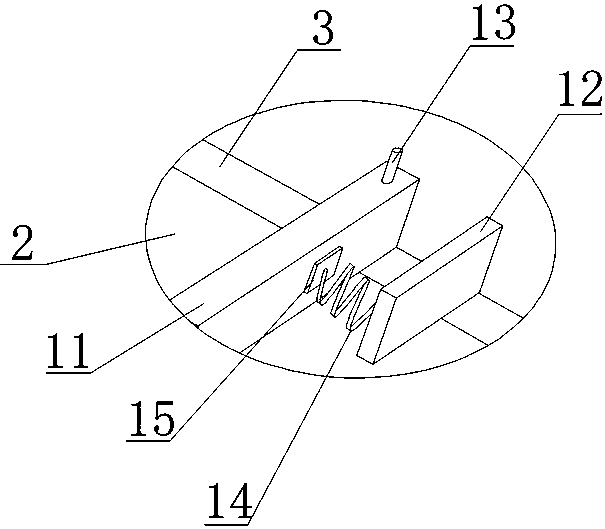

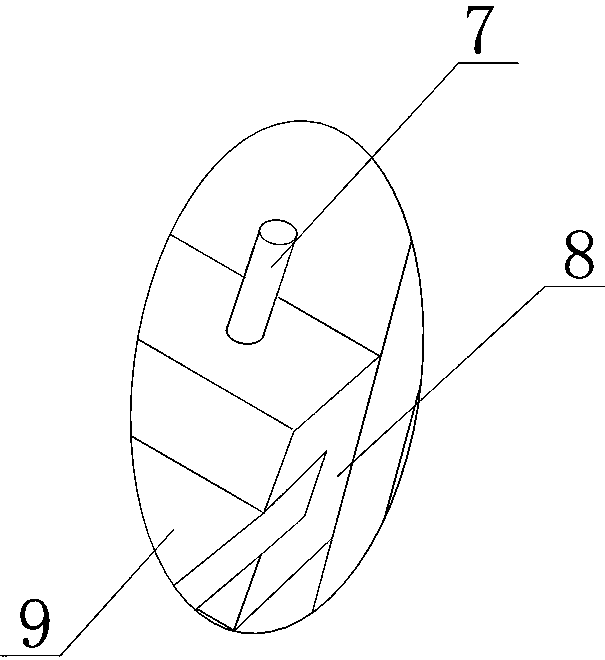

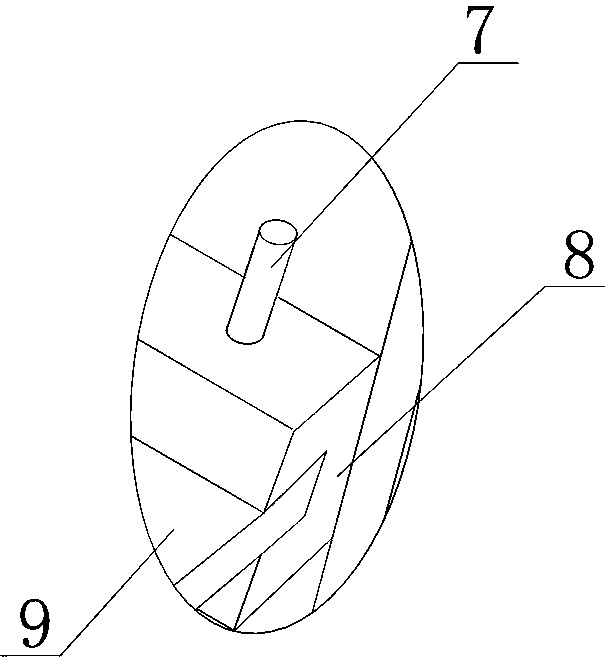

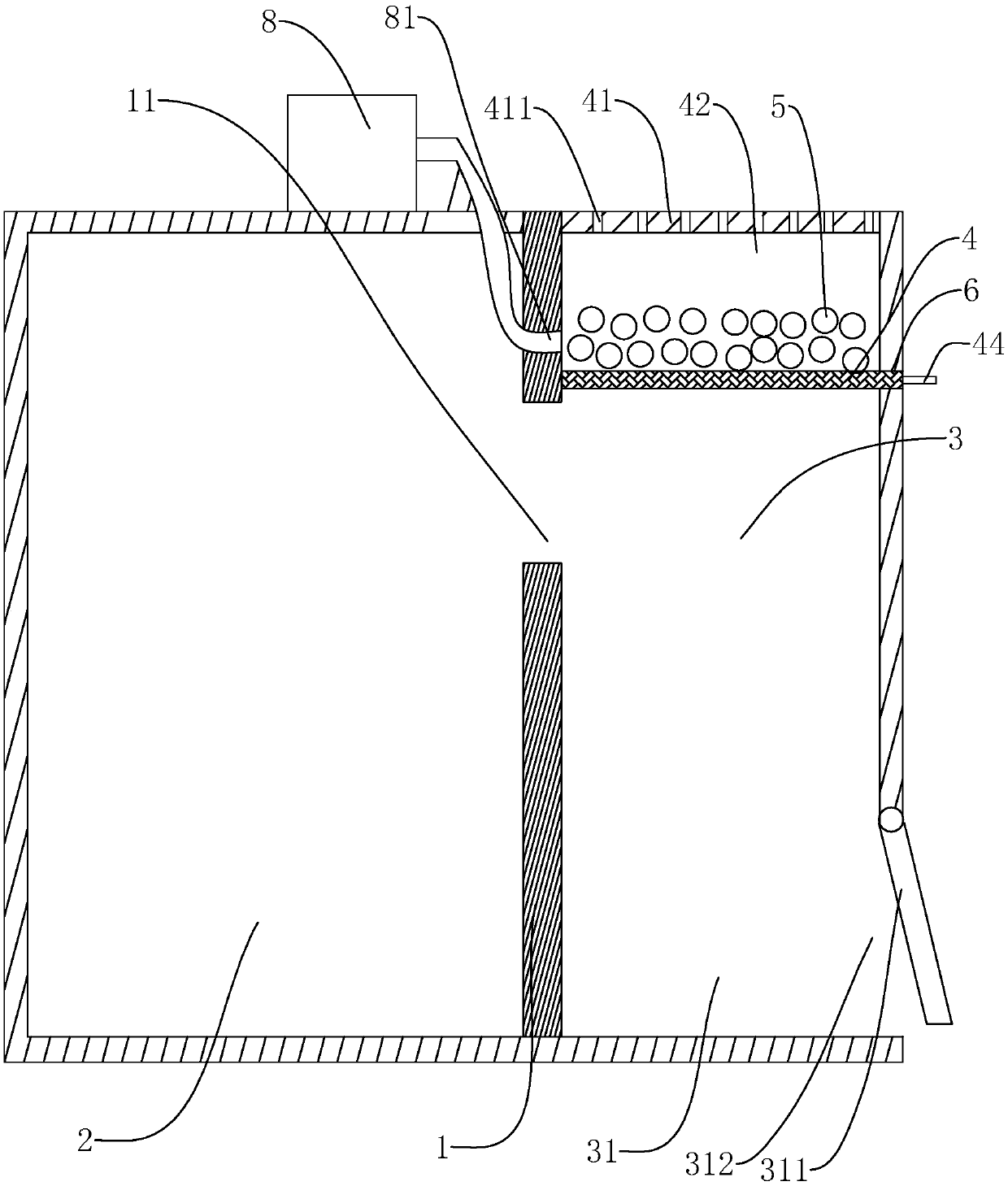

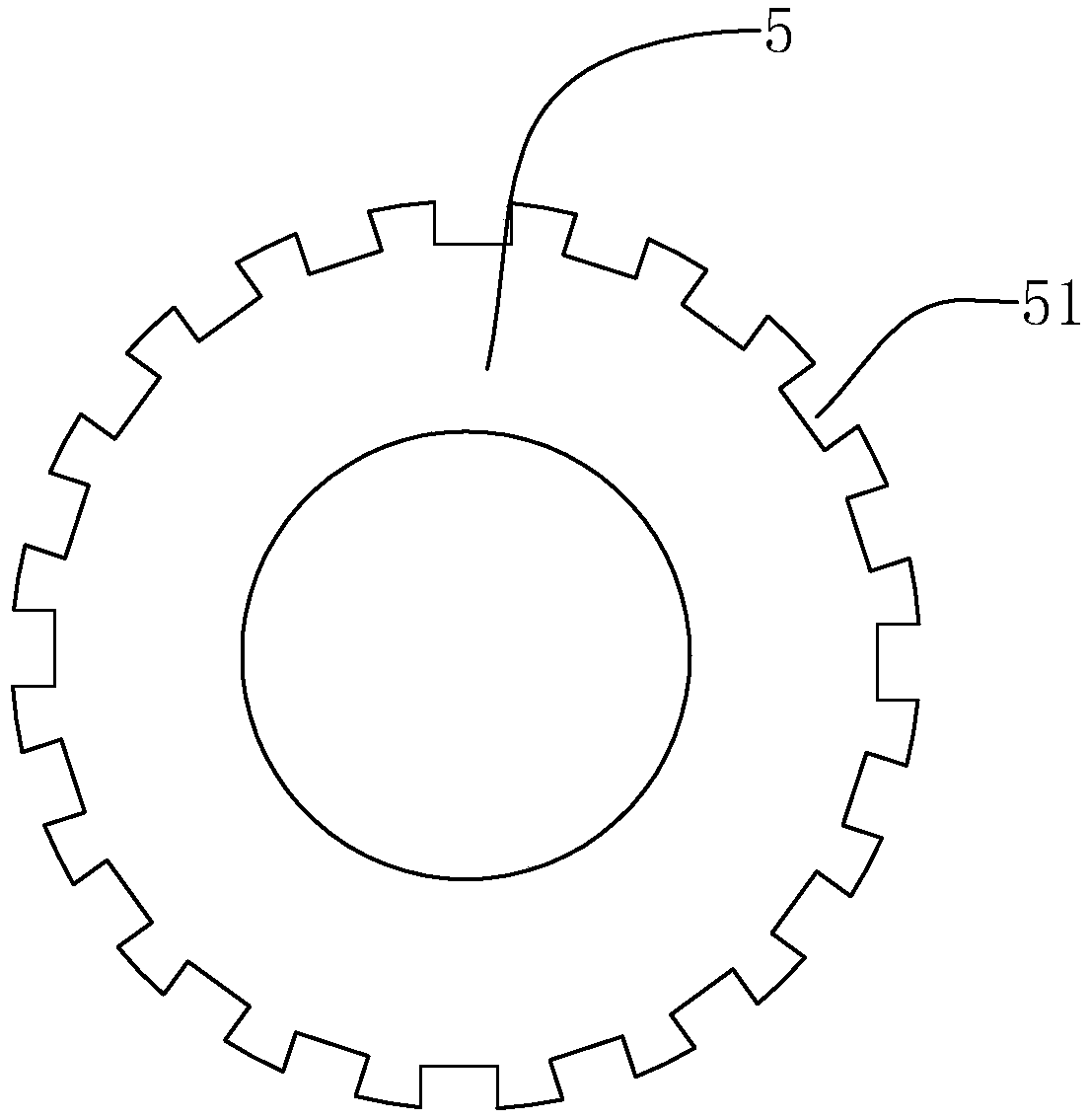

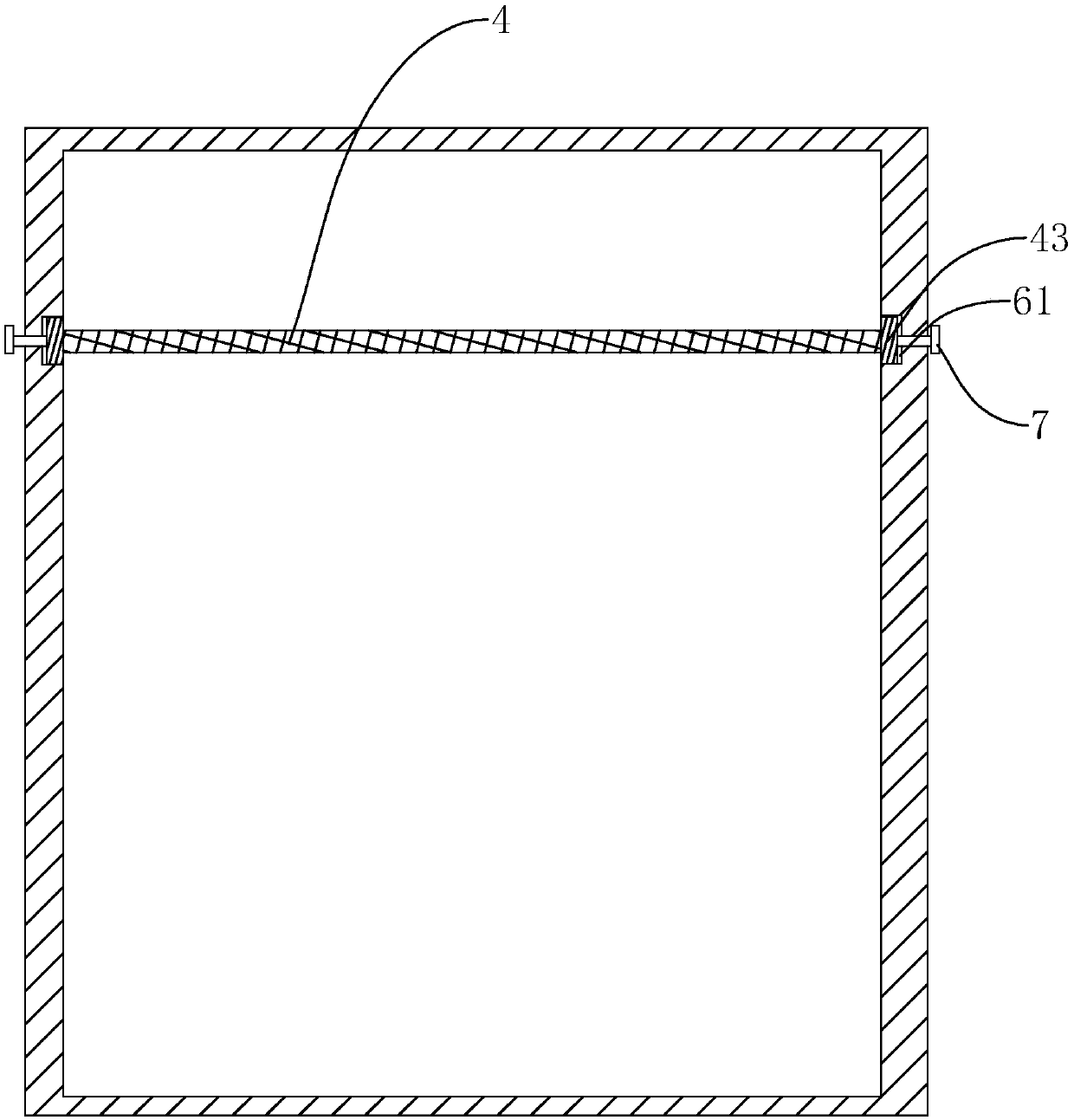

The invention discloses a juice extraction machine, which comprises a base, a driving unit, a container, a cover, a spiral extraction device and a juice extraction net, wherein the bottom wall of the container 30 is provided with a through hole and a residue outlet, and the peripheral wall of the container 30 is provided with a juice outlet. The cover 40 can be covered and connected onto the peripheral wall of the container 30 and is provided with a material input opening. The spiral extraction device 50 is arranged in the container 30, and the driving unit is connected with the rotating extraction unit 50 for driving the spiral extraction device 50 to rotate relative to the container 30 for realizing the juice extraction. The juice extraction net 60 is arranged in the container 30 and is positioned outside the rotating extraction device 50, the inner wall of the juice extraction net 60 is provided with a plurality of jade cutter ribs 61 capable of realizing the jade cutter effects, and the jade cutter ribs 61 are in inclined arrangement at intervals. The juice extraction machine has the following advantages that the jade cutter ribs are in inclined arrangement at intervals and are matched with the spiral extraction device, the extracted object vortex effect can be generated and enhanced, the extraction time number and the collision time number of the extracted objects are increased, the juice extraction rate is improved, the operation speed of the extracted objects can be accelerated, and the juice extraction speed is accelerated.

Owner:漳州依莱科技有限公司

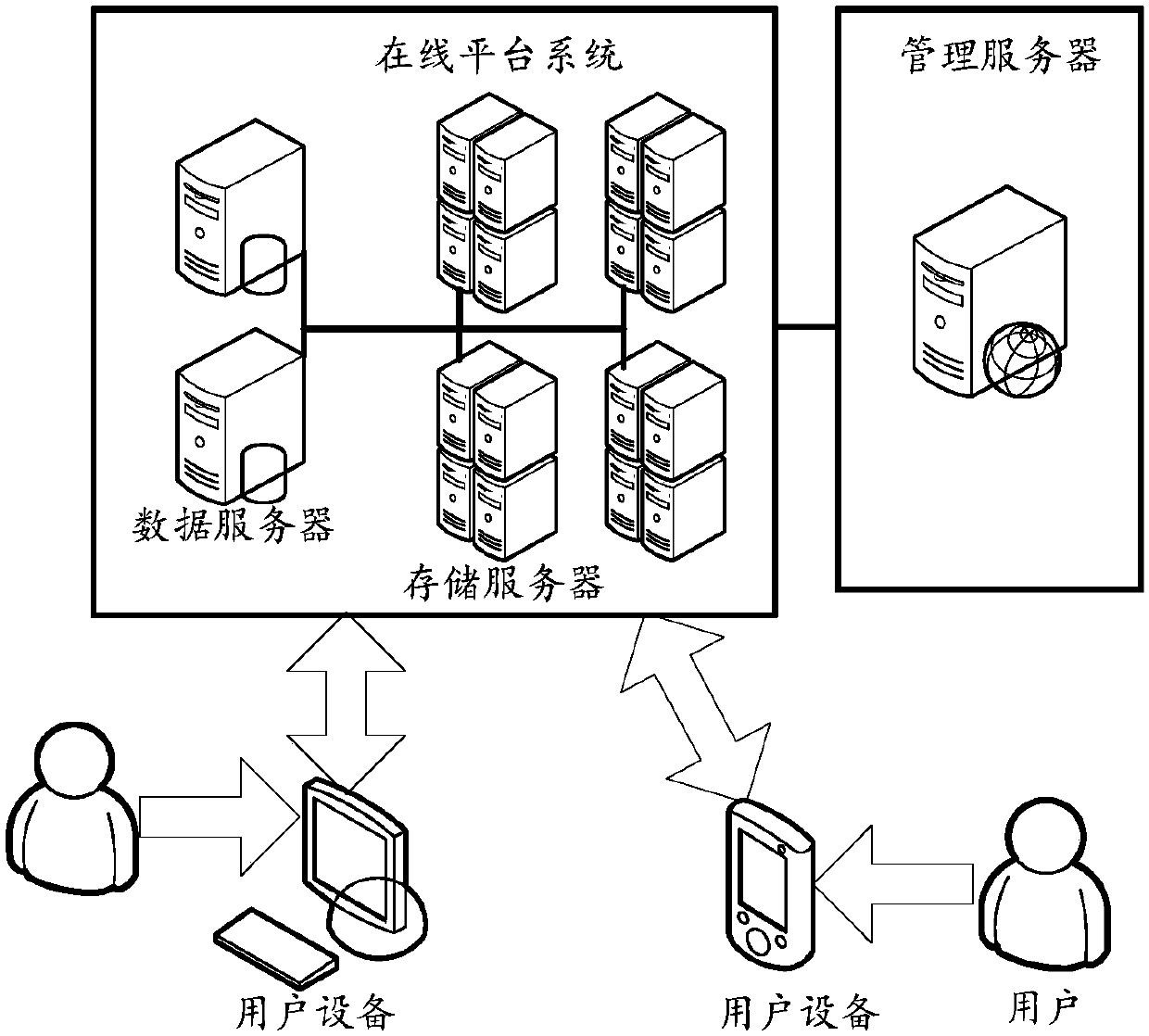

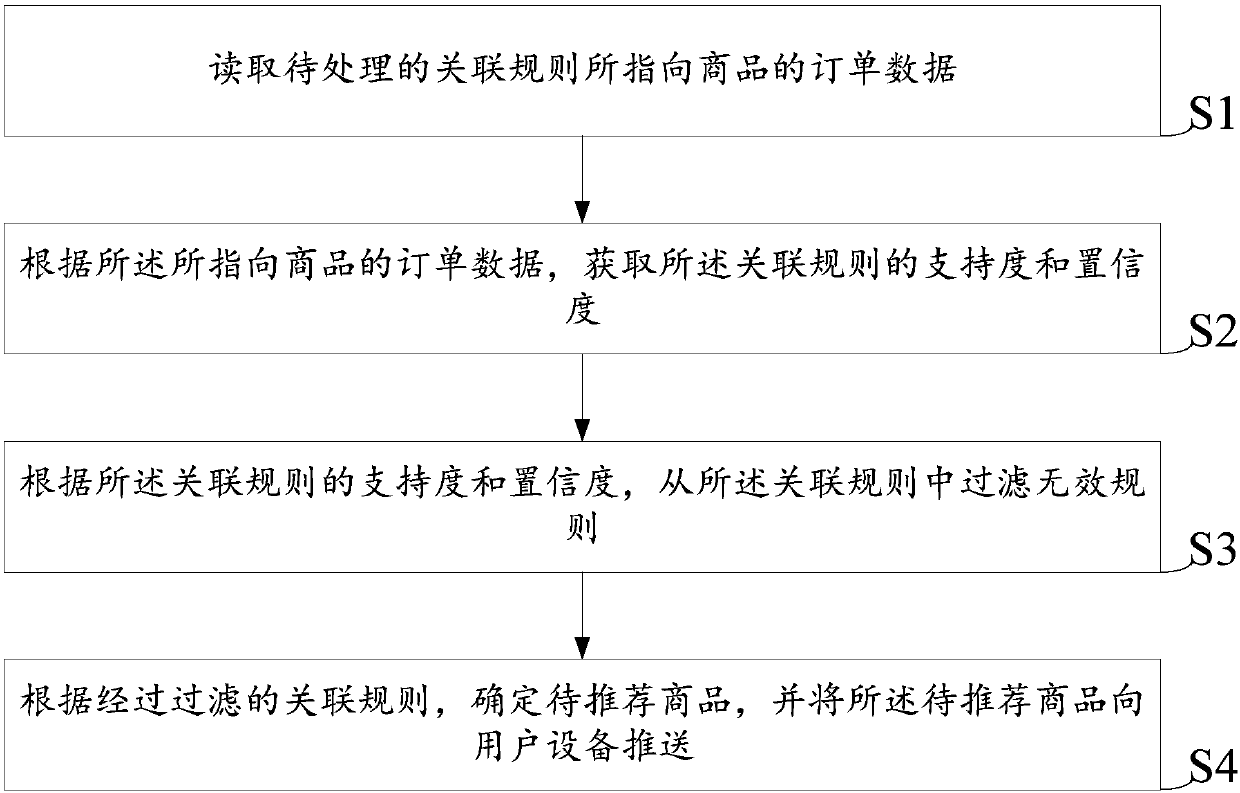

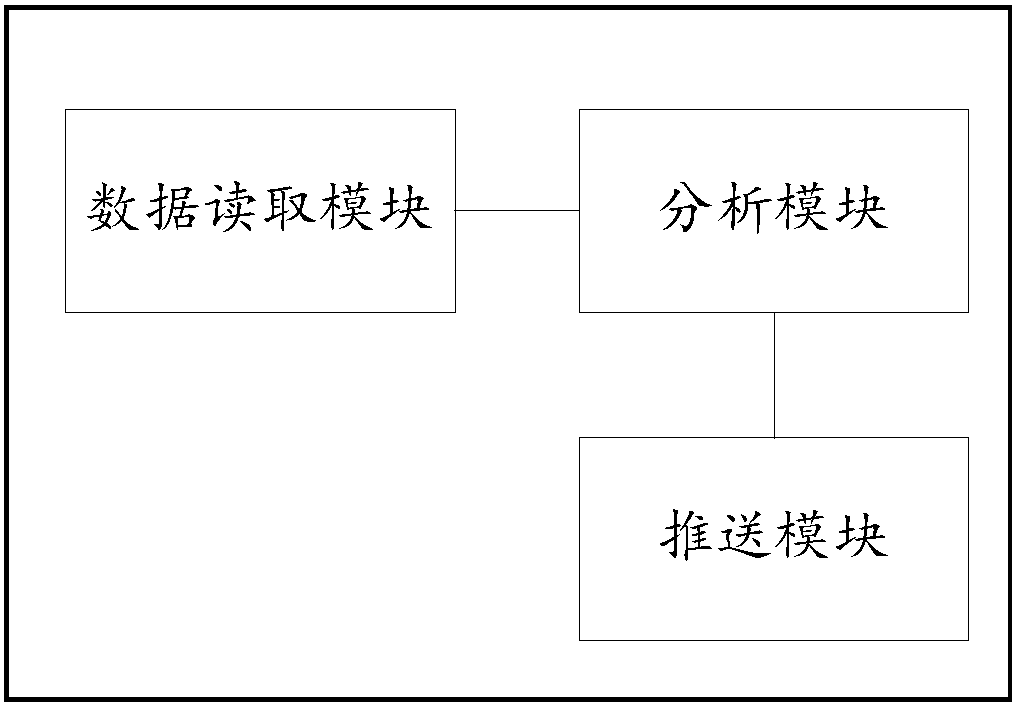

Commodity pushing method and apparatus for online transaction

InactiveCN107730336AIncrease the number of hitsImprove accuracyBuying/selling/leasing transactionsGranularityThe Internet

Embodiments of the invention disclose a commodity pushing method and apparatus for online transaction, which relates to the technical field of the internet and can improve the accuracy of commoditiesrecommended to users. The method comprises the steps of reading to-be-processed order data of commodities which correlation rules point to, wherein the correlation rules are used for representing at least two commodities with a correlation relationship; according to the order data of the commodities which the correlation rules point to, obtaining a support degree and a confidence degree of the correlation rules, wherein the support degree is used for representing a conditional probability of the commodities which the correlation rules point to in date granularity, and the confidence degree isused or representing a conditional probability of the commodities which the correlation rules point to in sales volume; according to the support degree and the confidence degree of the correlation rules, filtering invalid rules from the correlation rules; and according to the filtered correlation rules, determining to-be-recommended commodities, and pushing the to-be-recommended commodities to user equipment. The commodity pushing method and apparatus is suitable for commodity pushing in related online transactions during shopping of the users.

Owner:SUNING COM CO LTD

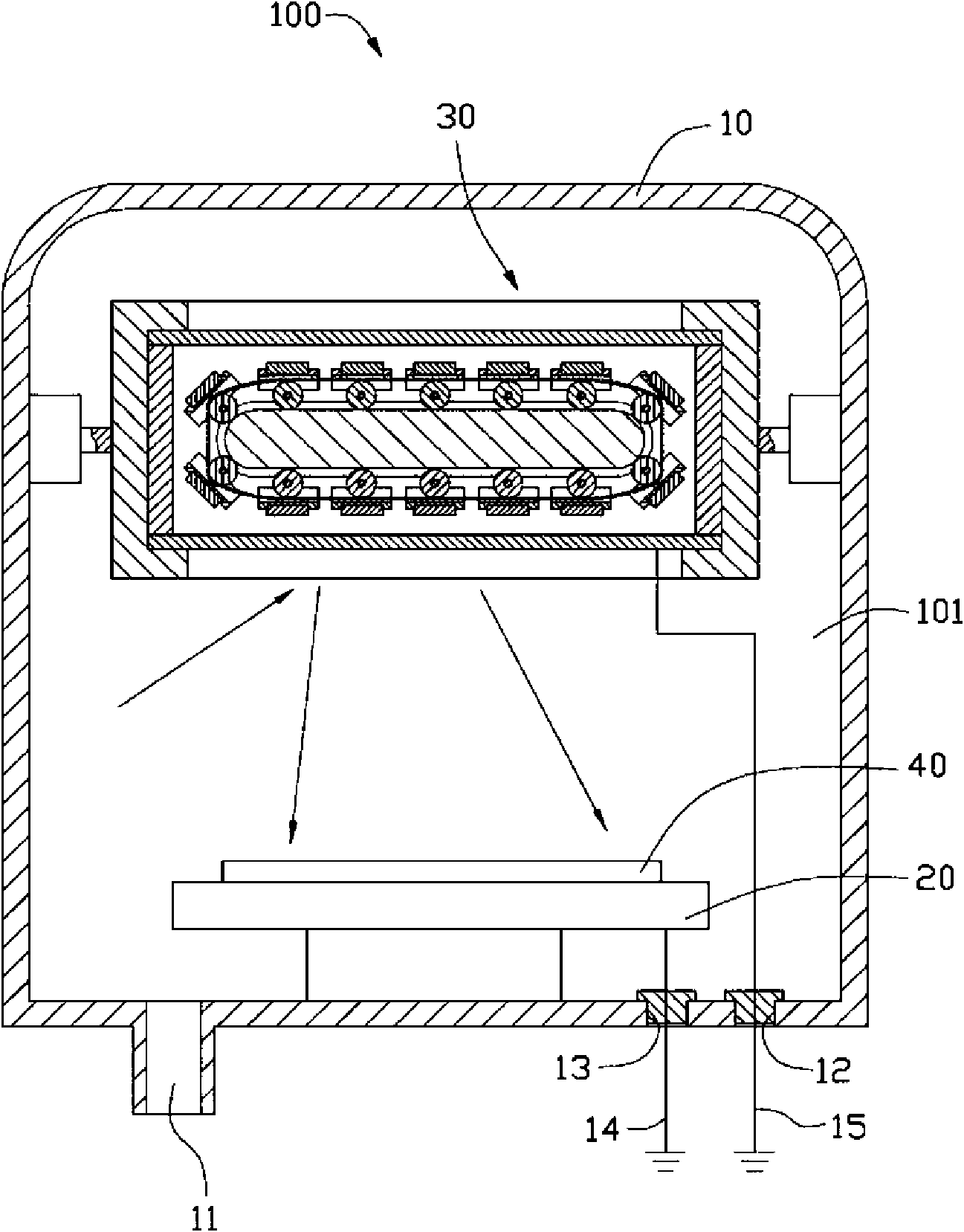

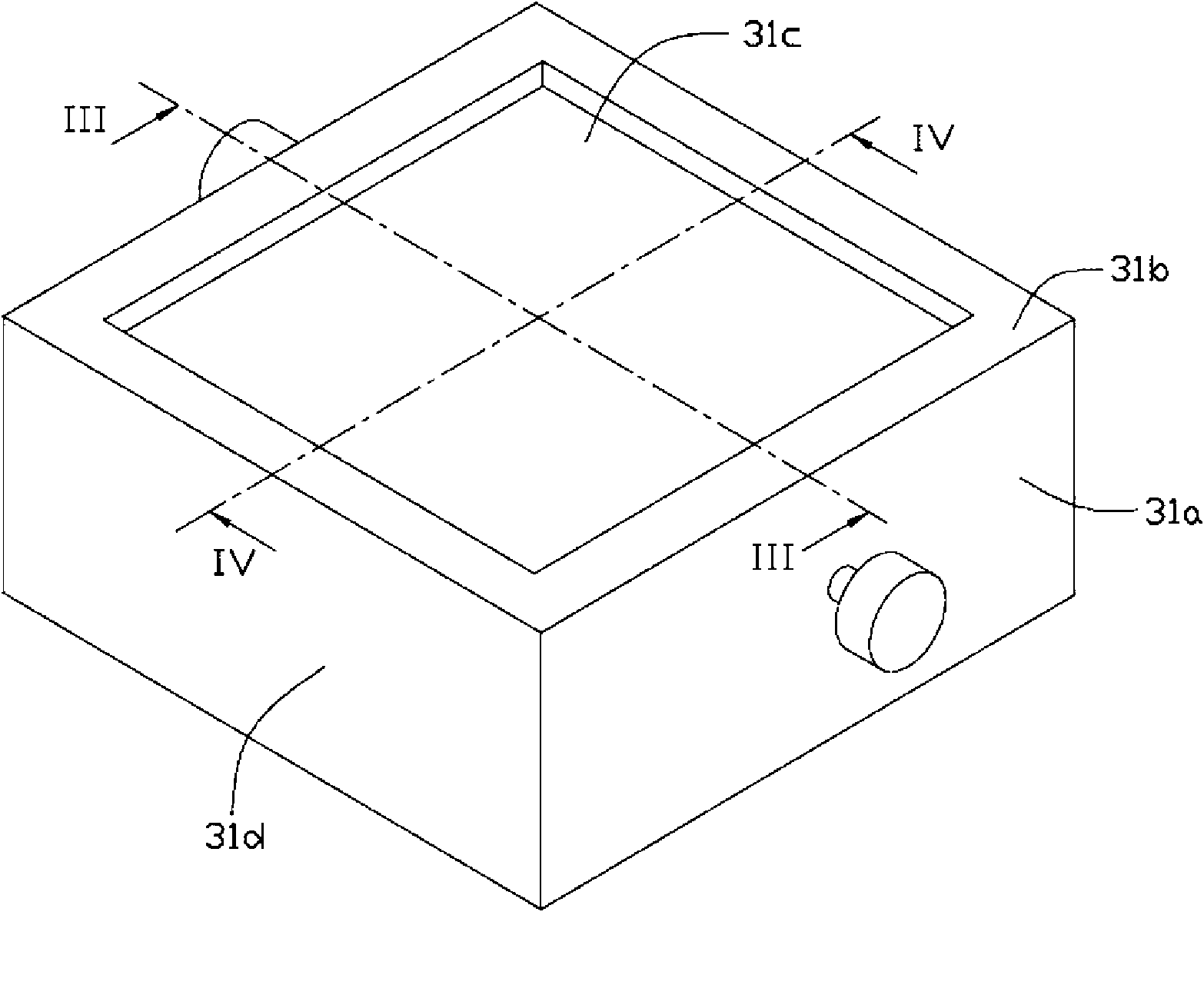

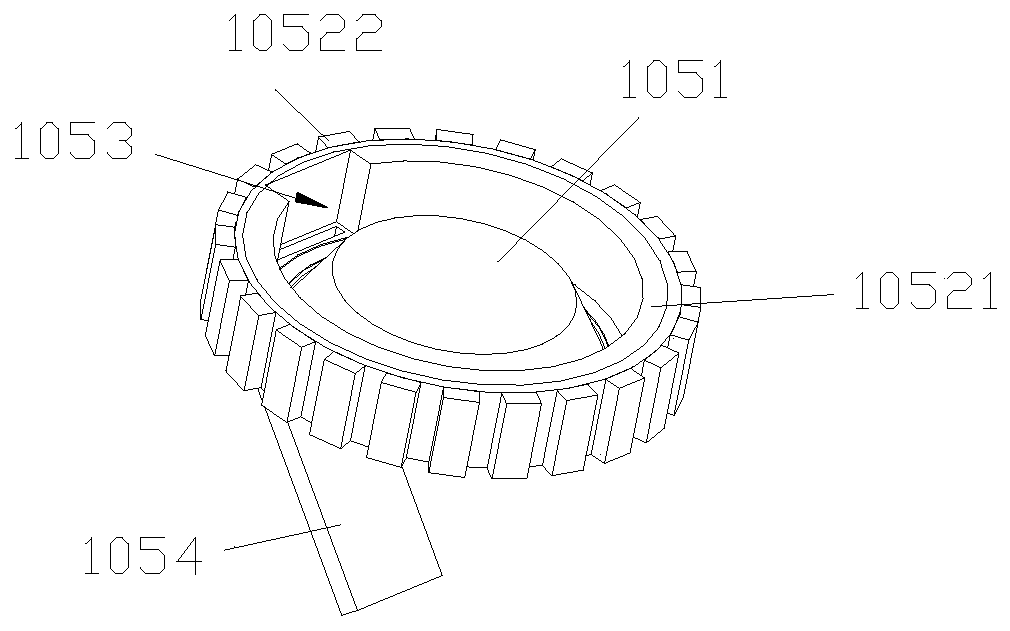

Magnetron sputtering target and magnetron sputtering device adopting same

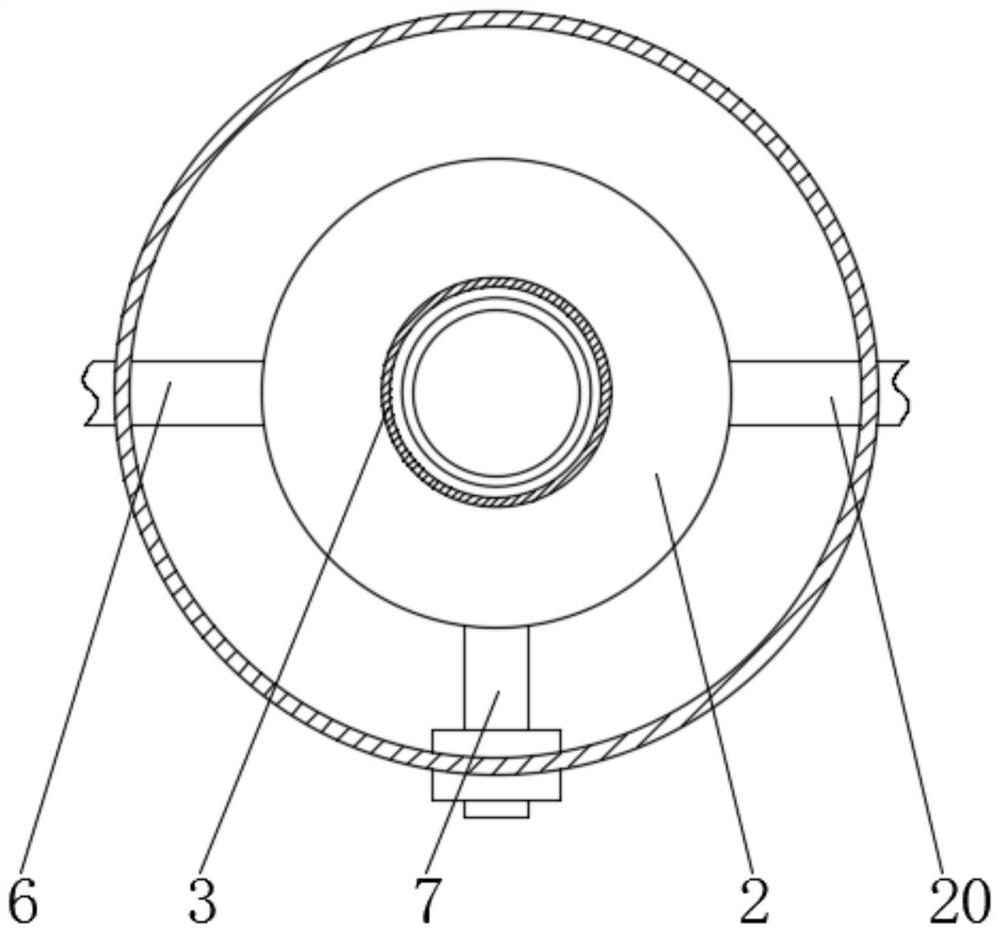

InactiveCN101988189AIncrease the number of hitsIncrease profitElectric discharge tubesVacuum evaporation coatingEngineeringElectrical and Electronics engineering

The invention relates to a magnetron sputtering device which comprises a shielding cover, a substrate bearing seat and a magnetron sputtering target, wherein the shielding cover is provided with a first cavity, and the substrate bearing seat, a substrate and the magnetron sputtering target are positioned in the first cavity; the substrate bearing seat is arranged opposite to the magnetron sputtering target, the substrate is installed on the substrate bearing seat, and the magnetron sputtering target is pivoted on the inner wall of the shielding cover; the magnetron sputtering target comprises a target seat, at least one target material, a plurality of magnetic cores and a magnetic core translation mechanism, and the target material is fixed on the target seat; the plurality of magnetic cores are fixed on the magnetic core translation mechanism; the magnetic properties of every two adjacent magnetic cores are opposite; the magnetic core translation mechanism comprises a supporting plate, a plurality of roll shafts and transmission strips, and the edge of the supporting plate is fixed on the target seat and is parallel with the target material; the plurality of roll shafts are arranged on the supporting plate and can rotate relative to the supporting plate; the transmission strips are arranged around the plurality of roll shafts and the supporting plate; and the magnetic core translation mechanism can drive the plurality of magnetic cores to translate relative to the target material. The invention also provides a magnetron sputtering target.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

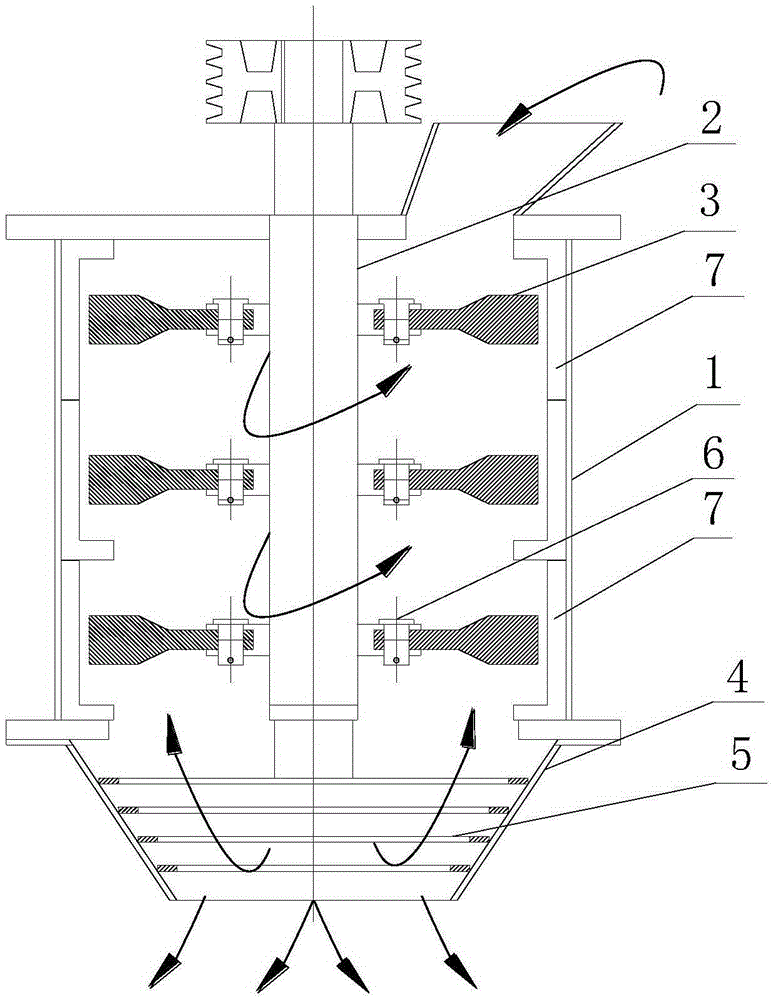

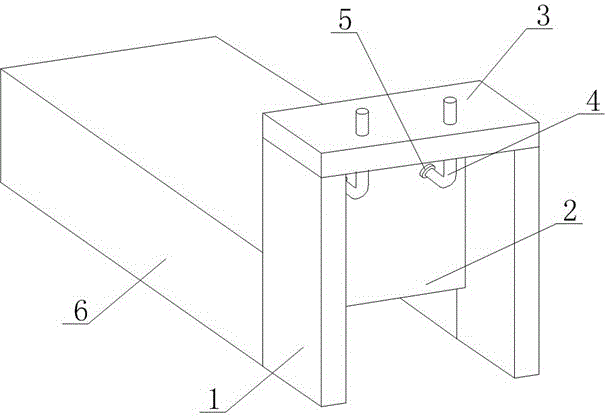

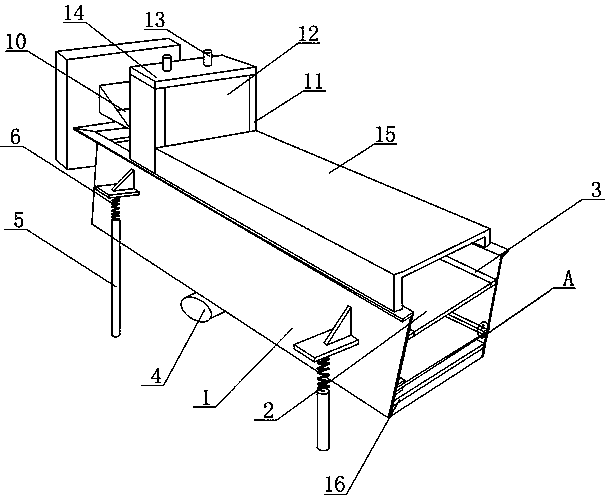

Ball mill for grinding soft magnetic core

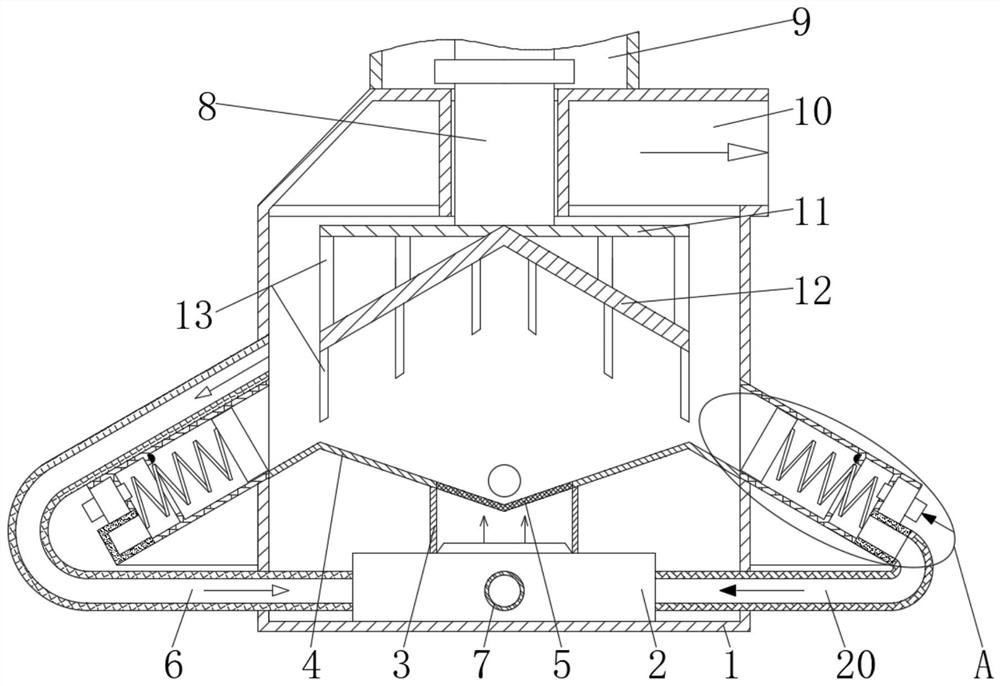

ActiveCN111420759AImprove impact efficiencyExtend the trajectoryGrain treatmentsGear wheelIndustrial equipment

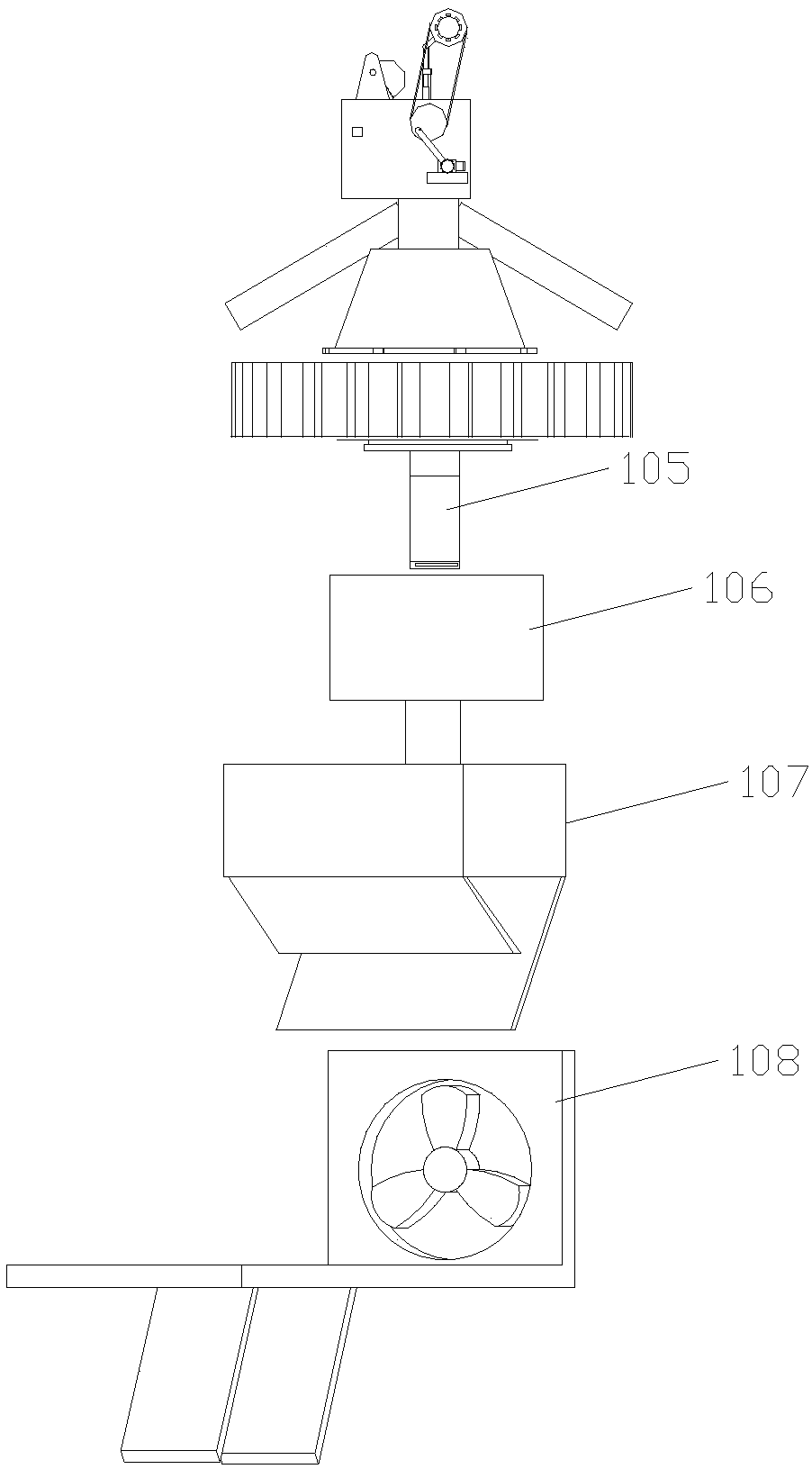

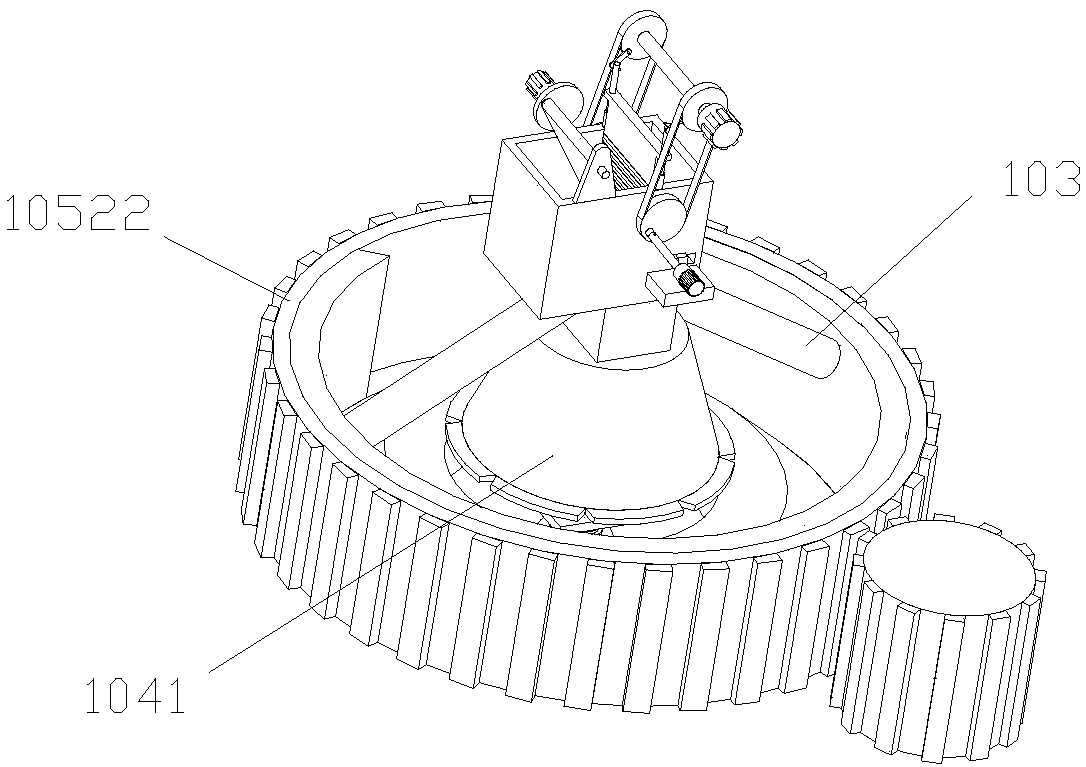

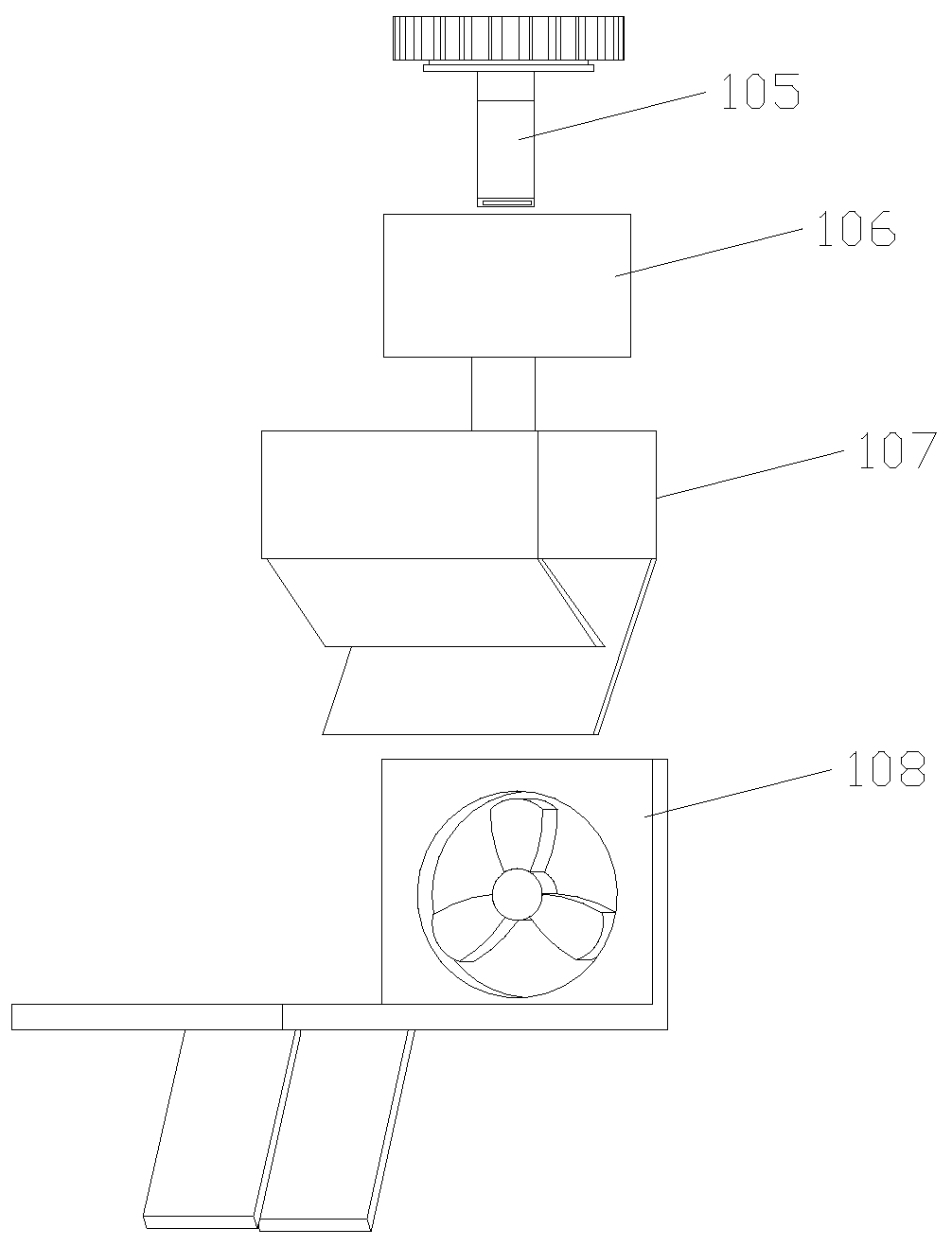

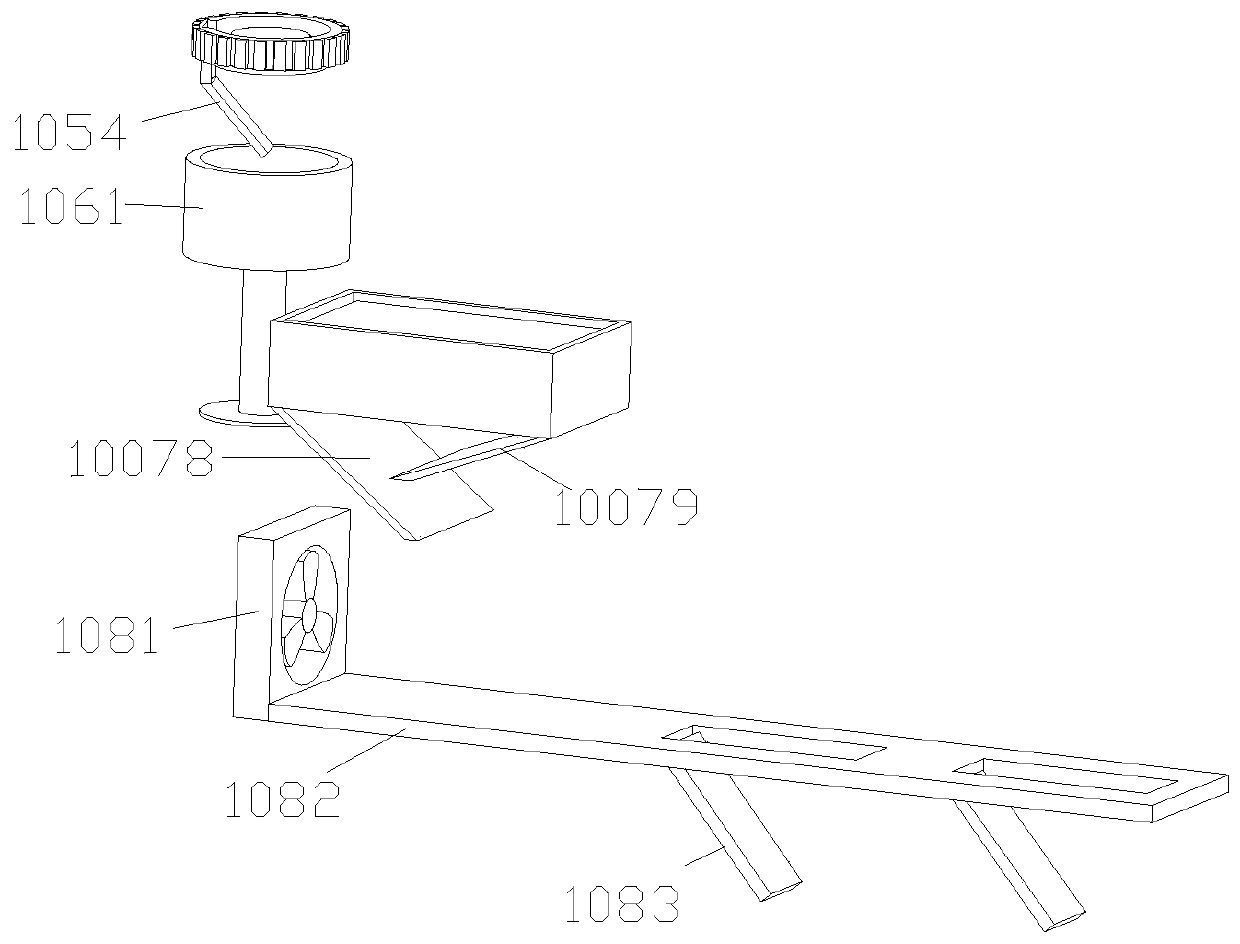

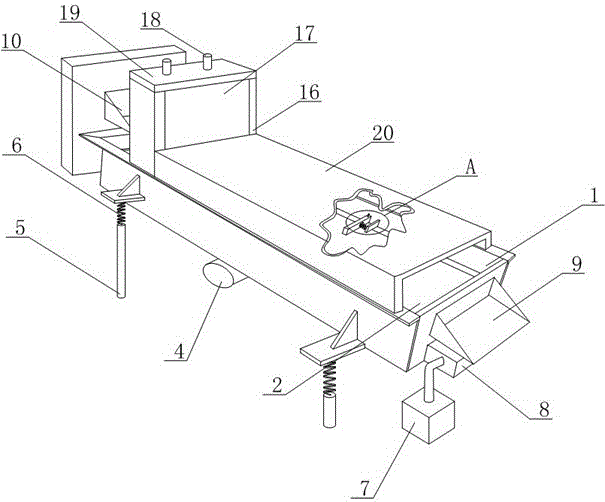

The invention relates to the technical field of industrial equipment, and discloses a ball mill for grinding a soft magnetic core. The ball mill comprises a fixing box, a rotating cylinder, a lining,grinding steel balls, an outer gear and a key, wherein the lining is fixedly arranged on the inner wall of the rotating cylinder, the outer gear is fixedly arranged at the bottom of the rotating cylinder in a sleeving mode, the grinding steel balls are movably arranged inside the lining, a bottom support seat is fixedly arranged on the fixing box, and a large thrust bearing is fixedly arranged inside the bottom support seat. Due to the arrangement of the rotating cylinder and a partitioning device, the space inside the rotating cylinder is equally divided, the effective grinding space is further compressed, the impact efficiency between the grinding steel balls and a material is improved, the grinding effect in the area is improved, and the grinding efficiency is improved; and the rotatingcylinder and the partitioning device are rotated in different directions, so that the movement track and the movement speed of the grinding steel balls are increased, the impact times among the grinding steel balls and between the grinding steel balls and the material are increased, and the grinding effect on the material is further improved.

Owner:LOUDI CITY LITONG MAGNETOELECTRICITY SCI & TECH

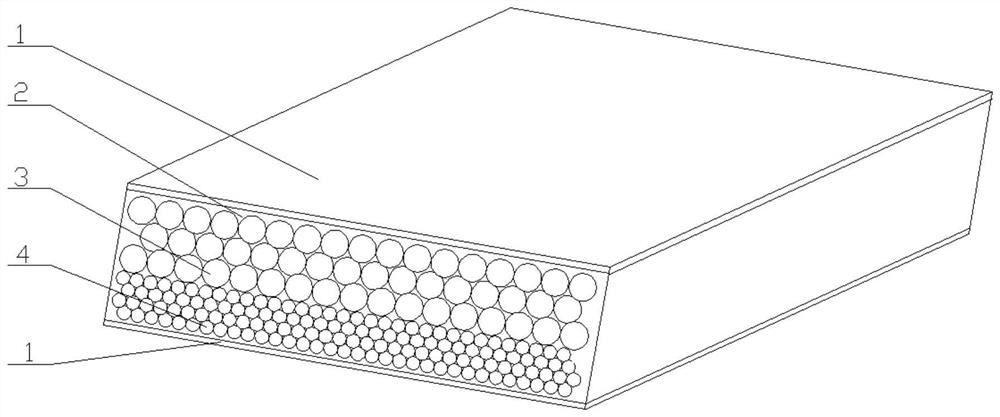

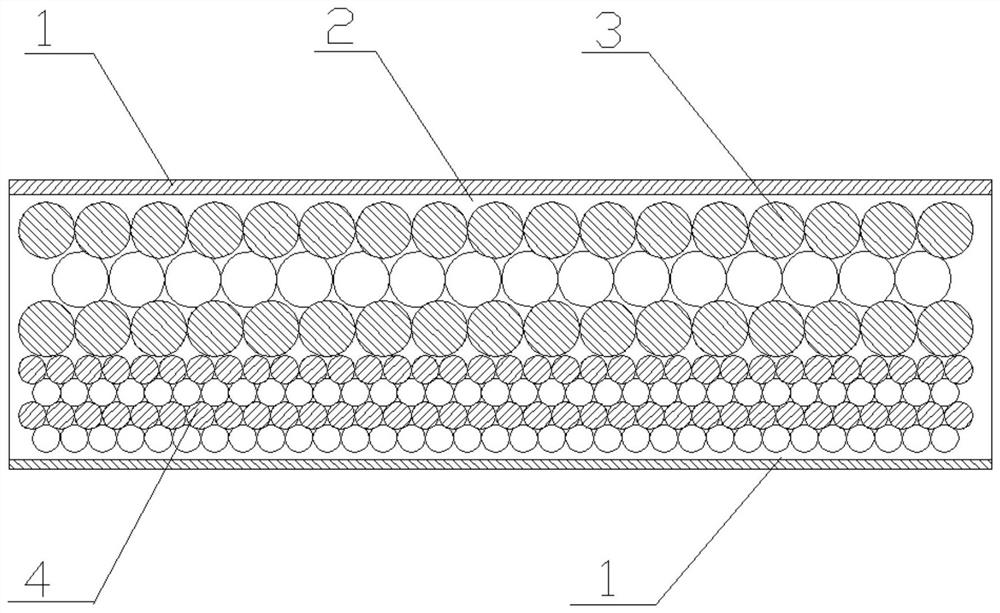

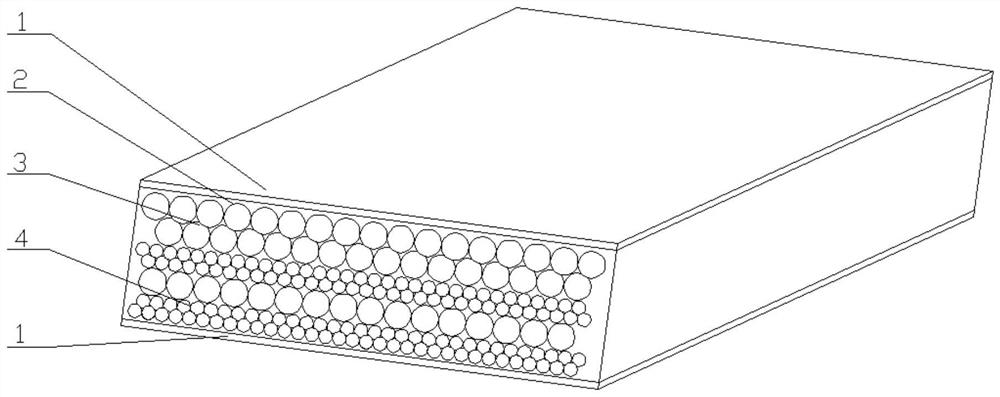

Composite protection plate with non-equal-diameter ceramic balls and application and manufacturing method

PendingCN111912296AImprove the performance of participation in anti-penetration integrationIncrease the bearing areaArmoured vehiclesArmour platesPolymerMacromolecule

The invention discloses a composite protection plate with non-equal-diameter ceramic balls. The composite protection plate comprises panels arranged up and down and a whole core material made of a polymer viscoelastic material, wherein the space between the panels is filled with the core material. At least two layers of the ceramic balls are coated in the core material, the adjacent layers of theceramic balls are arranged in a staggered manner, and the diameters of the ceramic balls on the same layer are the same. The ceramic balls with at least two different diameters are arranged in the core material, and the ceramic balls which resist penetration first are large-diameter ceramic balls. The ceramic balls with different diameters are arranged in the protection plate in a staggered manner, and it is ensured that deflection can be realized when a projectile body penetrates at any angle. The ceramic balls with different diameters are arranged in the protection plate, and after the projectile body performs hitting, the ceramic balls rapidly transmit impact force to the surrounding ceramic balls, so that the whole protection structure plate is driven to participate in resisting the impact of the projectile body, and the integral performance of the whole plate participating in penetration resistance is obviously improved.

Owner:JIANGSU UNIV OF SCI & TECH

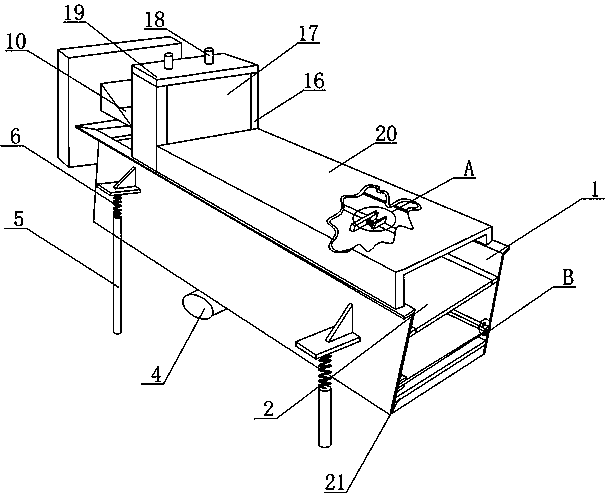

Device for separation of solid phase and liquid phase in drilling fluid

ActiveCN105863533AEasy to collectThe speed of liquid phase sieving is acceleratedFlushingWell drillingEngineering

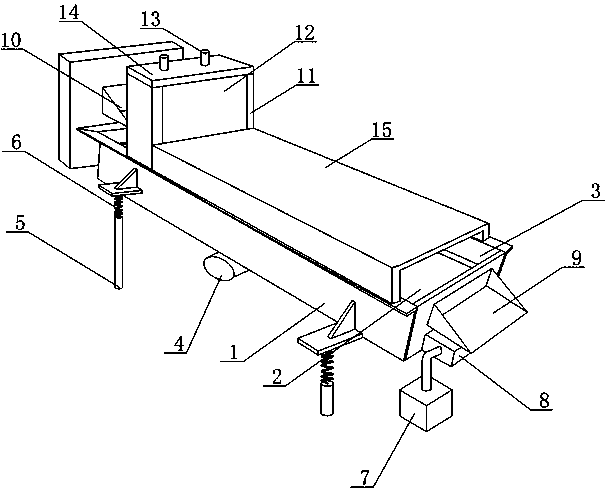

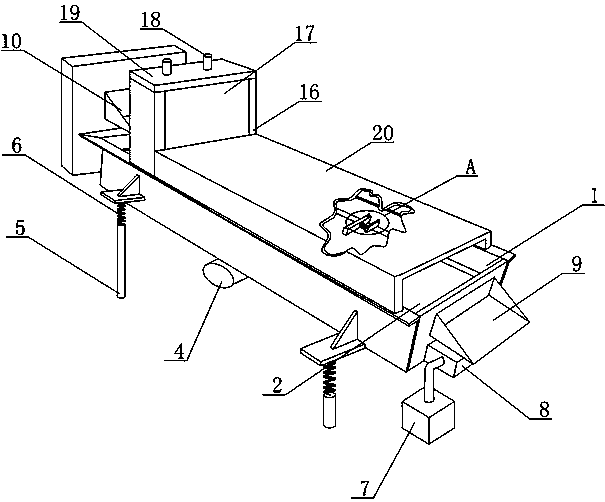

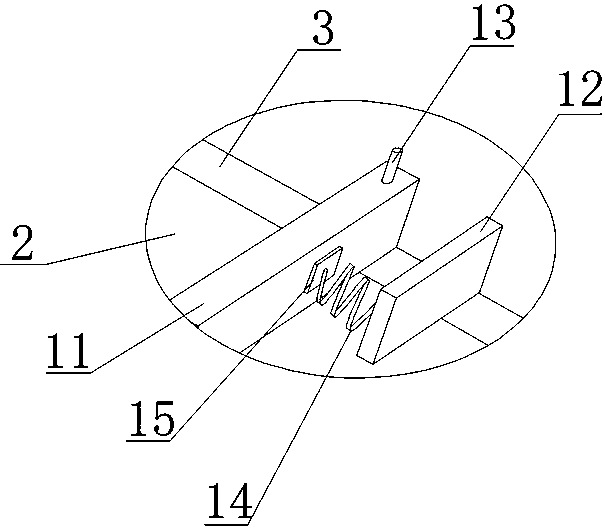

The invention discloses a device for separation of a solid phase and a liquid phase in drilling fluid. The device comprises a sieve box, a vibration motor, tension springs, a blowout preventer and a shield. Two ends of the sieve box are provided with a feeding port and a discharging port respectively, a sieve frame and a coarse screen are arranged in the sieve box, a fine screen is arranged below the coarse screen, concave grooves are formed between the coarse screen and the fine screen and provided with through holes and extend from the discharging port to the feeding port, and a liquid phase receiving plate is arranged in the concave grooves and parallel to the coarse screen. The device further comprises studs which pass through the through holes of the concave grooves to penetrate the liquid phase receiving plate, and a plurality of spring stop devices are arranged at equal intervals on the sieve frame. The device has the advantages that in an early stage of exploitation, screening speed of the liquid phase in the drilling fluid is increased, and treatment capacity of a drilling fluid vibration sieve is improved; in a later stage of exploitation, even solid-phase particles are smaller in size, the drilling fluid can be screened by the screens, and accordingly separation efficiency of the drilling fluid vibration sieve is improved.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

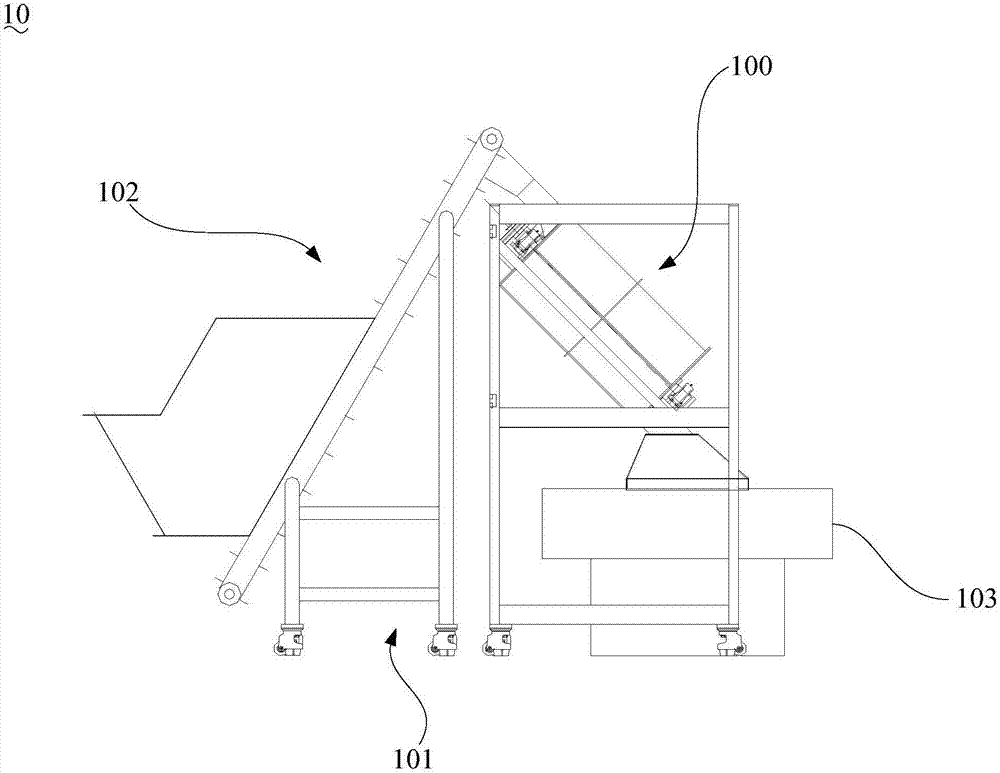

Crushing production line device and crushing method for processing waste concrete recycled aggregates

The invention discloses a crushing production line device for processing waste concrete recycled aggregates. The crushing production line device successively comprises a three-level crushing machine,a pre-crushing disc assembly, a centrifugal crushing blanking apparatus and a pin-roll lamination crushing apparatus according to the sequence of a technological process; the three-level crushing machine is used for crushing the concrete blocks with no iron impurities and non-iron impurities for three times, the pre-crushing disc assembly is used for centrifugally pre-crushing agglomerates and blocks in the crushed particles, and the centrifugal crushing blanking apparatus is used for secondarily crushing the pre-crushed particles and intermittently blanking the secondarily crushed particles;and the pin-roll lamination crushing apparatus is used for vertically extruding the secondarily crushed particles and also rolling crushing the particles. The crushing production line device of the invention has the advantages that the raw material can be crushed in various manners, the equipment integration degree is high, the raw material can be thoroughly crushed, the crushing efficiency is high, the smashing effect is good, the aggregate recycling rate of the recycled concrete is improved, the smashing effect is good, and the aggregate recycling rate of the recycled concrete can be improved.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

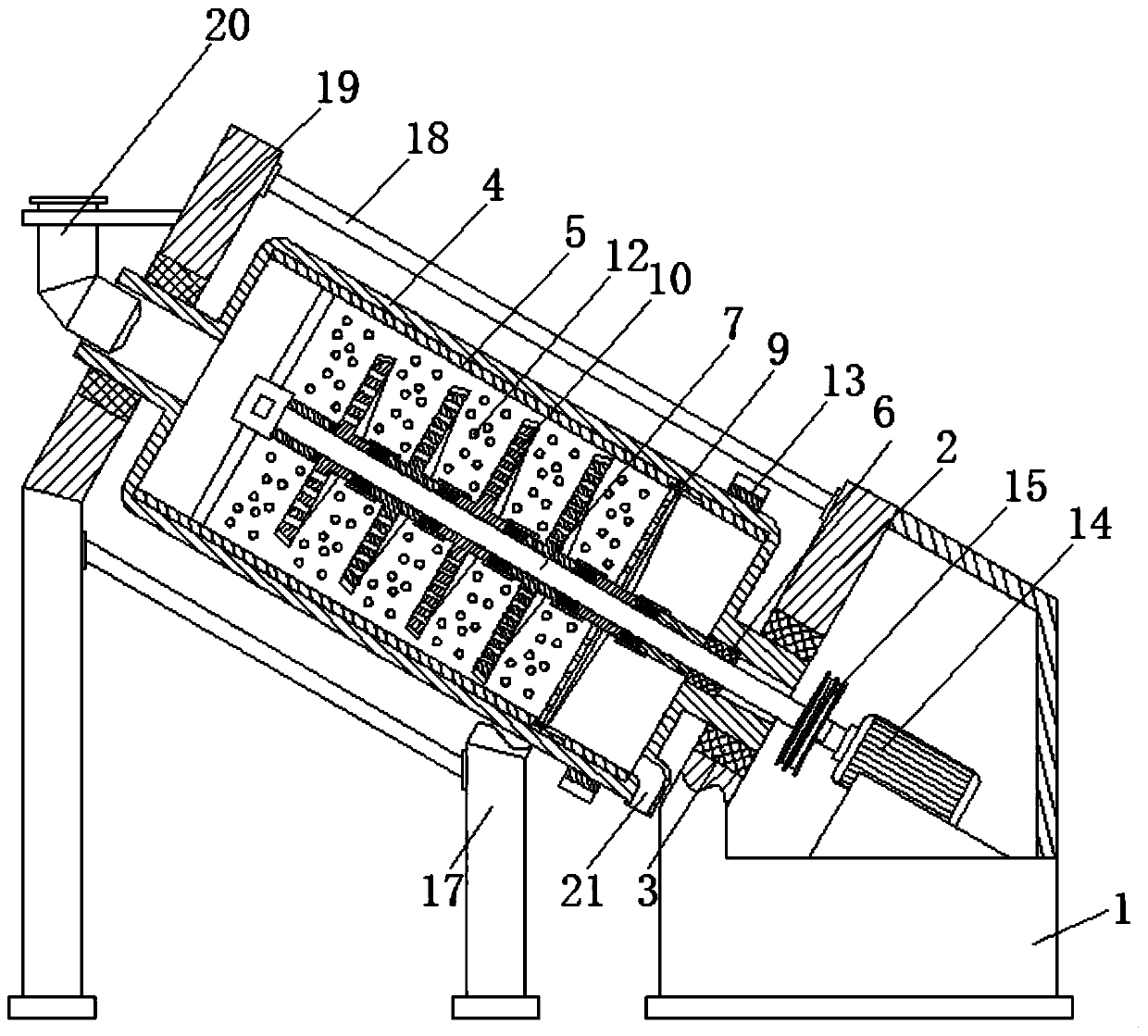

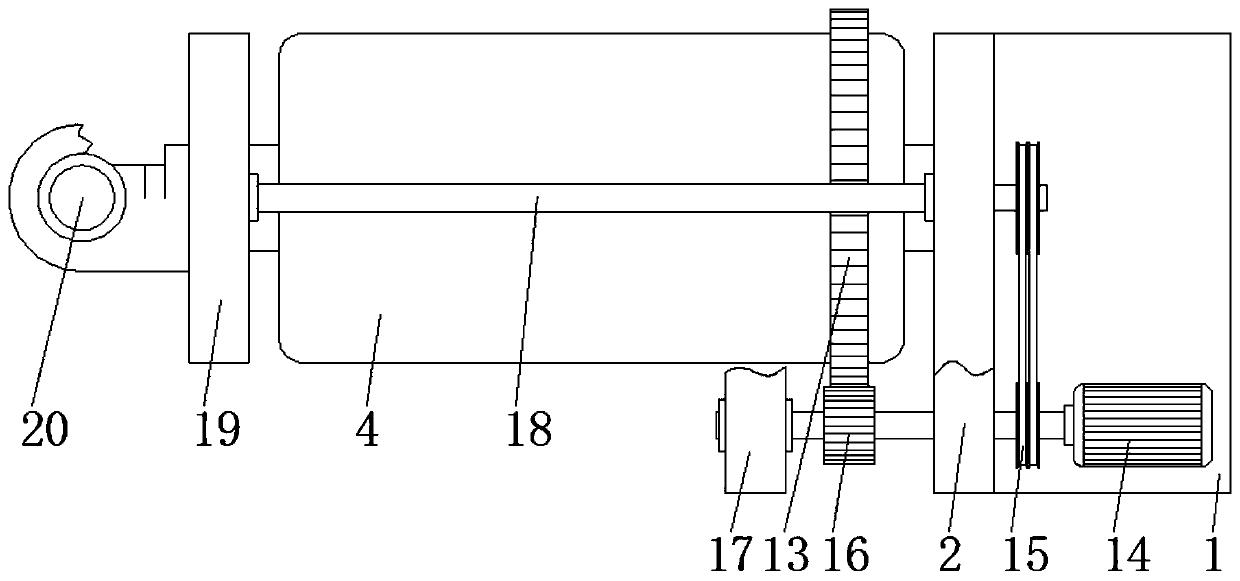

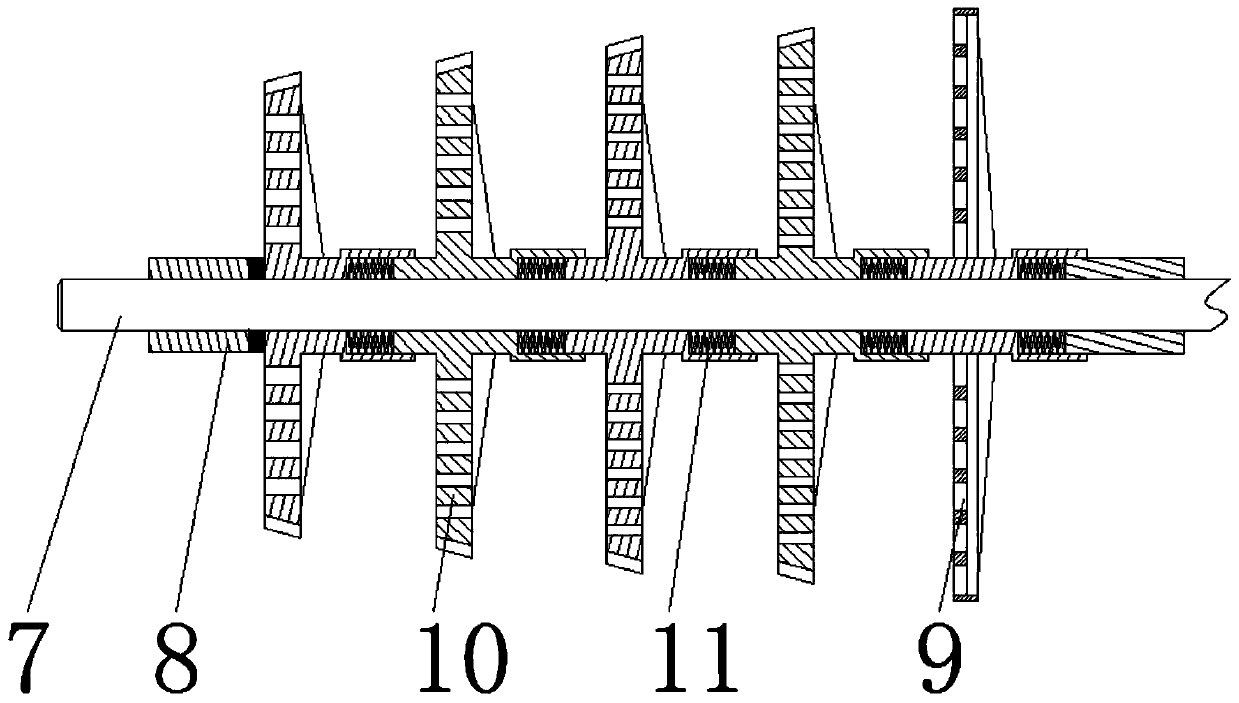

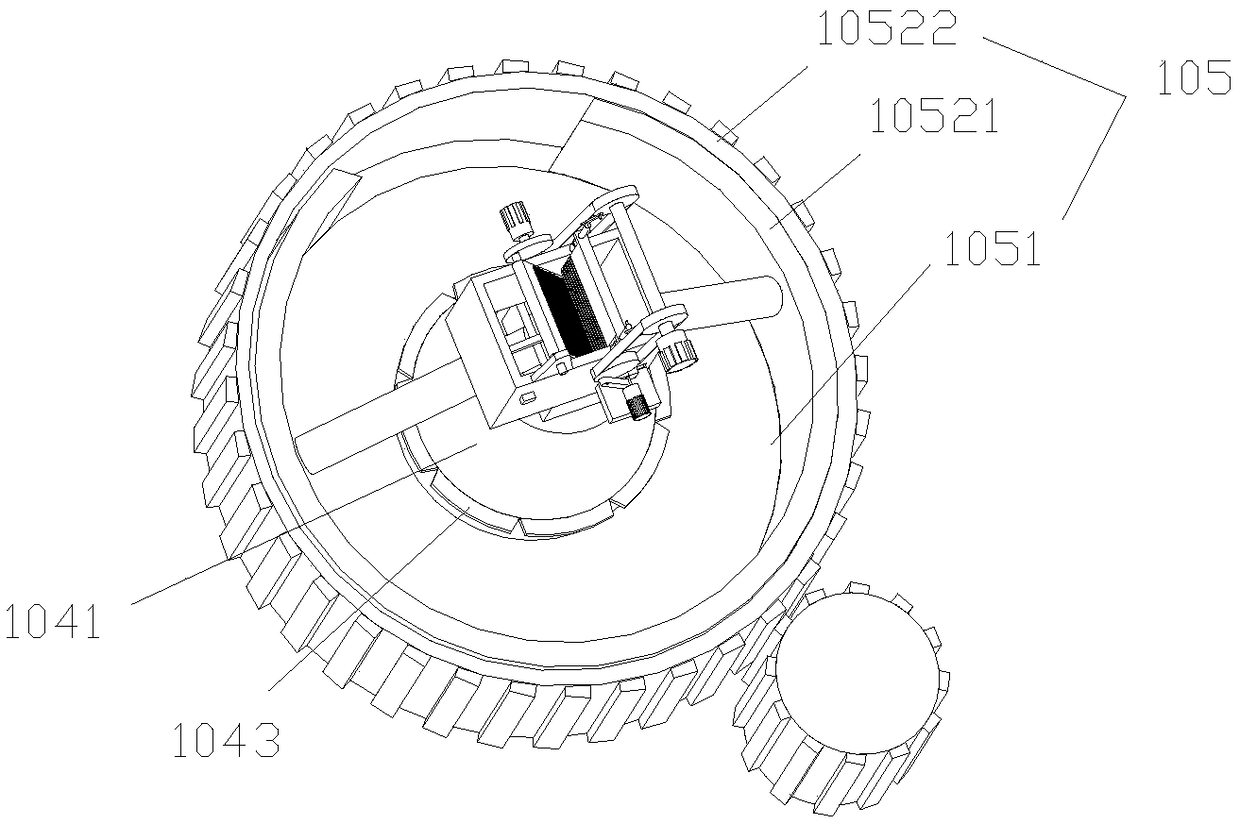

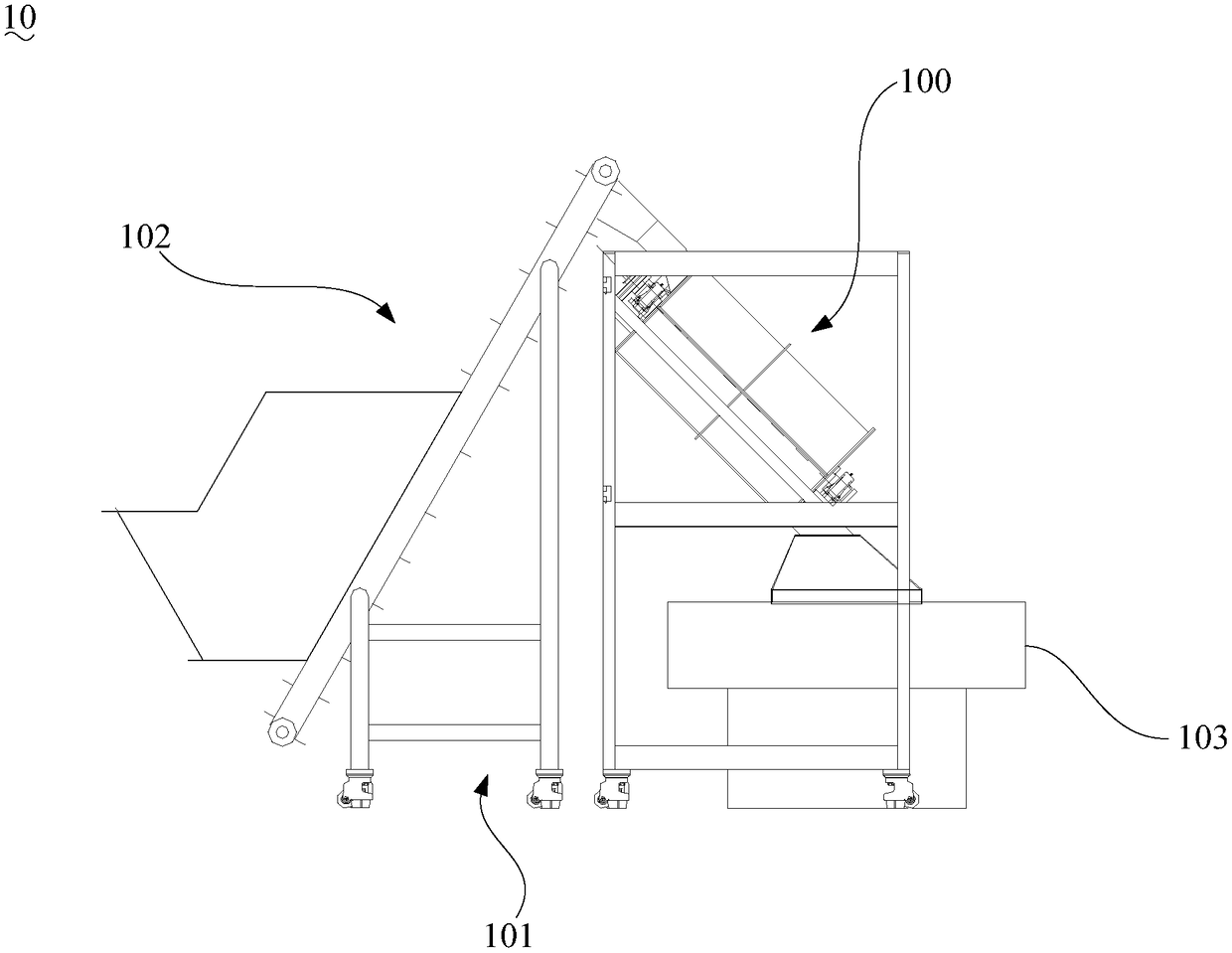

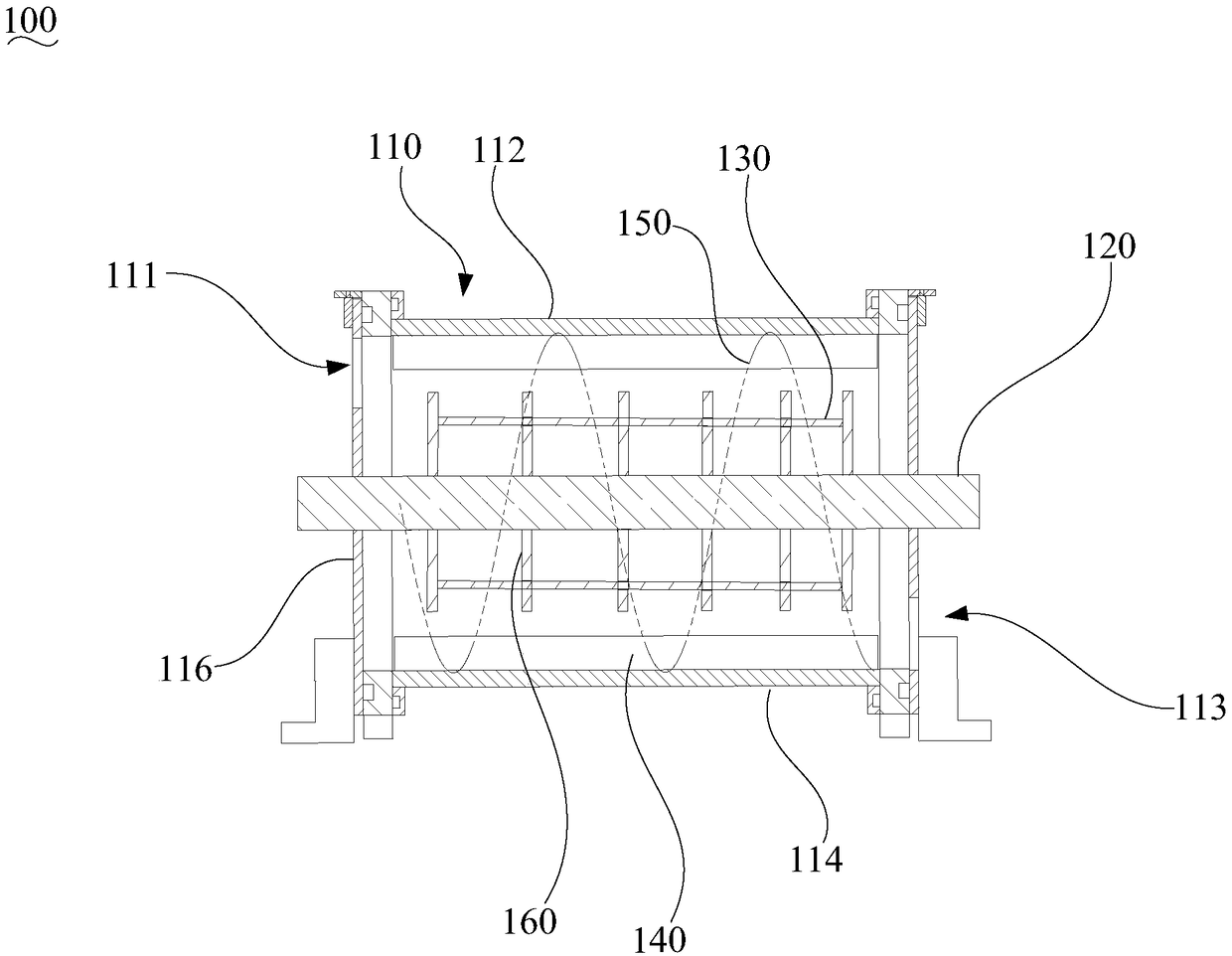

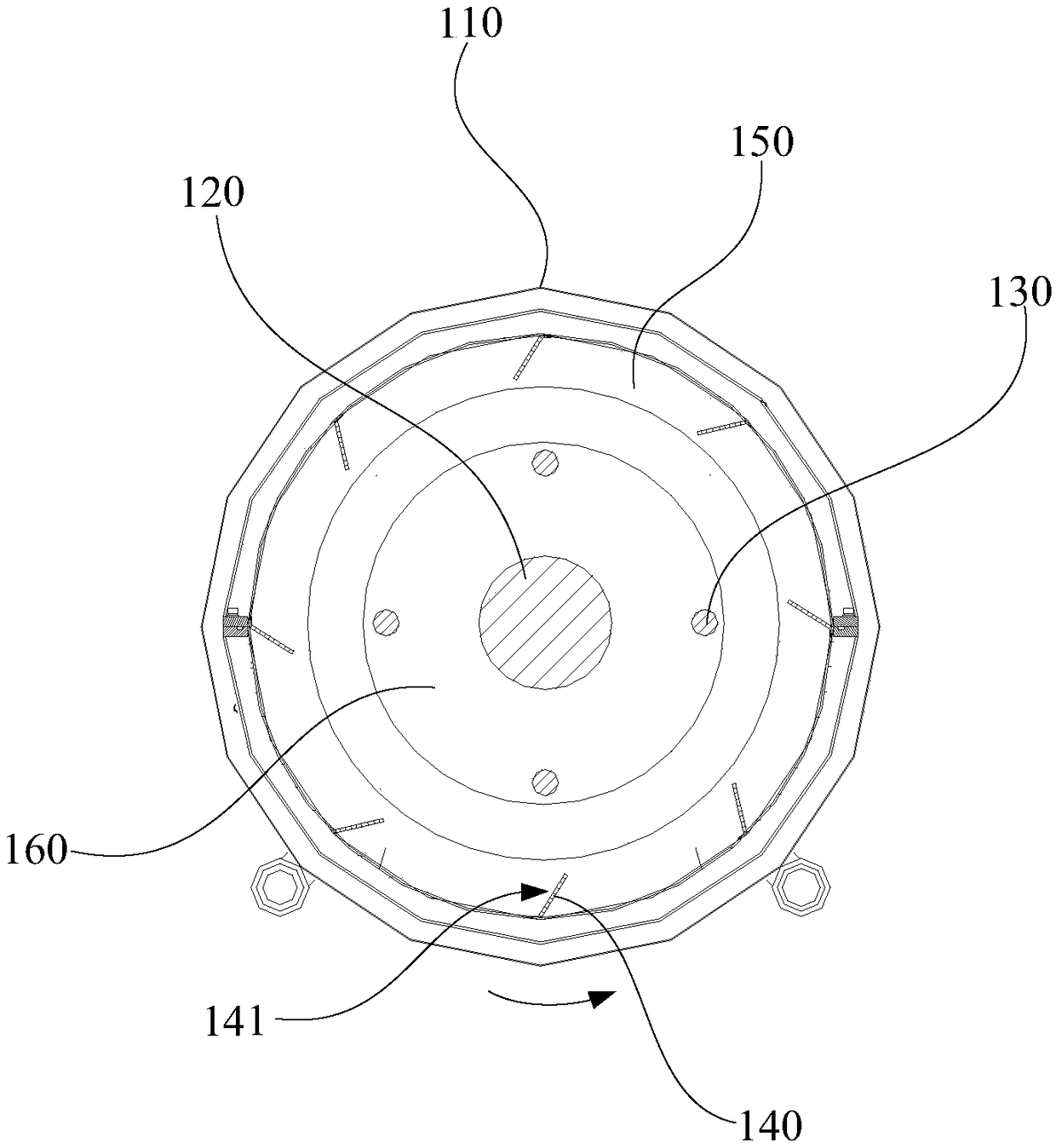

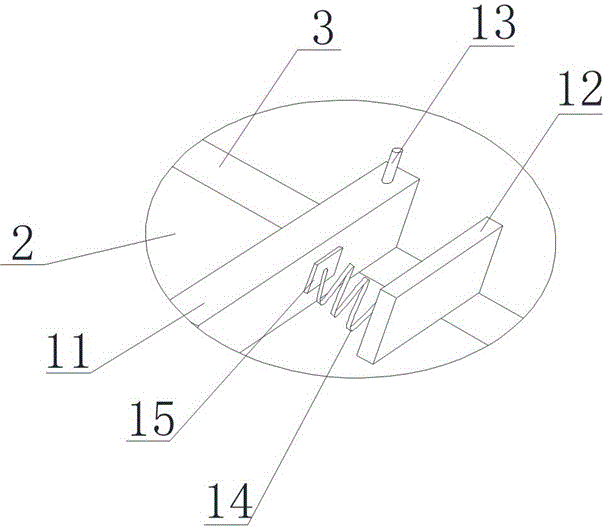

Tobacco shred recovery system and spiral waste cigarette crushing device thereof

ActiveCN106944194AExtended stayHigh recovery rateCigarette manufactureGrain treatmentsStop timeSmoke paper

The invention relates to a tobacco shred recovery system and a spiral waste cigarette crushing device thereof. Waste cigarettes are beaten by a beating module after entering an accommodating cavity to fall into an outer cylinder. Along with rotation of the outer cylinder, a concave-convex structure, formed on the inner wall of the outer cylinder, of a cigarette lifting module is collided with the falling waste cigarettes to raise up the waste cigarettes in the outer cylinder, and the waste cigarettes are fed in a beating area of the beating module again. Through multiple times of circulation, the waste cigarettes in the outer cylinder can be repeatedly beaten by the beating module for multiple times. Under guidance of a spiral guide piece, the waste cigarettes move from a feed port to a discharge port in a spiral path, so that the stop time of the waste cigarettes in the accommodating cavity is prolonged, and the beating times of the waste cigarettes can be further increased. Even if the rotating speed of the beating module is lower, the waste cigarettes can be sufficiently beaten through increasing effective beating times, so that tobacco shreds are thoroughly separated from cigarette papers. The tobacco shred recovery system and the spiral waste cigarette crushing device thereof can effectively increase the tobacco shred recovery rate.

Owner:CHANGDE RUIHUA MFG

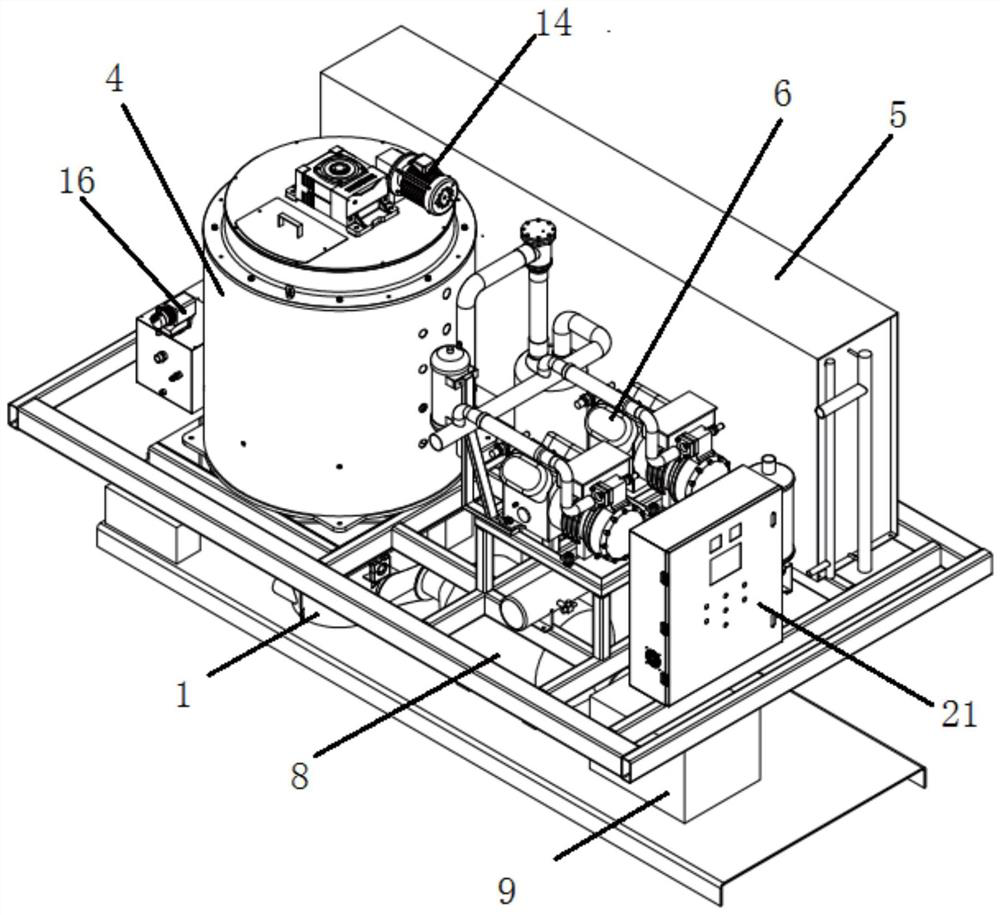

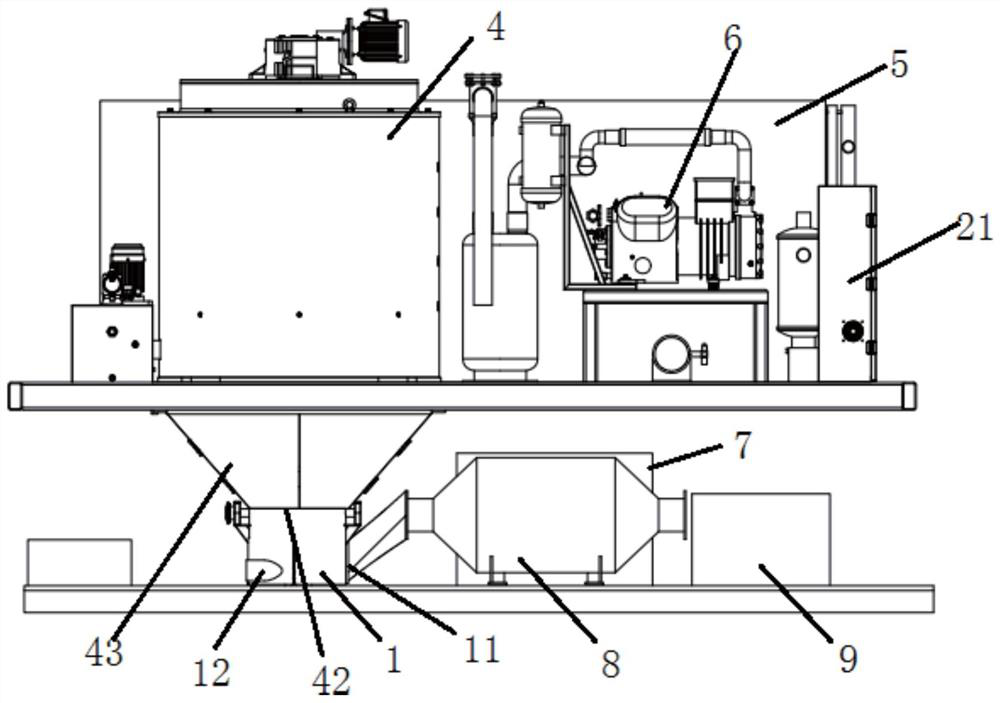

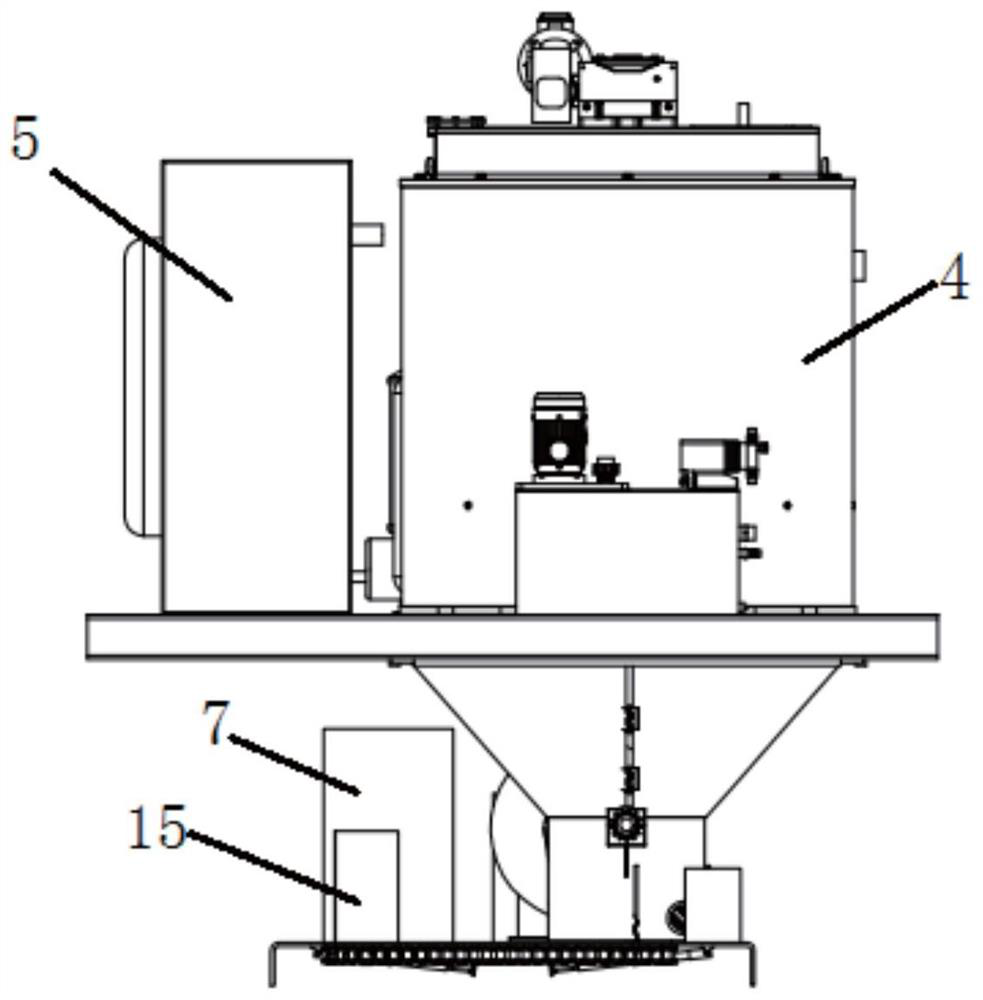

Artificial snow making device

PendingCN112815588AReduce weightReduce consumptionRecreational ice productionEvaporators/condensersImpellerDrive shaft

The invention discloses an artificial snow making device. The artificial snow making device comprises an ice making machine and a smashing snow making machine, wherein the ice making machine comprises an ice bucket, a condenser and a compressor, one end of the compressor is connected with an evaporator in the ice bucket, and the other end of the compressor is connected with the condenser; the smashing snow making machine comprises a cylinder body, a closed impeller, a smashing impeller, a smashing motor, an air conditioner outdoor unit, a cooler and a fan, the upper end of the cylinder body is connected with a flake ice output port at the lower end of the ice bucket, the closed impeller is pivoted at the upper end of the cylinder body in a mode of being capable of closing the flake ice output port, the smashing impeller is pivoted in the cylinder body and comprises a smashing driving shaft and smashing blades fixedly connected to the smashing driving shaft. According to the artificial snow making device, the evaporator is integrally cast and formed, and deformation in the welding process is completely avoided, so that the product consistency and the product quality are greatly improved, the production workload is reduced, and the working efficiency is improved.

Owner:株洲天桥奥悦冰雪科技有限公司

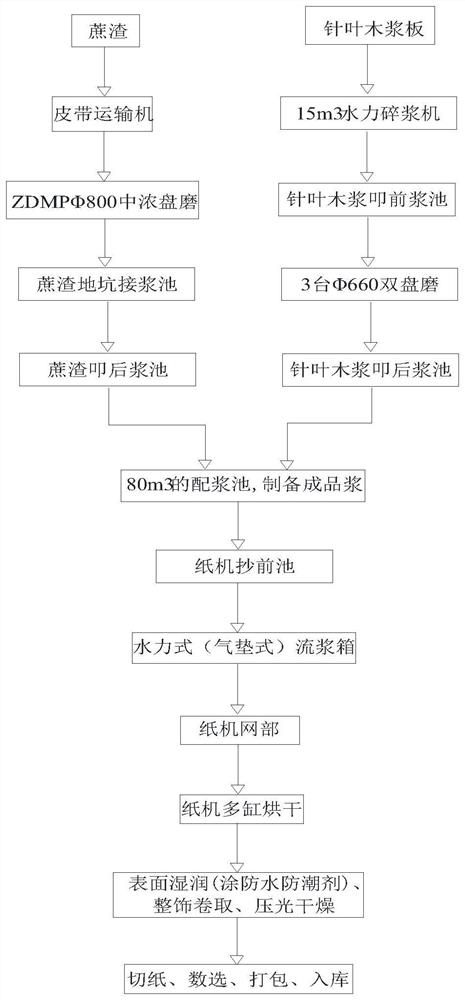

Method for producing food packaging paper by using bagasse pulp

The invention discloses a method for producing food packaging paper by using bagasse pulp. According to the method, mainly bagasse is used as a raw material and is matched with a small amount of imported softwood pulp board; and the method comprises the following steps: S1, separately pulping bagasse and softwood pulp board to prepare bagasse pulp and softwood pulp; S2, conveying the bagasse pulpand the softwood pulp prepared in the step S1 into a pulp preparation pool, and uniformly mixing to prepare finished pulp; S3, conveying the finished pulp prepared in the step S2 into a pre-papermaking pool of a paper machine, and making the finished pulp into paper so as to finish papermaking; and S4, wetting the surface of the paper prepared in the step S3, carrying out finishing coiling and calendaring drying, and finally slitting by adopting a slitting machine to obtain finished paper. According to the invention, bagasse is adopted as a raw material and matched with a small amount of imported softwood pulp boards, the proportion of expensive long fibers in paper can be reduced, the proportion of bagasse pulp is increased, the production cost is reduced, resources are saved, environmental protection is facilitated, and the produced product is high in quality, stable and reliable.

Owner:GUILIN QIFENG PAPER

Reaction type compound crusher

ActiveCN105233924ARaise the blowIncrease the number of hitsGrain treatmentsEngineeringConical cavity

The invention discloses a reaction type compound crusher which comprises a cylinder, a rotating shaft, a crushing hammer, a cover plate, a reaction ring and a driving mechanism. One end of the cylinder is open, and the other end of the cylinder is closed. An installation hole and a feeding inlet are formed in the end face of the closed end. One end of the rotating shaft stretches into the cylinder, and the other end of the rotating shaft is located outside the cylinder and is in transmission connection with the driving mechanism. The crushing hammer is installed on the rotating shaft. The cover plate is installed at the open end of the cylinder. The cover plate and the cylinder are matched to form a conical cavity communicated with an inner cavity of the cylinder. The reaction ring is installed inside the conical cavity. The reaction ring comprises a plurality of concentrically-arranged check rings. The check rings are arranged inside the conical cavity at intervals from the end close to the cylinder to the end far away from the cylinder. The inner diameters of the check rings are gradually decreased in sequence from the end close to the cylinder to the end far away from the cylinder. A discharging outlet is formed in the cover plate. Accordingly, the crushing effect rate of granular materials is greatly increased, the uniformity of finished granules is good, and the quality is high.

Owner:ANHUI NINGHUO NEW MATERIAL

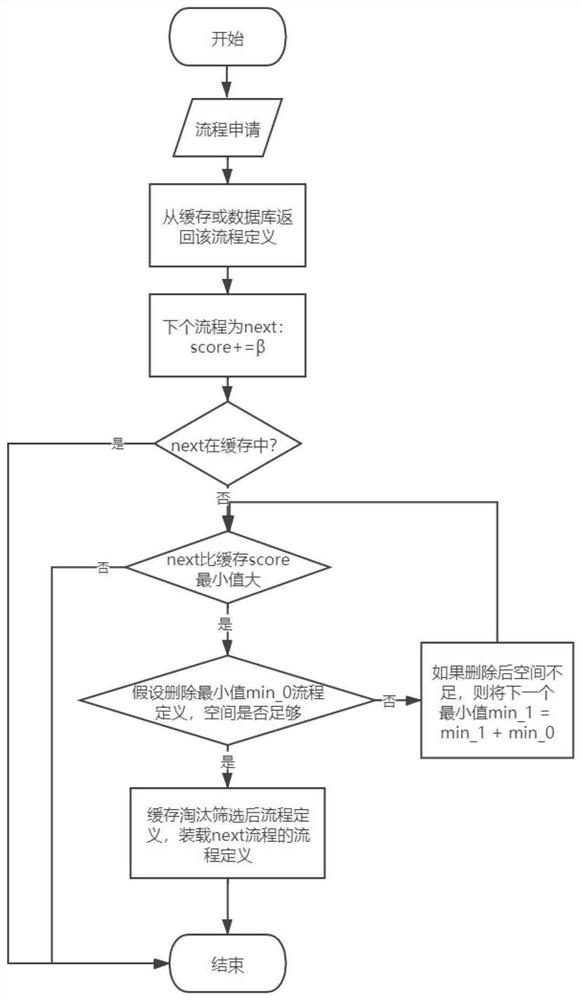

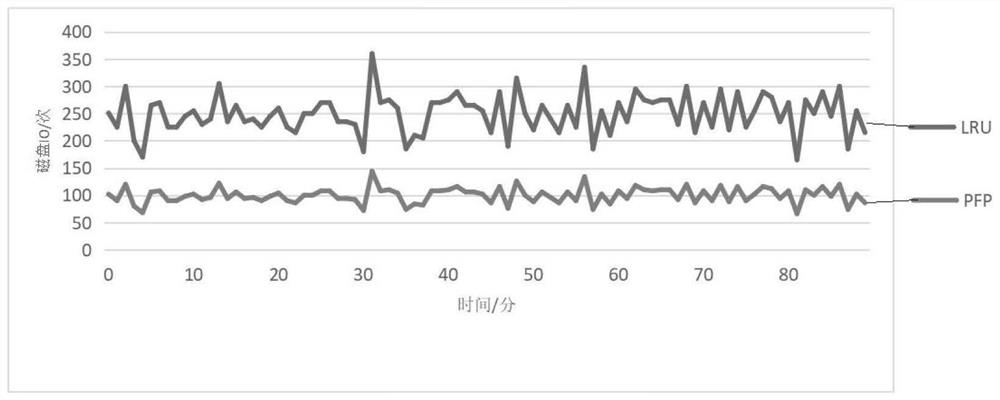

Workflow engine cache elimination method based on industrial process background

PendingCN112926206AIncrease the number of hitsReduce disk IODesign optimisation/simulationOffice automationProcess engineeringProcess definition

The invention discloses a workflow engine cache elimination method based on an industrial process background. The importance, response speed requirements and industrial process application data are defined according to an industrial process, the industrial process application probability p and the industrial process size standardization auxiliary parameter Z in the final score are determined based on the industrial process applied probability calculated based on real data, the industrial process size standardization is determined, the final score S of each industrial process is calculated, and cache loading is carried out according to the number when the system is in cold start. A specific industrial process and a rapid final score sequence are searched, and which process definitions are loaded into a cache and eliminated from the cache is determined through a LinkedHashMap type variable. The cache insertion, updating, deleting and searching of the industrial process are rewritten in the Flowable workflow engine cache class. According to the method, the hit rate of the cache process definition can be improved, and the process with high importance and high time sensitivity in the industrial process is specially processed in algorithm, so that the process can quickly respond to server calling in a cache.

Owner:BEIJING UNIV OF TECH

The anti-splash device of the mud regeneration device in the drilling process

ActiveCN105903258BReduce use costIncrease profitMoving filtering element filtersLarge screenEngineering

The invention discloses an anti-splash device for a mud regeneration device in the drilling and production process. The anti-splash device comprises anti-splash plates and a top plate, a guide rail is placed below each anti-splash plate, a first sliding block and a second sliding block which are matched with each other are installed on each guide rail, the first sliding blocks are fixed at the bottoms of the anti-splash plates, an anti-spray plate is arranged between the anti-splash plates, multiple water inlet elbows are installed on the the top plate, the bottom ends of the water inlet elbows penetrate through the top of the top plate to the portions below the top plate, and a water spray head is connected to each water inlet elbow; the anti-splash device further comprises two metal racks, and a blocking hood is connected between the metal racks. According to the anti-splash device for the mud regeneration device in the drilling and production process, due to the fact that the anti-spray plate, the anti-splash plates and the baffle are arranged, it is guaranteed that a drilling fluid passes through a larger screen area, the use ratio of a screen is increased, the situation that solid particles move to a screen outlet under the condition of being not separated from a fluid phase is avoided, it is guaranteed that the drilling fluid cannot splash out of a drilling fluid vibrating screen, the circulating fluid phase is reserved to the maximum extent, the use cost of the drilling fluid is reduced, and meanwhile the environment is protected.

Owner:广州智创知识产权运营有限公司

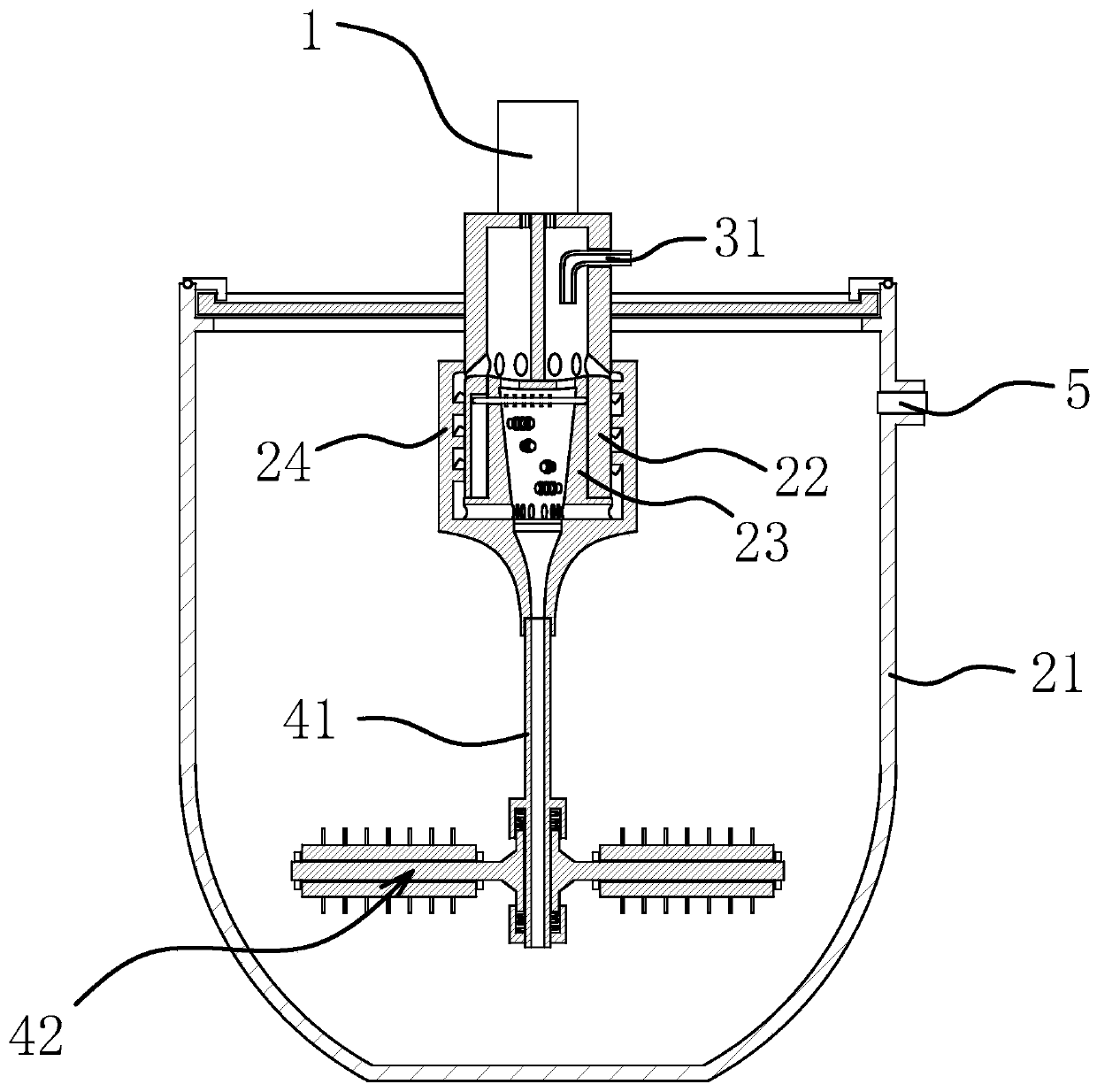

Energy-saving and environment-friendly hydraulic pulper

InactiveCN113152133AIncrease the number of hitsSolve wastePaper recyclingRaw material divisionSlurryCentrifugal force

The invention relates to the technical field of hydraulic repulping, and discloses an energy-saving and environment-friendly hydraulic pulper, which comprises a tank body, a sieve plate is movably installed on the lower middle portion of the tank body, a spiral rotor is movably installed in the center of the tank body, and a pulp discharging opening is fixedly communicated with one side of the tank body. Slurry is ground to generate centrifugal vortex rotation through rotation of the spiral rotor, the inclined rod cutters slide towards the outer side under the action of centrifugal force, the horizontal rod cutters and the blades longitudinally and transversely cut and grind the slurry rotating on the outer side, and the slurry on the outer side is guided to the central spiral rotor through the curved surfaces of the cutters; slurry moves from top to bottom under the action of the spiral rotor, is thrown to the inner wall of the tank body from the bottom of the rotor and then is brought to the spiral rotor again by the curved surface of the cutter to form a strong vortex, so that the impact frequency of the slurry on the spiral rotor is increased; the problem that energy is wasted due to the fact that slurry does centrifugal vortex rotating motion only under the action of a spiral rotor and needs to be ground for a long time is solved.

Owner:刘胜蓝

Drilling fluid regeneration device

The invention discloses a drilling fluid regenerating device. The drilling fluid regenerating device comprises a sieve box, a vibration motor, a supporting plate, a baffle cover and a blowout preventer. A feeding port is formed in the upper portion of one end of the sieve box, a solid-phase discharging port is formed in the other end, the sieve box is internally provided with a screen cloth frame, and the screen cloth frame is internally provided with screen cloth. A liquid-phase discharging box communicated with the sieve box is arranged below the solid-phase discharging port, a liquid-phase discharging port is formed in the bottom of the liquid-phase discharging box, the side face of the liquid-phase discharging box is connected with an exhaust tube, and the exhaust tube is connected with an exhaust fan. After drilling fluid impacts on the screen cloth, liquid phase disengaging from solid-phase particles can enter the part below the screen cloth more easily and will not block the screen cloth, the handling capacity of a drilling fluid vibration sieve to the drilling fluid is increased, and airflow can increase the impacting force when the drilling fluid impacts on the screen cloth to enable the solid-phase particles to be separated from the liquid phase more easily.

Owner:辽宁金兴石油集团有限公司

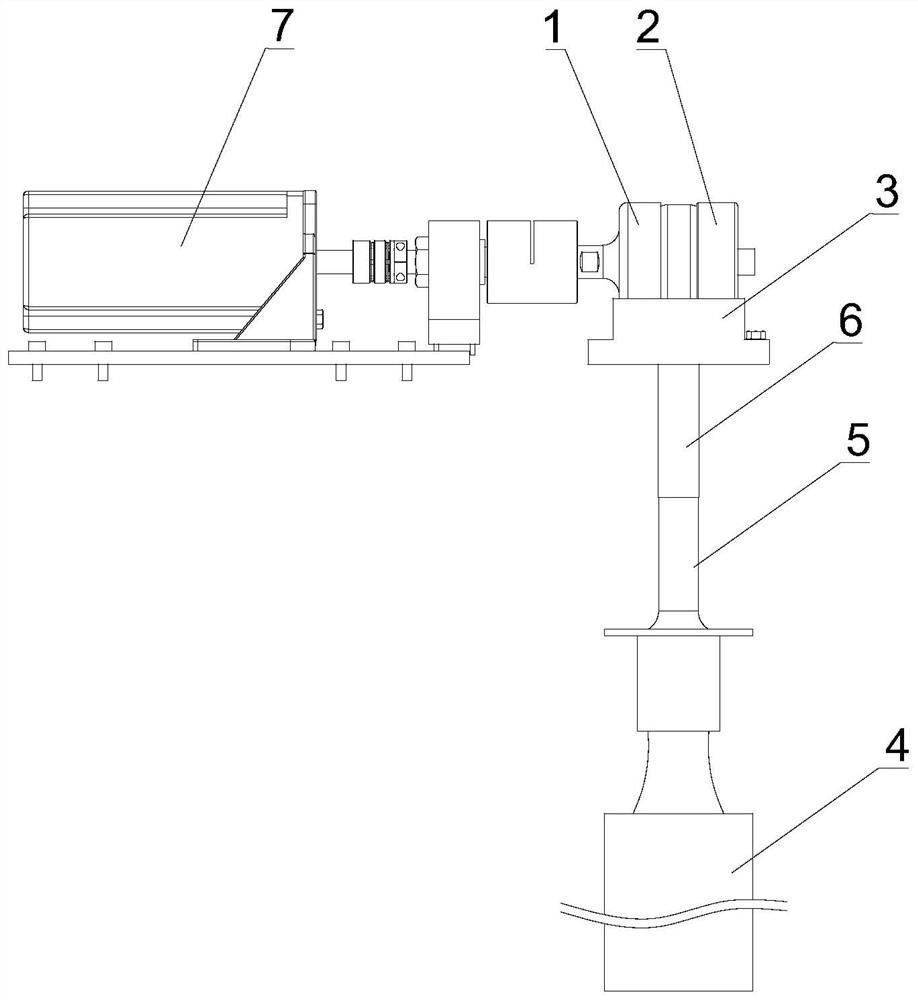

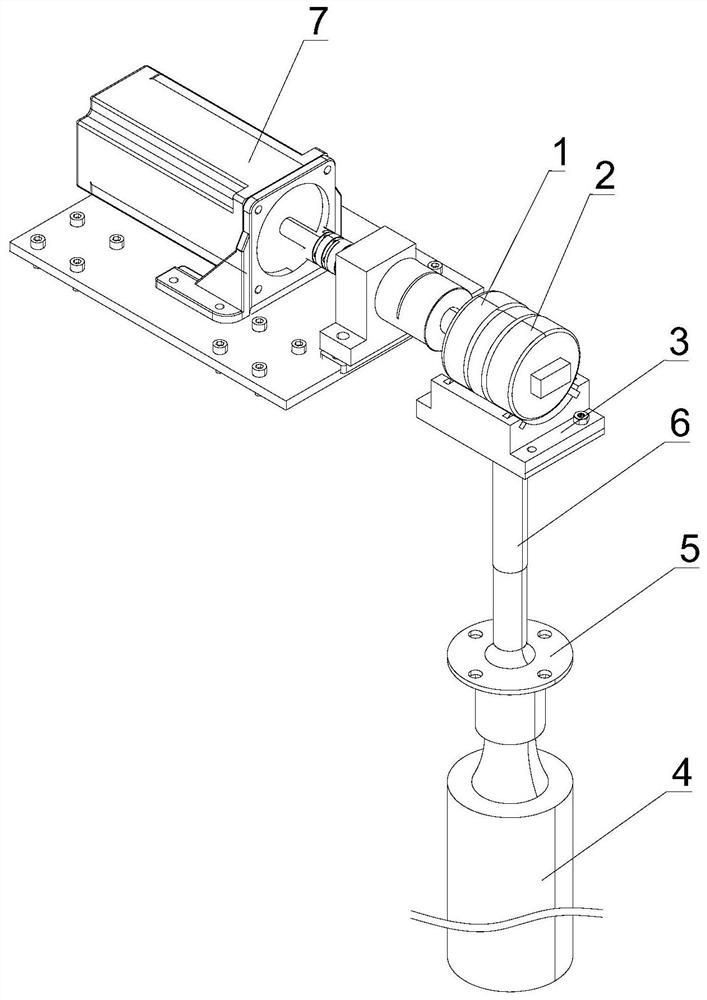

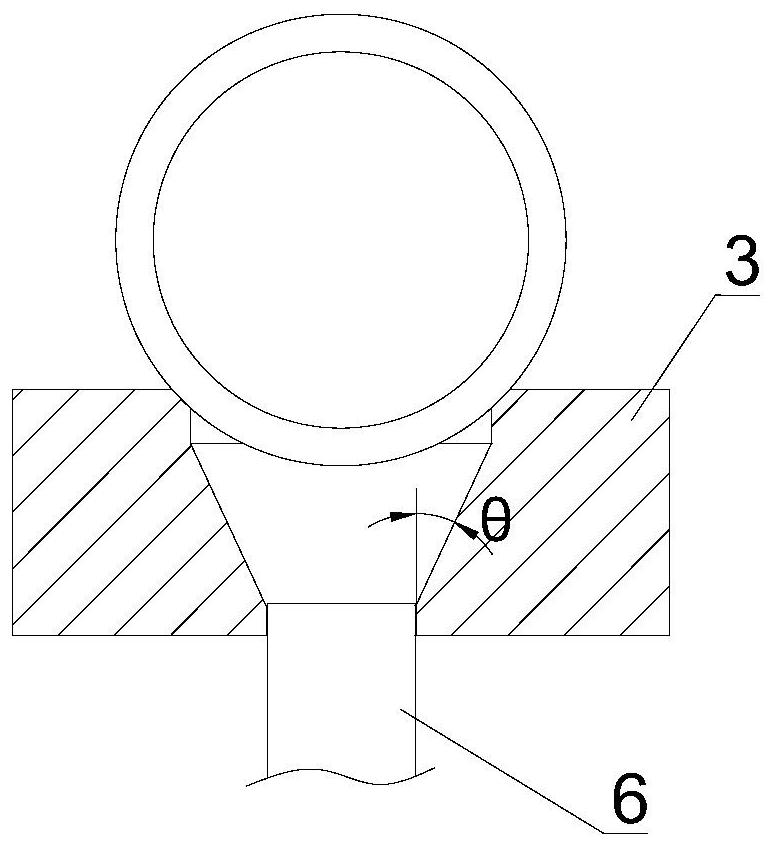

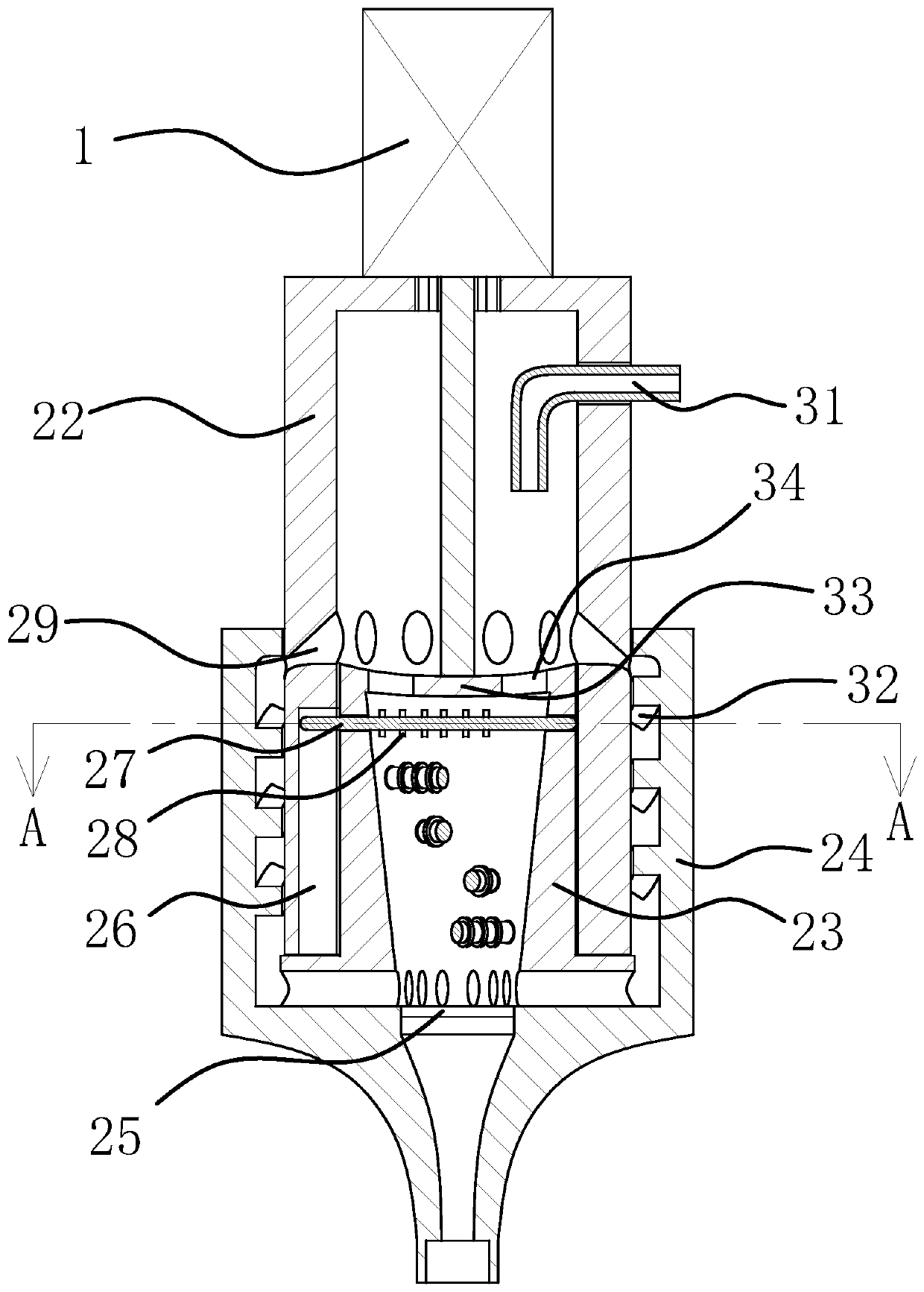

A high-efficiency ultrasonic enhanced grinding equipment and method

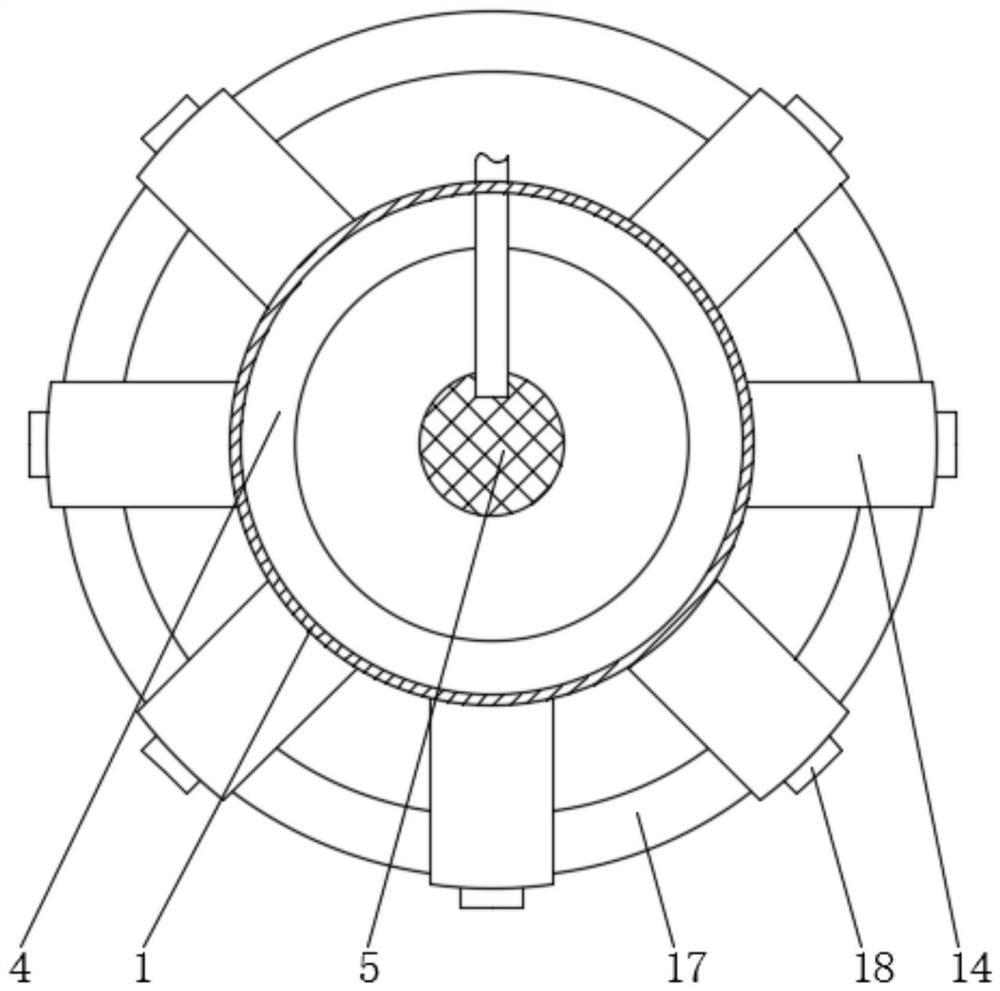

ActiveCN113681445BIncreased impact angleIncrease the number of hitsEdge grinding machinesPolishing machinesUltrasonic machiningEngineering

The invention discloses a high-efficiency ultrasonic intensified grinding equipment and method. The equipment includes a rotary clamping mechanism and an ultrasonic processing mechanism; the rotary clamping mechanism includes a coaxial rotary clamp and a rotary drive mechanism, and the coaxial rotary clamp and the rotary drive The driving end of the mechanism is connected; the ultrasonic processing mechanism includes an ultrasonic processing seat, an ultrasonic transducer and an ultrasonic tool head, and the ultrasonic processing seat is provided with a vertically penetrating high-efficiency processing cavity, and the inner wall of the high-efficiency processing cavity is from the bottom The upper side is inclined outward, and the angle between the inner side wall and the vertical direction is 25°-35°; in the working state, the abrasive material is placed on the end surface of the ultrasonic tool head extending to the bottom of the high-efficiency machining cavity, and the workpiece The surface to be machined is placed on top of the efficient machining chamber. The invention has the advantages of wide and random impact angles, many impact times and high average impact speed, and can effectively improve the processing efficiency and effect of intensified grinding.

Owner:GUANGZHOU UNIVERSITY

Two-stage impact superfine grinder

The invention discloses a two-stage impact superfine grinder, and relates to the technical field of grinding equipment. The two-stage impact superfine grinder comprises a first grinder and a second grinder, wherein a grinding cavity of the first grinder communicates with a grinding cavity of the second grinder to form a grinding channel; a classifier is arranged above the second grinder; a classification channel of the classifier communicates with the grinding channel; a discharge port of the classifier is connected with a negative pressure device; and a feeding port of the grinding cavity ofthe first grinder communicates with a feeding channel. According to the two-stage impact superfine grinder, the technical problems of low grinding efficiency and fineness of grinding equipment in theprior art are solved, high-efficiency and high-fineness grinding on materials are carried out, so that the material accumulation is effectively avoided; and meanwhile, the two-stage impact superfine grinder has the advantages of low manufacturing cost, convenient operation and maintenance, and small damage to the properties of the materials, so that the two-stage impact superfine grinder is suitable for materials that are difficult to be crushed.

Owner:潍坊帕尔曼粉体设备有限公司

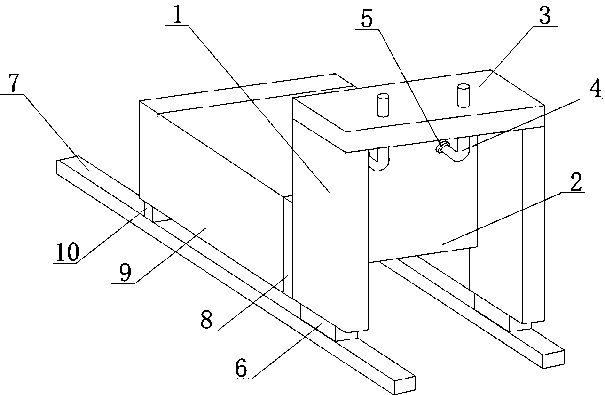

Mechanical impact mill

PendingCN113893934AAvoid dischargeImprove crushing qualityGrain treatmentsThermodynamicsMechanical impact

The invention relates to the technical field of bioengineering equipment, and discloses a mechanical impact mill. The mechanical impact mill comprises a fixed box, an air extractor is fixedly arranged in the center of the bottom of an inner cavity of the fixed box, an air conveying pipe is fixedly arranged on the upper surface of the air extractor, a middle separating plate is fixedly arranged in the inner cavity of the fixed box and located above the air conveying pipe, a separation net is fixedly arranged in the middle of the middle separating plate and located right above the air conveying pipe, an air return pipe is fixedly connected to the left side of the air conveying pipe, and the top end of the air return pipe fixedly communicates with the inner cavity of the fixed box. Through the arrangement of the air return pipe, air in the fixed box is pumped through the air return pipe, air flow in the fixed box is pumped, pressurized and released within a certain time, self-circulation is achieved, the situation that a lot of air flow carries materials which do not reach the fineness to be discharged is avoided, the crushing quality of the materials is improved, subsequent treatment processes are reduced, and the preparation cost is reduced.

Owner:王相春

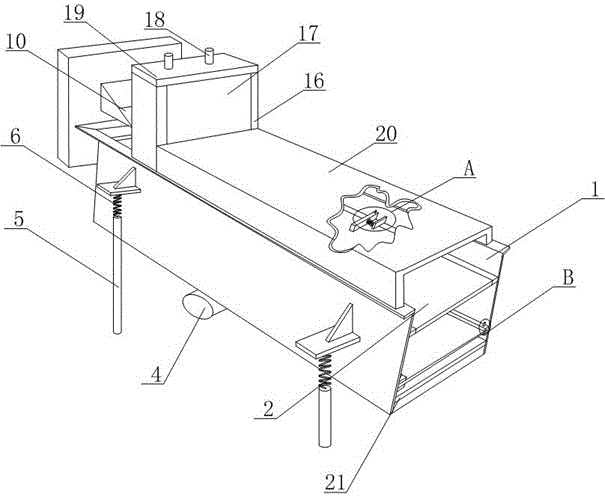

Shredded Tobacco Recovery System and Its Spiral Waste Smoke Crushing Device

ActiveCN106944194BHigh recovery rateHit fullyCigarette manufactureGrain treatmentsConvex structureStop time

The invention relates to a tobacco shred recovery system and a spiral waste cigarette crushing device thereof. Waste cigarettes are beaten by a beating module after entering an accommodating cavity to fall into an outer cylinder. Along with rotation of the outer cylinder, a concave-convex structure, formed on the inner wall of the outer cylinder, of a cigarette lifting module is collided with the falling waste cigarettes to raise up the waste cigarettes in the outer cylinder, and the waste cigarettes are fed in a beating area of the beating module again. Through multiple times of circulation, the waste cigarettes in the outer cylinder can be repeatedly beaten by the beating module for multiple times. Under guidance of a spiral guide piece, the waste cigarettes move from a feed port to a discharge port in a spiral path, so that the stop time of the waste cigarettes in the accommodating cavity is prolonged, and the beating times of the waste cigarettes can be further increased. Even if the rotating speed of the beating module is lower, the waste cigarettes can be sufficiently beaten through increasing effective beating times, so that tobacco shreds are thoroughly separated from cigarette papers. The tobacco shred recovery system and the spiral waste cigarette crushing device thereof can effectively increase the tobacco shred recovery rate.

Owner:CHANGDE RUIHUA MFG

Juice extraction machine

InactiveCN102813442BEnhance swirl effectIncrease the number of hitsStrainersEngineeringMechanical engineering

The invention discloses a juice extraction machine, which comprises a base, a driving unit, a container, a cover, a spiral extraction device and a juice extraction net, wherein the bottom wall of the container 30 is provided with a through hole and a residue outlet, and the peripheral wall of the container 30 is provided with a juice outlet. The cover 40 can be covered and connected onto the peripheral wall of the container 30 and is provided with a material input opening. The spiral extraction device 50 is arranged in the container 30, and the driving unit is connected with the rotating extraction unit 50 for driving the spiral extraction device 50 to rotate relative to the container 30 for realizing the juice extraction. The juice extraction net 60 is arranged in the container 30 and is positioned outside the rotating extraction device 50, the inner wall of the juice extraction net 60 is provided with a plurality of jade cutter ribs 61 capable of realizing the jade cutter effects, and the jade cutter ribs 61 are in inclined arrangement at intervals. The juice extraction machine has the following advantages that the jade cutter ribs are in inclined arrangement at intervals and are matched with the spiral extraction device, the extracted object vortex effect can be generated and enhanced, the extraction time number and the collision time number of the extracted objects are increased, the juice extraction rate is improved, the operation speed of the extracted objects can be accelerated, and the juice extraction speed is accelerated.

Owner:漳州依莱科技有限公司

Primary Solids Control Device for Offshore Oil Wells

The invention discloses a primary solid control device for an offshore drilling well. The primary solid control device comprises a screening box, a vibrating motor, a supporting plate, a blocking hood and a blowout prevention device. A feed inlet is formed in the upper portion of one end of the screening box, a solid phase discharge outlet is formed in the other end of the screening box, a screen frame is arranged in the screening box, and a screen is arranged in the screen frame. A liquid phase discharging box communicating with the screening box is arranged below the solid phase discharge outlet, a liquid phase discharge outlet is formed in the bottom of the liquid phase discharging box, and the side face of the liquid phase discharging box is connected with a suction pipe which is connected with a suction fan. A plurality of spring baffle devices are arranged on the screen frame at equal intervals in the direction from the feed inlet to the solid phase discharge outlet. By means of the primary solid control device, after drilling fluid impacts the screen, the liquid phase with the solid phase particles removed can enter the space below the screen more easily, the screen is prevented from being blocked, and the drilling fluid treatment amount of the drilling fluid vibratory screen is increased; and airflow enables the impact impulsive force to be increased when the drilling fluid impacts the screen, and the solid phase particles and the liquid phase can be separated more easily.

Owner:DAQING RUISID PETROLEUM MASCH MFG CO LTD

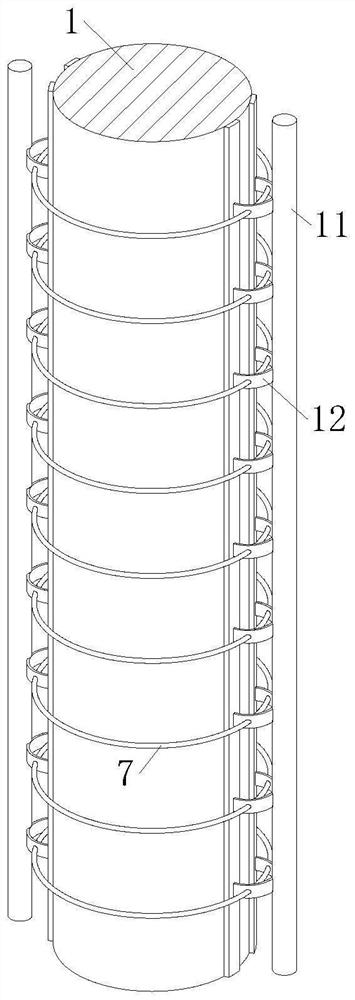

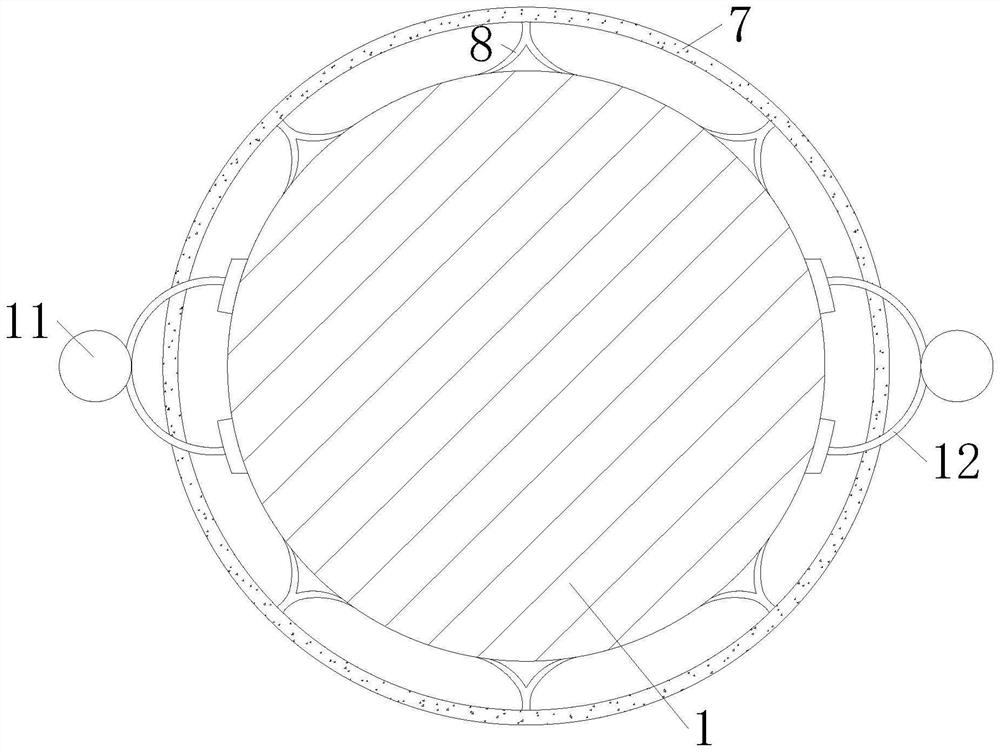

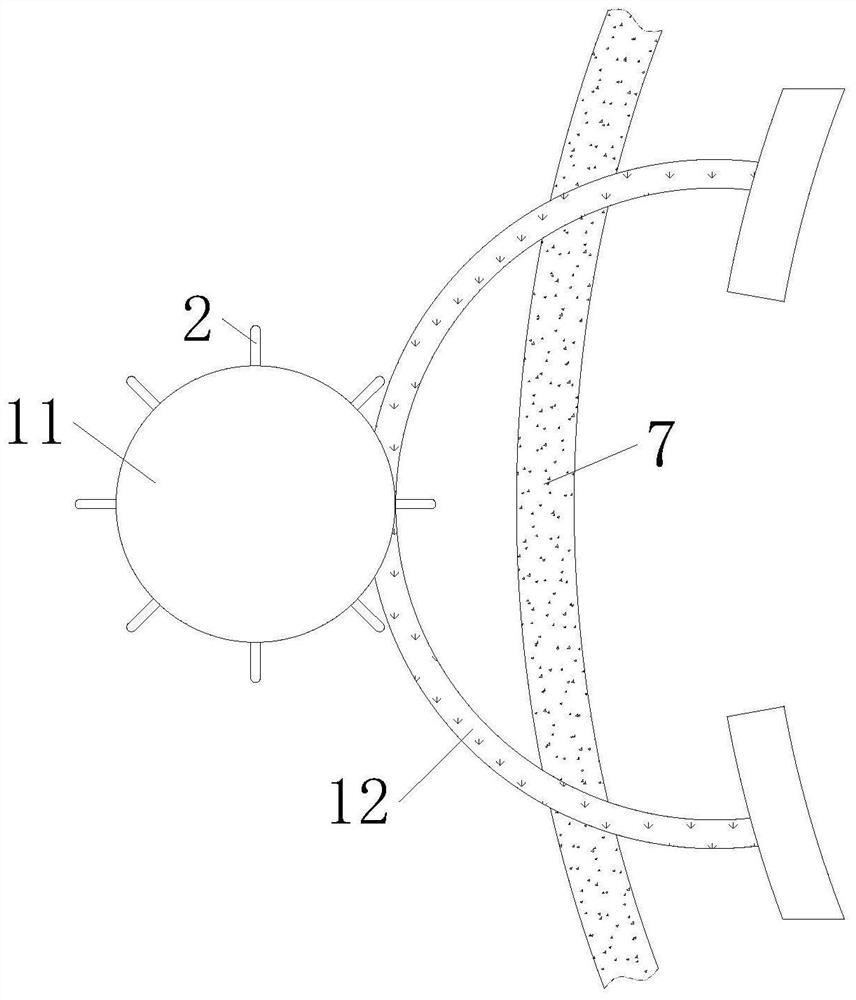

Pile-forming construction device of composite foundation pile

ActiveCN114561950AEasy to reinforceImprove stabilityWind energy generationBulkheads/pilesArchitectural engineeringElectric machinery

The invention discloses a pile forming construction device of a composite foundation pile. The foundation pile comprises a foundation pile body, multiple sets of elastic supporting legs are arranged on the side wall of the foundation pile body and connected with a vibration rod, a motor is arranged in the vibration rod and connected with a rotating rod, and multiple sets of balancing weights are arranged on the rotating rod. The device has the advantages that cement can rapidly fall down in the foundation pile hole when the cement is poured for filling, and the foundation pile hole is rapidly filled and reinforced.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Device for separating solid and liquid phases in drilling mud

ActiveCN105863533BThe speed of liquid phase sieving is acceleratedIncrease throughputFlushingStops deviceEngineering

The invention discloses a device for separation of a solid phase and a liquid phase in drilling fluid. The device comprises a sieve box, a vibration motor, tension springs, a blowout preventer and a shield. Two ends of the sieve box are provided with a feeding port and a discharging port respectively, a sieve frame and a coarse screen are arranged in the sieve box, a fine screen is arranged below the coarse screen, concave grooves are formed between the coarse screen and the fine screen and provided with through holes and extend from the discharging port to the feeding port, and a liquid phase receiving plate is arranged in the concave grooves and parallel to the coarse screen. The device further comprises studs which pass through the through holes of the concave grooves to penetrate the liquid phase receiving plate, and a plurality of spring stop devices are arranged at equal intervals on the sieve frame. The device has the advantages that in an early stage of exploitation, screening speed of the liquid phase in the drilling fluid is increased, and treatment capacity of a drilling fluid vibration sieve is improved; in a later stage of exploitation, even solid-phase particles are smaller in size, the drilling fluid can be screened by the screens, and accordingly separation efficiency of the drilling fluid vibration sieve is improved.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Vibrating screen drilling fluid anti-splash mechanism for desert petroleum drilling

InactiveCN105903257AReduce use costIncrease profitMoving filtering element filtersWell drillingLarge screen

The invention discloses a vibrating screen drilling fluid anti-splash mechanism for desert petroleum drilling. The drilling fluid anti-splash mechanism comprises anti-splash plates and a block cover, a top plate is installed at the tops of the anti-splash plates and connected with the anti-splash plates, an anti-spray plate is arranged between the anti-splash plates and are perpendicular to the anti-splash plates, a gap exists between the bottom of the anti-spray plate and the plane where the bottoms of the anti-splash plates are located, multiple water inlet elbows are installed on the upper portion of the top plate, the bottom ends of the water inlet elbows penetrate through the top of the top plate to the portion below the top plate, the portions, located below the top plate, of the water inlet elbows are right opposite to the anti-spray plate, and a water spray head is connected to each water inlet elbow. According to the vibrating screen drilling fluid anti-splash mechanism for desert petroleum drilling, due to the fact that the anti-spray plate, the anti-splash plates and the baffle are arranged, it is guaranteed that a drilling fluid passes through a larger screen area, the use ratio of the screen is increased, the situation that solid particles move to a screen outlet under the condition of being not separated from a liquid phase is avoided, it is also guaranteed that the drilling fluid cannot splash out of the drilling fluid vibrating screen, the circulating liquid phase is reserved to the maximum extent, the use cost of the drilling fluid is reduced, and meanwhile the environment is protected.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

Improved Structure of Drilling Fluid Shaker

ActiveCN105903255BThe speed of liquid phase sieving is acceleratedIncrease throughputSeparation devicesFlushingSolid particleEngineering

Owner:DAQING RUISID PETROLEUM MASCH MFG CO LTD

Fine crushing wind screening mechanism and crushing mechanism for waste concrete recycled aggregate

The invention discloses a fine powder smashing and wind-screening mechanism for waste concrete recycled aggregates. The fine powder smashing and wind-screening mechanism comprises a pre-smashing circular disc assembly, a centrifugal type smashing unloading device, a licker-in pressing type smashing device and a wind-screening device, wherein the centrifugal type smashing unloading device is positioned below the pre-smashing circular disc assembly; the licker-in pressing type smashing device is positioned below the centrifugal type smashing unloading device; and the wind-screening device is used for screening powder which drops from an unloading through hole. The fine powder smashing and wind-screening mechanism integrates various smashing ways such as centrifugal smashing, grinding and smashing, and rolling and smashing, and performs pre-smashing by utilizing the advantages of large capacity and large load of centrifugal smashing, so that load of next smashing is relieved, and next smashing efficiency is improved; at a transition unloading stage, transition smashing is performed in a mode of unloading during centrifugal smashing, and complete smashing of particles is realized by fierce extruding and stirring on a target position through a smashing way which integrates grinding smashing and rolling smashing.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Dustproof textile equipment

InactiveCN109091969AQuick cleanDisassembly does not need to be frequentDispersed particle filtrationTransportation and packagingEngineeringHigh pressure

The invention discloses dustproof textile equipment and relates to the technical field of textile equipment. The dustproof textile equipment comprises a casing, wherein a partition board is arranged in the casing and divides the casing into an equipment chamber and a dedusting chamber, a channel for communicating the equipment chamber with the dedusting chamber is formed in the upper end of the partition board, and a dust storage cavity is formed in the lower part of the dedusting chamber; a dedusting strainer is arranged in the dedusting chamber close to the upper end, a baffle plate is arranged at the upper end of the dedusting strainer, a collision cavity is formed between the baffle plate and the dedusting strainer and filled with a plurality of balls, and air holes for communicating the collision cavity with the outside of the casing are formed in the baffle plate; an air pump is arranged on the casing, and an air outlet of the air pump is communicated with the collision cavity. According to the scheme, the dedusting strainer can be cleaned to a greater extent by collision between high-pressure gas and the balls, dust is enabled to fall into the dust storage cavity, the dedusting strainer is not needed to be dismounted frequently, and the equipment is convenient and fast.

Owner:JIANGSU JINDA TEXTILE IND

Primary solid control device for offshore drilling well

The invention discloses a primary solid control device for an offshore drilling well. The primary solid control device comprises a screening box, a vibrating motor, a supporting plate, a blocking hood and a blowout prevention device. A feed inlet is formed in the upper portion of one end of the screening box, a solid phase discharge outlet is formed in the other end of the screening box, a screen frame is arranged in the screening box, and a screen is arranged in the screen frame. A liquid phase discharging box communicating with the screening box is arranged below the solid phase discharge outlet, a liquid phase discharge outlet is formed in the bottom of the liquid phase discharging box, and the side face of the liquid phase discharging box is connected with a suction pipe which is connected with a suction fan. A plurality of spring baffle devices are arranged on the screen frame at equal intervals in the direction from the feed inlet to the solid phase discharge outlet. By means of the primary solid control device, after drilling fluid impacts the screen, the liquid phase with the solid phase particles removed can enter the space below the screen more easily, the screen is prevented from being blocked, and the drilling fluid treatment amount of the drilling fluid vibratory screen is increased; and airflow enables the impact impulsive force to be increased when the drilling fluid impacts the screen, and the solid phase particles and the liquid phase can be separated more easily.

Owner:DAQING RUISID PETROLEUM MASCH MFG CO LTD

Sweet osmanthus flower granule crushing mechanism

PendingCN110038477AEfficient crushingCrushed fullyTransportation and packagingRotary stirring mixersEngineeringHigh pressure

The invention provides a sweet osmanthus flower granule crushing mechanism, and belongs to the technical field of agriculture. The crushing mechanism includes a motor, a material mixing cylinder, an inner rotating cylinder and an outer rotating cylinder. A reflux cavity is formed between the outer rotating cylinder and the material mixing cylinder. The cavity of the inner rotating cylinder communicates with the cavity of the material mixing cylinder. A filter screen is arranged on the bottom of the inner rotating cylinder. A plurality of longitudinally distributed grooves are arranged in the inner wall of the material mixing cylinder. The grooves are circumferentially and uniformly distributed on the inner wall of the material mixing cylinder. The adjacent grooves are smoothly transited. When the inner rotating cylinder rotates relative to the material mixing cylinder, a crushing shaft moves reciprocally along an axis direction of the crushing shaft due to limitation of the grooves. Afeeding pipe is connected to the upper end of the cavity of the material mixing cylinder. The feeding pipe is connected to a high-pressure air source. An output shaft of the motor is fixedly connectedto the inner rotating cylinder. The diameter of the cavity of the inner rotating cylinder gradually decreases from top to bottom. The sweet osmanthus flower granule crushing mechanism has the advantages of being efficient, retaining the original flavor of sweet osmanthus flowers and the like.

Owner:HUBEI UNIV OF SCI & TECH

A kind of impact type compound crusher

ActiveCN105233924BRaise the blowIncrease the number of hitsGrain treatmentsConical cavityEngineering

The invention discloses an impact compound crusher, comprising: a cylinder body, a rotating shaft, a crushing hammer, a cover plate, an impact ring and a driving mechanism, one end of the cylinder body is open, the other end is closed, and the end surface of the closed end is provided with a mounting hole. and the feed port; one end of the rotating shaft extends into the cylinder, and the other end of the rotating shaft is located outside the cylinder and connected with the drive mechanism; the breaking hammer is installed on the rotating shaft; the cover is installed on the open end of the cylinder, and the cover and The cylinder cooperates to form a conical cavity that communicates with the inner cavity of the cylinder; the counter-attack ring is installed in the conical cavity, and the counter-attack ring includes a plurality of retaining rings arranged concentrically. The end far away from the cylinder is arranged at intervals, and the inner diameter of each retaining ring decreases successively from the end close to the cylinder to the end far away from the cylinder; a discharge port is provided on the cover plate. The present invention thus greatly improves the crushing effect rate of granular raw materials, and the finished particles have good uniformity and high quality.

Owner:ANHUI NINGHUO NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com