Double-rocking-fan heat dissipation type motor based on self-vibration phenomenon

A motor and heat dissipation technology, applied in the field of electric motors, can solve the problems of high production cost and operating cost, reduced motor efficiency, ablation, etc., and achieve the effects of comprehensive and uniform heat dissipation, promoting air flow, and increasing the beating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

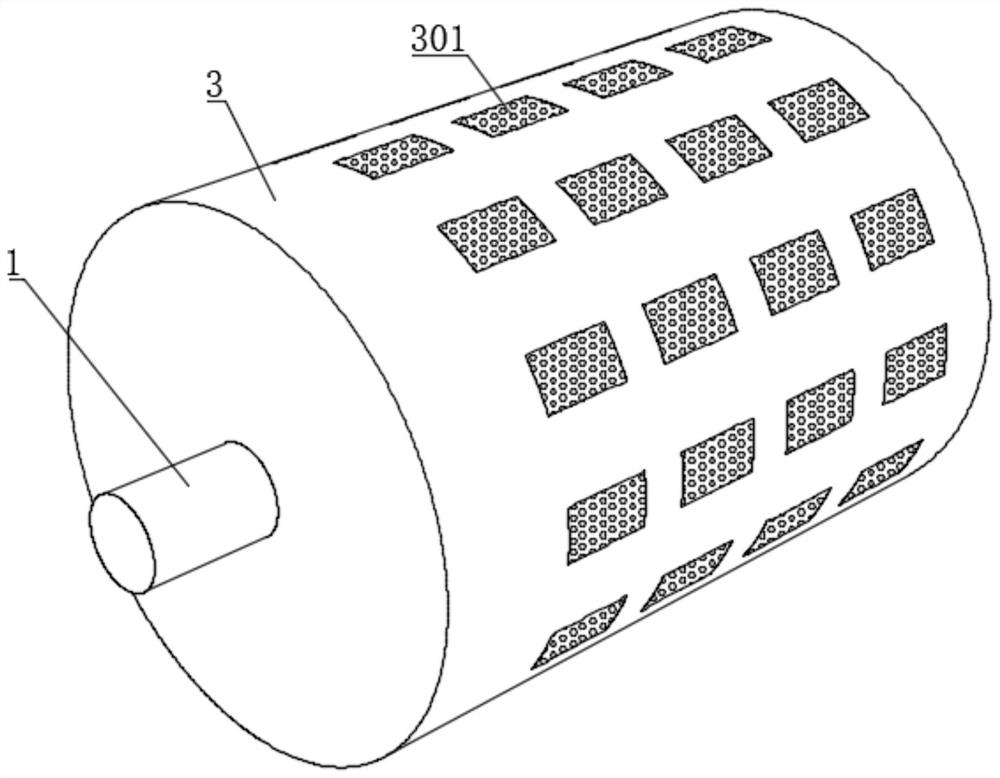

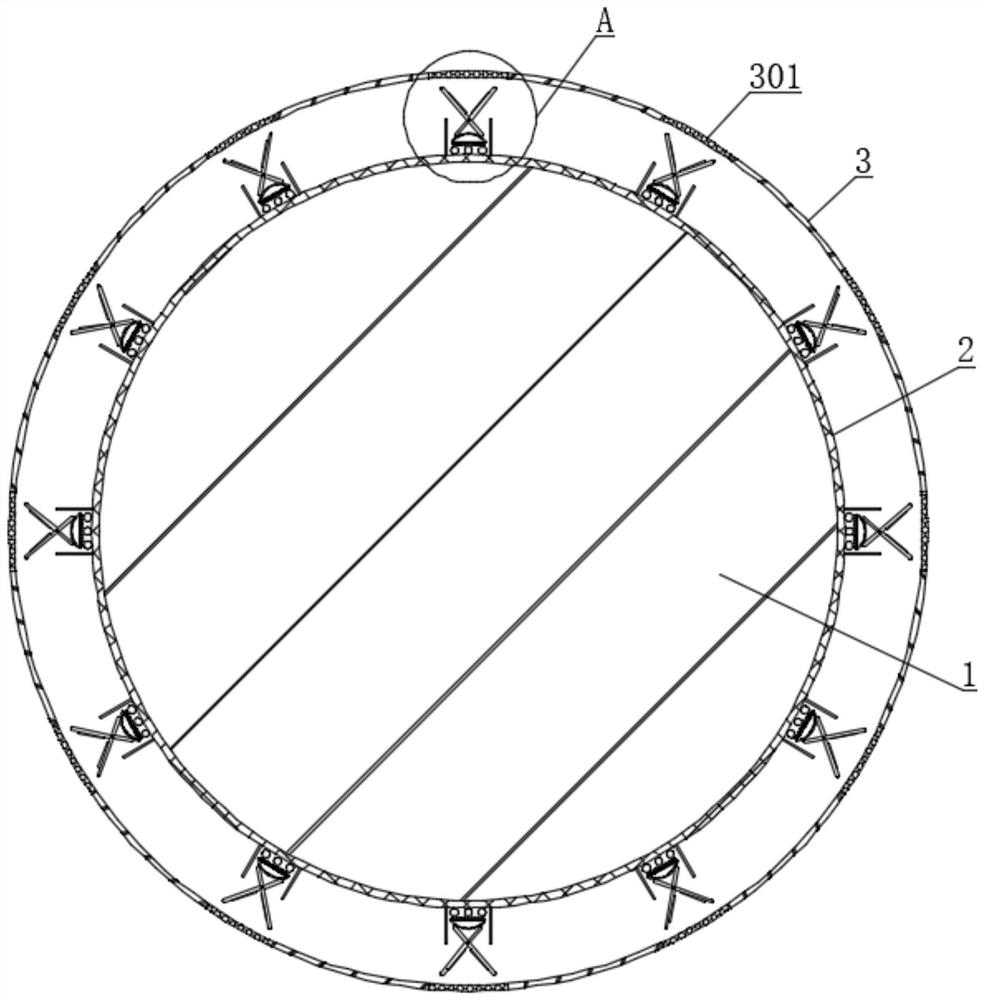

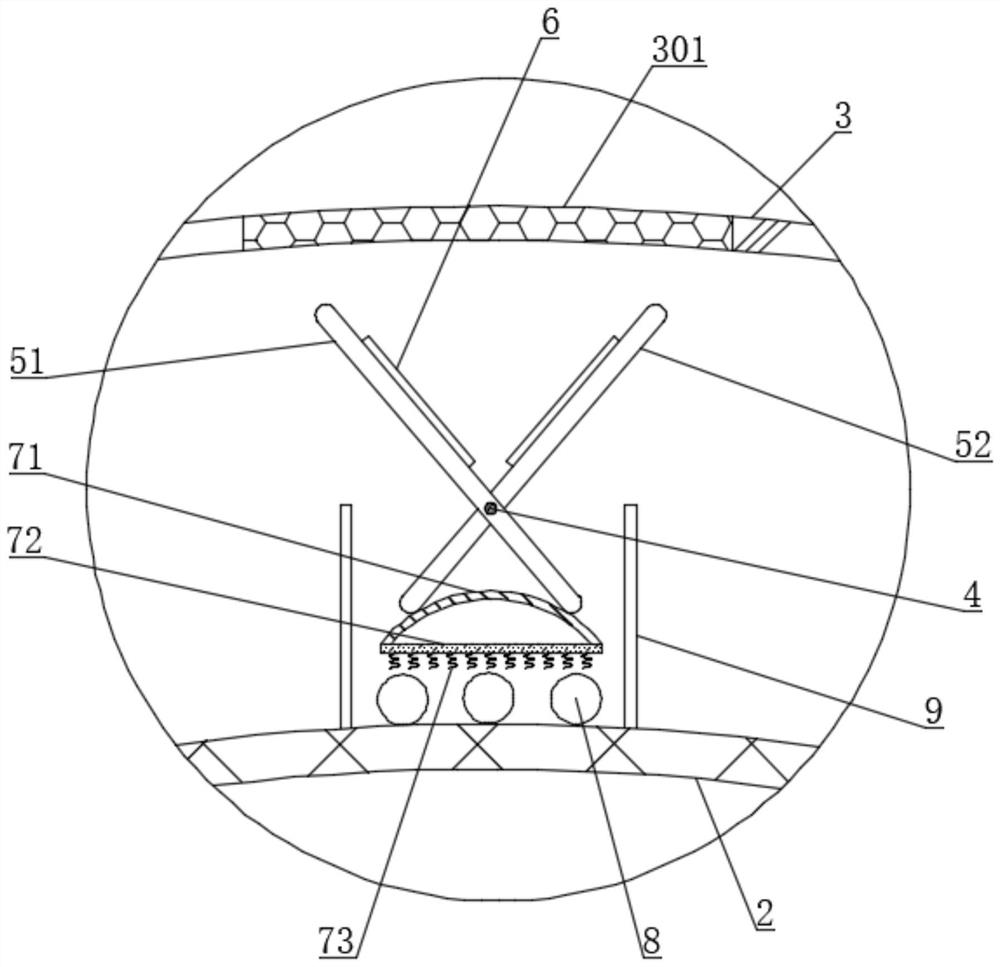

[0041] see figure 1 , figure 2 and Figure 5 , a double fan heat dissipation motor based on self-vibration phenomenon, including a motor body 1, the outer surface of the motor body 1 is fixedly connected with a heat conduction plate 2, and the outer end of the heat conduction plate 2 is fixedly connected with a casing 3, through which the heat conduction plate 2 absorbs The heat generated during the operation of the motor body 1 transfers the heat to the cavity between the heat conduction plate 2 and the casing 3. There are multiple evenly distributed double-sided fan racks between the heat conduction plate 2 and the casing 3. Please refer to image 3 and Figure 4 , the double-sided rocking fan frame includes a fixed rod 4, the outer end of the fixed rod 4 is rotatably connected with a plurality of main rotating rods 51 and a plurality of auxiliary rotating rods 52, and a circular through hole is provided on the main rotating rod 51 and the auxiliary rotating rods 52 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com