Patents

Literature

87results about How to "Achieve agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

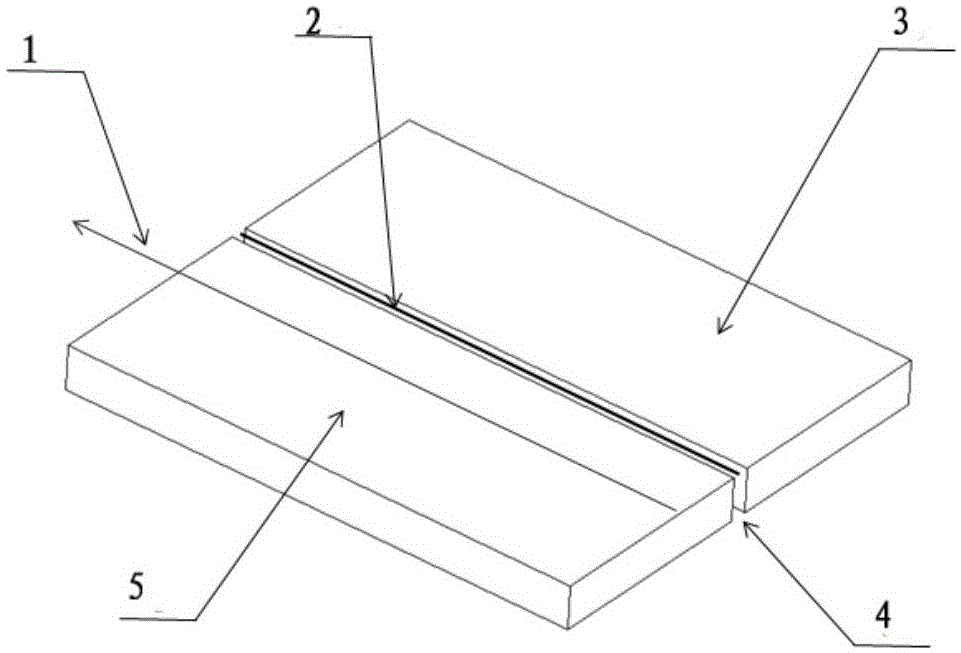

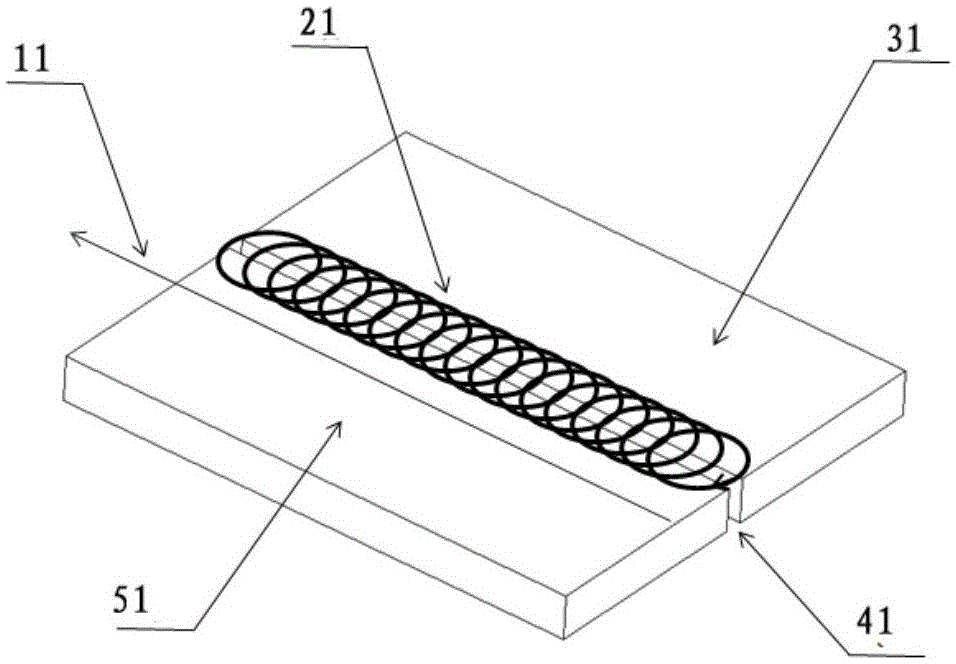

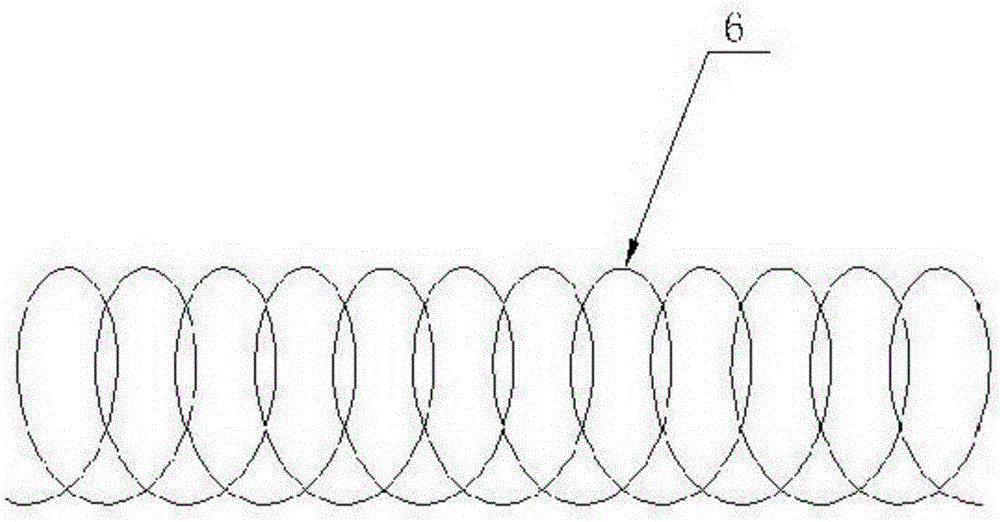

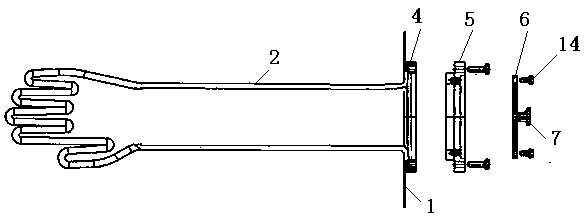

Laser welding method for large-gap weld

InactiveCN104999179AIncreased laser irradiation rangeAchieve laser direct weldingLaser beam welding apparatusOptoelectronicsIrradiation

The invention is suitable to be used for the field of laser welding, and provides a laser welding method for large-gap welds. Through reciprocating tracks or overlaying tracks, laser welding is performed, and additional solder or heat resource (composite welding energy source) is not needed. The method increases laser irradiation range just through changing welding paths (that is, laser irradiation paths) of laser, so as to increase melting area and melting quantity of a welding pool, improve tolerance of welding gaps, and increase applicability and convenience for laser welding.

Owner:HANS LASER TECH IND GRP CO LTD

Photobioreactor

ActiveCN102296022AChange shapeDegree of changeBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorCulture fluid

Owner:ENN SCI & TECH DEV

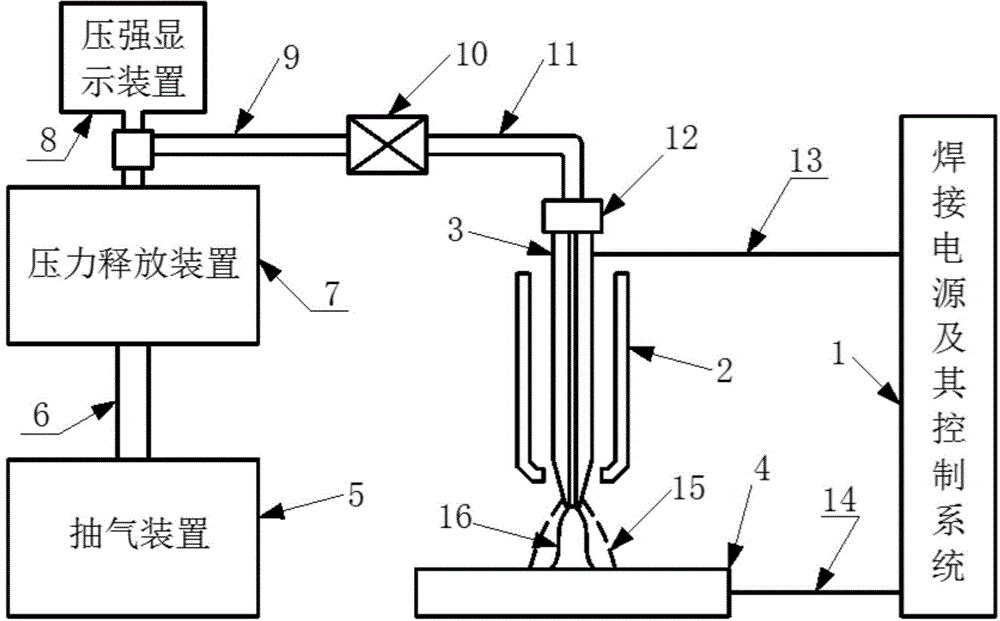

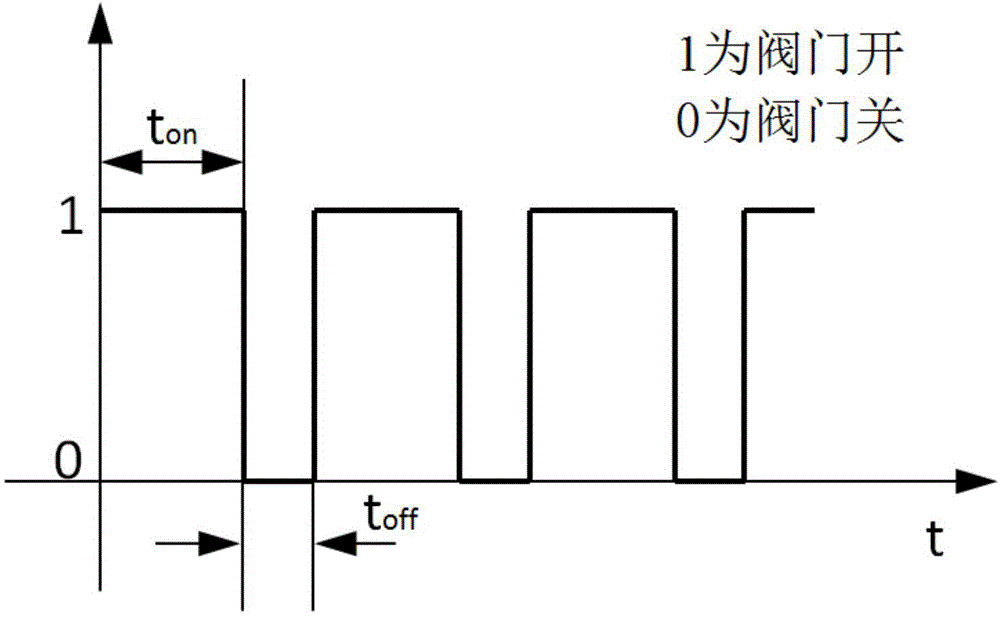

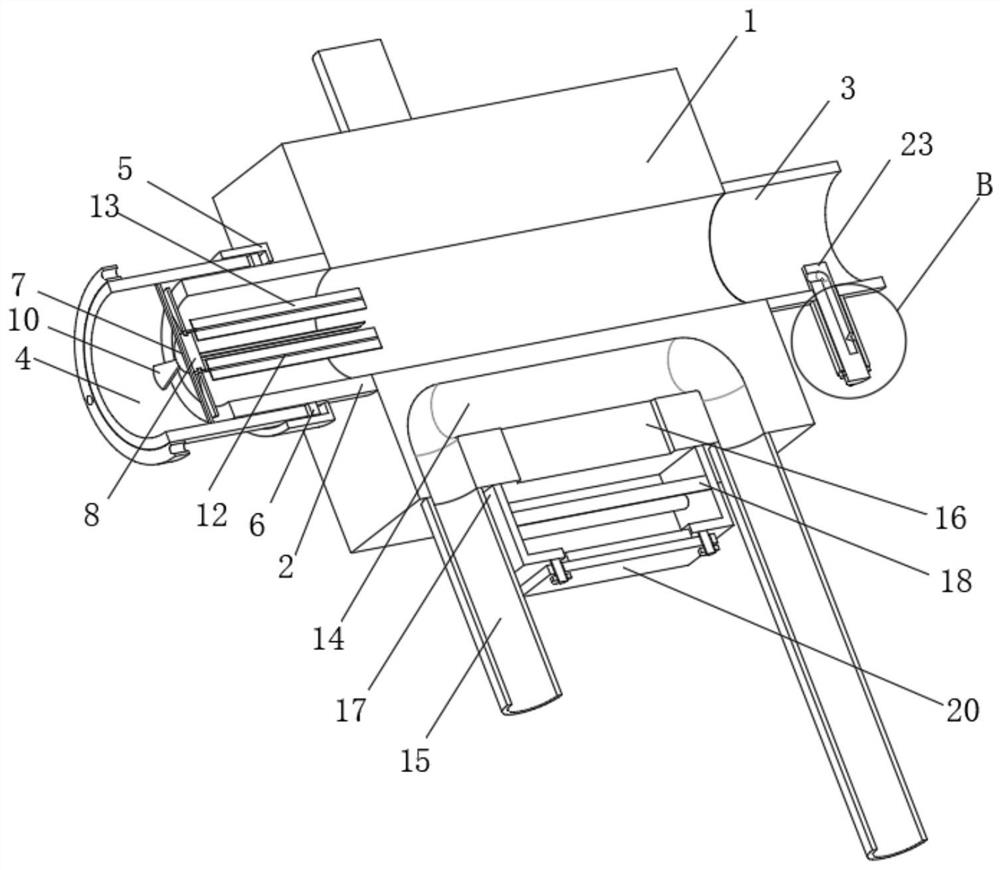

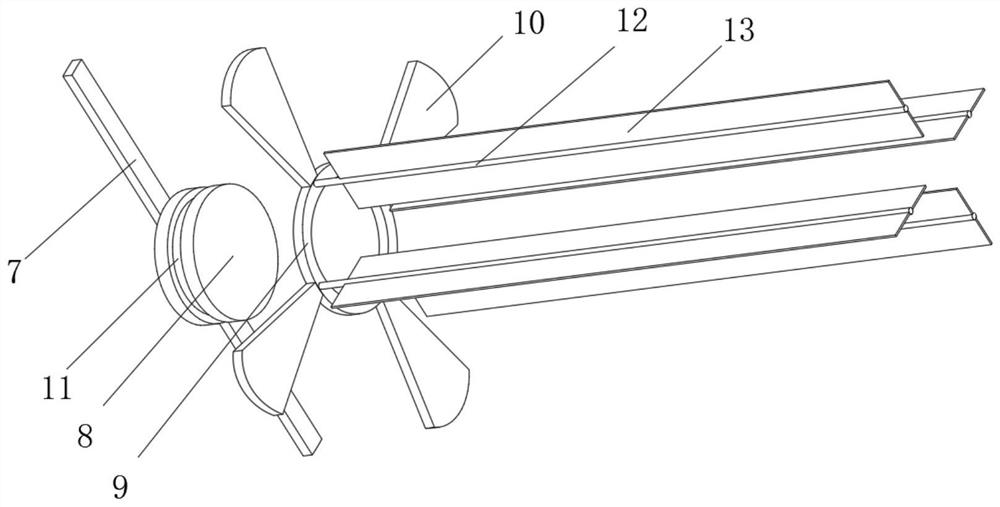

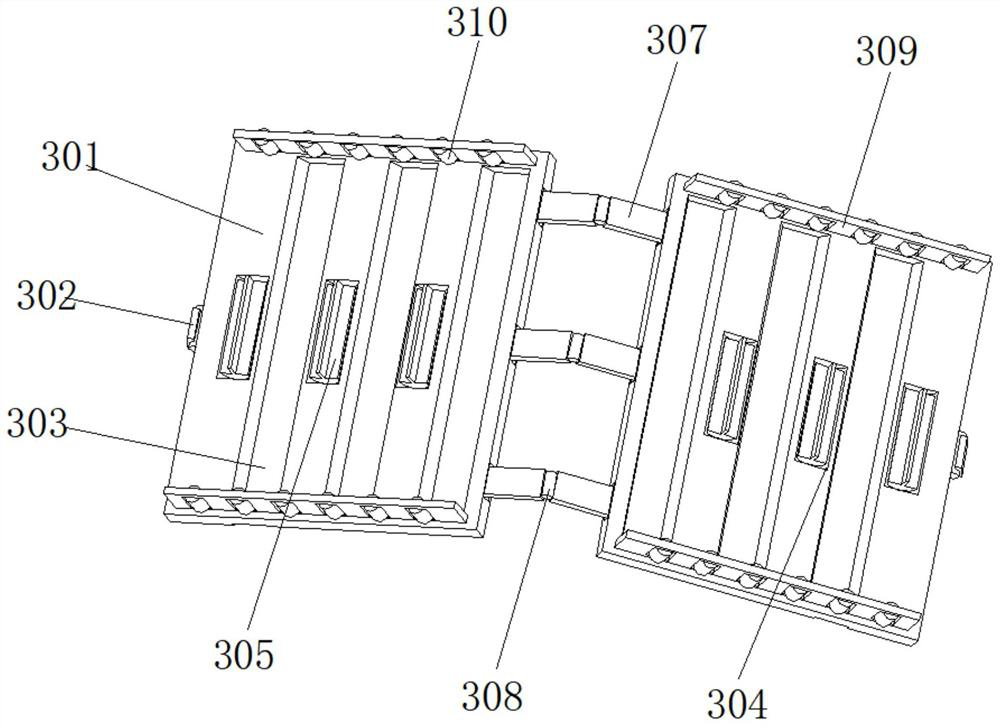

Central pulsation negative-pressure arc welding device and method

ActiveCN104308342AAchieve agitationAchieve oscillationElectrode accessoriesCompression actionEngineering

The invention relates to a central pulsation negative-pressure arc welding device and method, and belongs to the technical field of welding equipment and methods. An inner cavity of a hollow tubular electrode and the center of an arc below the hollow tubular electrode enter a periodic negative-pressure state by virtue of an air extraction device, and when the center of the arc is in a normal-pressure state, the arc is in a free arc form; when the center of the arc is in a negative-pressure state, the arc is in a restrained state under the compression action of external atmospheric pressure; therefore, the arc is switched between a free arc and a restrained arc to implement the central pulsation negative-pressure arc welding method. The pulsation arc produced by the welding device and method has oscillation and stirring functions for a welding pool, so that liquid metal forms tiny isometric crystals, the formation of air holes is suppressed, and the mechanical performance of a welding joint is improved; the pulsation frequency and duty ratio of the arc are regulated to accurately control the oscillation and stirring of the welding pool, the welding penetration and heat input.

Owner:BEIJING UNIV OF TECH

Refining and mixing system adopted in wet-process phosphoric acid refining process by solvent extraction method

ActiveCN106379879AImprove uniformityImprove stirring effectPhosphorus compoundsPhosphoric acidLubrication

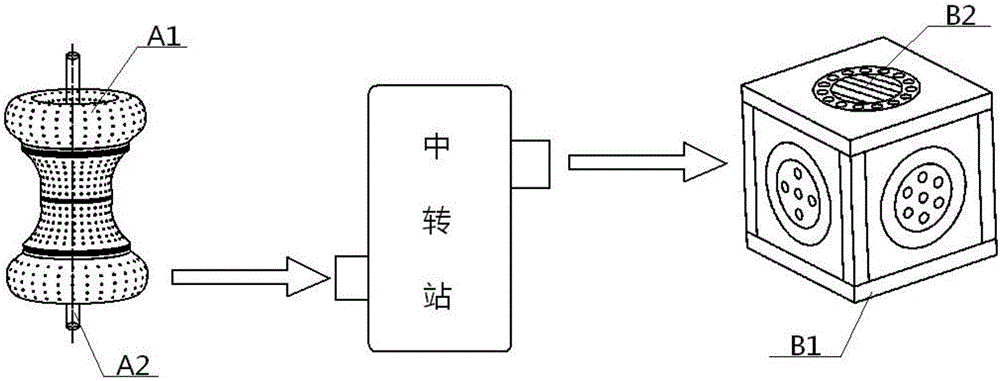

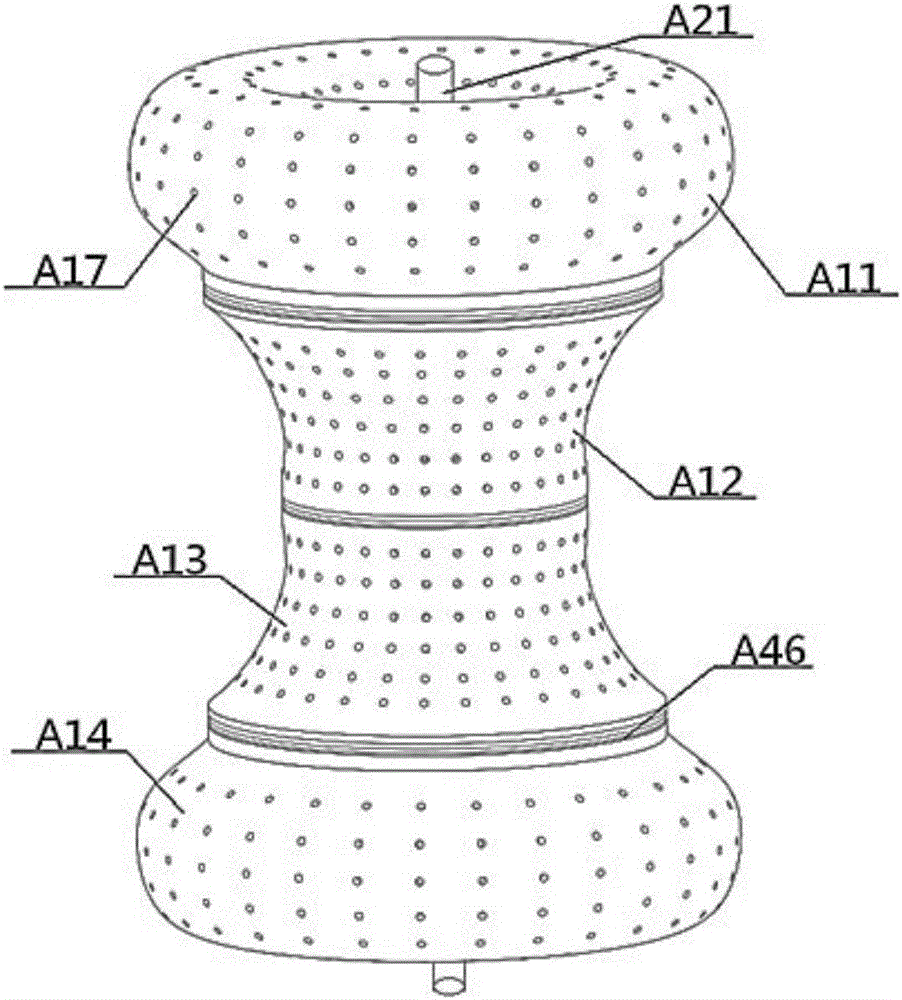

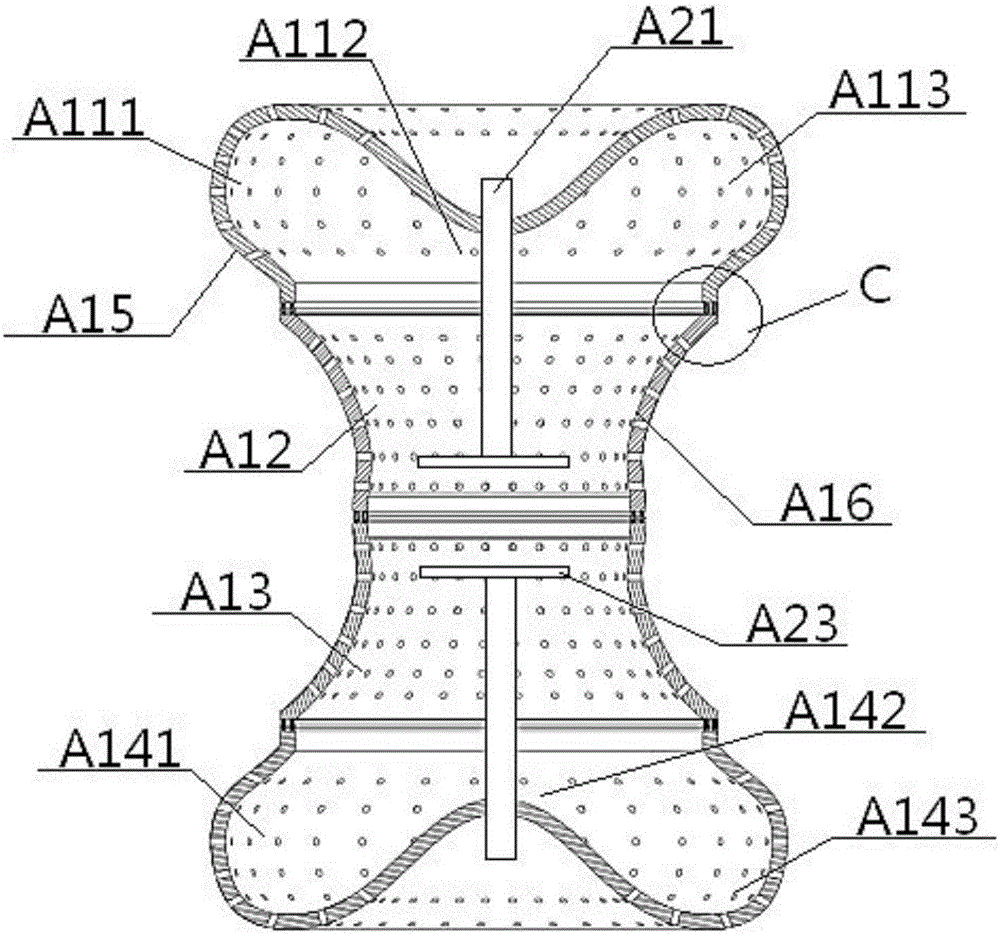

A refining and mixing system adopted in a wet-process phosphoric acid refining process by a solvent extraction method is used for liquid-liquid mixing or liquid-powder mixing and comprises an A type mixing device, a transfer station and a B type mixing device which communicate with each other successively, wherein the A type mixing device has functions including that an external containing body can rotate, a heating body can be arranged and a rotating airflow can be generated, and a stirrer has three functions of body stirring, airflow stirring and enhanced stirring; the B type mixing device has functions including that an external containing body can generate a rotating airflow, a heating body can be arranged and a module can be replaced, and a stirrer has four functions of body stirring, airflow stirring, enhanced stirring, and midway addition of raw materials. The system can eliminate a fluid stagnation zone, can heat a mixed object, has the advantages of good mixing performance and high uniformity, can achieve rotation of an external container, strong lubrication effect, various stirring functions and midway addition, and has a wide range of application.

Owner:HUAZHONG NORMAL UNIV

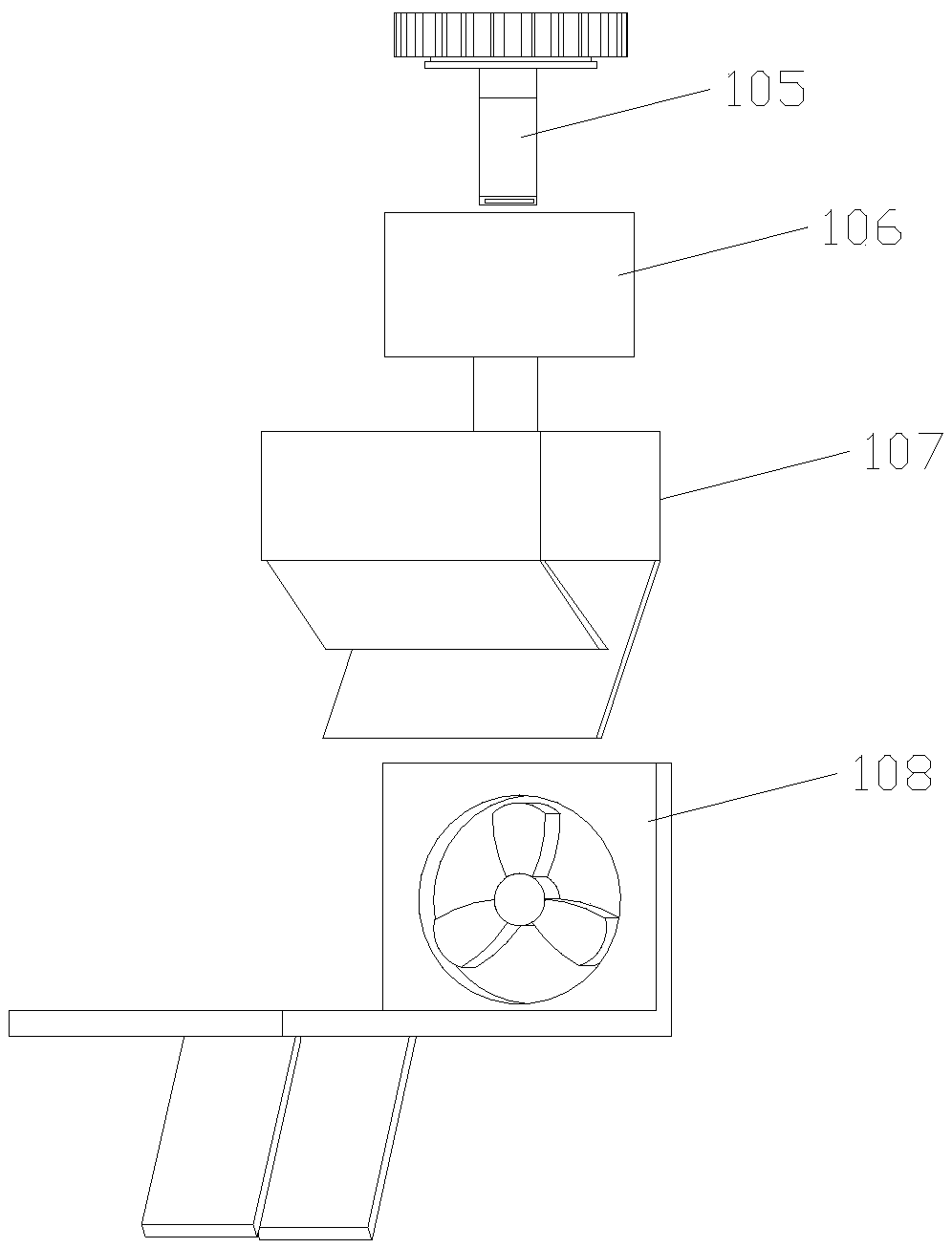

Reaction kettle

InactiveCN106732260AStir wellAvoid underreactionChemical/physical/physico-chemical stationary reactorsControl engineeringReaction rate

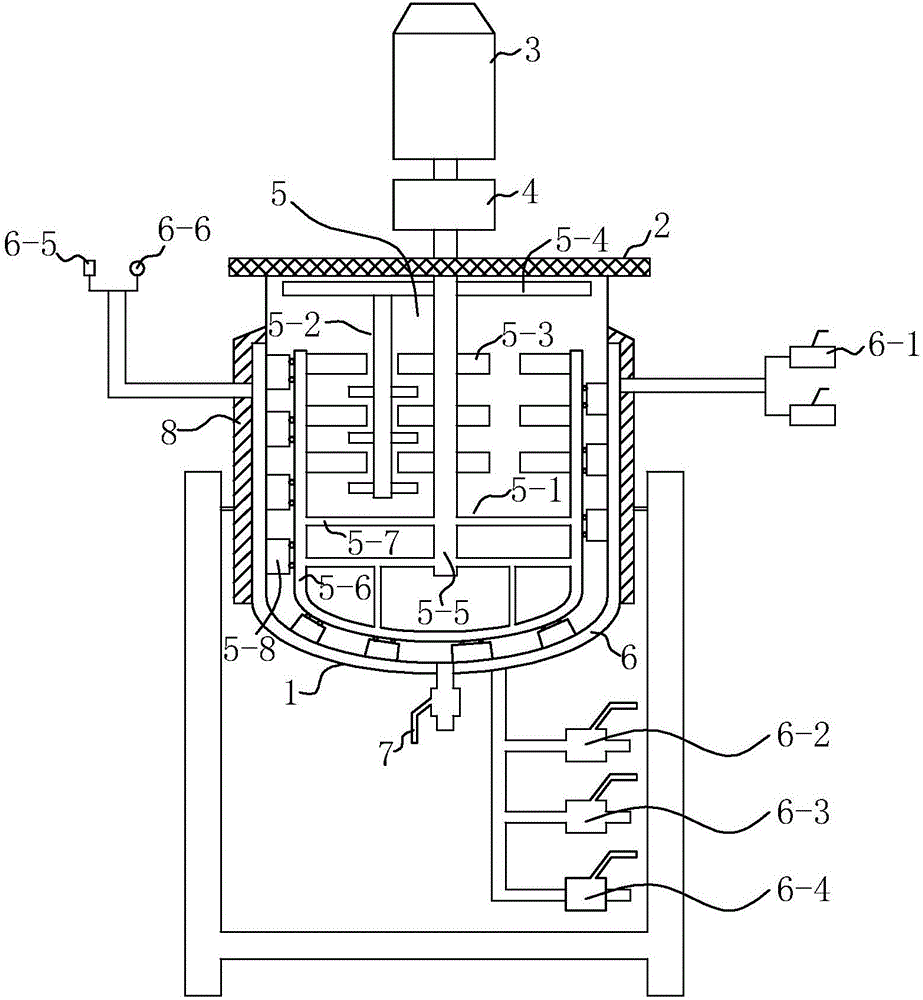

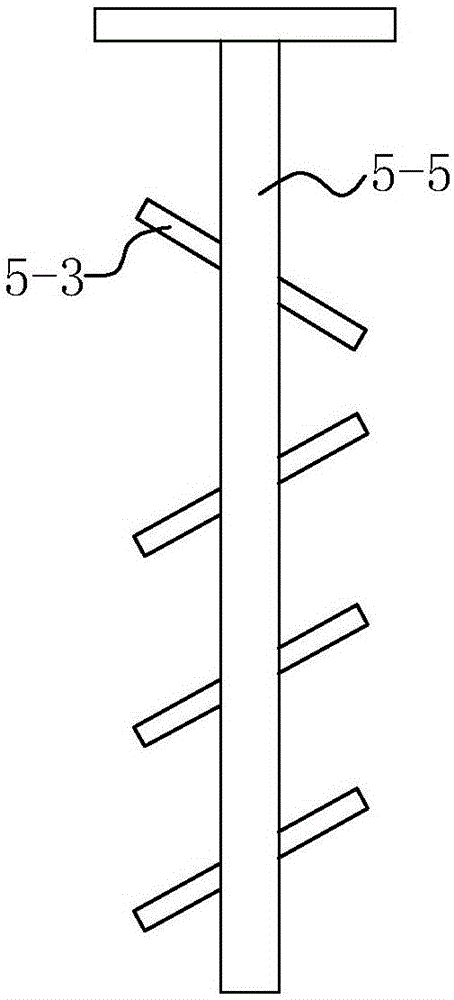

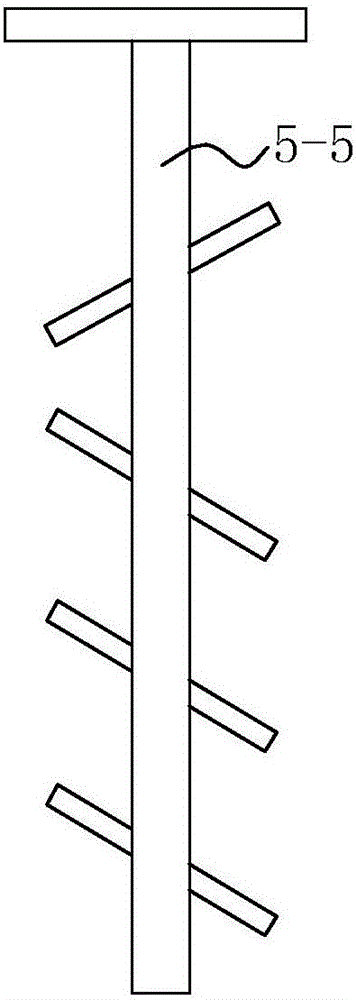

The invention discloses a reaction kettle which comprises a kettle body and a kettle cover, wherein a motor is arranged on the kettle cover; the lower part of the motor is connected with a speed reducer; the speed reducer is provided with an output shaft; the lower part of the output shaft of the speed reducer is connected with a reaction paddle; the kettle body comprises a closed jacket composed of an outer wall and an inner wall; the reaction paddle comprises a first reaction paddle and a second reaction paddle which is perpendicular to the first reaction paddle; the first reaction paddle and second reaction paddle are respectively provided with multilayer blades in the vertical direction; and the inclination directions of the blades of the first reaction paddle are not completely consistent. The reaction kettle can implement large-amplitude stirring in the horizontal direction, stirring on various levels in the vertical direction and impact fusion in different stirring directions, so that the stirring is more sufficiently and uniformly, thereby greatly enhancing the reaction rate and reaction quality.

Owner:鹤山市知墨印刷粘合材料有限公司

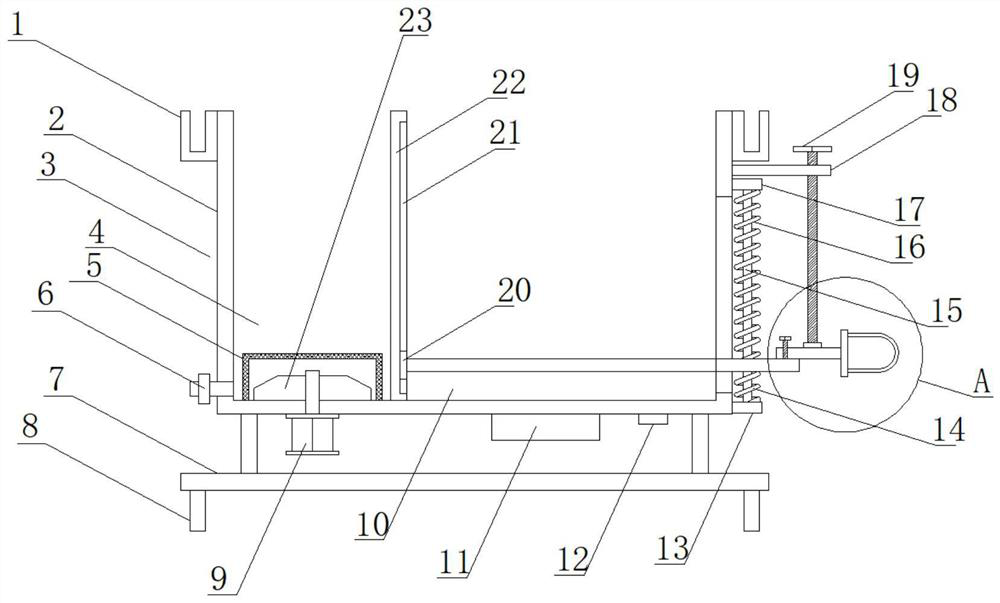

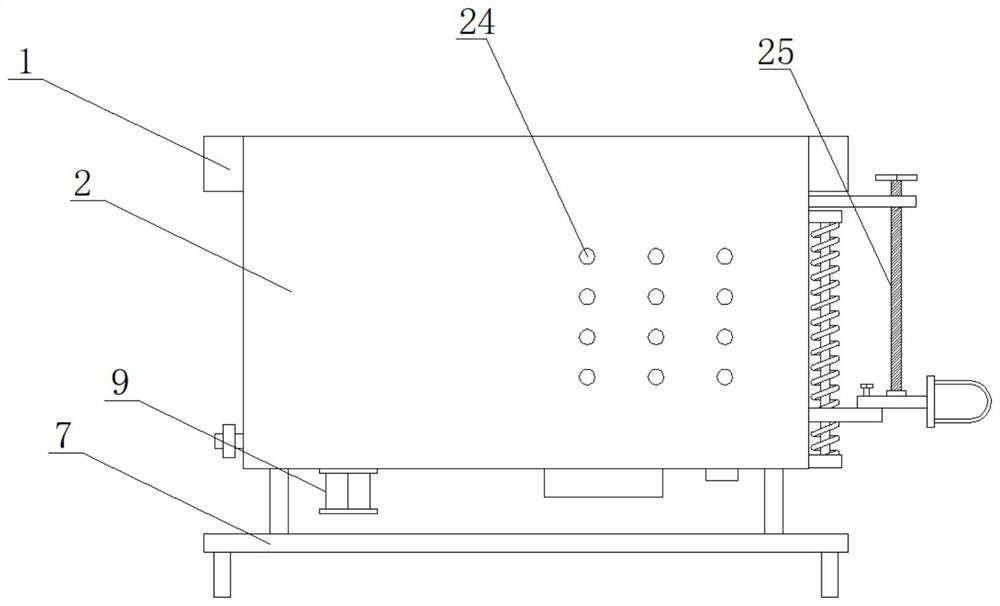

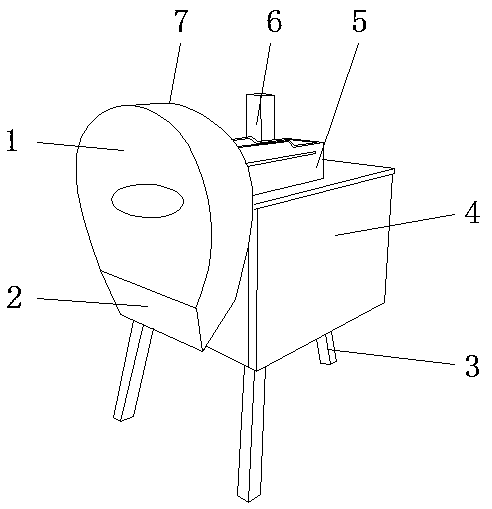

Paper impregnation device used for processing film adhesive

ActiveCN108999028AAchieve agitationPrevent precipitationPaper/cardboardPulp material addition processesAdhesivePulp and paper industry

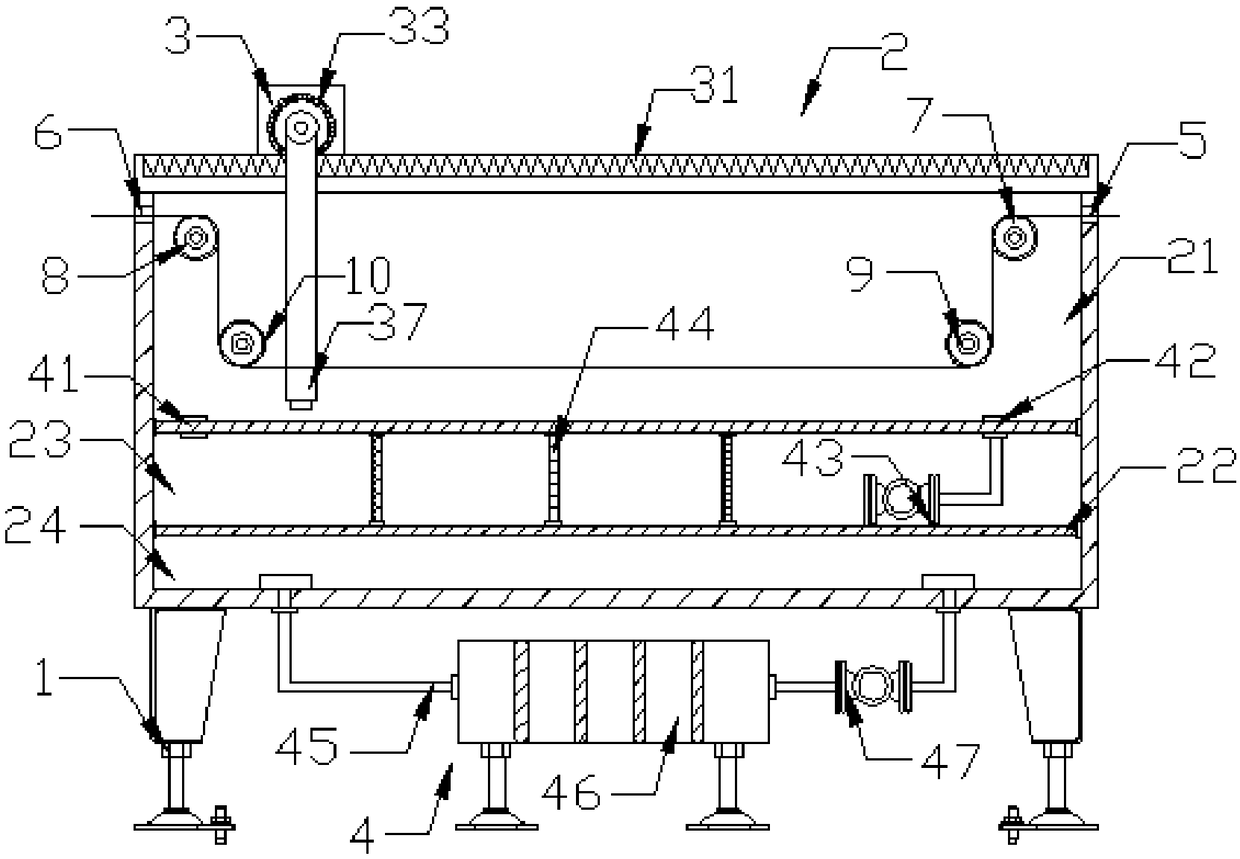

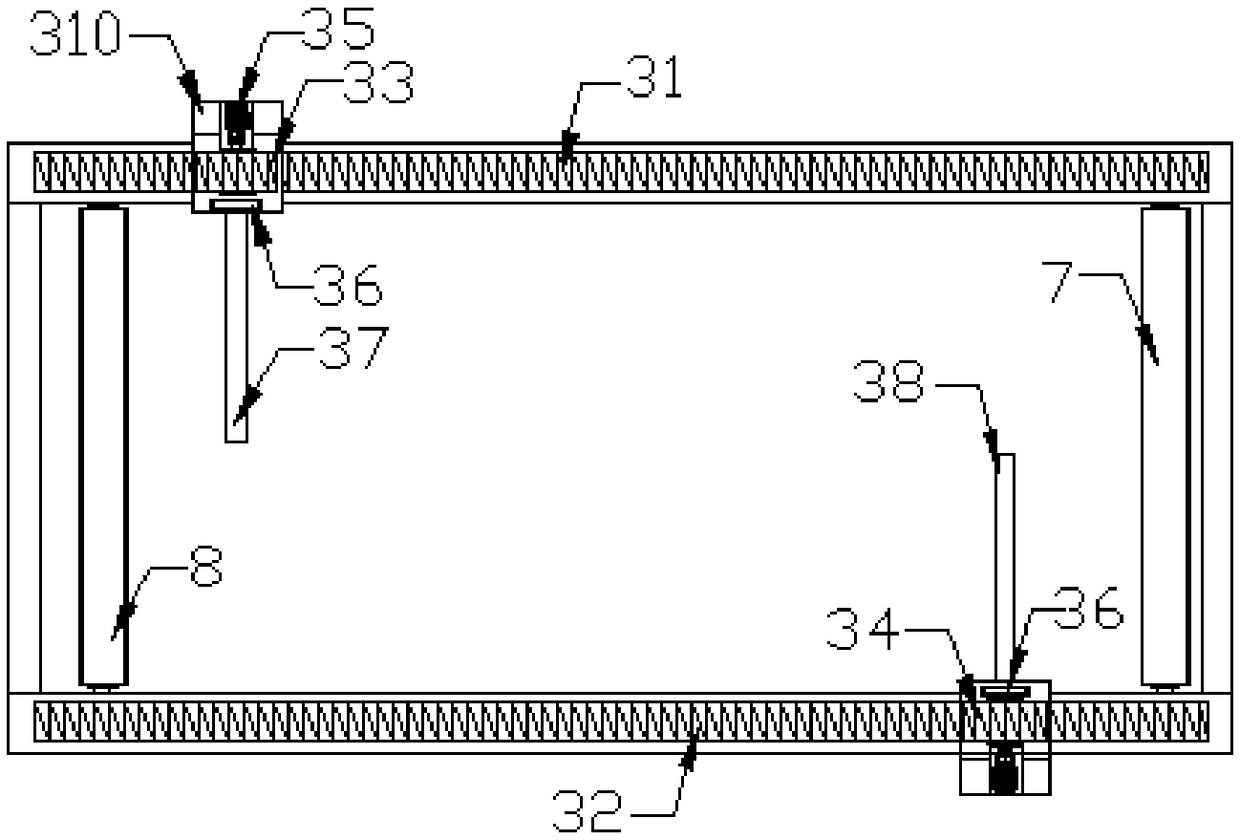

The invention discloses a paper impregnation device used for processing film adhesive. The device includes four support frames, an impregnation tank body, a driving mechanism, a circulating mechanism,a feeding roller shaft, a discharge roller shaft, a first guiding roller, and a second guiding roller. The impregnation tank body is fixedly installed on the tops of the four support frames and includes an impregnation liquid trough, two seal separation plates, a circulating trough and a heat insulation trough, wherein the two seal separation plates divide the impregnation tank body into the impregnation liquid trough, the circulating trough and the heat insulation trough from top to bottom. The driving mechanism is installed on the top of the impregnation tank body. The circulating mechanismis installed on the bottom of the impregnation tank body. The device has reasonable and simple structure, is convenient to use and can stir the impregnation liquid for avoiding settlement of the impregnation liquid. Due to high stability of gear and rack driving, splash of the impregnation liquid is prevented. By cleaning the impregnation liquid trough, the quality and temperature of the impregnation liquid are guaranteed, thereby effectively increasing qualification rate of impregnated paper products. The device has better practicability.

Owner:温州一树纸业有限公司

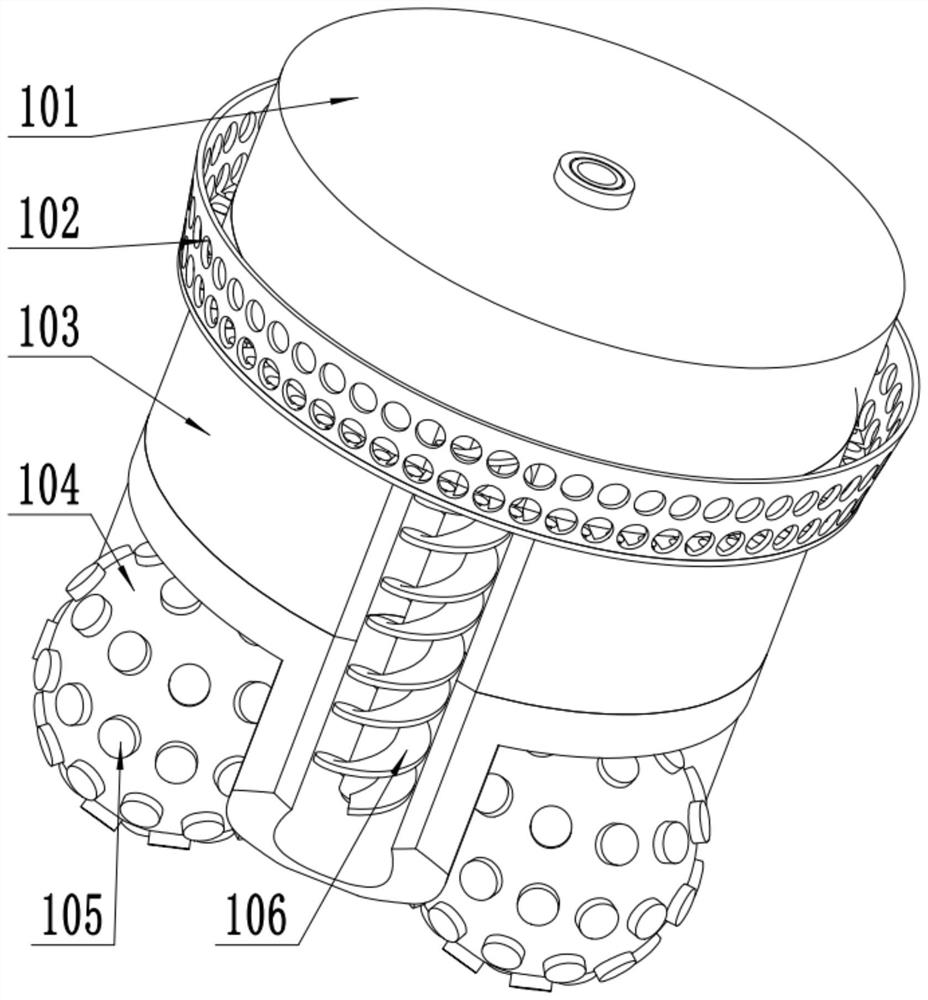

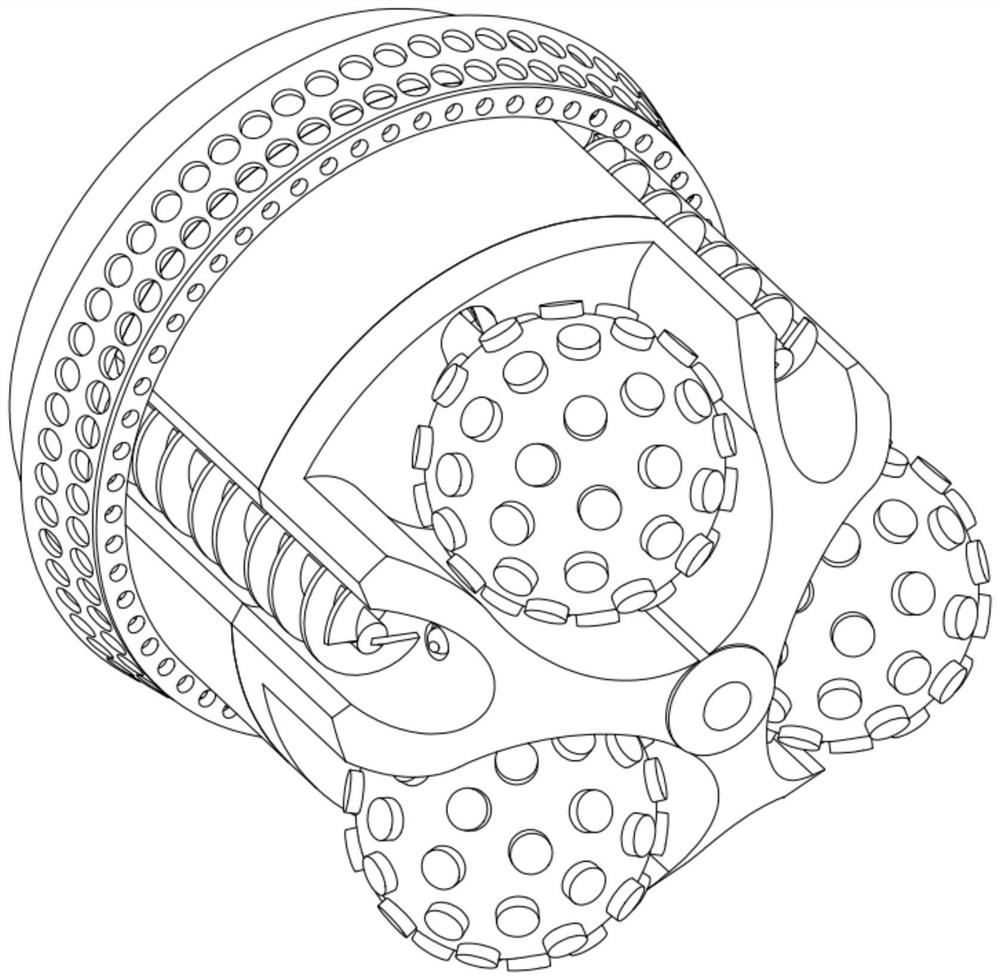

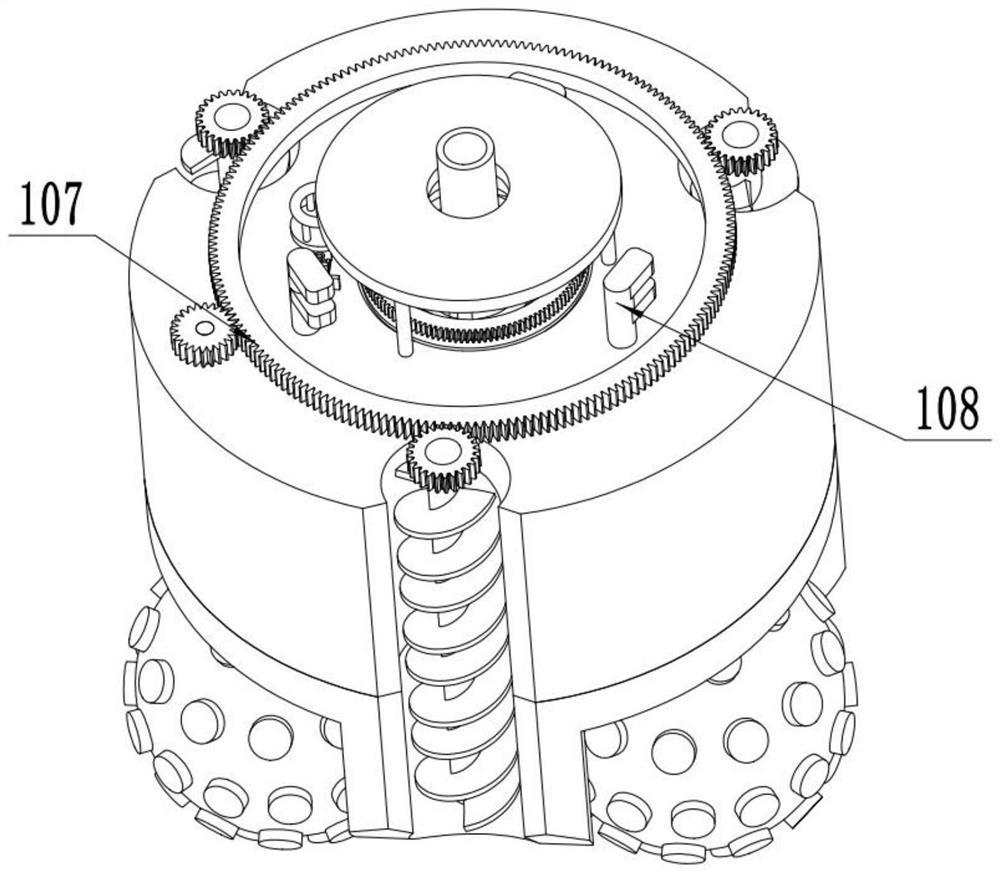

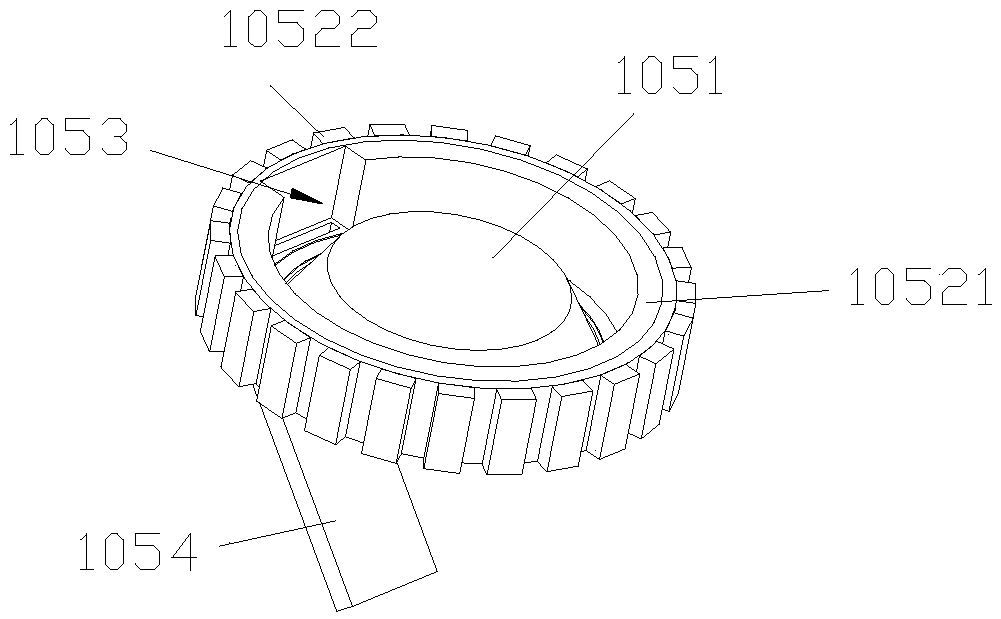

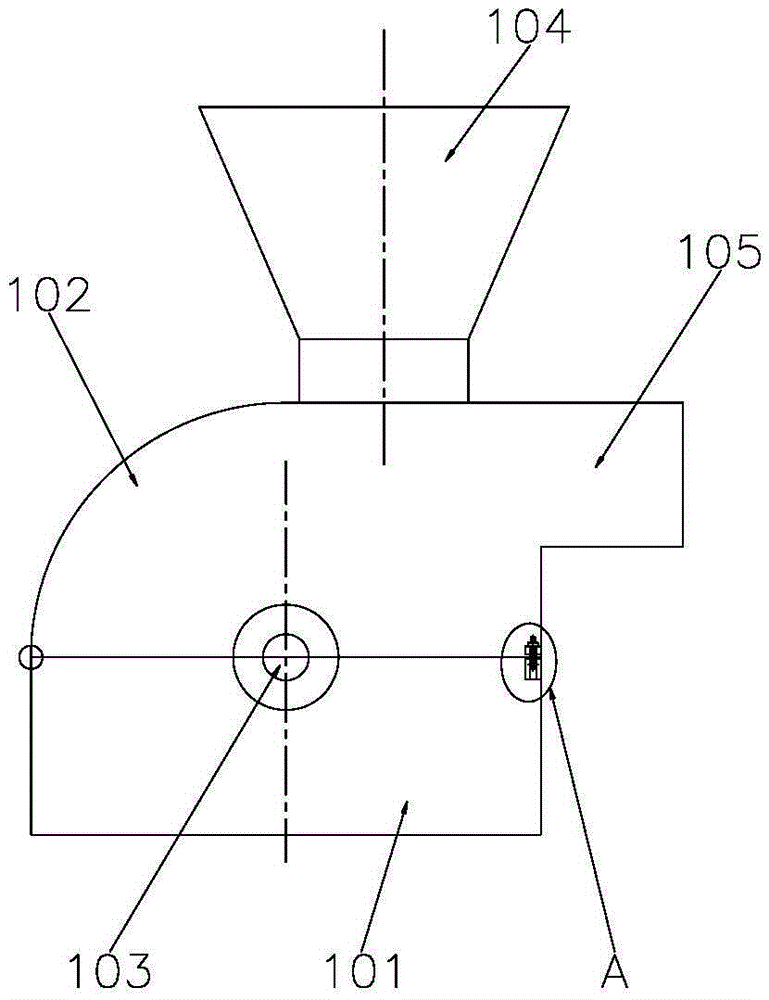

PDC bit capable of achieving salvaging while drilling

ActiveCN113389495ARealize individual rotation adjustmentAchieve agitationDrill bitsBorehole/well accessoriesGear wheelEngineering

The invention discloses a PDC bit capable of achieving salvaging while drilling, and belongs to the technical field of bits. The PDC bit comprises a base with a plurality of radial chutes, spherical drill teeth are slidably mounted in the radial chutes, the spherical drill teeth slide on the base under the action of cams and springs, and a plurality of composite sheets for cutting are arranged on the spherical drill teeth; and a gear with a spline is coaxially and fixedly installed on the spherical drill teeth. An annular plate sliding in the axial direction of the bit is arranged in the PDC bit capable of achieving salvaging while drilling, a plurality of sets of fixed rods and rotating rods are arranged on the annular plate, splines are arranged on the fixed rods and the rotating rods, and the splines are used for driving the specific spherical drill teeth located in the bit to rotate. According to the PDC bit capable of achieving salvaging while drilling, when the composite sheets on the spherical drill teeth fall off, the spherical drill teeth are rotated, a working face is converted, the spherical drill teeth do not need to be replaced immediately, and the working efficiency is greatly improved. Meanwhile, the composite sheets are salvaged by rotating a winch installed on a shell, the conception is ingenious, and the cost is saved.

Owner:潍坊盛德石油机械制造有限公司

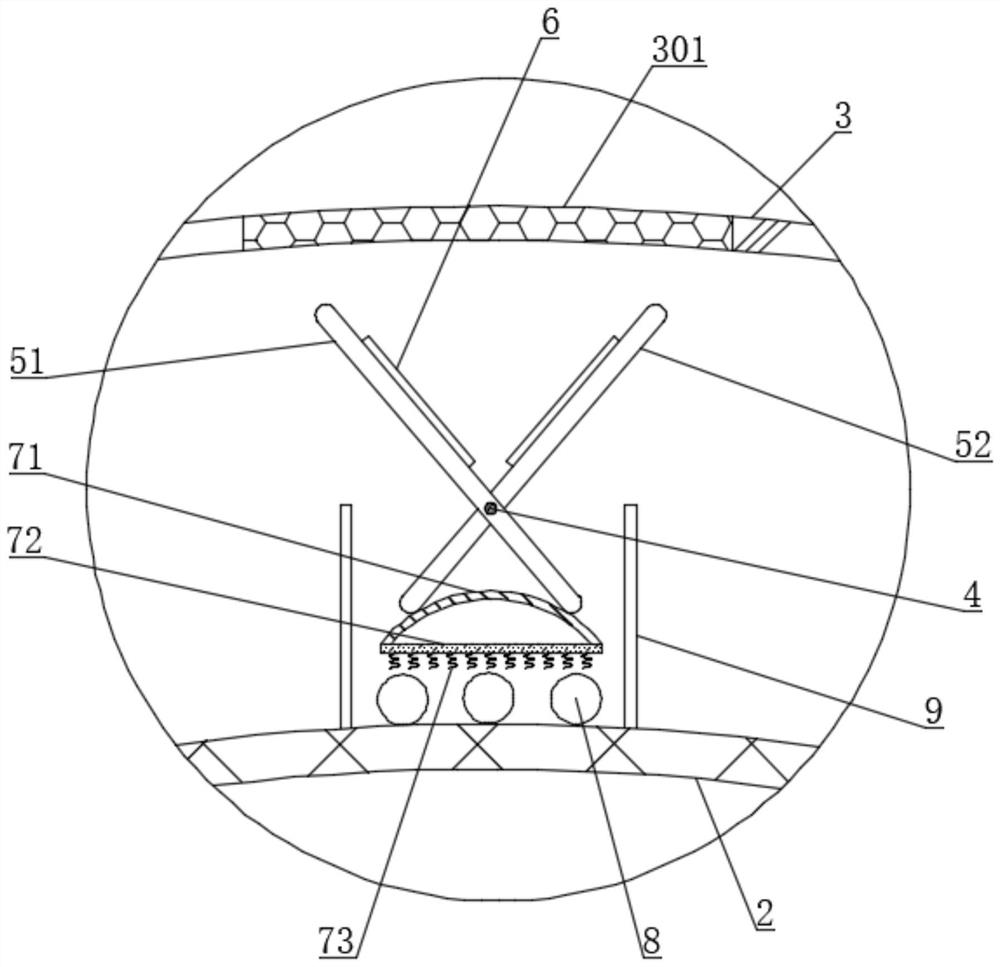

Novel aquaculture pond oxygenation equipment

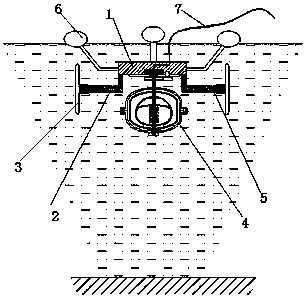

InactiveCN107751077AIncrease contact areaImprove oxygen dissolving capacityPisciculture and aquariaPropellerEngineering

The invention discloses a novel aquaculture pond oxygenation equipment, which comprises a frame, a floating ball, a propeller frame, a propeller and an oxygenation component. A propeller is arranged on the bottom wall of the frame by a propeller frame, an oxygen-enhancing assembly is arranged on the lower bottom surface of the frame, and the oxygen-enhancing assembly is rotatably arranged, and an oxygen pipe is connected to the oxygen-enhancing assembly. In the present invention, the oxygen-increasing component is arranged in a rotatable one, which can not only improve the uniform dispersion of oxygen in the water, but also set up a water stirring frame to realize the stirring of the water, increase the contact area between the water and the oxygen, and improve the dissolved oxygen in the water. In addition, the present invention is also provided with an outgoing airbag and an inward airbag, so that the gas passes through the inner airbag after passing through the hollow shaft, and is dispersed from the lower half of the inner airbag, and then evenly dispersed by the outgoing airbag, which can effectively Improve the uniformity of oxygen distribution and improve the oxygen-enhancing effect of the pool.

Owner:黄浩

Tail gas treatment device for cremation machine

PendingCN114811588AGuaranteed filtering effectIncrease contact timeTransportation and packagingCremation furnacesEngineeringMechanical engineering

The invention relates to the technical field of cremation machines, and discloses a cremation machine tail gas treatment device in order to solve the problem that when an existing cremation machine tail gas treatment device is used, the recovery efficiency of heat energy in tail gas is low, the cremation machine tail gas treatment device comprises a shell, an air exhaust component is arranged on the side, away from a smoke exhaust component, of the shell, and the cremation machine tail gas treatment device further comprises a fixing mechanism; and a heat exchange mechanism. When the device is used, the first filter screen plate filters tail gas entering the heat exchange shell and recycles heat energy in the tail gas, meanwhile, the driving part drives the rotating shaft and the dust collection shell to rotate, and when the dust collection shell rotates, the movable magnetic part horizontally rotates along with the dust collection shell and gets close to and away from the magnetic shell in a reciprocating mode; under the action of the magnetic force of the movable magnetic component on the magnetic shell, when the movable magnetic component passes through the magnetic shell, the magnetic shell swings in the heat exchange cavity under the action of the magnetic force and the elasticity of the elastic component, so that heat exchange liquid in the heat exchange cavity is stirred, and the heat exchange efficiency is improved.

Owner:江西方明环保科技有限公司

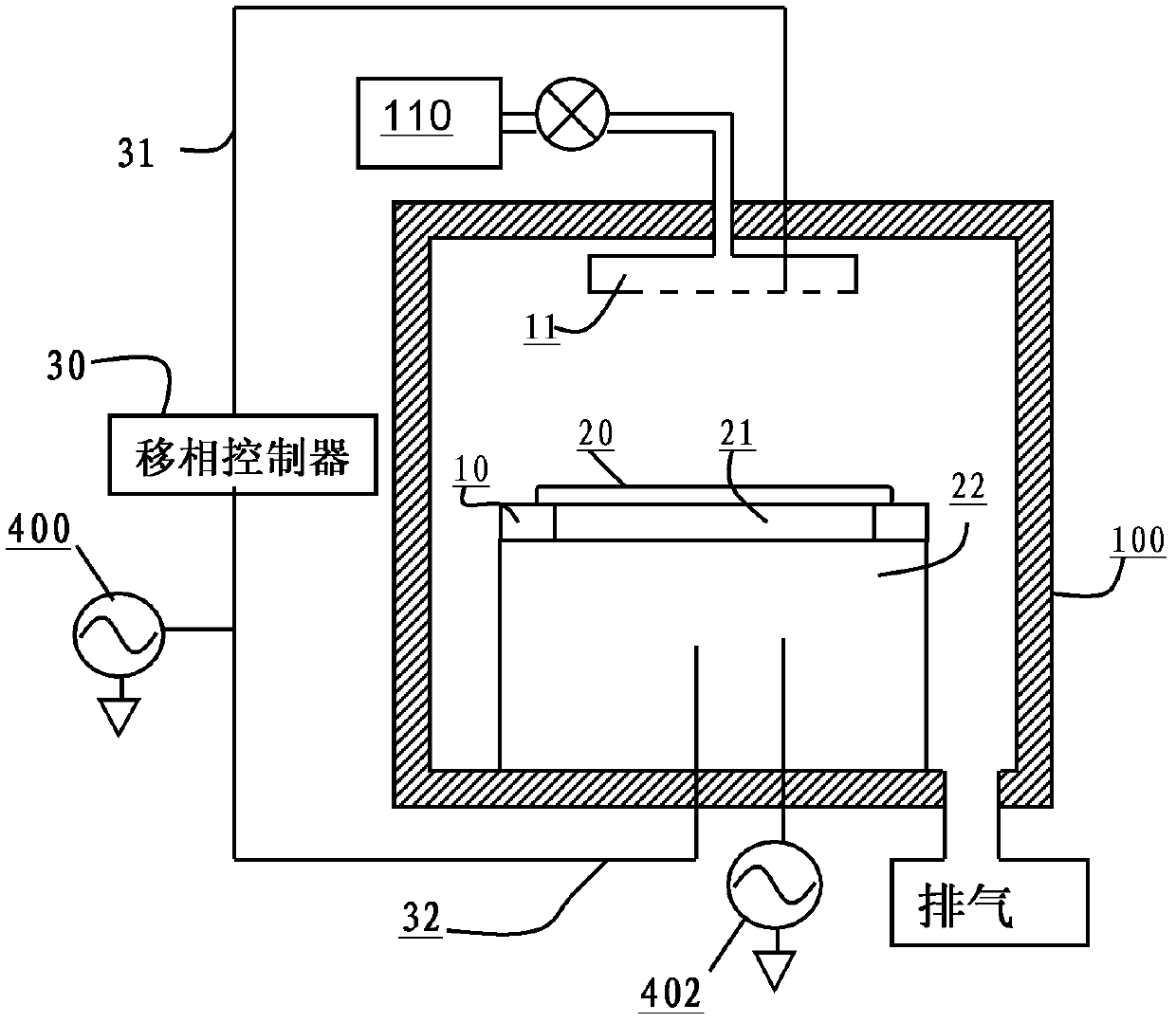

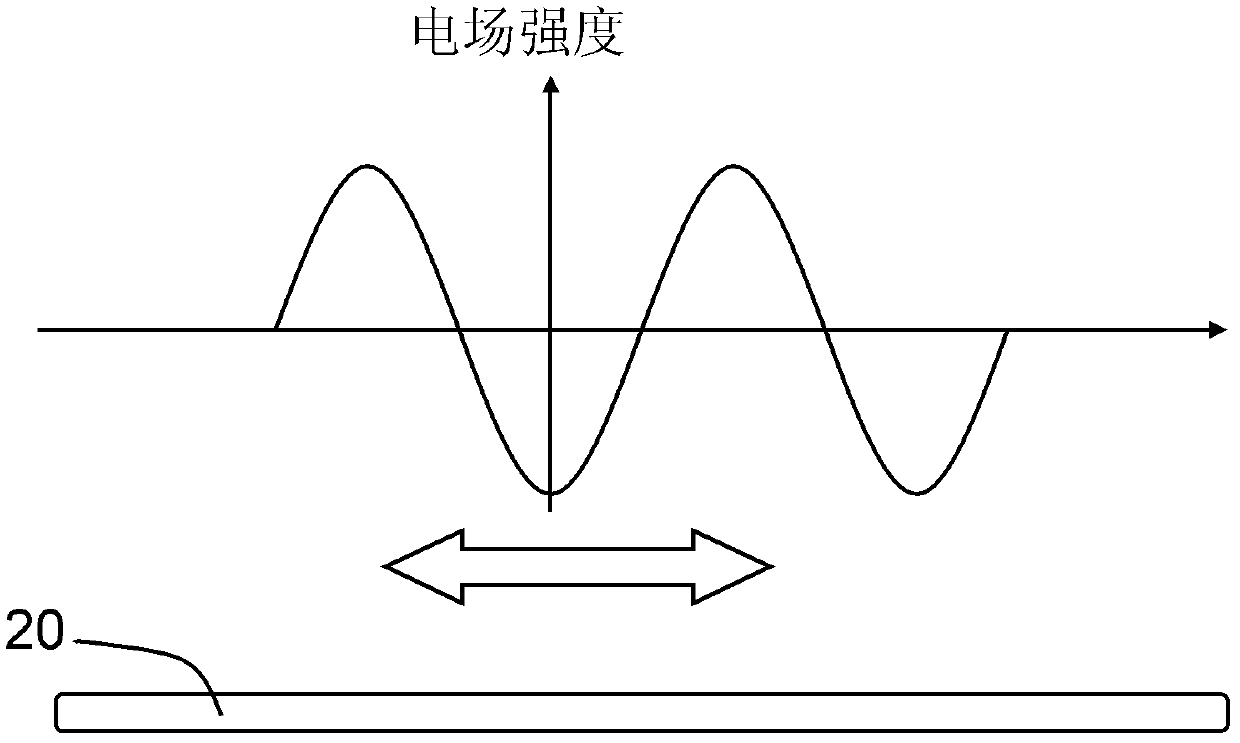

Capacity coupling plasma reactor and control method thereof

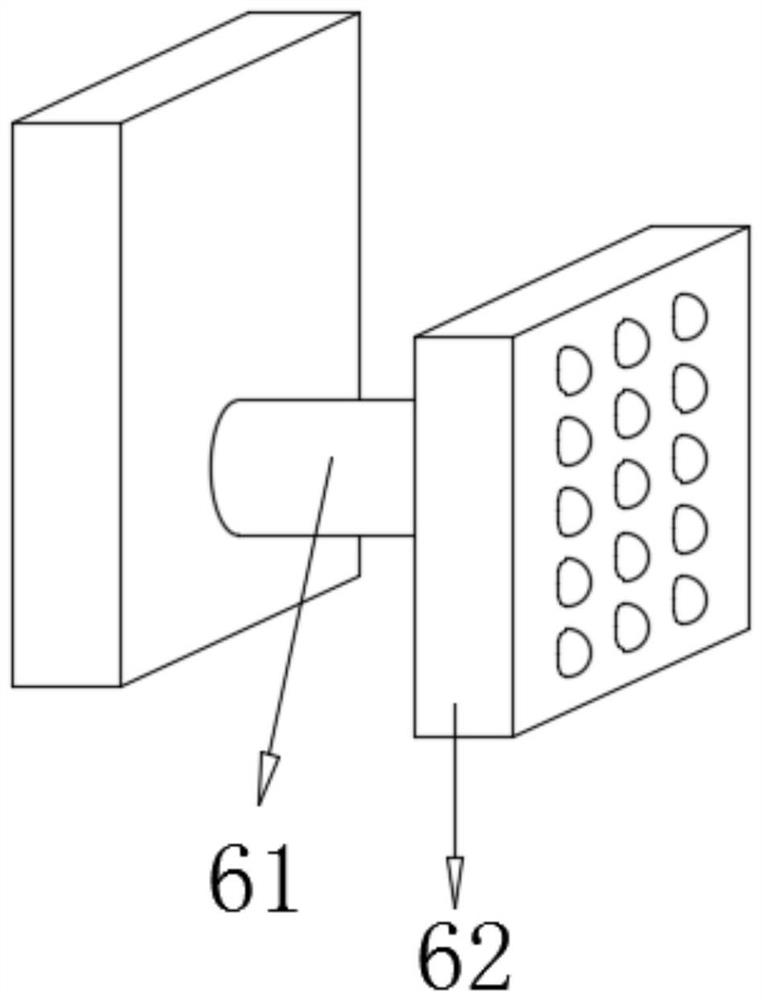

InactiveCN103327723AAchieve agitationGood distribution uniformityPlasma techniqueCapacitancePhase shifted

The invention provides a capacity coupling plasma reactor which comprises a pedestal located at the bottom of the reactor. The pedestal comprises a bottom electrode inside and a top electrode. A high-frequency radio-frequency power supply, wherein the top electrode is opposite to the bottom electrode and located on the top of the reactor, the high-frequency radio-frequency power supply is connected to the bottom electrode and provides first high-frequency radio-frequency power, and the high-frequency radio-frequency power supply is connected to the top electrode and provides second high-frequency radio-frequency power. A low-frequency radio-frequency power supply is connected to the bottom electrode and provides low-frequency radio-frequency power. The capacity coupling plasma reactor is characterized by further comprising a phase shift controller connected between the high-frequency radio-frequency power supply and the top electrode or the bottom electrode. The phase shift controller enables phase difference between the first high-frequency radio-frequency power and the second high-frequency radio-frequency power to continuously change to stir plasma distributed on the surface of a substrate and achieve more even distribution of plasma concentration.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

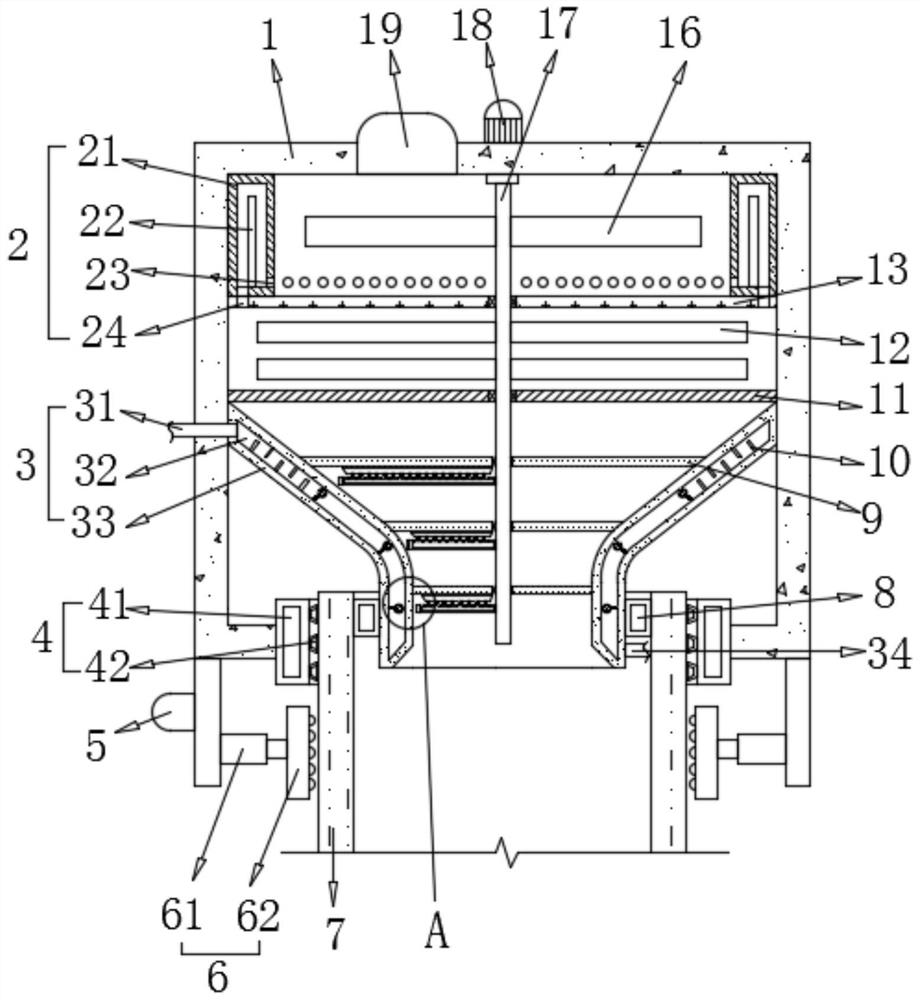

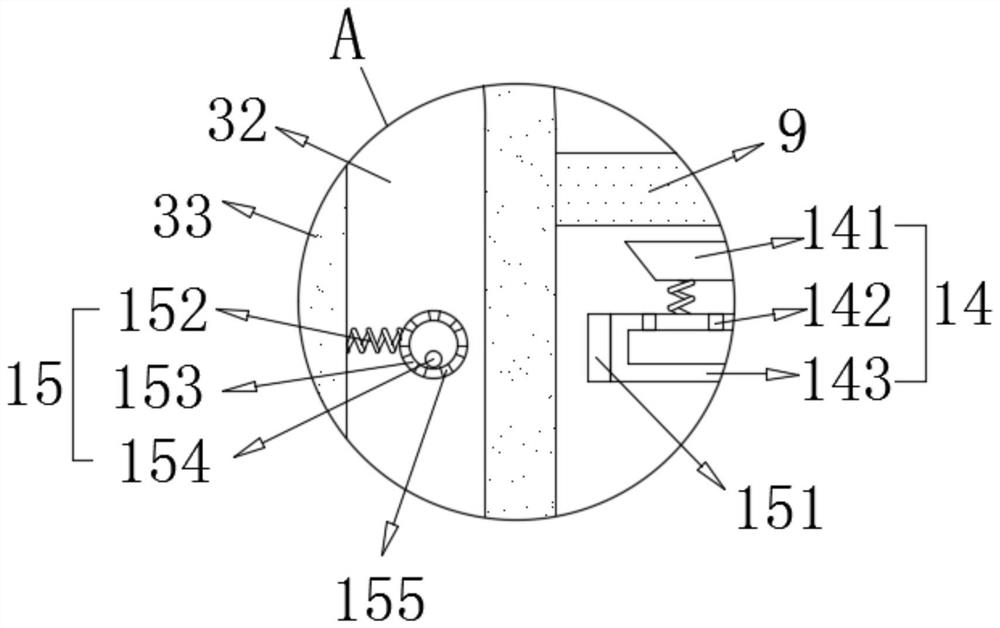

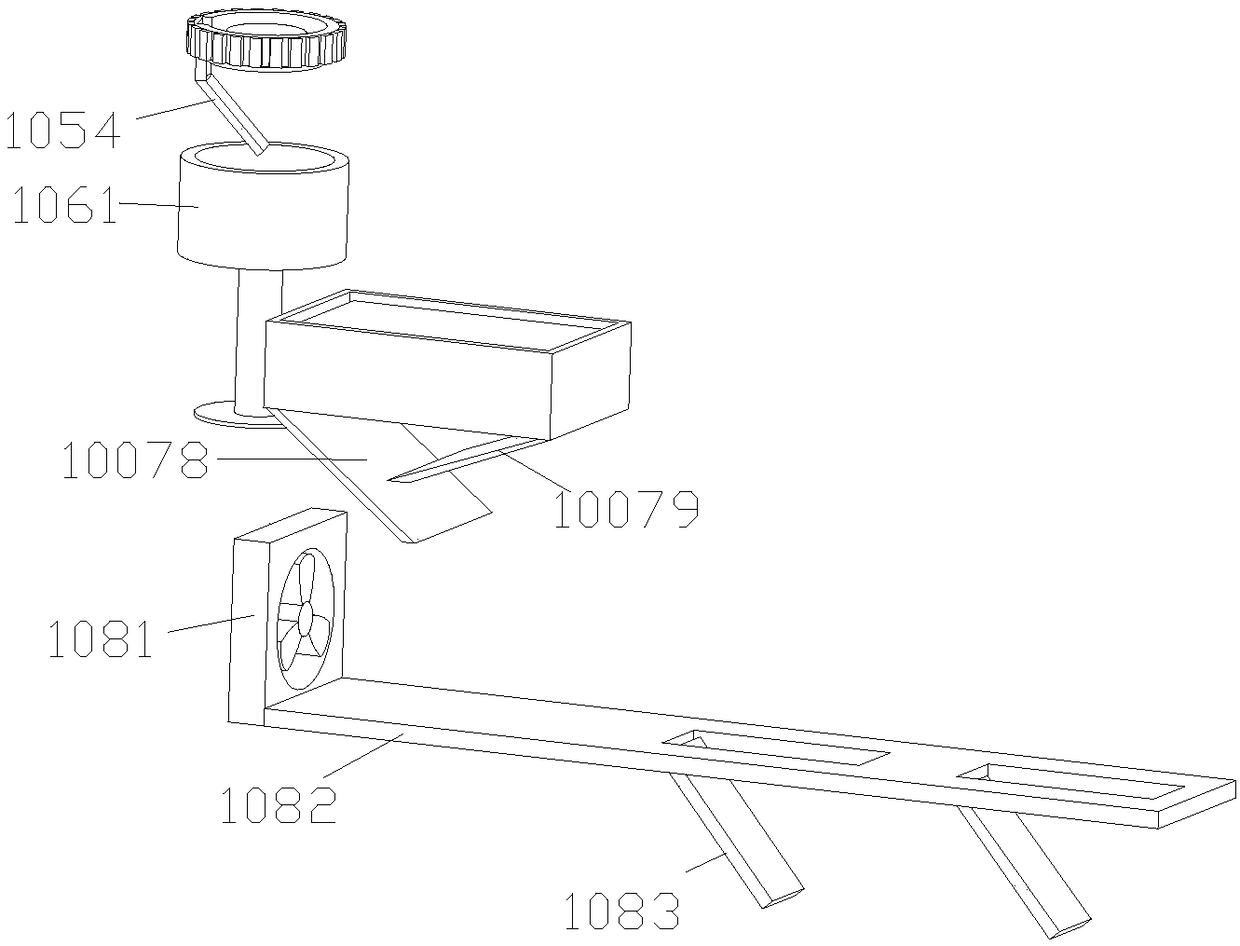

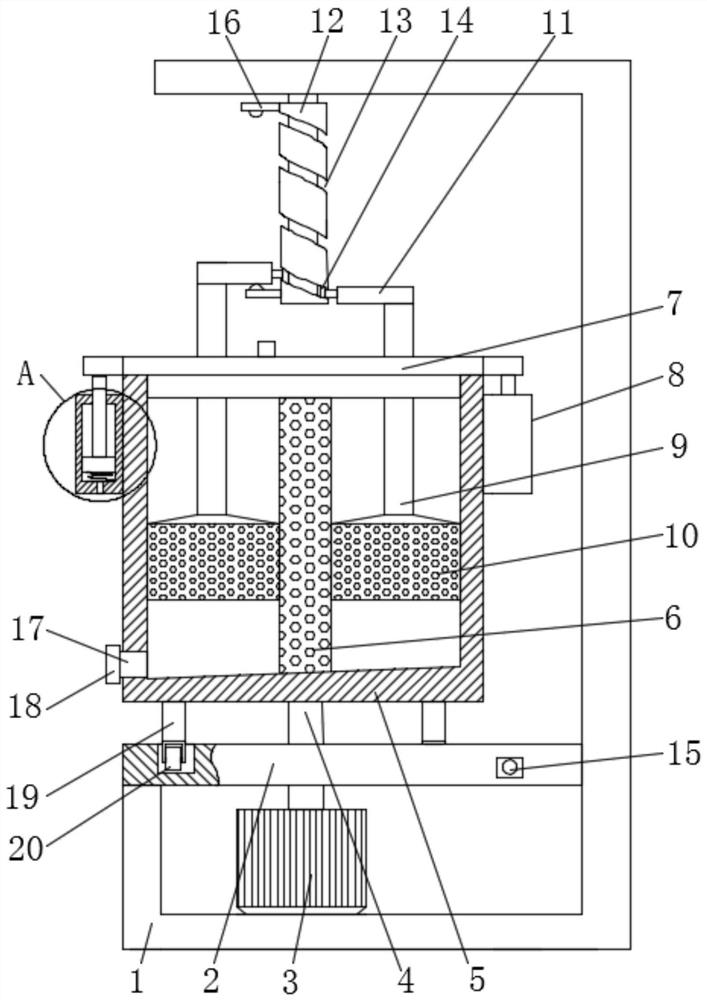

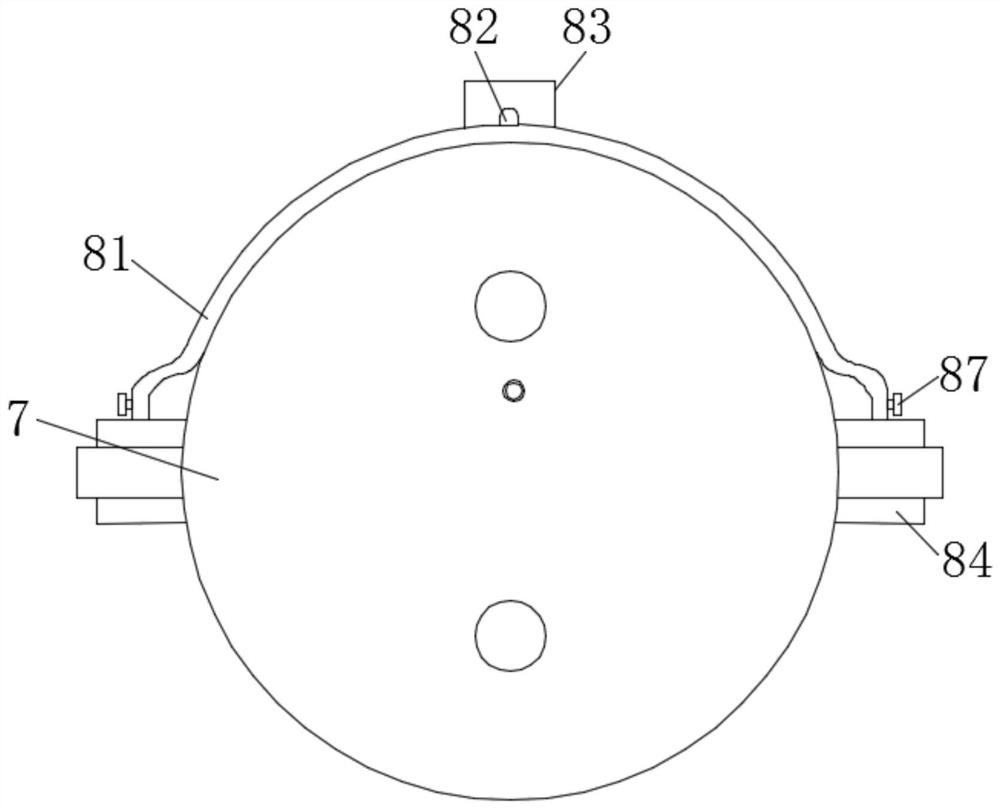

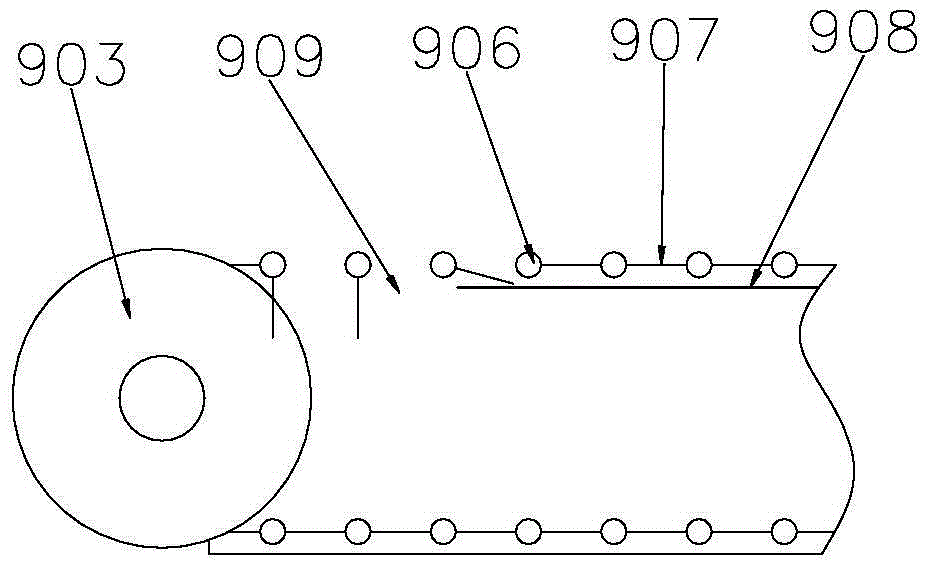

Fine powder smashing and wind-screening mechanism for waste concrete recycled aggregates

The invention discloses a fine powder smashing and wind-screening mechanism for waste concrete recycled aggregates. The fine powder smashing and wind-screening mechanism comprises a pre-smashing circular disc assembly, a centrifugal type smashing unloading device, a licker-in pressing type smashing device and a wind-screening device, wherein the centrifugal type smashing unloading device is positioned below the pre-smashing circular disc assembly; the licker-in pressing type smashing device is positioned below the centrifugal type smashing unloading device; and the wind-screening device is used for screening powder which drops from an unloading through hole. The fine powder smashing and wind-screening mechanism integrates various smashing ways such as centrifugal smashing, grinding and smashing, and rolling and smashing, and performs pre-smashing by utilizing the advantages of large capacity and large load of centrifugal smashing, so that load of next smashing is relieved, and next smashing efficiency is improved; at a transition unloading stage, transition smashing is performed in a mode of unloading during centrifugal smashing, and complete smashing of particles is realized by fierce extruding and stirring on a target position through a smashing way which integrates grinding smashing and rolling smashing.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

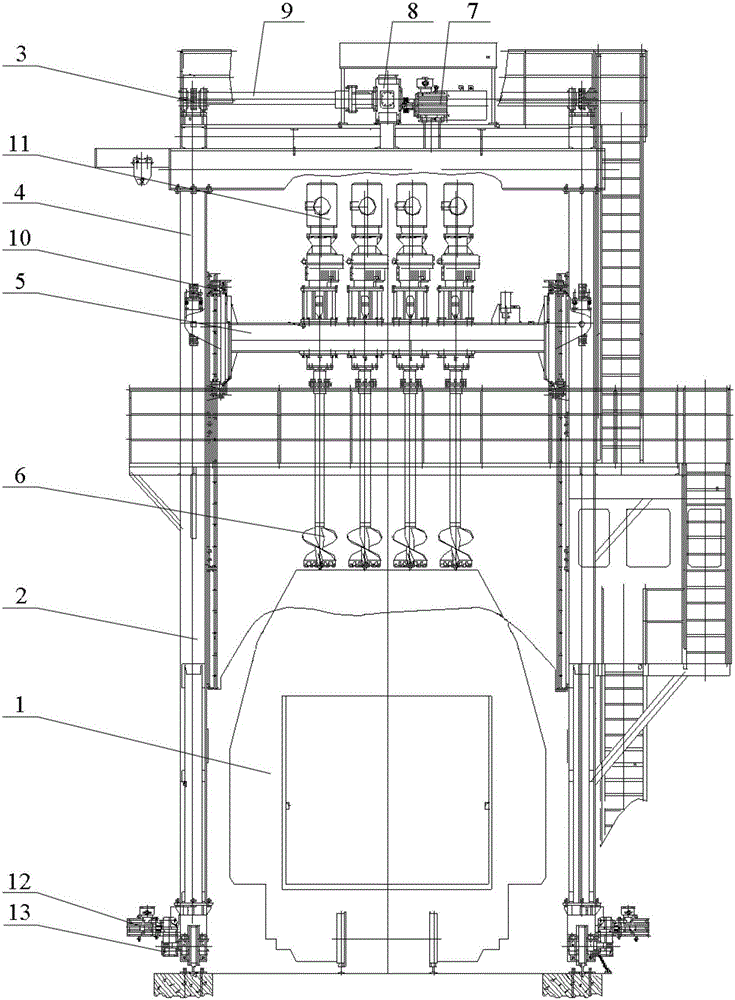

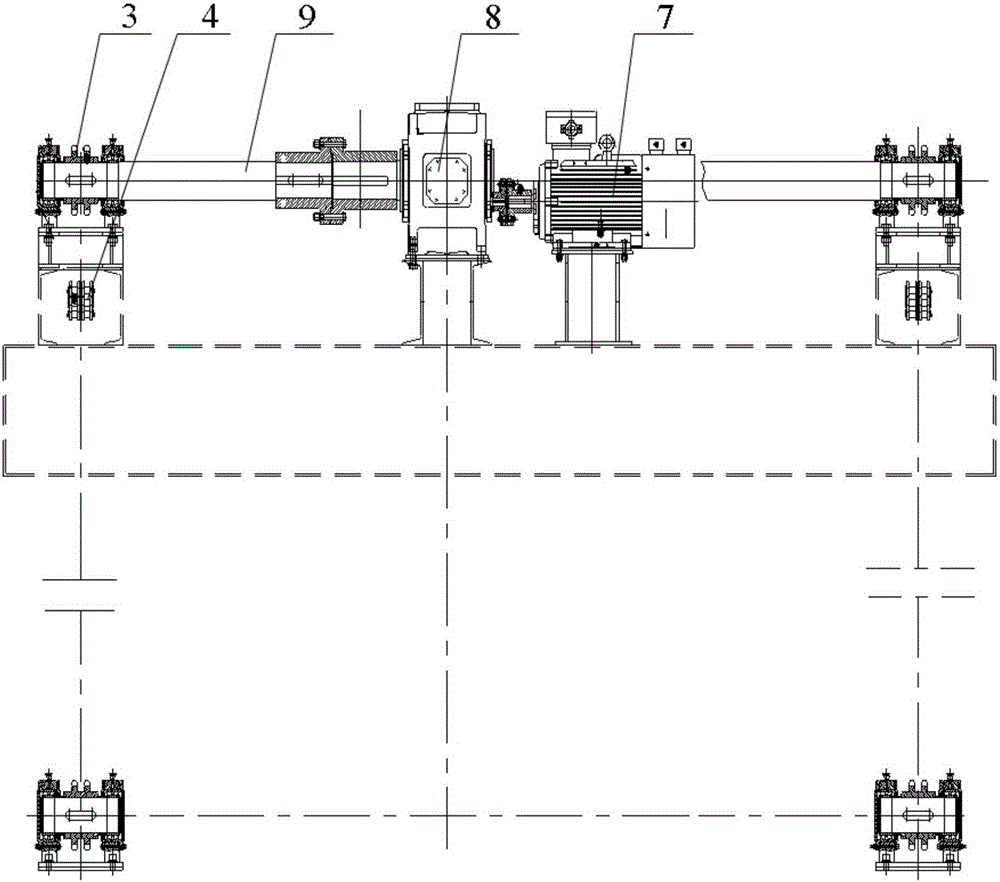

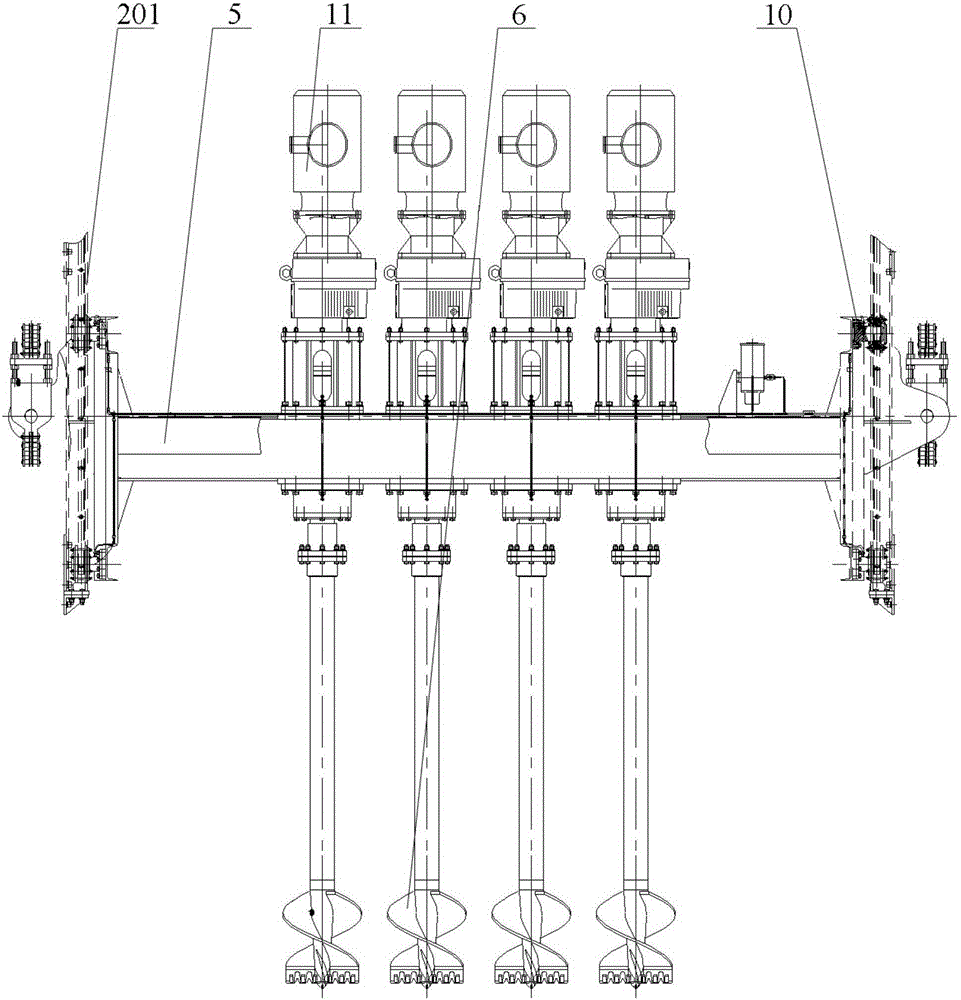

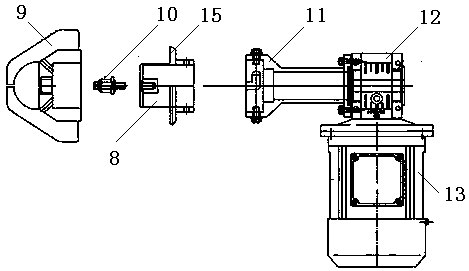

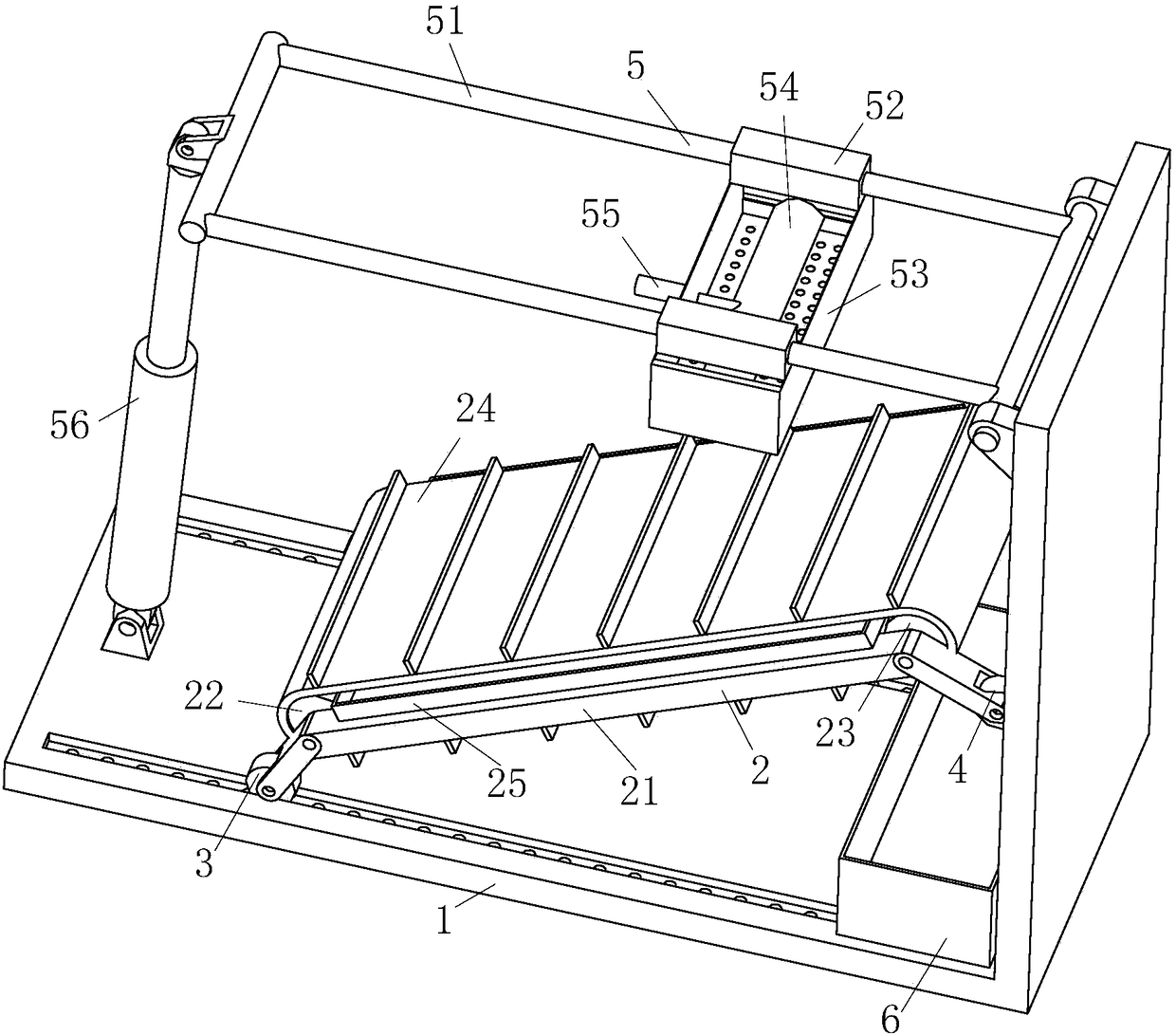

Material loosening machine

ActiveCN105197626AImprove transmission efficiencyMechanism structure is simple and reliableLoading/unloadingEngineeringSprocket

The invention discloses a material loosening machine. The machine comprises a rack and a lifting power output mechanism, wherein the rack stretches across a carriage and rails to operate, the lifting power output mechanism is arranged at the top of the rack, the mechanism comprises two output ends which are distributed oppositely, each output end is provided with a chain wheel, and each chain wheel is sleeved with a chain matched with the corresponding chain wheel; a loosening rack is connected between the two chains, multiple auger drill bits used for loosening materials in the carriage are arranged on the loosening rack, each auger drill bit is driven by an independent speed-reduction motor separately, and the rotation directions of every two adjacent auger drill bits are opposite. According to the material loosening machine, the loosening rack is lifted through a transmission mechanism composed of the chain wheels and the chains, the machine is simple and reliable in structure, low in production cost, high in transmission efficiency and capable of achieving automatic feeding, and the drilling force degree of the auger drill bits is increased. The rotation directions of every two adjacent auger drill bits on the loosening rack are opposite, the materials can be stirred better, block hardened materials can be subjected to grinding in opposite directions and cutting, and the material loosening effect is substantially improved.

Owner:HUNAN WANTONG TECH

Vegetable fresh-keeping transportation equipment

PendingCN112722517AImprove efficiency and effectivenessStack stableFood preservationPackaging under vacuum/special atmosphereBiologyEngineering

The invention discloses vegetable fresh-keeping transportation equipment. The equipment comprises a placement groove, a bottom plate, a motor, a rotating disc and a placement block, cleaned vegetables are placed in an immersion cleaning groove, ozone water is further injected into the immersion cleaning groove to realize immersion sterilization of the vegetables, and discoloration and deterioration of the vegetables caused by breeding of residual bacteria on the vegetables are avoided, the rotating disc is rotated, so as to push a pressing plate to move downwards, and push a connecting plate to move downwards to compress and stretch a first spring and a second spring respectively, a placement plate is further driven to move downwards, the vegetables soaked in the ozone water can be conveniently placed into a storage bin by a user, when it is necessary to take out the vegetables in the storage bin, a positioning bolt is rotated to be separated from the connecting plate, the pressing plate is rotated to be moved away from the position over the connecting plate, and therefore the connecting plate moves upwards under the action of the first spring and the second spring, the placement plate is further driven to move upwards, and the user can conveniently take out the vegetables from the storage bin.

Owner:重庆赐康果蔬有限公司

Oxygen-increasing device for aquaculture ponds

InactiveCN107751086AIncrease contact areaImprove oxygen dissolving capacityPisciculture and aquariaGas passingAquatic product

The invention discloses an oxygen-increasing device for aquaculture ponds. The oxygen-increasing device for the aquaculture ponds comprises a machine frame, floating balls, propeller frames, propellers and an oxygen-increasing assembly, wherein a plurality of floating balls are arranged on the machine frame utilizing connection of connecting rods; the propellers are arranged on the bottom wall ofthe machine frame utilizing the propeller frame; and the oxygen-increasing assembly is arranged on the lower bottom surface of the machine frame in a rotatable mode, and the oxygen-increasing assemblyis connected with an oxygen pipe. According to the oxygen-increasing device for the aquaculture ponds, the oxygen-increasing assembly is arranged to be rotatable, so that uniform dispersion of oxygenin water can be improved, moreover, a water stirring frame is arranged, so that stirring of water is realized, contact area between water and oxygen is increased, and oxygen-dissolving effect of water is increased; in addition, an outer air-releasing bag and an inner air-releasing bag are arranged, so that after passing through a hollow rotating shaft, a gas first passes through the inner air-releasing bag, and is dispersed out from the lower half part of the inner air-releasing bag, and then is evenly dispersed out by the outer air-releasing bag, so that uniformity of oxygen dispersion can be effectively improved, and oxygen-increasing effect of ponds is improved.

Owner:CHANGZHOU INST OF TECH

Planting and processing slicing machine for traditional Chinese medicinal materials

InactiveCN108297144AEasy to moveImprove transmission efficiencyVegetable peelingMetal working apparatusMedicinal herbsEngineering

The invention discloses a planting and processing slicing machine for traditional Chinese medicinal materials. The machine comprises a working tank, a feeding opening and a slicing machine main body.The working tank is mounted on the side end face of the slicing machine main body and comprises a tool insertion rest. A hydraulic push rod is connected to the upper end of the tool insertion rest inan extending-and-contracting manner. A fastening rotary knob is fixed to one side of the tool insertion rest, and a motor is connected to the other side of the tool insertion rest. Support rods are fixed to the upper end of the motor. A connection pulley is rotatably connected to each support rod in a limiting manner. A fixing track is connected to the support rods in a sliding manner through theconnection pulleys. A connecting bracket is fixed to the fixing track in a limiting manner. A discharging opening is formed below the working tank in a limiting manner. A fixing bracket is fixed to the discharging opening through the working tank. Support bases are fixed to the lower end of the fixing bracket in the triangular form. The feeding opening is formed in the fixing bracket in a limitingmanner and comprises a first communicating groove. The planting and processing slicing machine for the traditional Chinese medicinal materials can assist in slicing the medicinal materials and is convenient to replace.

Owner:HAINING IDIOU ANIMAL HEALTH PROD TECH CO LTD

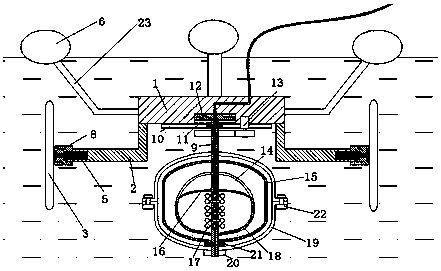

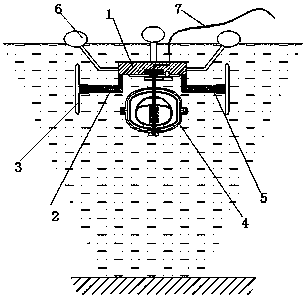

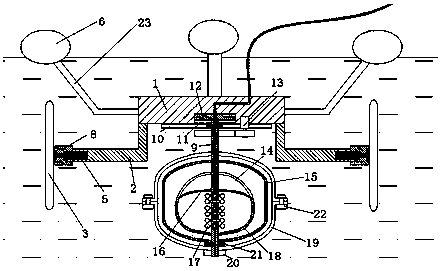

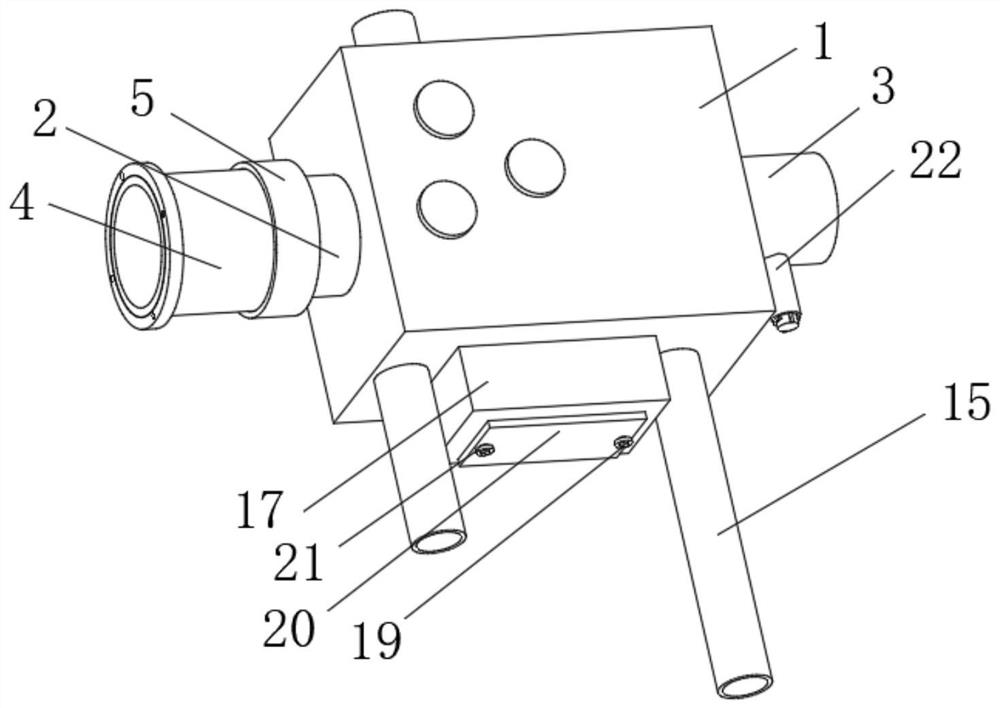

Annular wellhead flow device

InactiveCN113389516AAchieve agitationWell mixedInsulationWell/borehole valve arrangementsStructural engineeringPetroleum oil

The invention relates to the technical field of oil exploitation, and discloses an annular wellhead flow device. The device comprises a combination valve body, the left side and the right side of the combination valve body fixedly communicate with a connecting pipe and an oil outlet pipe correspondingly, the outer surface of the connecting pipe is movably sleeved with a mounting pipe, and the inner surface of the mounting pipe is fixedly connected with a connecting plate; and the inner side face of the connecting plate is fixedly connected with a mounting disc, and the outer surface of the mounting disc is movably sleeved with a movable ring. According to the annular wellhead flow device, the outer side of the connecting pipe is sleeved with the mounting pipe, mounting is achieved through a locking sleeve, a connecting plate is additionally arranged on the inner surface of the mounting pipe, the outer surface of the mounting disc on the side face of the connecting plate is movably sleeved with the movable ring, the side face of the movable ring is connected with blades, and the blades rotate when petroleum flows; and a fixed rod on the end face of the movable ring drives a stirring plate to rotate, stirring during petroleum circulation is achieved, mixing and uniform stirring of petroleum are improved, the circulation efficiency is improved, and the use effect is good.

Owner:李宝娟

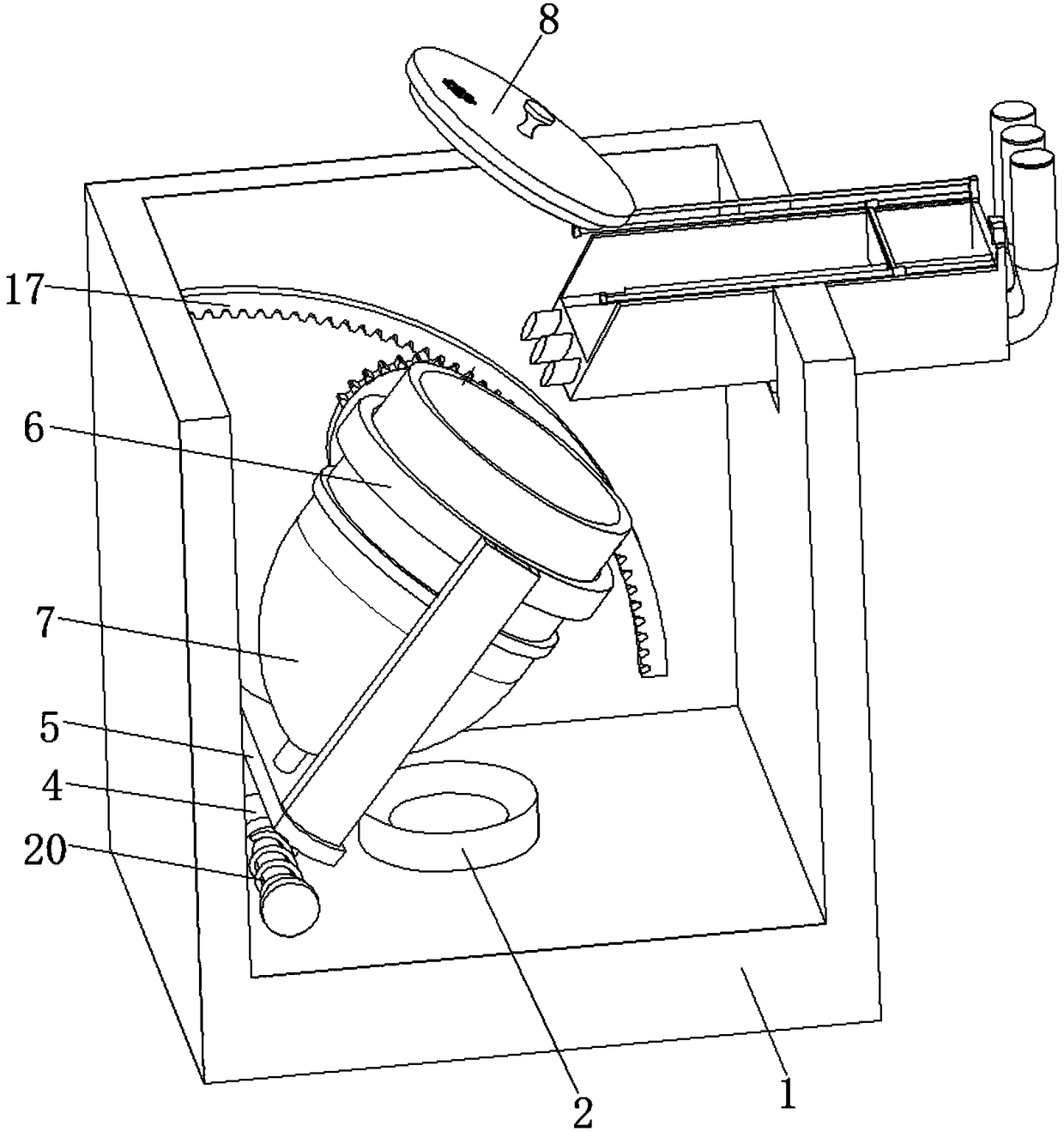

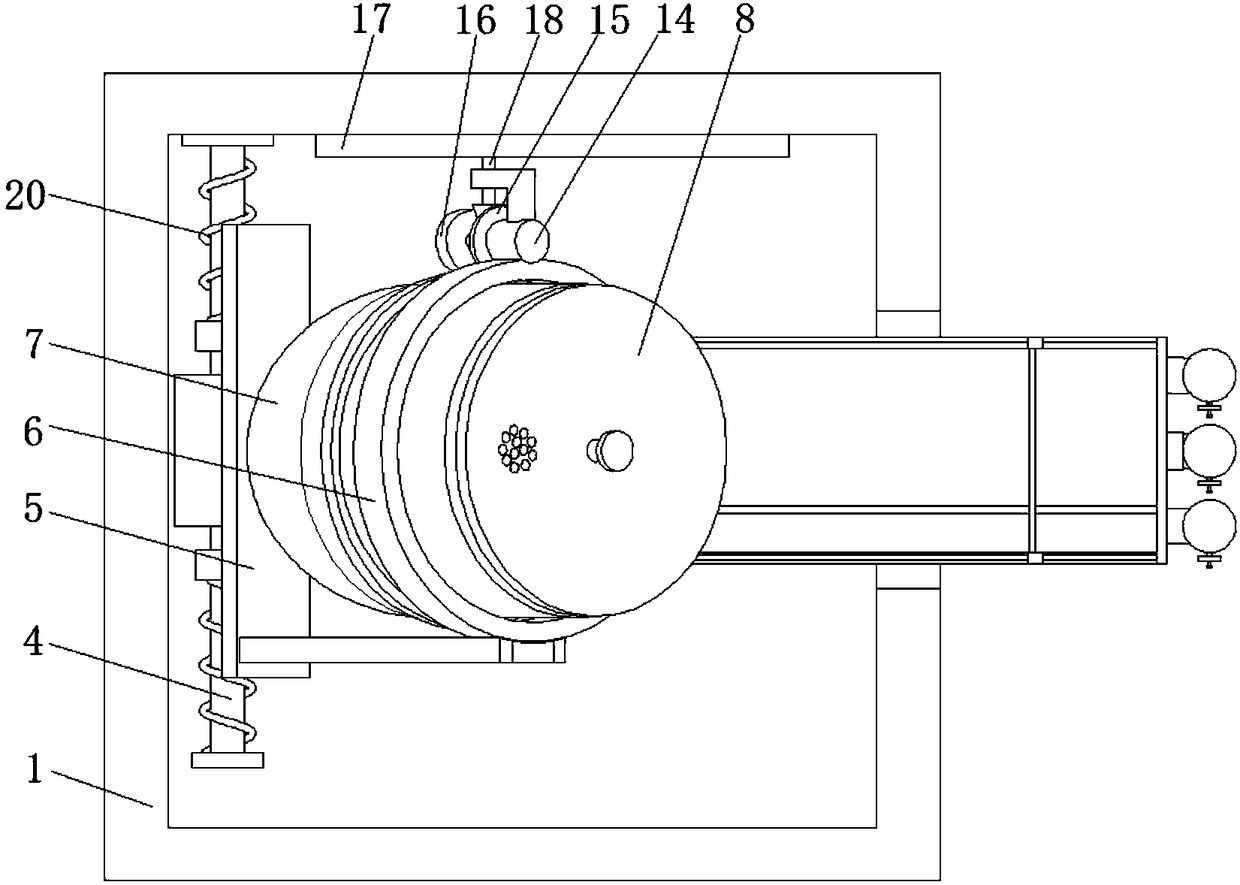

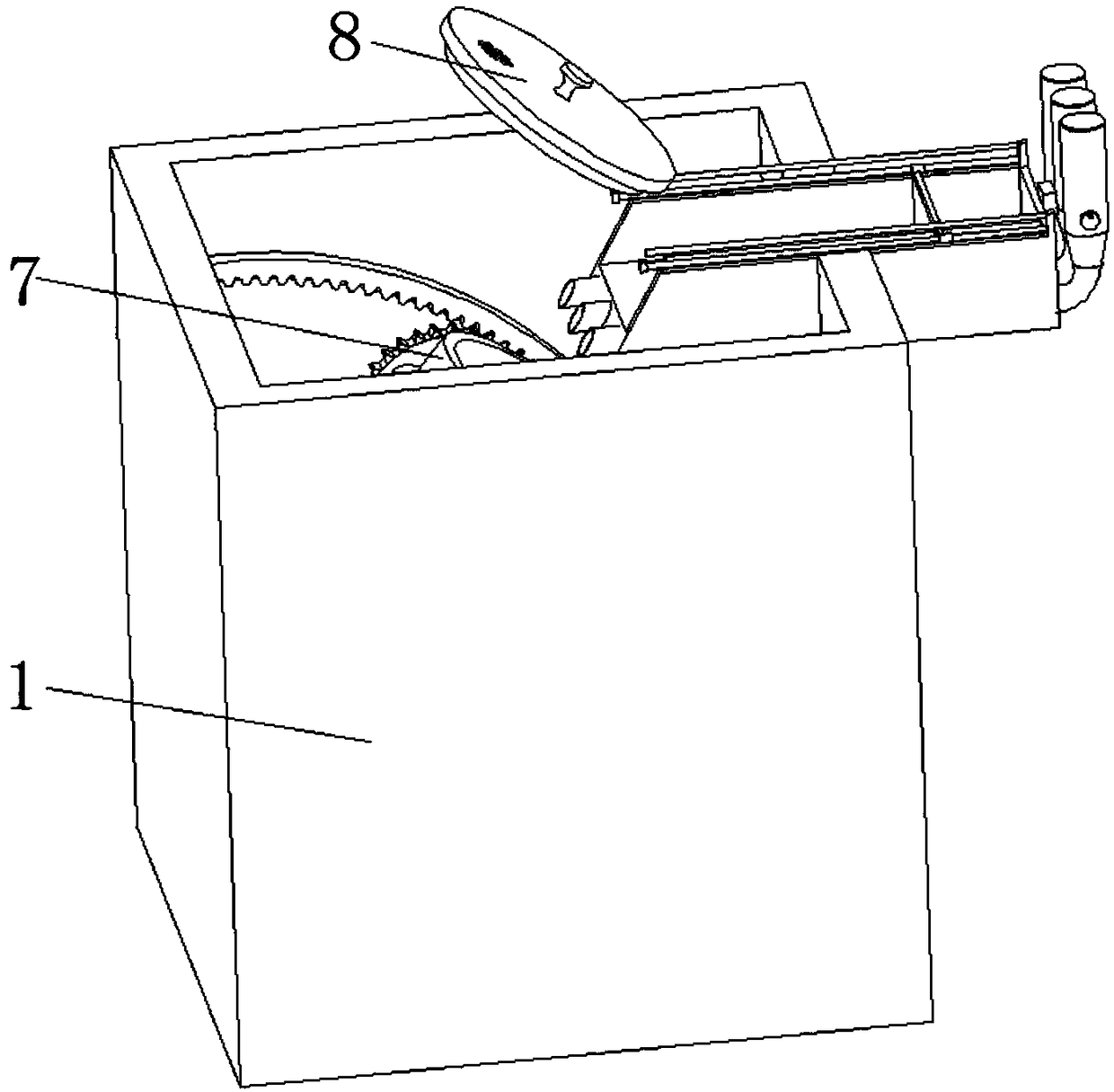

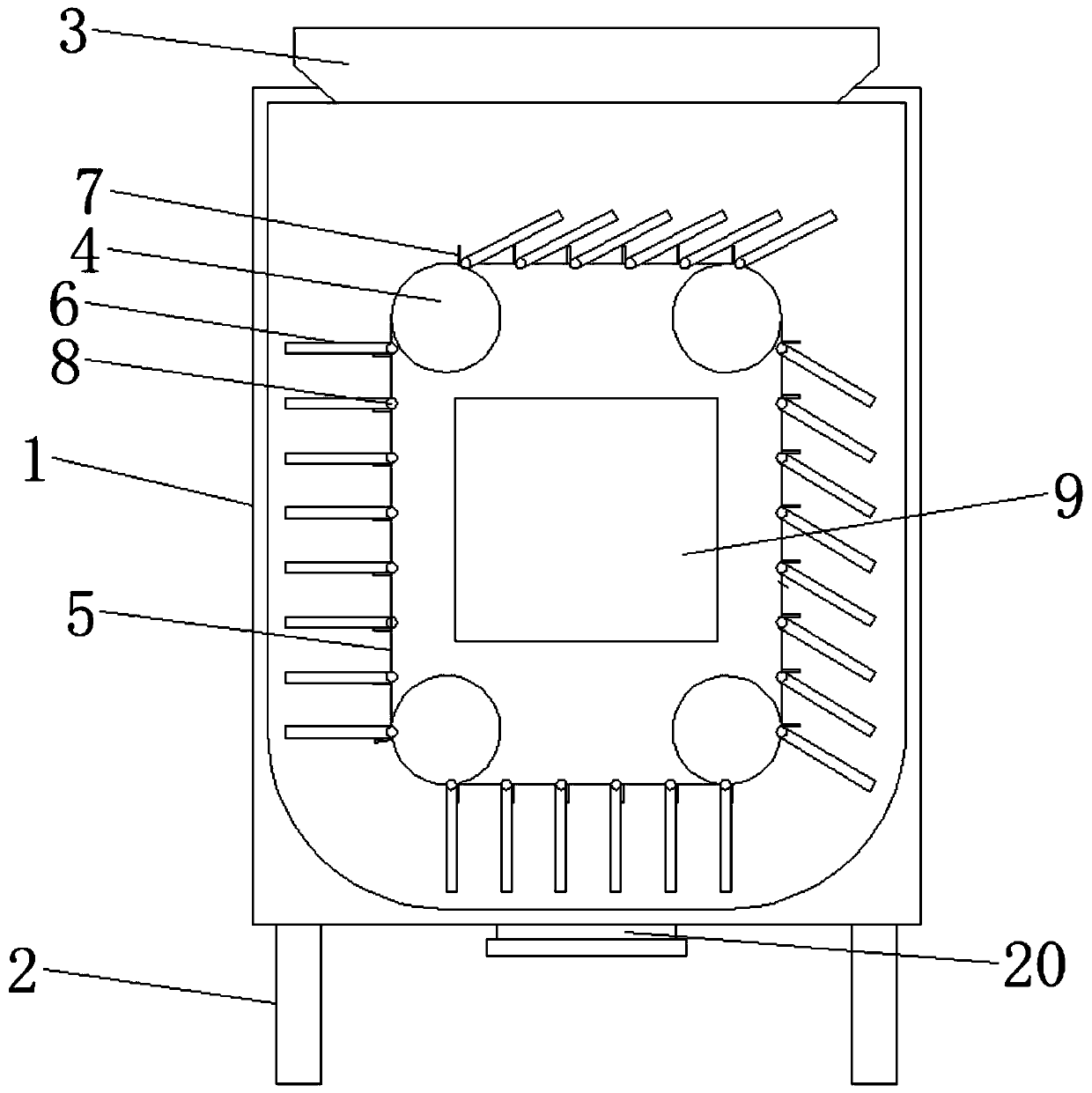

Automatic cooker having lampblack treating function

ActiveCN108523630ATake advantage ofFirmly connectedDomestic stoves or rangesLighting and heating apparatusEngineeringCooking process

The invention discloses an automatic cooker having a lampblack treating function and belongs to the technical field of cooking devices. The automatic cooker having the lampblack treating function comprises a box body, wherein the box body comprises a base plate, a back plate and side plates, the back plate and the side plates are vertically and fixedly connected to the top of the base plate, a heating chassis is arranged on the base plate, a rotary shaft is connected to the base plate through supporting blocks, the rotary shaft located between the supporting blocks is fixed sleeved with a supporting plate, the supporting plate is fixedly connected with a lantern ring through a supporting rod, the lantern ring is located at the top end of the supporting rod, the central position of the supporting plate is fixedly connected with a connecting column, the supporting plate is fixedly connected with a cooker body through the connecting column, the cooker body is located in the lantern ring,a material inlet box is connected to the top of one side plate, the end, arranged in the box body, of the material inlet box is located at the upper end of the cooker body, and the cooker body is in sealed connection with a cooker cover. The automatic cooker is convenient to operate, collects lampblack produced in the cooking process, uses the lampblack as a heat source for heating and achieves effective lampblack treatment and utilization.

Owner:浙江欧路莎贸易有限公司

Concrete processing equipment adopting annular stirring

InactiveCN110877409AShorten mixing timeWell mixedDischarging apparatusCement mixing apparatusStructural engineeringMechanical engineering

The invention relates to the field of concrete processing, and particularly discloses concrete processing equipment adopting annular stirring. The concrete processing equipment comprises a stirring tank, supporting legs, a feeding hopper and a discharging outlet; four driving rollers in the horizontal directions are arranged in the stirring tank and located on the four corners correspondingly, andthe four driving rollers are located at the bottom and the upper part of the stirring tank correspondingly and arranged in a left-right symmetrical mode; a driving band is wound around the four driving rollers and forms a rectangular ringlike structure; and a plurality of pushing plates are rotatably connected to the outer side wall of the driving band through fixedly-mounted hinges and evenly distributed on the driving band at equal distances. According to the concrete processing equipment, the rectangular driving band is arranged in the stirring tank and located at the upper part and the bottom, and the stirring range of the concrete processing equipment is expanded; and the multiple pushing plates are rotatably mounted on the outer side of the driving band, in the moving process of thedriving band, internal concrete raw materials move through the pushing plates, and thus the internal raw materials are stirred.

Owner:曹元国

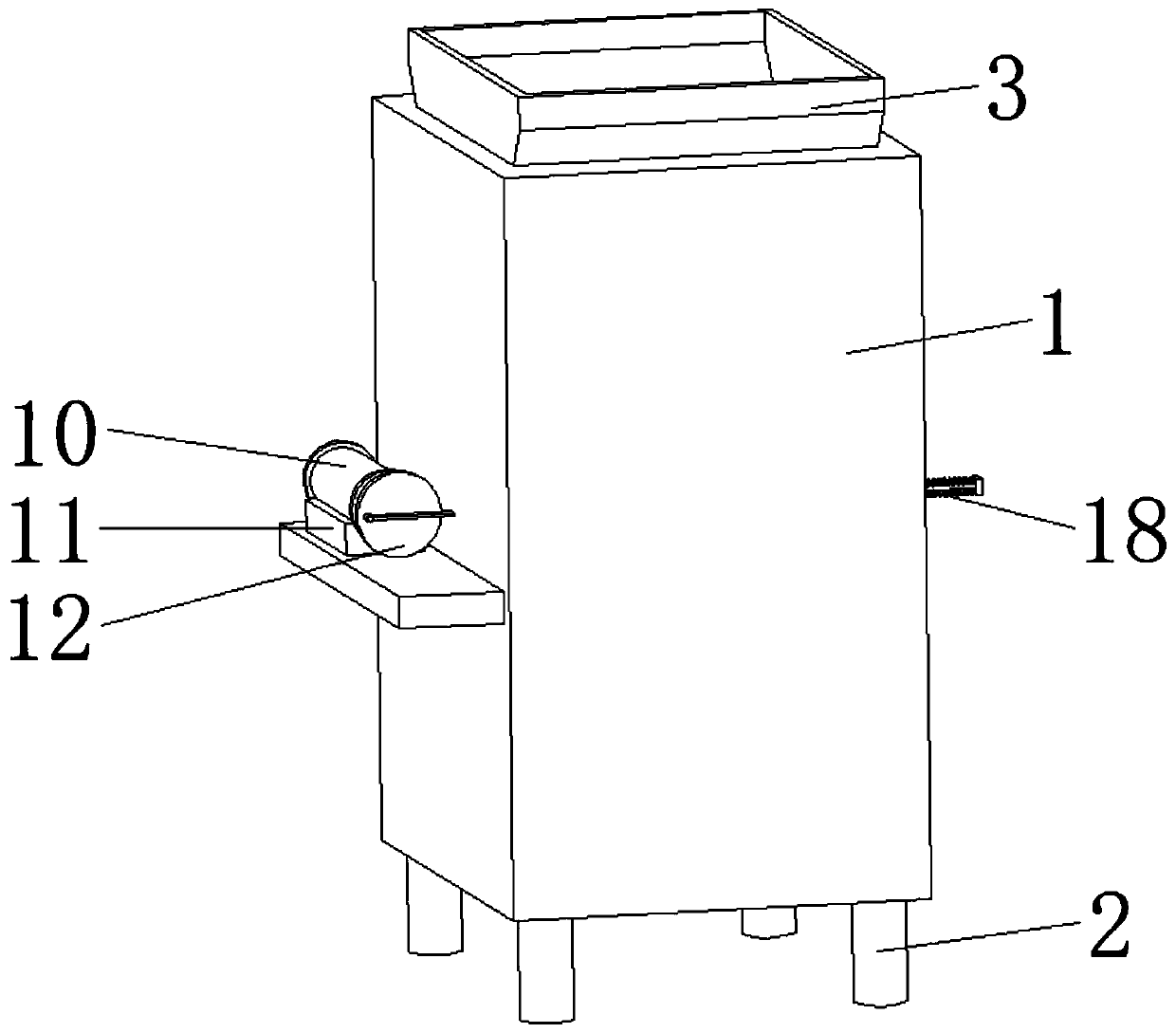

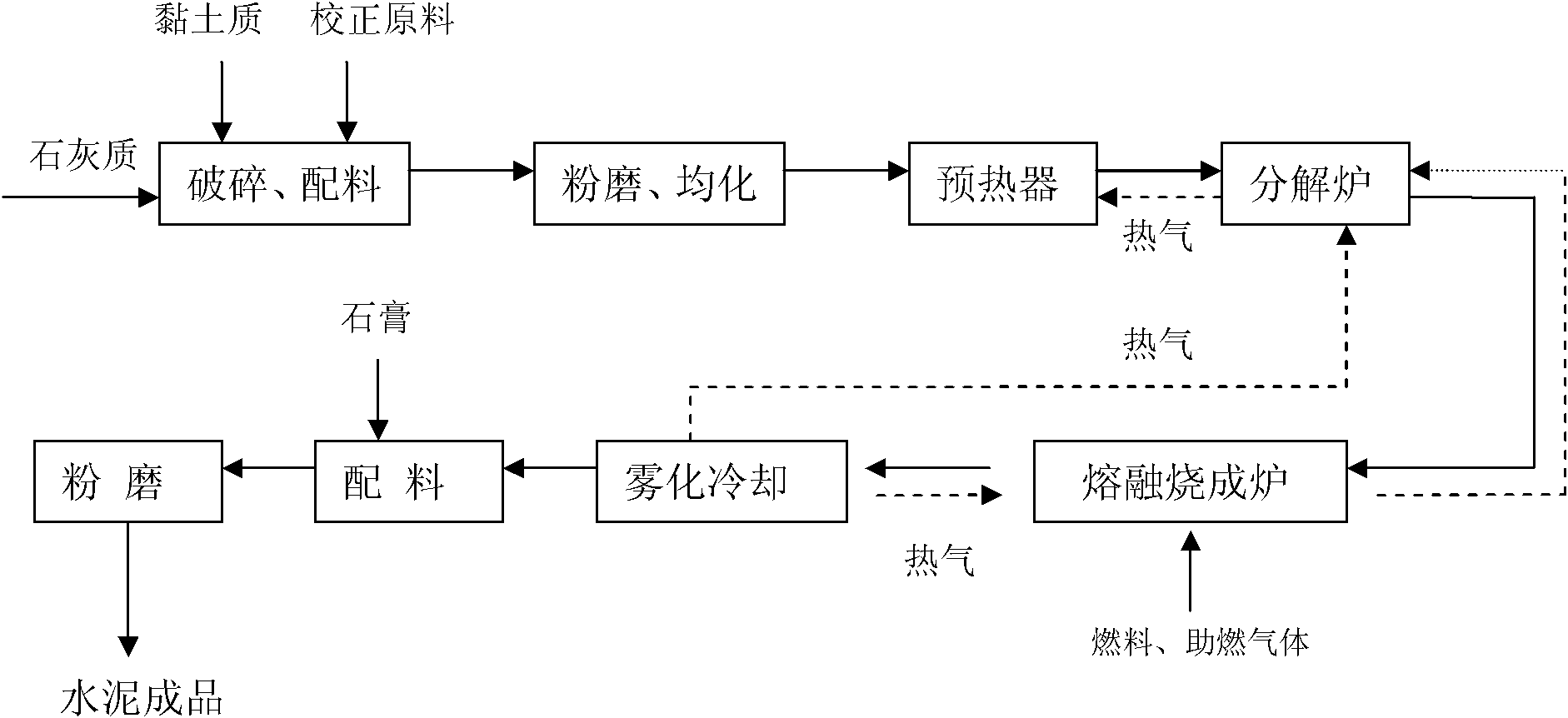

Cement production method

ActiveCN101811838BIncreased mass and heat transfer ratesIncrease production capacityClinker productionMelting tankCombustion

The invention relates to a novel cement production method and belongs to the technical field of cement production. The invention aims at solving the technical problem of reducing the energy consumption in the cement production process. The cement production method is characterized in that after being pre-heated and pre-decomposed, a cement raw meal is placed into a high-temperature molten pool at 1350DEG C to 1650DEG C to be transformed into molten mass; fuel and combustion-supporting gas are sprayed in through a spray gun which is immersed into the molten mass to provide energy; cement melting and sintering reaction is carried out; and the sintered molten clinker is cooled, proportioned and grinded continuously, thus producing the finished cement. The method adopts the full molten liquid phase reaction, the mass and heat transfer rate is greatly enhanced, the reaction time is short, and the transformation rate is high, thus enhancing the production capacity and saving a large amount of energy consumption.

Owner:GUIZHOU CHANHEN CHEM CO LTD

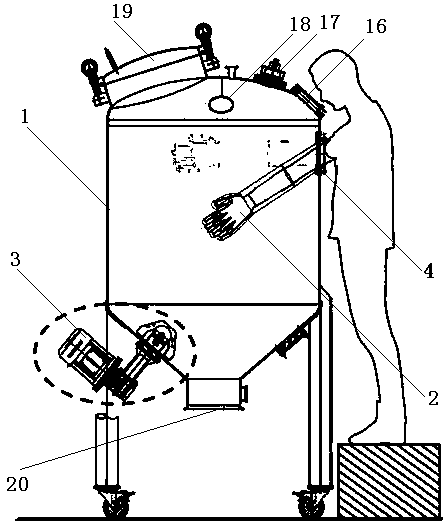

Biological reaction device for tissue culture of adventitious root of radix ginseng

InactiveCN107683766AReduce product costGuarantee product qualityHorticulture methodsPlant tissue cultureMagnetic stirrerCulture mediums

The invention relates to a biological reaction device, namely, a biological reaction device for tissue culture of the adventitious root of radix ginseng, which is particularly suitable for producing the adventitious root of radix ginseng. The biological reaction device comprises a reaction tank body, wherein one or more waterproof long-arm gloves inserted into the tank body are sealed and fixed atthe upper part of the tank body; an entrance of the long-arm glove is communicated with the outside of the tank body. A silica gel long-arm glove is mounted on the reaction tank body; since the silica gel long-arm glove has flexibility and is easy to control by manpower, an operator can move upward, downward, leftward and rightward in the tank through an arm, so as to realize stirring; then by use of a magnetic stirrer, the block of culture is dispersed cyclically and uniformly, thus, the problems such as necrosis of the culture failing to touch a culture medium are avoided, the product costis lowered, and the product quality is ensured. The long-arm glove and the magnetic stirrer are kept in sealing connection with the tank body, and pollution is avoided in a culture operation process.The mechanical structure is reasonable, and the using effect is remarkable.

Owner:TONGHUA DONGBAO PHARMA

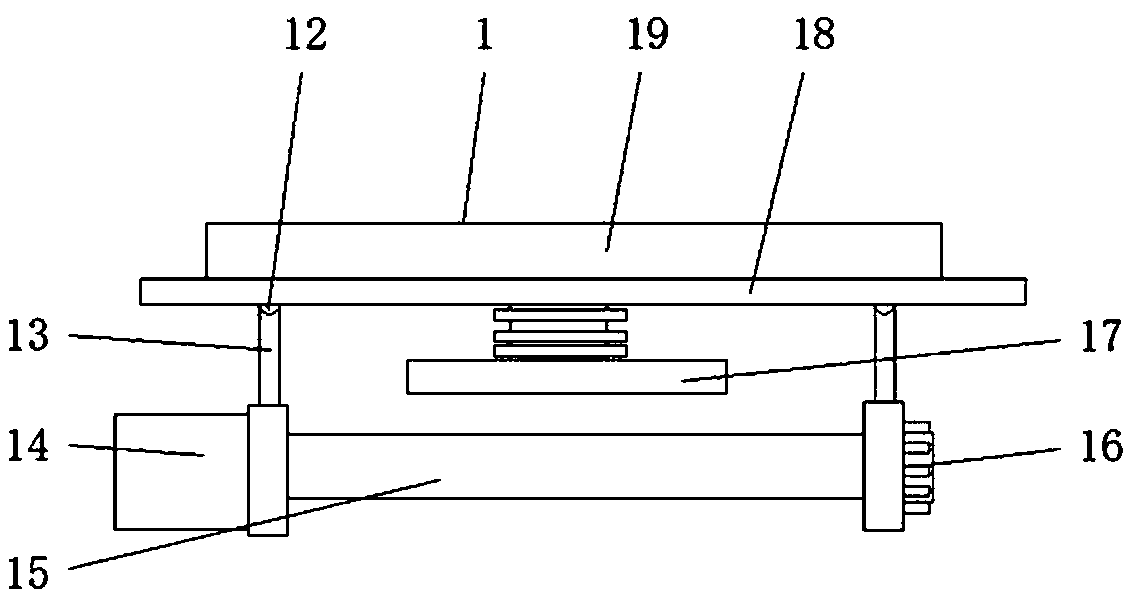

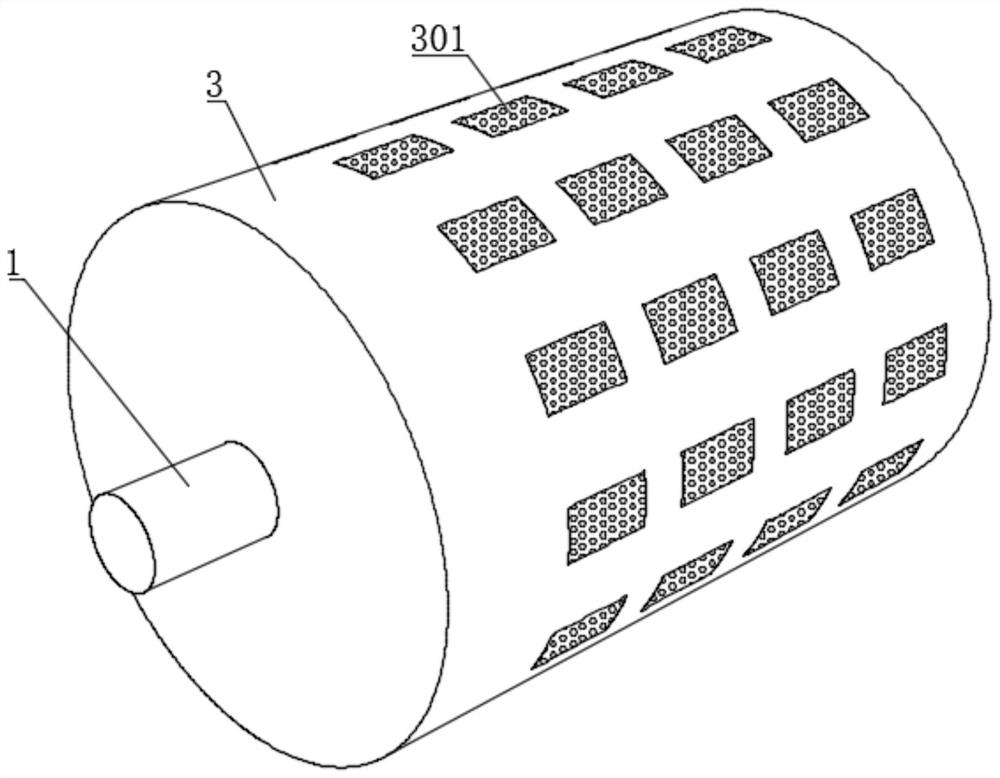

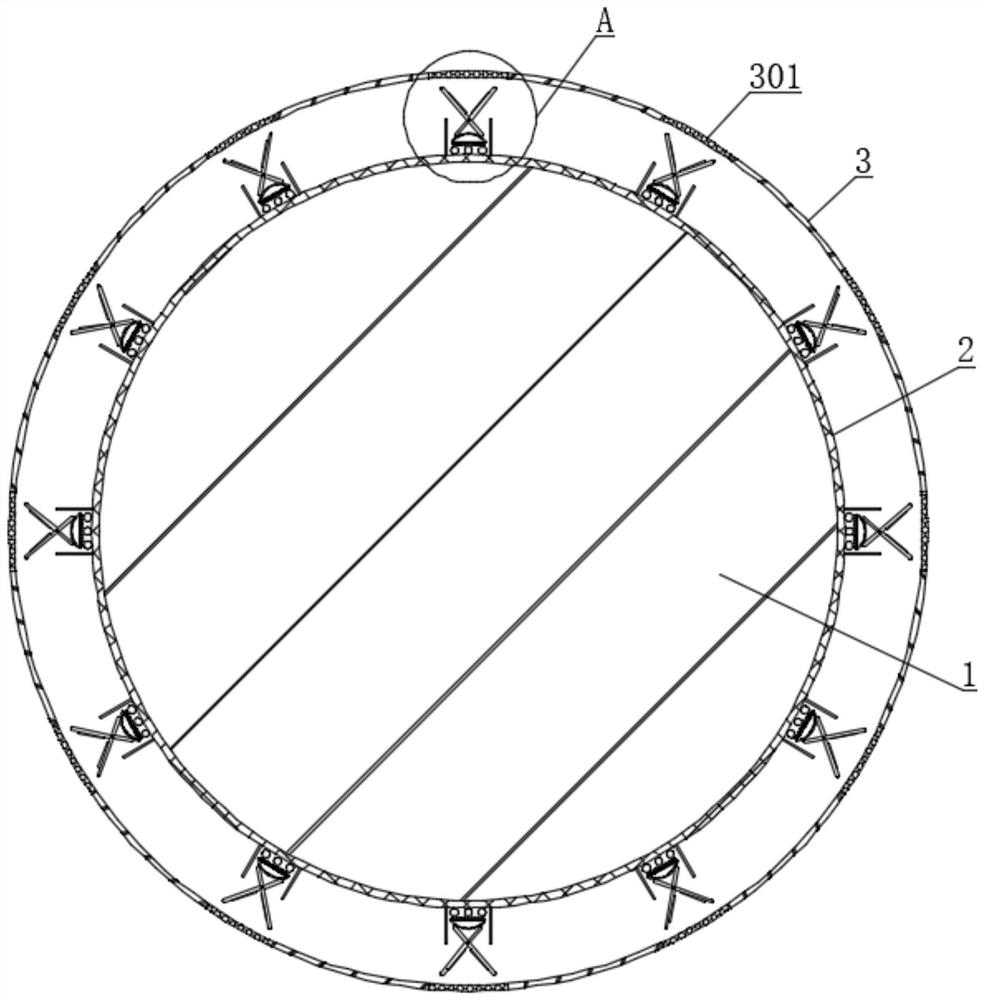

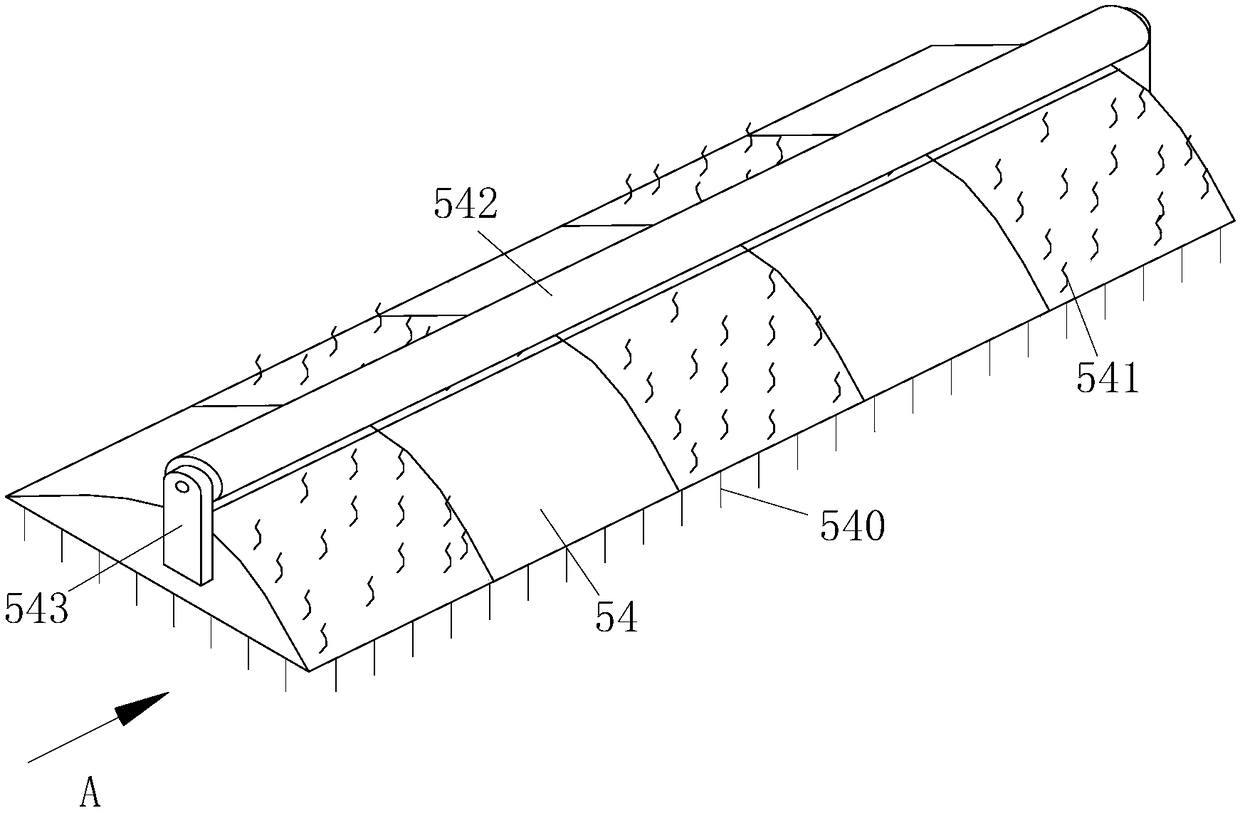

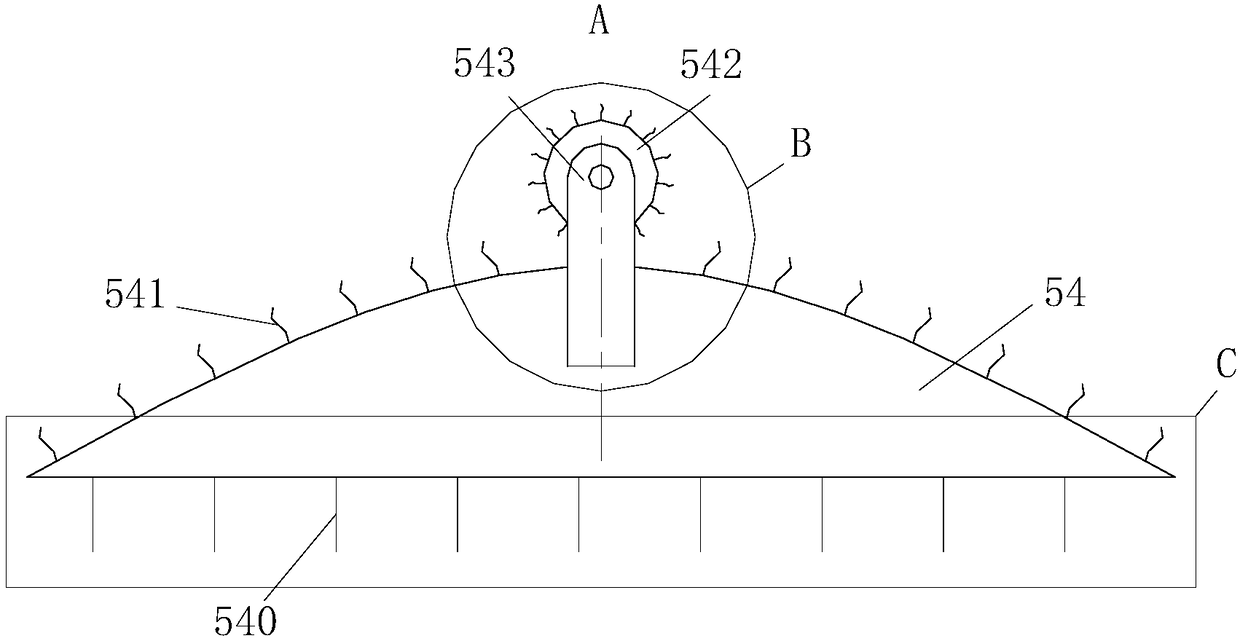

Rolling equipment for tea production and processing and rolling method of rolling equipment

PendingCN111903801AKnead to achieveRealize cycle liftingPre-extraction tea treatmentElectric machineryStructural engineering

The invention discloses rolling equipment for tea production and processing and a rolling method of the rolling equipment. The rolling equipment comprises a rack, a horizontally-arranged supporting table is installed on the rack, and a motor installed on the rack is arranged at the lower side of the supporting table; a center shaft is fixed to an output shaft of the motor through a shaft connector, the top end of the center shaft penetrates through the supporting table, and a rolling bucket is fixed to the top end of the center shaft; a first rolling cylinder is mounted at the inner bottom ofthe rolling bucket, a cover plate is clamped at the top of the rolling bucket, and mounting lugs are fixed to two sides of the cover plate; a limiting mechanism is mounted between the cover plate andthe rolling bucket, hanging rods are movably connected to the interiors of two through holes, and the bottom ends of the two hanging rods penetrate through the cover plate and are rotationally connected with a second rolling cylinder. According to the rolling equipment, the up-and-down rotary stirring and rolling of tea can be achieved, the rolling effect is good, the efficiency is high, workers can easily and rapidly open and close the cover plate, and the working efficiency is further improved; the tea can be conveniently taken out and the rolling bucket can be conveniently cleaned.

Owner:重庆市开州区珍茗农业发展有限公司

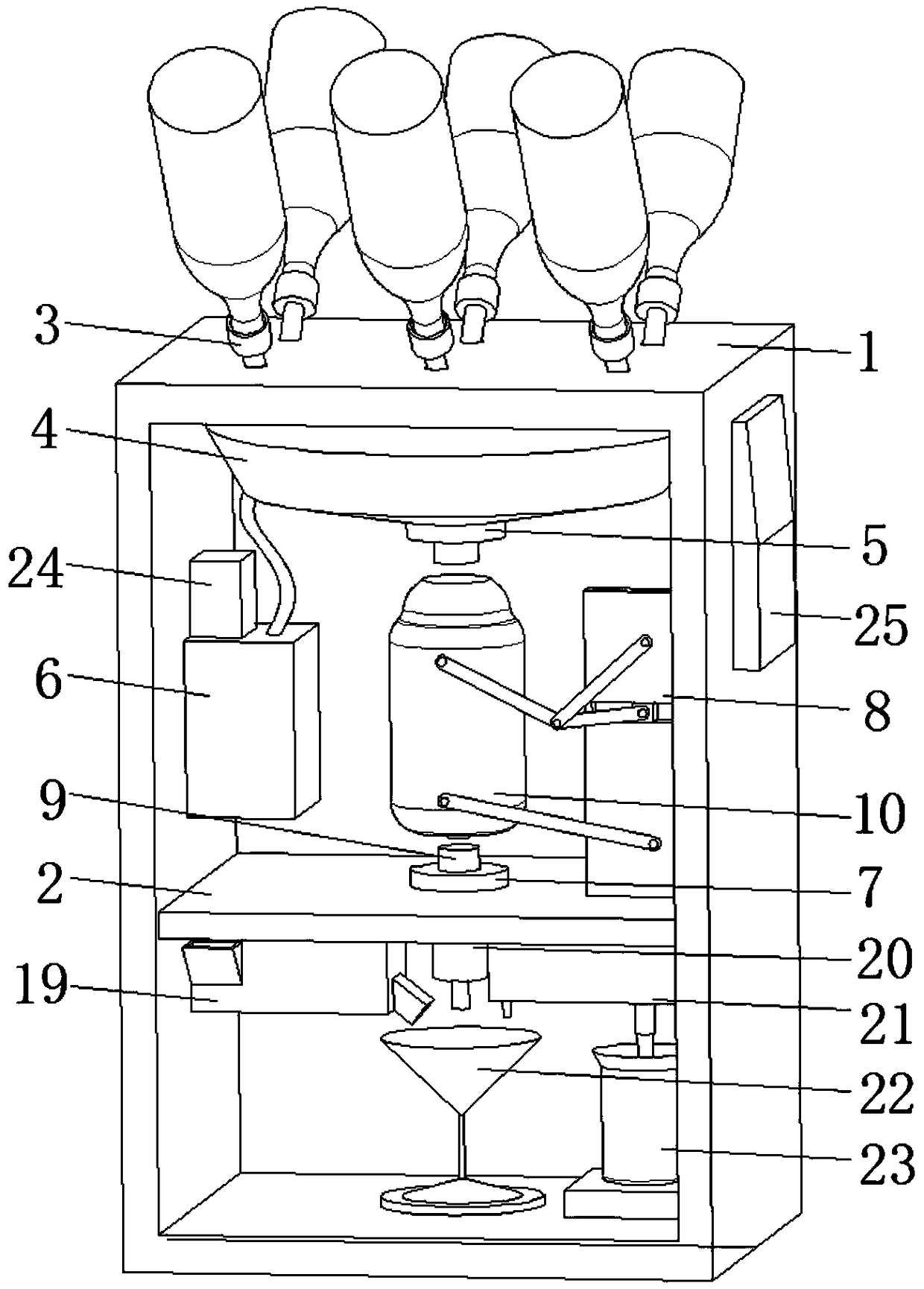

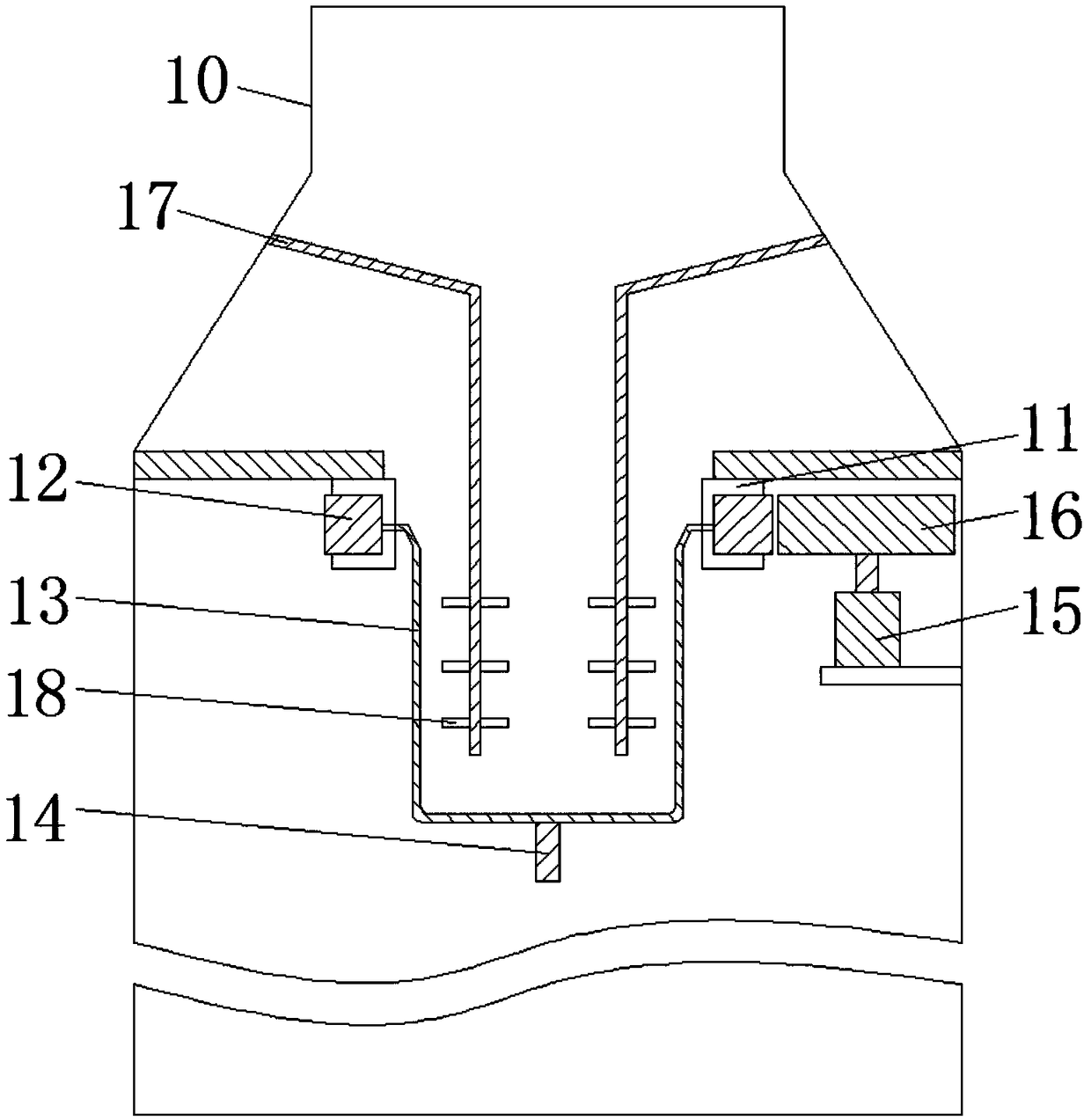

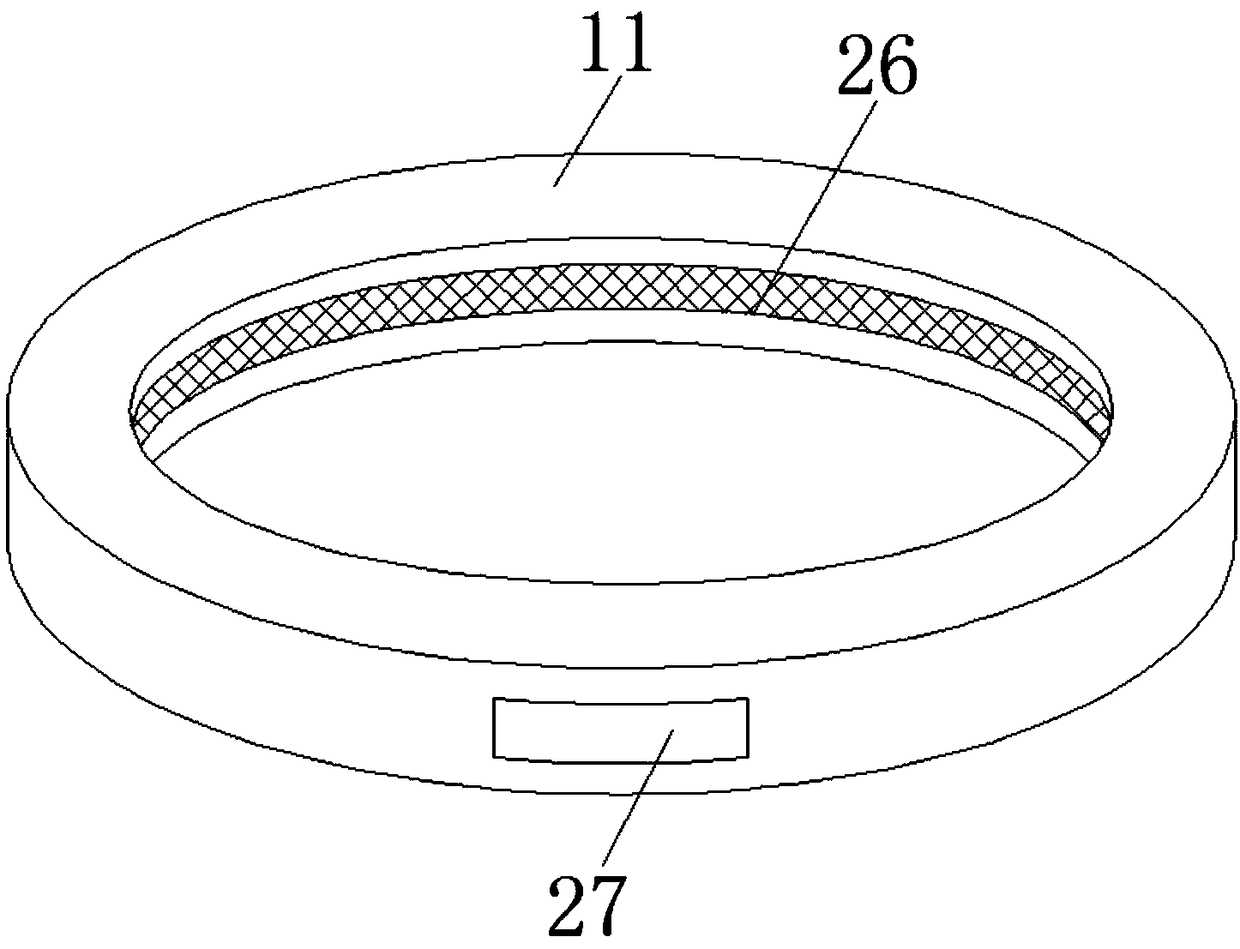

Automatic liquor mixing machine with function of mixing drinks sufficiently

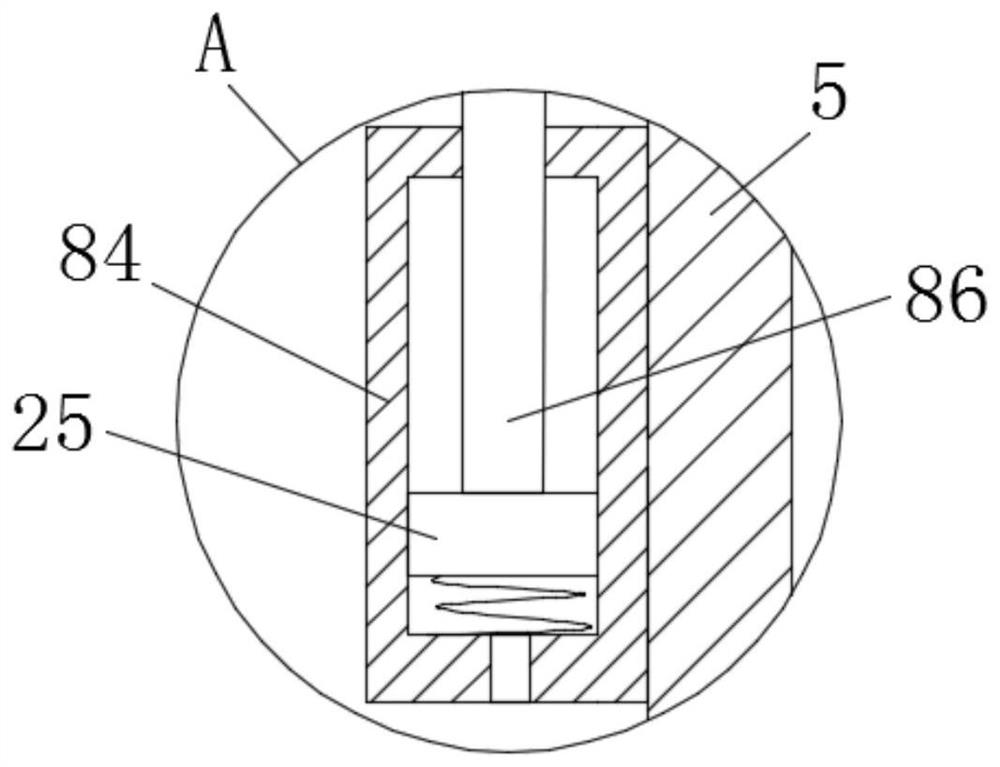

InactiveCN108753546AWell mixedAchieve shakingAlcoholic beverage preparationRefrigeration compressorGranularity

The invention discloses an automatic liquor mixing machine with a function of mixing drinks sufficiently and belongs to the technical field of automatic liquor mixing machines. The automatic liquor mixing machine with the function of mixing drinks sufficiently comprises a cabinet body, wherein a partition is fixedly connected with the inner wall of the cabinet body; six uniformly distributed bottle ports are connected with the top of the cabinet body; master control electromagnetic valves are connected onto the bottle ports; a liquor guiding groove casing is connected with the top of the cabinet body; a basic liquor filling port is connected with the bottom of the liquor guiding groove casing; the top of the partition is connected with a refrigeration compressor, a base and a liquor jug shaking mechanism; the output end of the refrigeration compressor is connected with the liquor guiding groove casing through a guide tube; a basic liquor suction port is connected onto the base; the liquor jug shaking mechanism is connected with a liquor jug through a connecting rod; the inner wall of the liquor jug is connected with an annular sleeve through a support rod, and a gear ring is rotationally connected into the annular sleeve. The automatic liquor mixing machine is simple in structure and convenient to operate, sufficiently mix different kinds of drinks during mixing of cocktail, and is suitable for mixing the drinks with different densities and different granularities.

Owner:佛山市墨宸智能科技有限公司

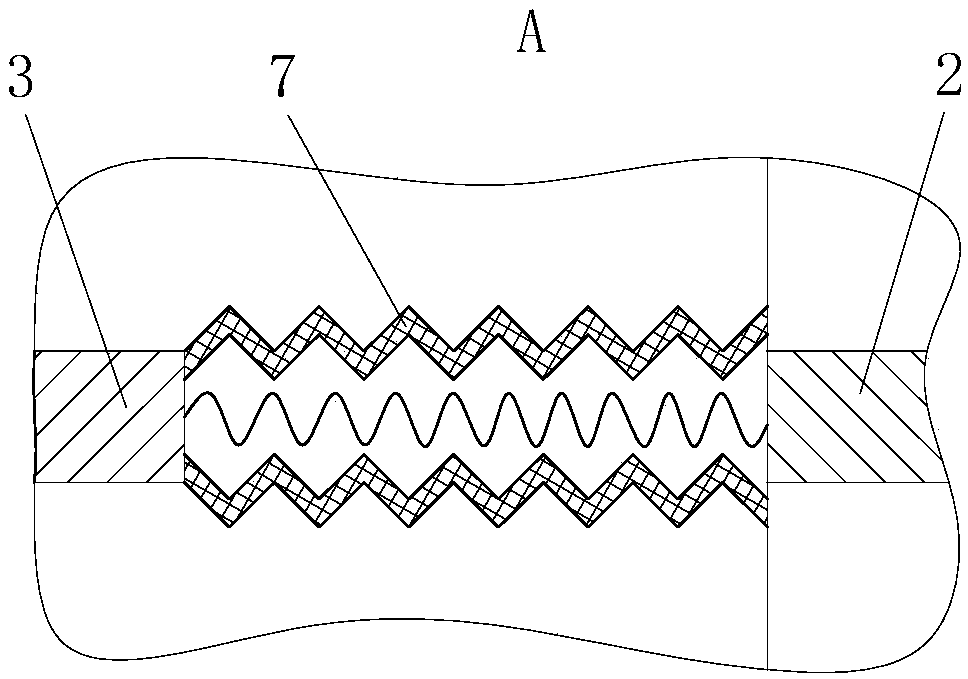

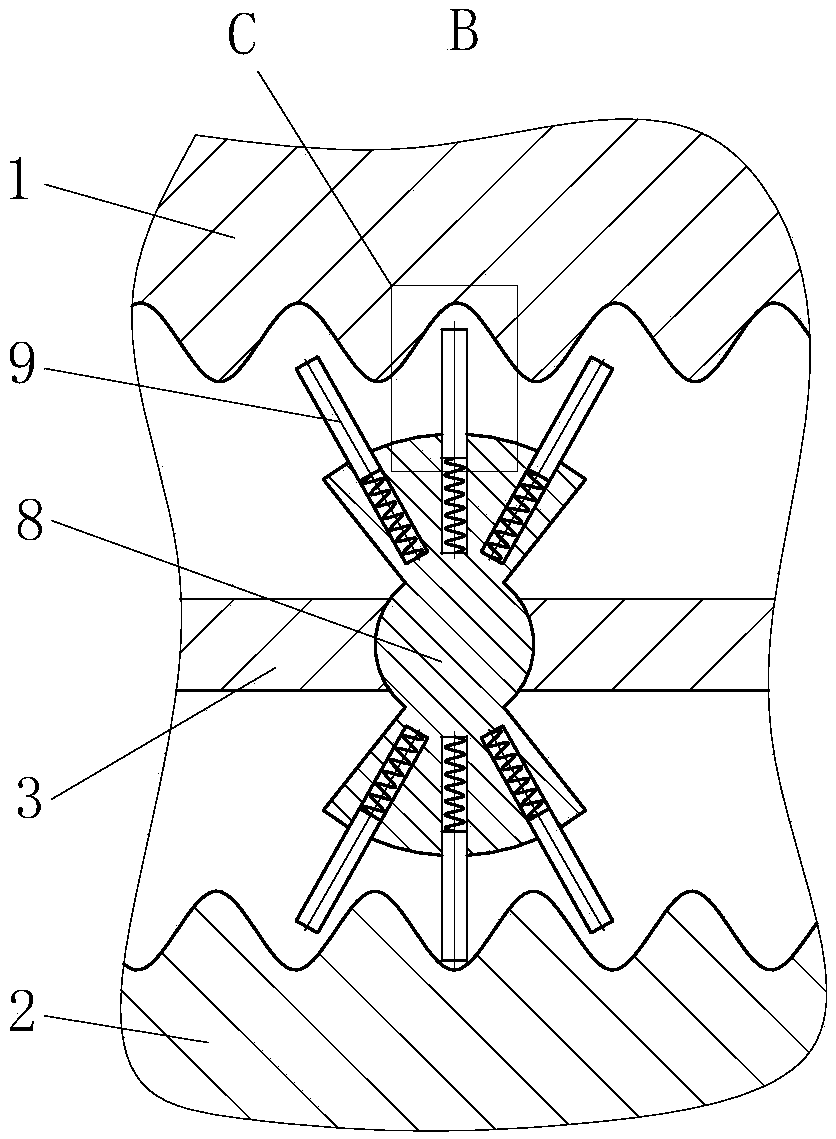

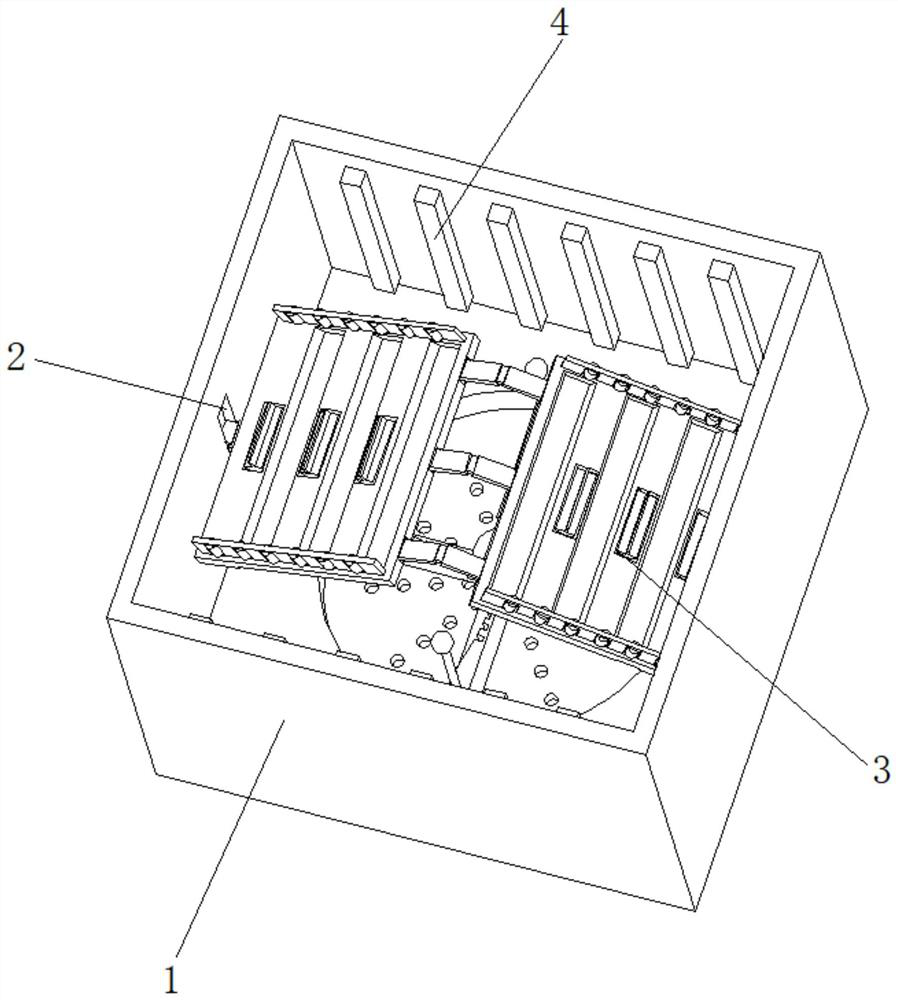

Heat exchanger for industrial production

PendingCN108981439AAchieve agitationImprove heat exchange efficiencyIndirect heat exchangersHeat transfer modificationMotor drivePlate heat exchanger

The invention belongs to the technical field of heat exchangers and particularly relates to a heat exchanger for industrial production. The heat exchanger comprises a left shell, a right shell, a first heat exchange baffle, a second heat exchange baffle, heat exchange oscillating plates, a drive cam, corrugated sleeves and springs; the right shell and the left shell are mounted together in a staggered manner; the step surface of the right shell is fixedly connected to one ends of the corrugated sleeves; the other ends of the corrugated sleeves are fixedly connected to the right end of the first heat exchange baffle; the other end of the first heat exchange baffle is hinged with one ends of the heat exchange oscillating plates; the other ends of the heat exchange oscillating plates are hinged with the second heat exchange baffle; the heat exchange oscillating plates in a rectangular groove of the right shell are connected with the heat exchange oscillating plates in the left shell through the second heat exchange baffle. The heat exchange oscillating plates are driven to oscillate through the motor drive cam, the second heat exchange baffle and the first heat exchange baffle are further driven to move, liquid in two closed cavities is agitated, and heat exchange efficiency is improved.

Owner:李洁

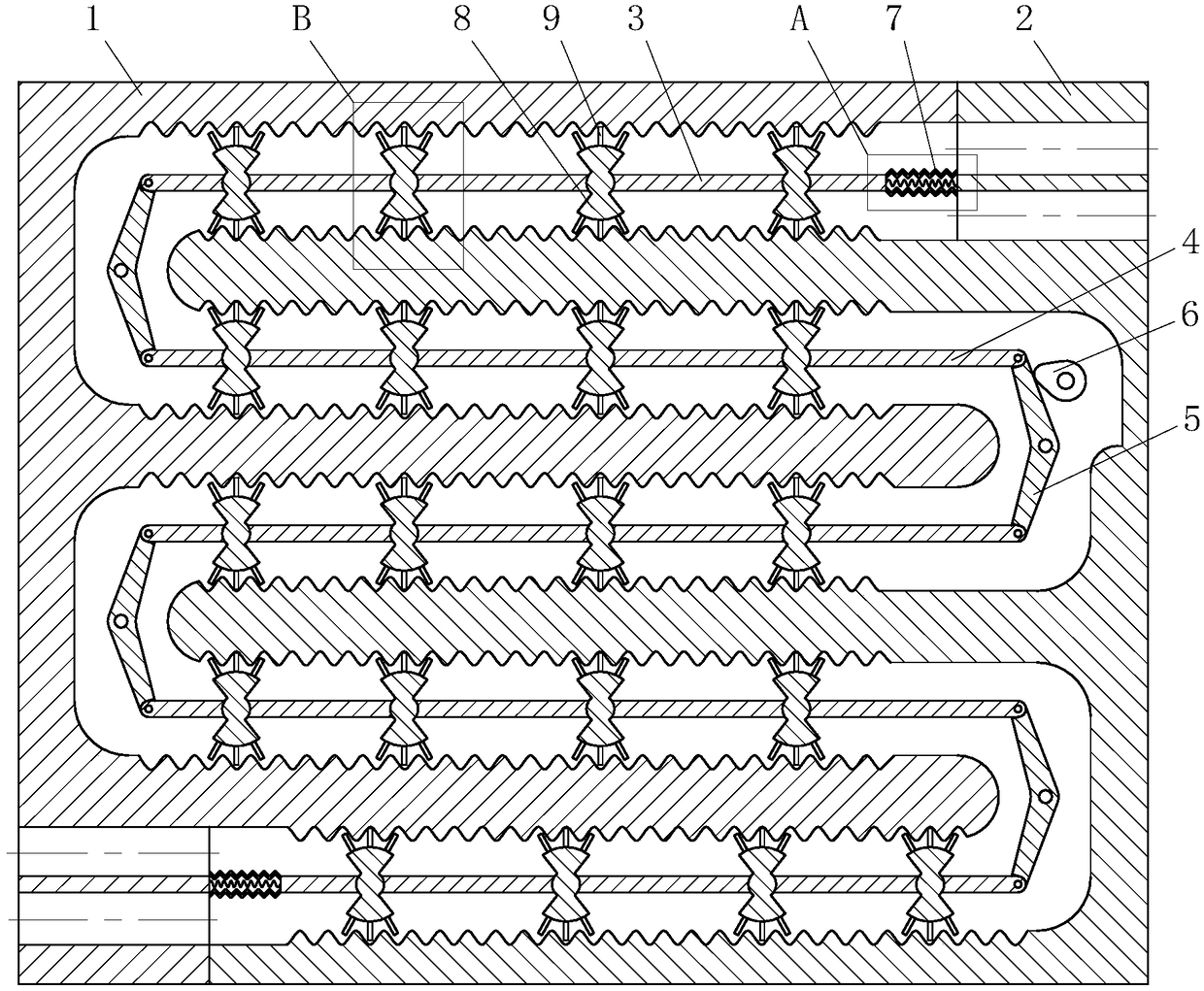

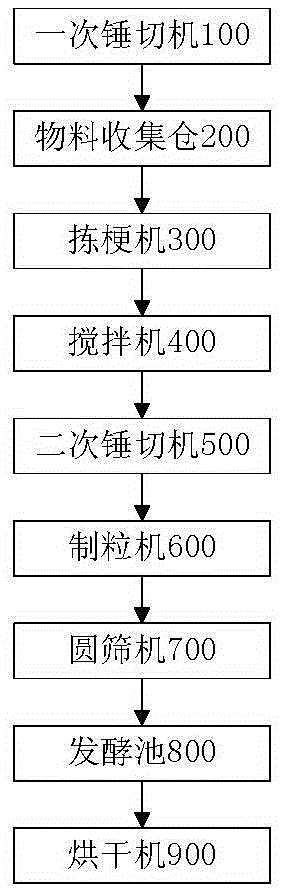

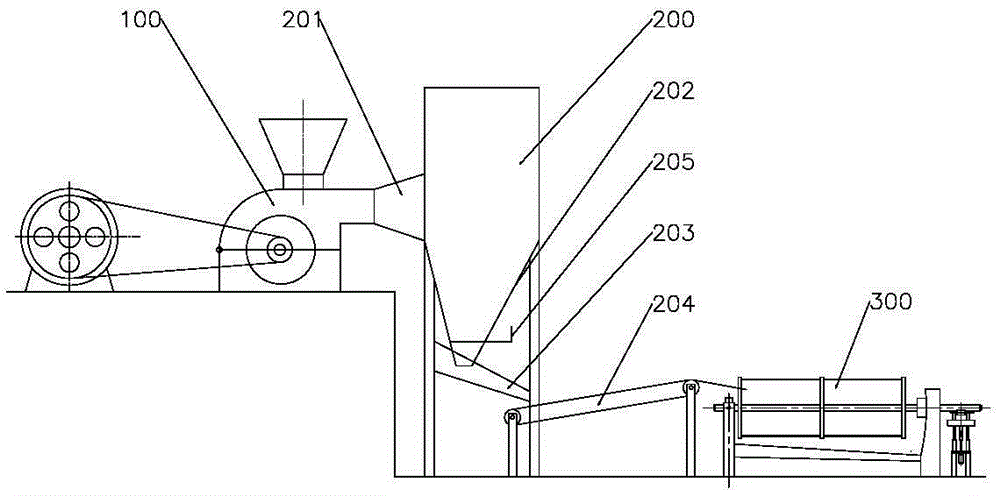

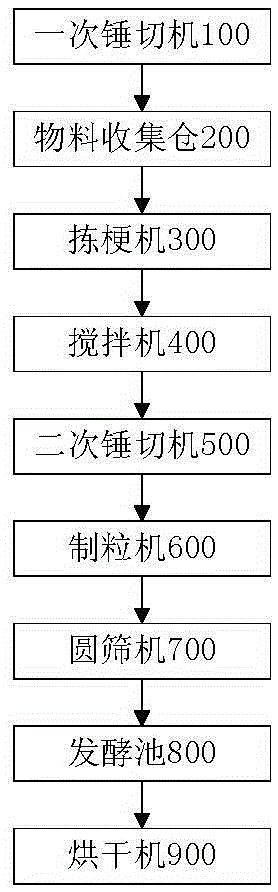

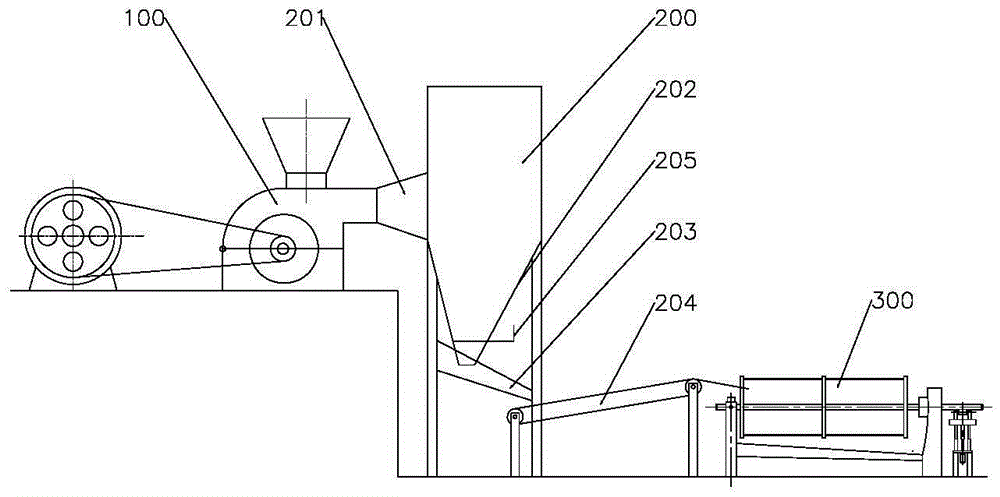

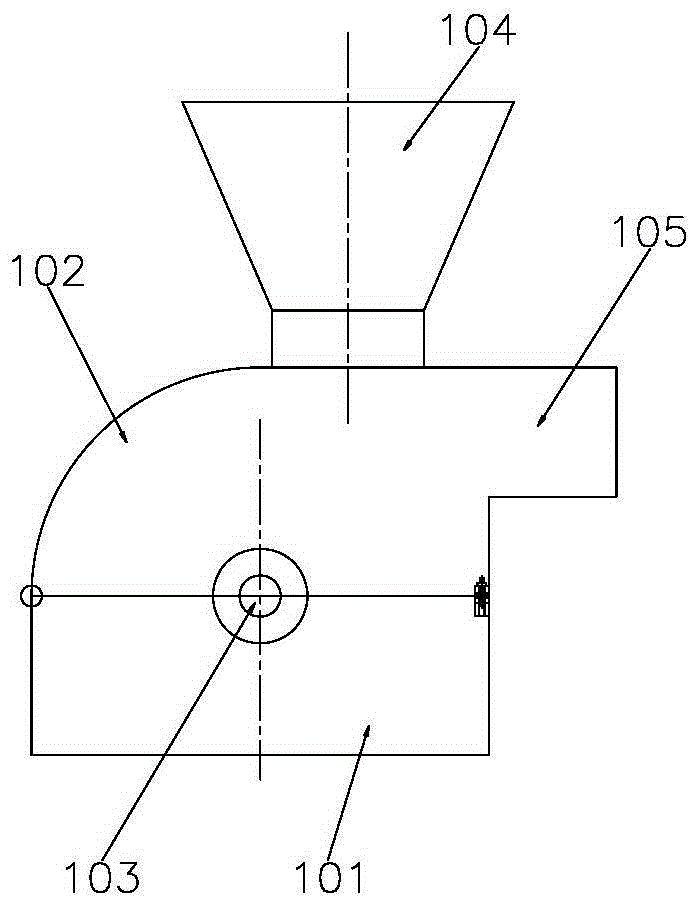

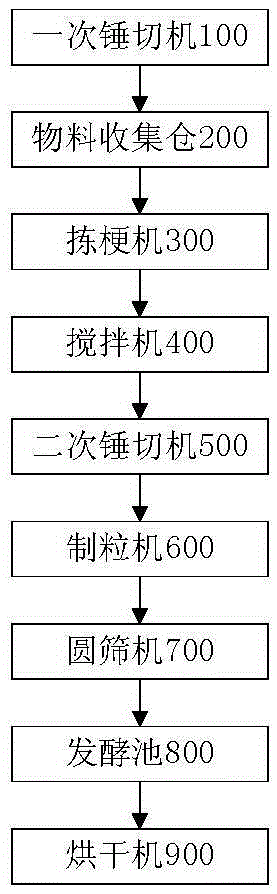

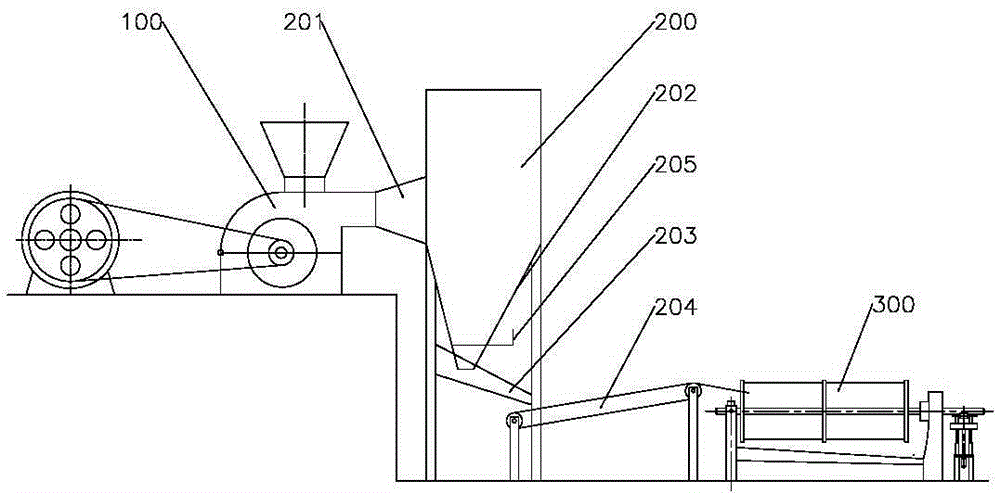

Convenient-to-maintain energy-saving broken black tea production line

InactiveCN106615242AEasy maintenanceAvoid polluting the environmentPre-extraction tea treatmentExhaust gasEngineering

The invention discloses a convenient-to-maintain energy-saving broken black tea production line. The conveniently-maintained energy-saving broken black tea production line comprises a primary hammer cutting machine, a stem picking machine, a stirring machine, a secondary hammer cutting machine, a granulating machine, a circular sieve machine, a fermenting tank and a drying machine which are sequentially arranged, wherein a material collecting bin is arranged between the primary hammer cutting machine and the stem picking machine. One end of an upper casing of the primary hammer cutting machine is hinged to a lower casing, and a quick dismounting and quick mounting mechanism is arranged between the upper casing and the lower casing, so that during cleaning and maintenance, the upper casing can be opened for cleaning and maintaining a material hammer cutting cavity, and maintenance is convenient; automatic transfer of a material between the primary hammer cutting machine and the stem picking machine can be achieved, and the stem picking machine has higher sieving efficiency and more thorough sieving effect; through arrangement of rollers and feed rollers in the box body of the drying machine, the material moves along with a material conveying belt and is continuously dried, so that the drying effect is more uniform and the drying efficiency can be effectively improved; furthermore, through arrangement of a suction passage on the top surface of the box body, the heat of exhaust gas can be effectively recycled, so that fuel is saved.

Owner:CHONGQING RONGFA TEA IMP & EXP CO LTD

Double-rocking-fan heat dissipation type motor based on self-vibration phenomenon

ActiveCN112134406AComprehensive and uniform heat dissipationSpeed up the flowCooling/ventillation arrangementSupports/enclosures/casingsEngineeringMechanics

Owner:淮北中易光电科技有限公司

Electroplating device

The invention discloses an electroplating device and relates to the technical field of electroplating. The electroplating device comprises an electroplating generation tank; adjusting sliding groovesare formed in the left side and the right side of the interior of the electroplating generation tank; electrode carrying mechanisms are slidably connected to the vertical positions of the interiors ofthe adjusting sliding grooves; electrode rods are evenly and fixedly connected to the front faces and the back faces of the interiors of the adjusting sliding grooves; a guide inner tank is fixedly connected to the middle position of the bottom end in the electroplating generation tank; a limiting baffle is fixedly connected to the position, close to the upper portion, in the guide inner tank; amotor driving shaft is rotationally connected to the middle position in the guide inner tank; stirring carrying plates are evenly and fixedly connected to the outer surface of the motor driving shaft;vortex generating mechanisms are fixedly connected to the surfaces of the tops of the stirring carrying plates; and filtering holes are evenly formed in the surfaces of the limiting baffle. Accordingto the electroplating device, the phenomenon of uneven electroplating of a rod piece due to traditional clamping is avoided, and meanwhile it is guaranteed that an electroplated piece is kept in a powered-on state when rolling in the device.

Owner:周孟林

Broken black tea production line

InactiveCN106615243AFulfilling Hammer Cutting RequirementsImplement automatic transferPre-extraction tea treatmentBlack teaMaterial transfer

The invention relates to a broken black tea production line. The broken black tea production line comprises a primary hammering and cutting machine, a stalk-sorting machine, a stirrer, a secondary hammering and cutting machine, a pelletizer, a round sifter, a fermenting tank and a drying machine which are sequentially arranged, wherein a material collecting bin is arranged between the primary hammering and cutting machine and the stalk-sorting machine, so that automatic material transfer between the primary hammering and cutting machine and the stalk-sorting machine can be realized, and the screening efficiency of the stalk-sorting machine is better, and more thorough; rotating rollers and feed rotating rollers are arranged in a box body of the drying machine, multilayer horizontal material conveyer segments are formed by a material conveyer belt arranged on the rotating rollers and the feeding rotating rollers in a sleeving manner, and a discharge notch is formed in a support track; in the movement process of the material conveyer belt, a material bearing plate at the discharge notch turns over under the action of gravity, and materials on the material bearing plate automatically fall into a horizontal material conveyer segment on a lower layer, so that automatic material transfer between every two layers of horizontal material conveyer segments is realized, and the materials are continuously dried along with the movement of the material conveyer belt; and therefore, not only is the drying efficiency more uniform, but also the continuous drying form can enable the drying efficiency to be effectively improved.

Owner:CHONGQING RONGFA TEA IMP & EXP CO LTD

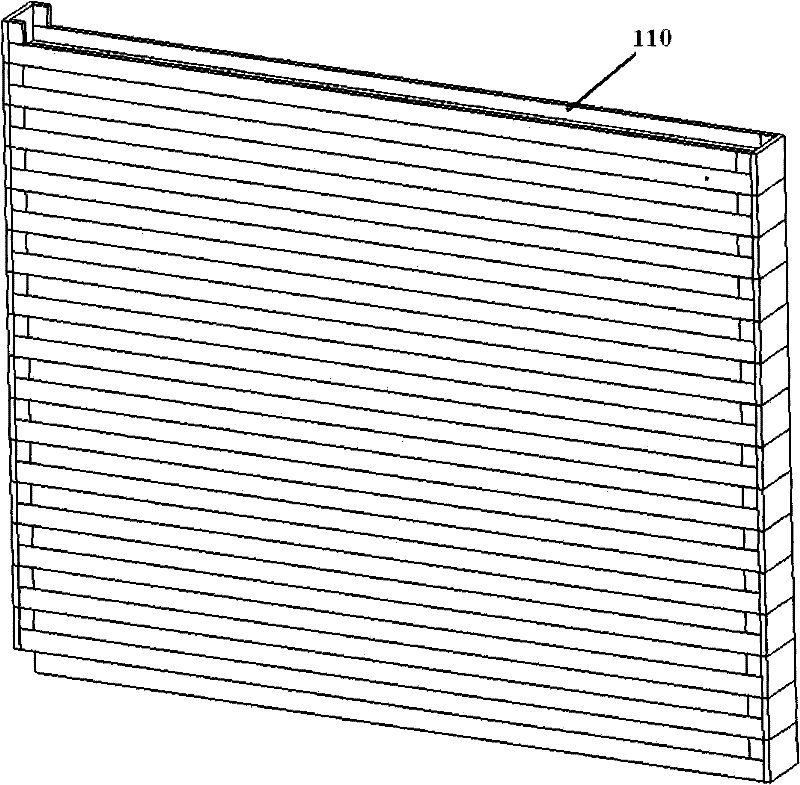

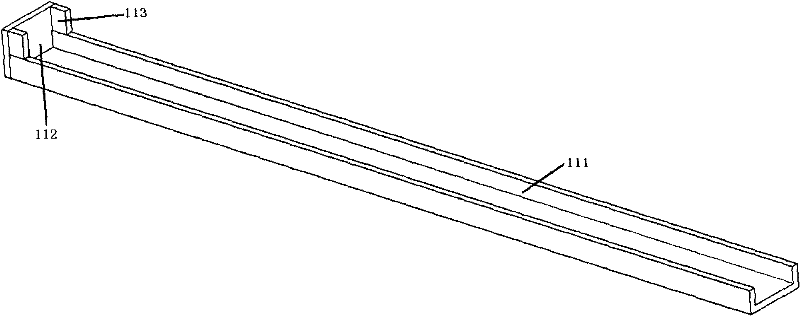

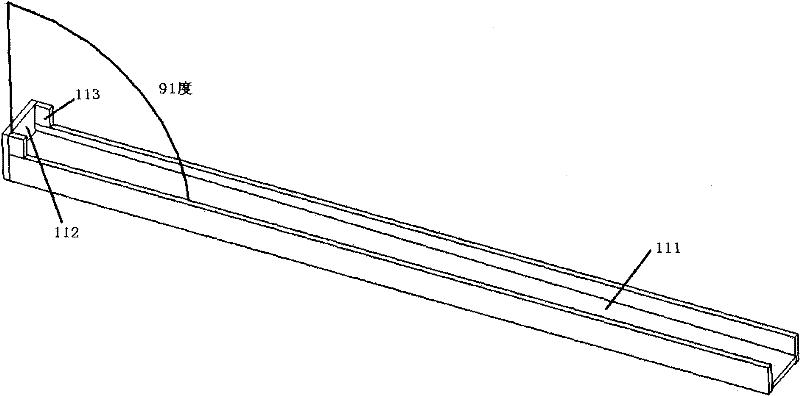

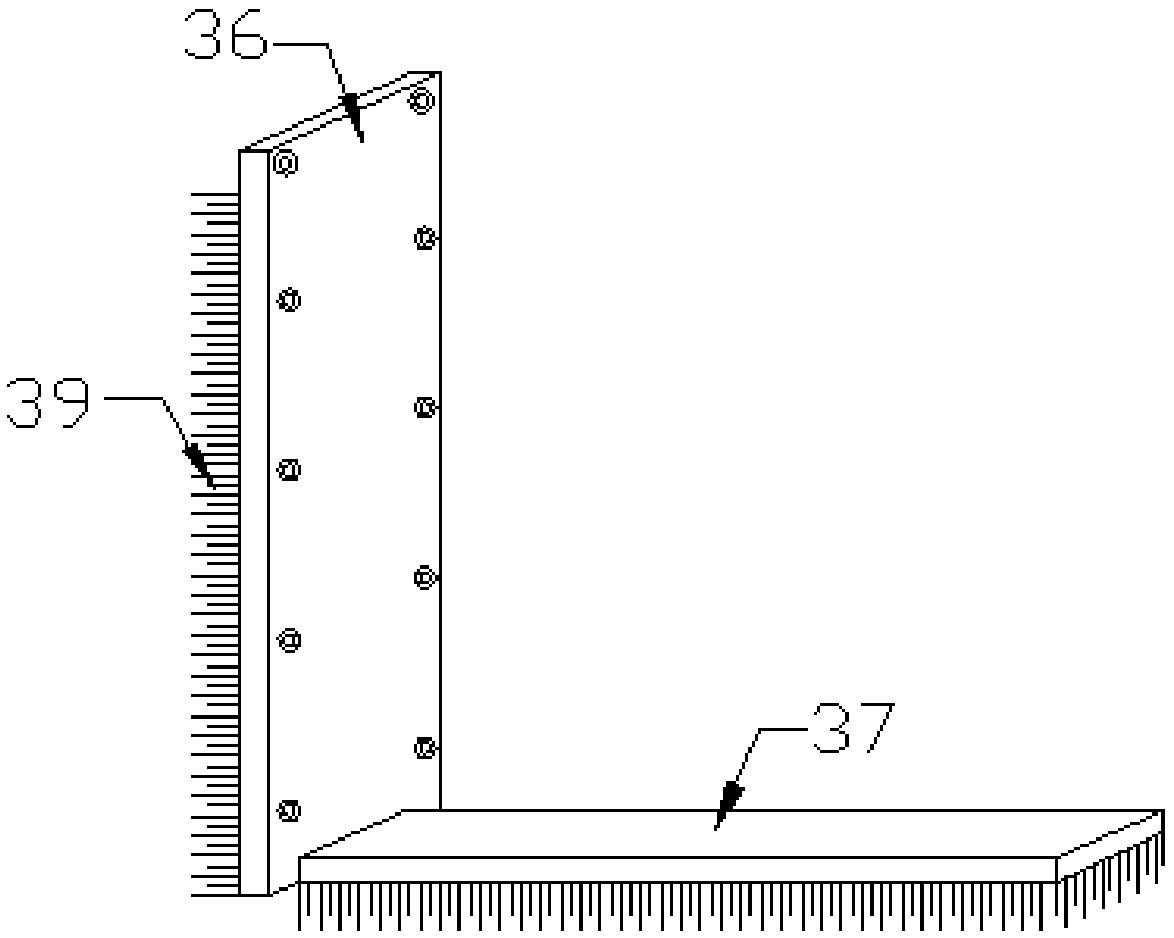

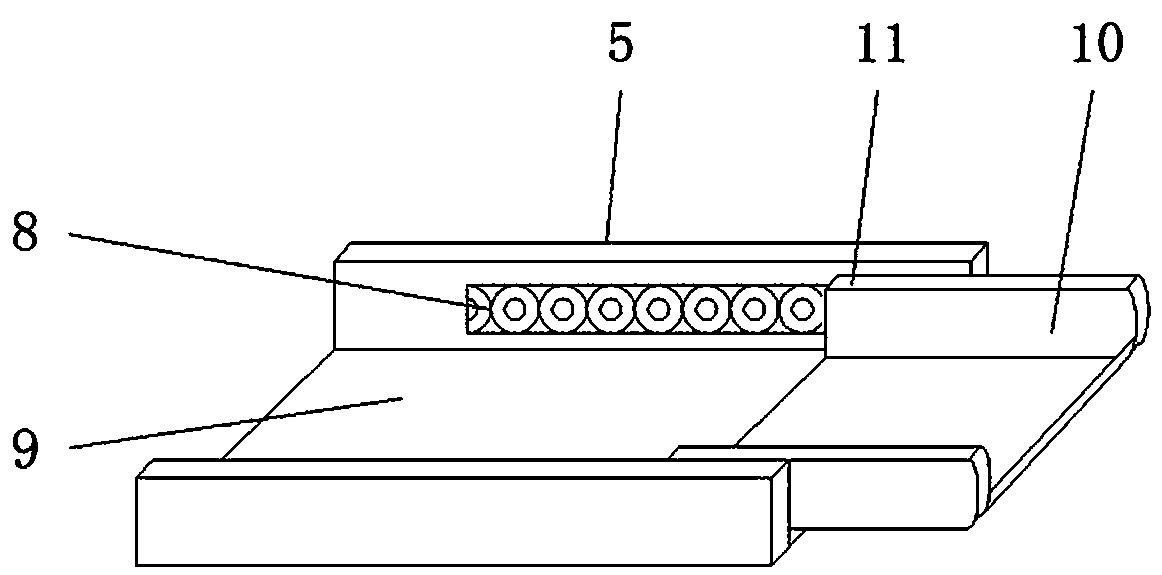

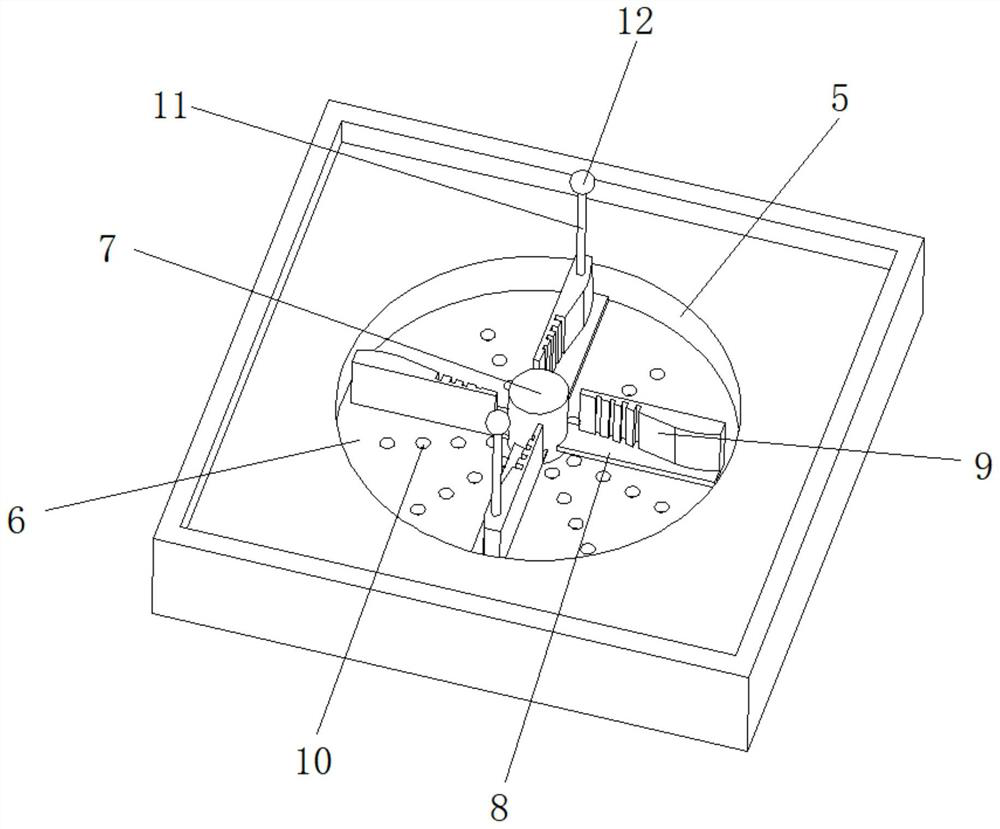

Solar cell panel module tester

ActiveCN108540094AImprove accuracyGuaranteed accuracyPhotovoltaic monitoringPhotovoltaic energy generationEngineeringSolar cell

The invention belongs to the technical field of solar cell production and particularly relates to a solar cell panel module tester. The tester comprises a tilt test board, a sand scattering device anda recovery box, wherein the tilt test board comprises a test support, a lower roller, an upper roller, a motor, a belt and an assembly frame, and the belt is arranged on the outer cylindrical surfaceof the lower roller and the outer cylindrical surface of the upper roller; an elongated partition board is arranged on the outer surface of the belt; the assembly frame is arranged on the upper surface of the test support; the sand scattering device is arranged above the tilt test board and used for scattering sand to the tilt test board. The sand scattering device is arranged above the tilt testboard and scatters sand downwards, the real rainy and snowy weather is simulated, and the accuracy of detection of compressive strength of cell modules is very high. Meanwhile, a brush plate is arranged in a sand box and can ensure sand scattering uniformity and smoothness, and the simulation accuracy is further guaranteed.

Owner:江苏悦阳光伏科技有限公司

Broken black tea production device being uniform in hammering and cutting and convenient to maintain

InactiveCN106615307AFulfilling Hammer Cutting RequirementsImplement automatic transferPre-extraction tea treatmentBlack teaPulley

The invention discloses a broken black tea production device being uniform in hammering and cutting and convenient to maintain. The broken black tea production device comprises a primary hammering and cutting machine, a stalk-sorting machine, a stirrer, a secondary hammering and cutting machine, a pelletizer, a circular screening machine, a fermenting tank and a drying machine, wherein the primary hammering and cutting machine comprises a lower housing and an upper housing, a feed opening is formed in the top surface of the upper housing, and a discharge opening is formed in the front end of the upper housing; the feed opening and the discharge opening are respectively located in two ends of a material hammering and cutting cavity; a fine material inlet is formed in a material collecting bin corresponding to the discharge opening, and a discharge guiding passage is formed between the fine material inlet and the discharge opening; a discharge hopper is arranged at the bottom of the material collecting bin, a material receiving hopper I is arranged under the discharge hopper, and a belt pulley conveyer device is arranged under the material receiving hopper I; the stalk-sorting machine comprises a cylindrical framework and a screen mesh, wherein a rotating shaft II is arranged in the center of the cylindrical framework, a rotary support mechanism is arranged at one end of the rotating shaft II, and a guiding support mechanism and a movable support mechanism are arranged at the other end of the rotating shaft II; and a discharge end of the belt pulley conveyer device extends into the screen mesh.

Owner:CHONGQING RONGFA TEA IMP & EXP CO LTD

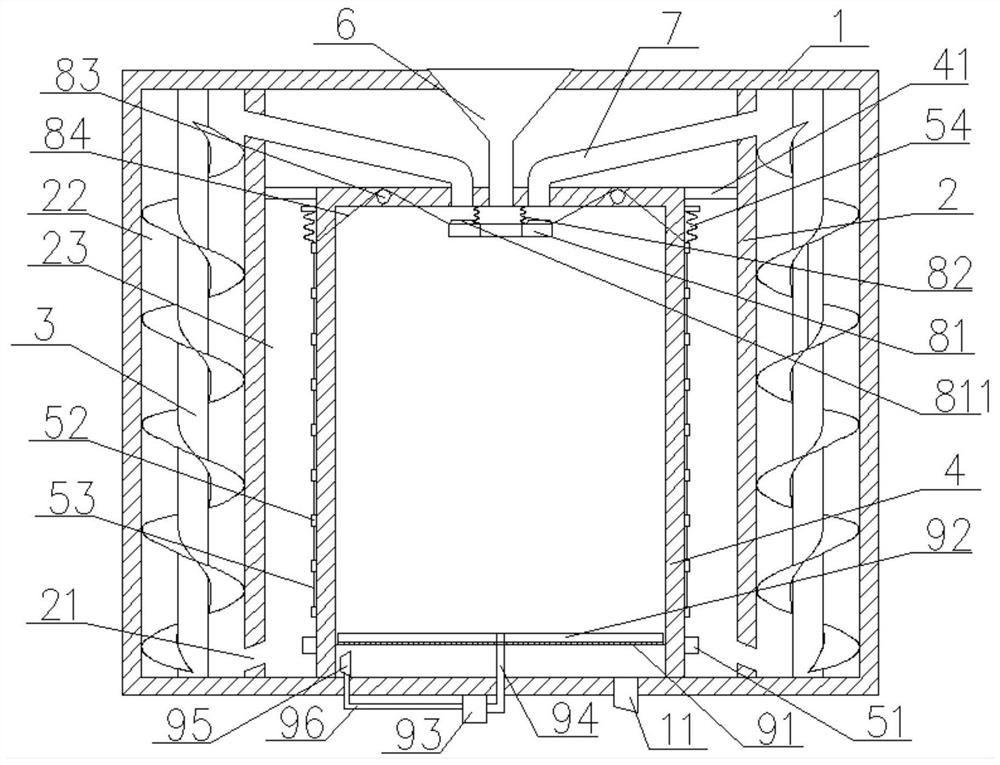

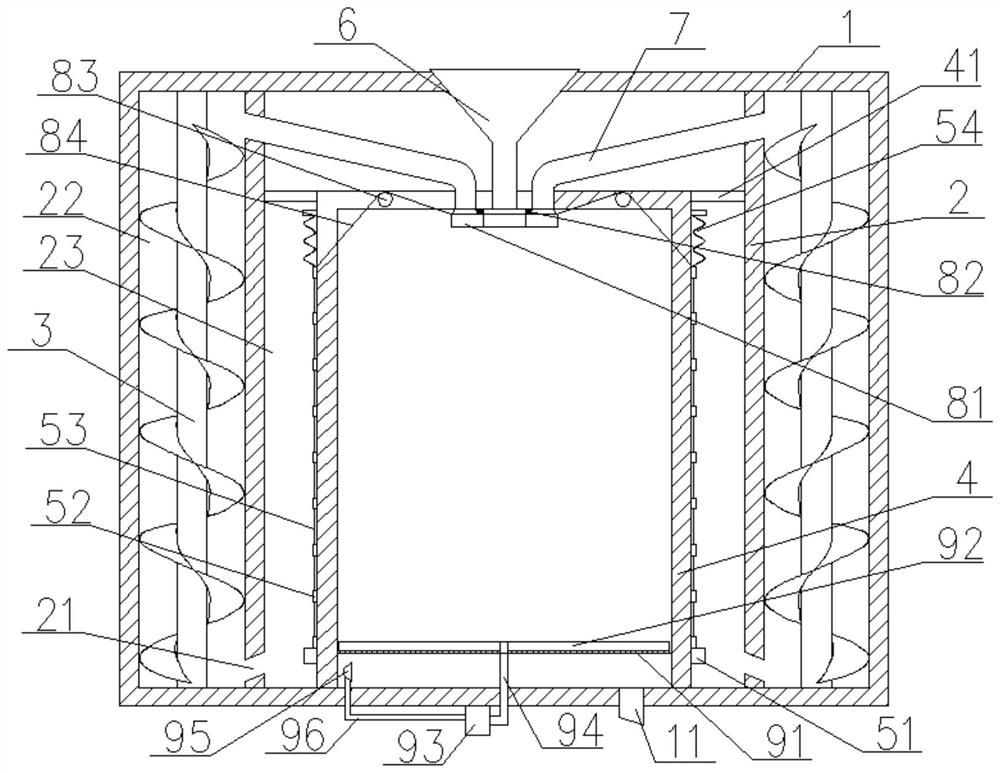

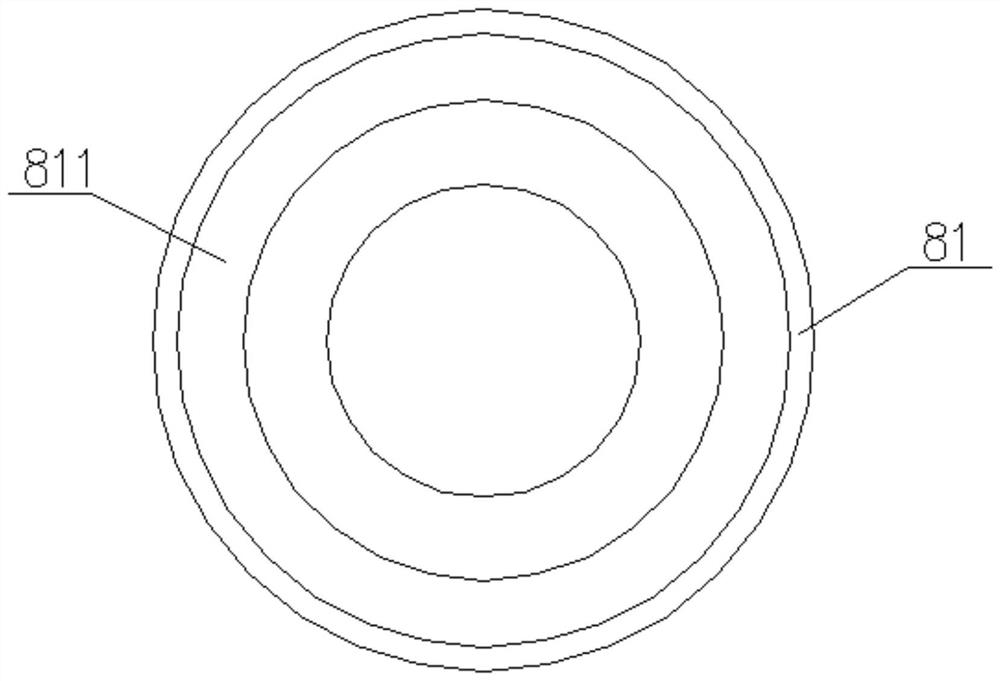

Energy-saving drying device for mixed oatmeal

ActiveCN111288768BQuick changeFrequent replacementDrying solid materials with heatDrying chambers/containersEngineeringEnergy conservation

The invention discloses an energy-saving mixed oatmeal drying device which comprises a shell body, an outer cylinder body, a plurality of screws, an inner cylinder body, a first material blocking mechanism, a feeding hopper, a plurality of material guide pipes and a second material blocking mechanism. The outer cylinder body is coaxially sleeved with the shell body. A first space is formed betweenthe outer cylinder body and the shell body. The screws are arranged in the first space. The inner cylinder body is coaxially sleeved with the outer cylinder body. The first material blocking mechanism comprises an electromagnet, a plurality of first baffles and a plurality of first springs. The upper end of the feeding hopper protrudes out of the top of the shell body. The lower end of the feeding hopper communicates with the interior of the inner cylinder body. The first space communicates with the inner cylinder body through the material guide pipes. The second material blocking mechanism comprises a second baffle, a plurality of second springs, a plurality of fixed pulleys and a plurality of rope bodies. By means of the energy-saving mixed oatmeal drying device, quartz sand in the inner cylinder body can be frequently replaced in the drying process, the high drying performance of the quartz sand is ensured, the drying effect and speed are further increased, heat is sufficiently utilized, energy waste is avoided, and the technical effect of energy conservation is realized.

Owner:北京臻味坊食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com