Pile-forming construction device of composite foundation pile

A composite foundation and construction device technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., to achieve the effect of improving vibration efficiency, improving vibration effect, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

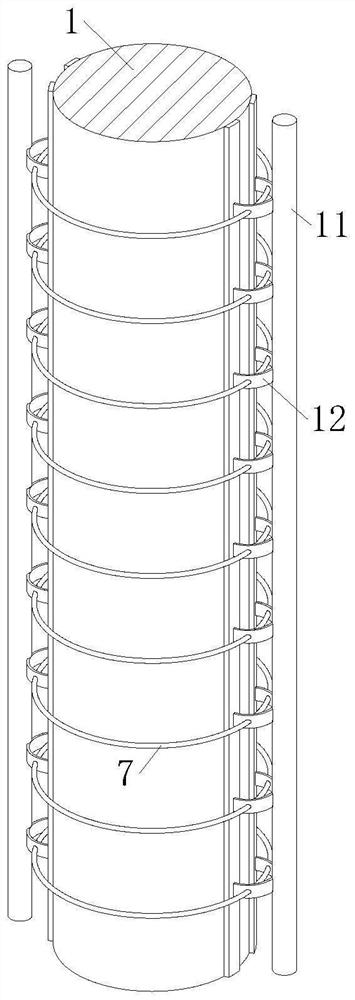

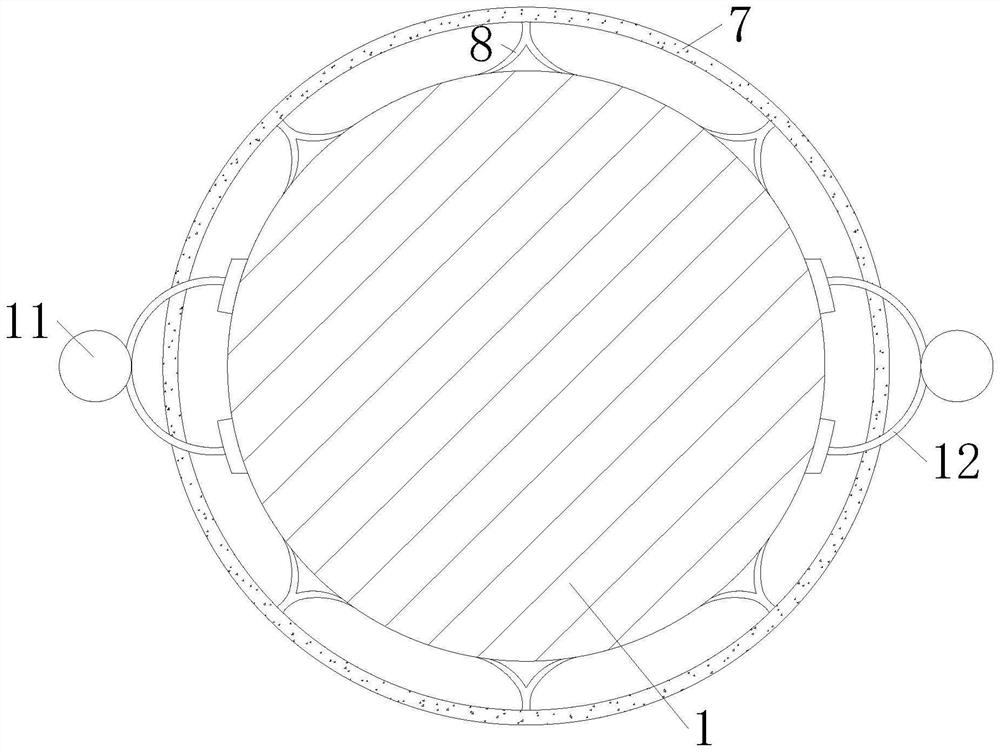

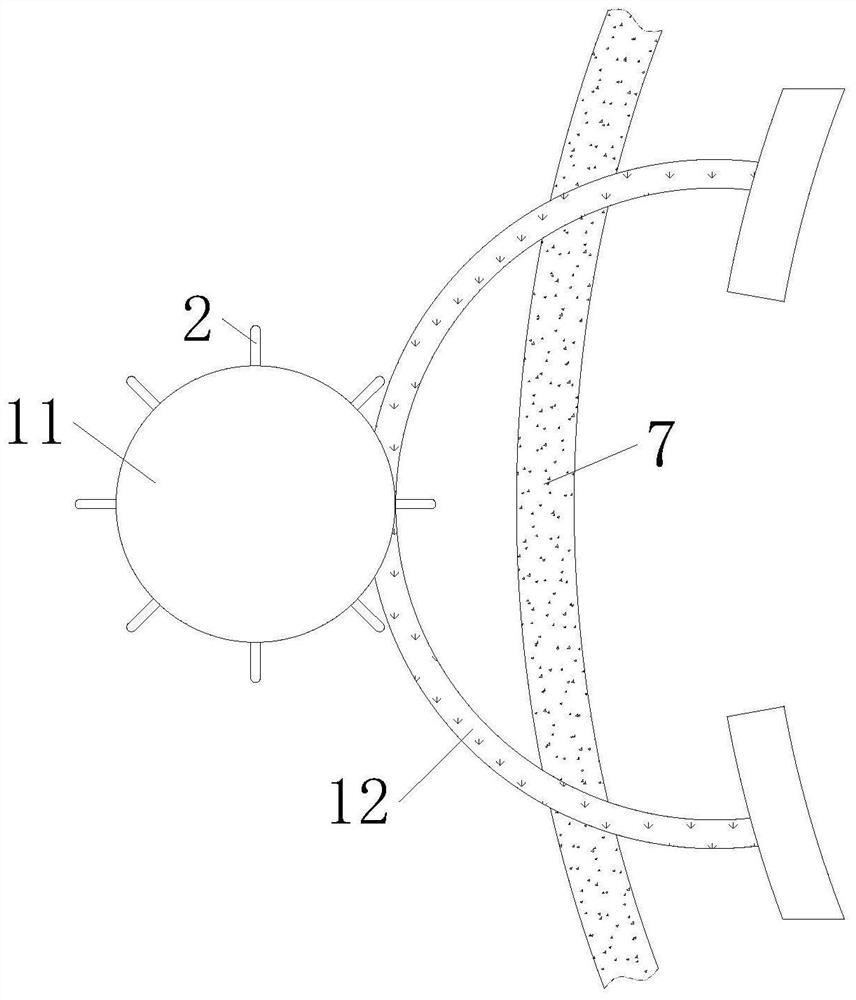

[0042] Example 1. A pile-forming construction device for a composite foundation pile, such as Figure 1 to Figure 2 As shown, the foundation pile body 1 is included; the side wall of the foundation pile body 1 is equipped with an elastic leg 12; the middle part of the elastic leg 12 is fixedly connected with a vibrating rod 11; a motor 13 is installed inside the vibrating rod 11; The output end of the motor 13 is fixedly connected with a rotating rod 14; the middle part of the rotating rod 14 is fixedly connected with multiple groups of counterweights 15; when in use, the vibrating rod 11 and the elastic leg 12 are first installed on the foundation pile body 1, and then Turn on the power supply of the motor 13 inside the vibrating rod 11 so that the motor 13 drives the rotating rod 14 to rotate inside the vibrating rod 11. At this time, the setting of the counterweight 15 will cause the motor 13 and the rotating rod 14 to vibrate inside the vibrating rod 11. At this time The ...

Embodiment 2

[0051] Example 2. A pile-forming construction device for composite foundation piles. Compared with Example 1, this embodiment is as follows: the middle part of the elastic rope 4 is connected with multiple sets of knocking balls 41; 41, when the counterweight 15 rotates, a plurality of percussion balls 41 will collide with the middle part of the elastic pad 3, and the number of impacts of the counterweight 15 on the elastic pad 3 in a single rotation will be improved, and the elastic pad 3, the vibrating block 32 and the elastic pad 3 will be promoted. The vibration frequency of the elastic sheath 2 enables the elastic sheath 2 to vibrate more soft soil near the vibrating rod 11 more tightly, further maintaining the stability of the pile body 1 inside the soil.

[0052] When the pile-forming construction device of the composite foundation pile is working, the vibrating rod 11 and the elastic leg 12 are first installed on the foundation pile body 1, and then the power supply of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com