Fine crushing wind screening mechanism and crushing mechanism for waste concrete recycled aggregate

A technology of waste concrete and recycled aggregates, which is applied in the field of building materials, can solve the problems of changing tools, low working precision, and small processing capacity per unit time, and achieve the effects of increasing intensity, improving crushing efficiency, and improving crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

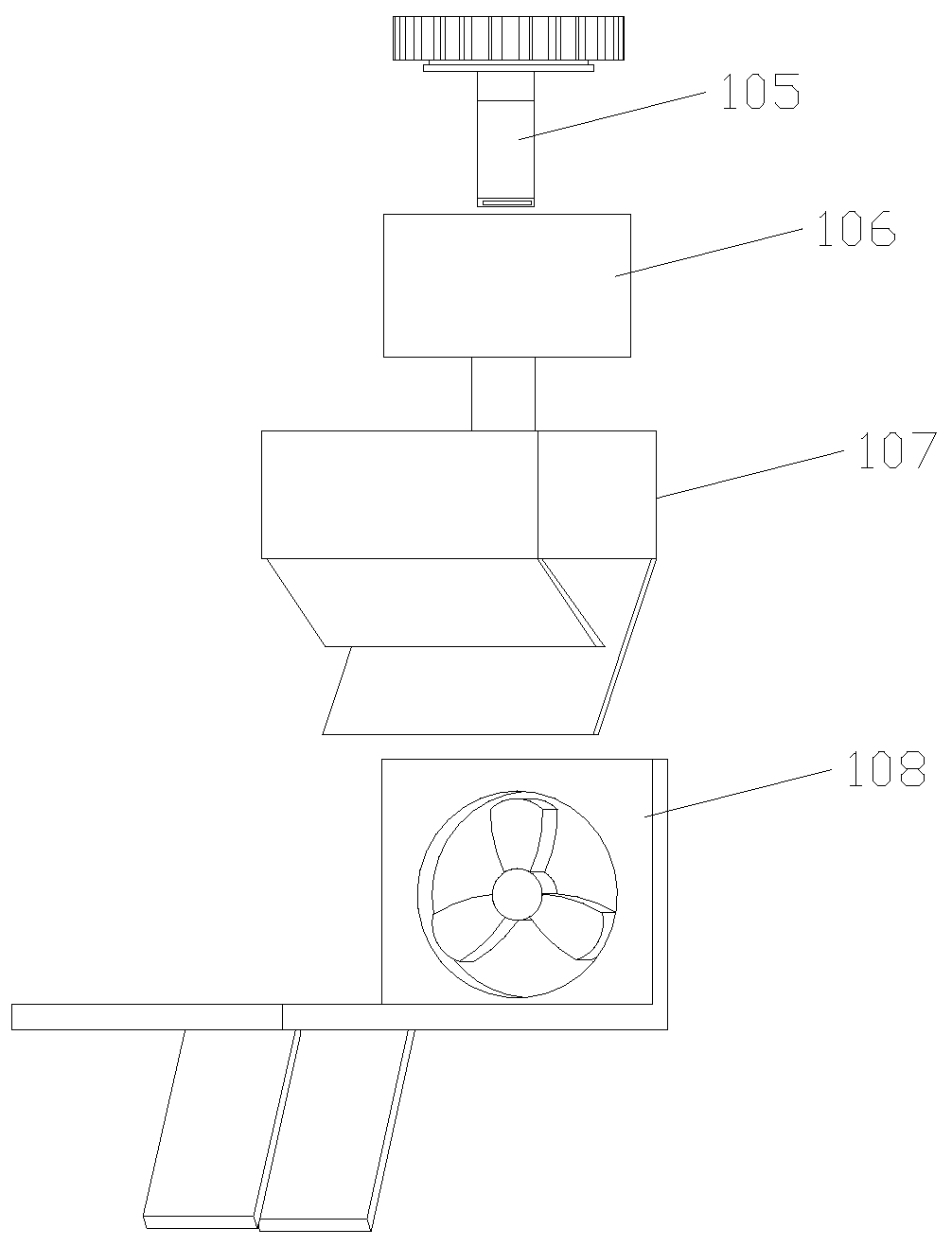

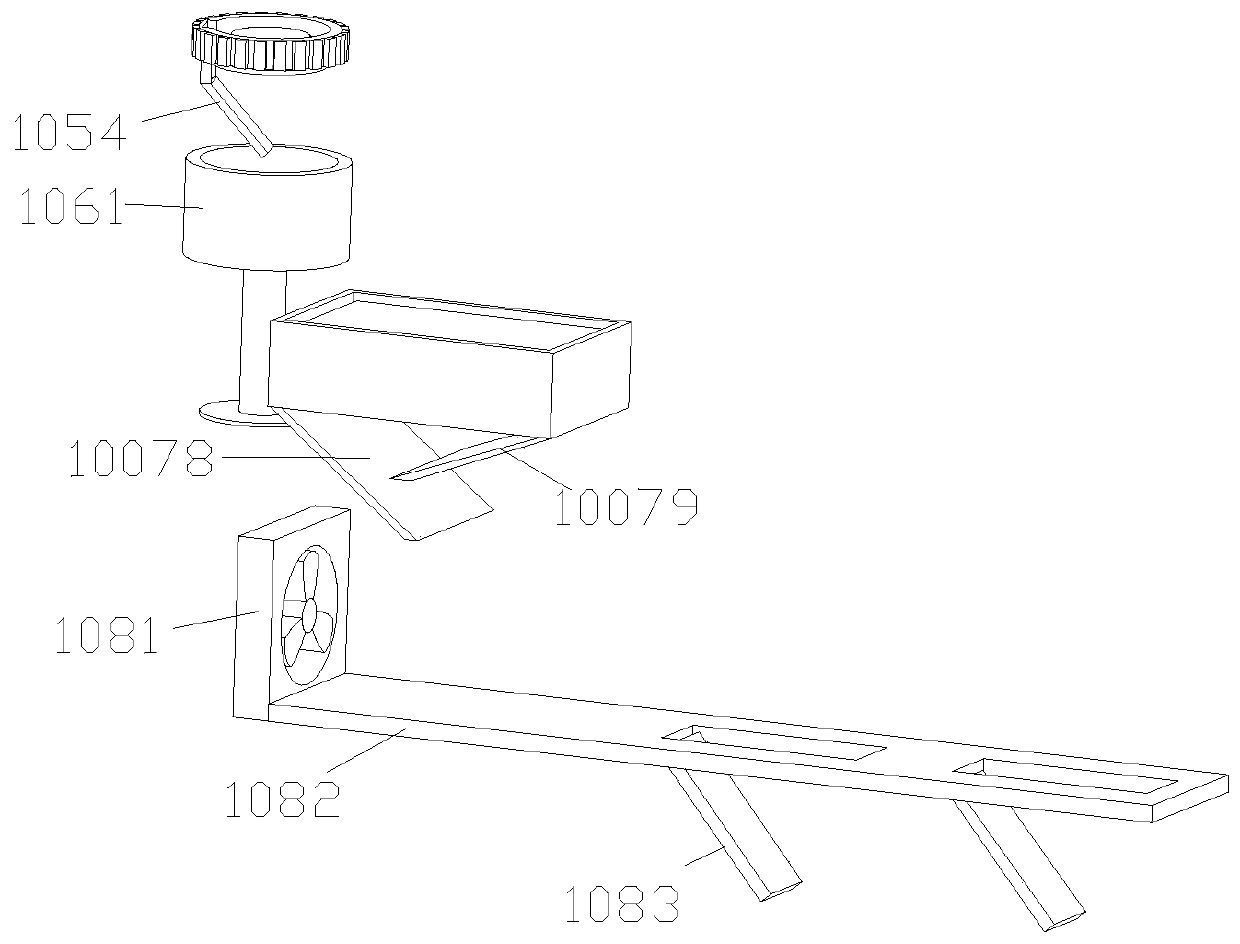

[0040] Such as figure 1 As shown, this embodiment discloses a finely crushed wind-powered screening mechanism for waste concrete recycled aggregates, including a pre-crushed disc assembly 105 , a centrifugal crushing and feeding device 106 , a licker-in crushing device 107 , and a wind-powered screening device 108 .

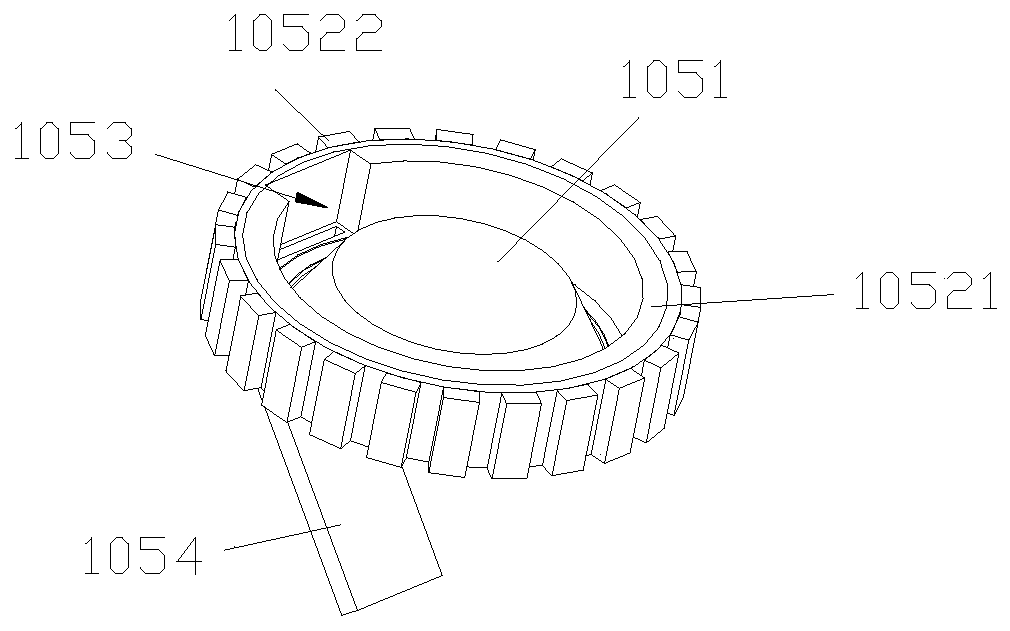

[0041] Such as Figure 2-3 As shown, the pre-shredded disc assembly 105 includes a guide table 1051 and a stopper. The guide platform 1051 is in the shape of a circular platform with a narrower upper end and a wider lower end. The periphery of the stopper is on the side of the guide platform 1051 and the bottom of the stopper is rotationally connected or in contact with the side surface of the guide platform 1051. It includes an inner stopper layer 10521 and an outer Layer stopper layer 10522 and inner stopper layer 10521 are provided with a blanking gap 1053 that penetrates up and down. Preferably, a screen (not shown) is installed at the blanking gap 1053 . A...

Embodiment 2

[0051] Such as Figure 7 , 8 As shown, the difference between this embodiment and the above-mentioned embodiments is that the bottom surface of the upper pressing plate 1071 and the top surface of the lower pressing plate 1072 are concave and convex surfaces. A plurality of screw mandrels 1075 are vertically arranged in the crushing chamber, and the thread directions of the upper section of each screw mandrel 1075 and the lower section of the screw mandrel 1075 are opposite. 1072 is sleeved on the lower section of the screw rod 1075 through the second screw sleeve. One end of the blanking plate 1074 is hinged with one side of the blanking port, and a second torsion spring 1078 is installed at the hinge of the blanking plate 1074 and the blanking port; The free end can snap or suck on the other side of the discharge port. The lower segment of the screw mandrel 1075 is slidably fitted with a sliding sleeve 1077, which is connected with the bottom of the lower pressing plate 1...

Embodiment 3

[0054] Such as Figure 7 As shown, the difference between this embodiment and the above-mentioned embodiment is that the number of needling rollers 1073 is an odd number, the end of each needling roller 1073 is sleeved with a first rolling wheel 10701, and all the first rolling wheels 10701 They are connected by the first rolling belt. One of the first scroll wheels 10701 is driven by a first scroll wheel motor, a first bevel gear 10702 is sleeved on the output shaft of the first scroll wheel motor, and a second bevel gear is sleeved on one of the screw rods 1075 10703, the mutual transmission between the first bevel gear 10702 and the second bevel gear 10703 is realized through a reversing assembly. The reversing assembly includes a third bevel gear 10704 and a fourth bevel gear 10705, the first bevel gear 10702 meshes with the third bevel gear 10704, the third bevel gear 10704 is connected with the fourth bevel gear 10705 through a shaft, The fourth bevel gear 10705 meshes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com