Concrete processing equipment adopting annular stirring

A kind of processing equipment and concrete technology, which is applied in the field of concrete processing equipment with circular agitation, can solve the problems of affecting the construction progress, slow mixing efficiency of raw materials, uneven mixing, etc., and achieve the effect of shortening the mixing time, improving the mixing effect and mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

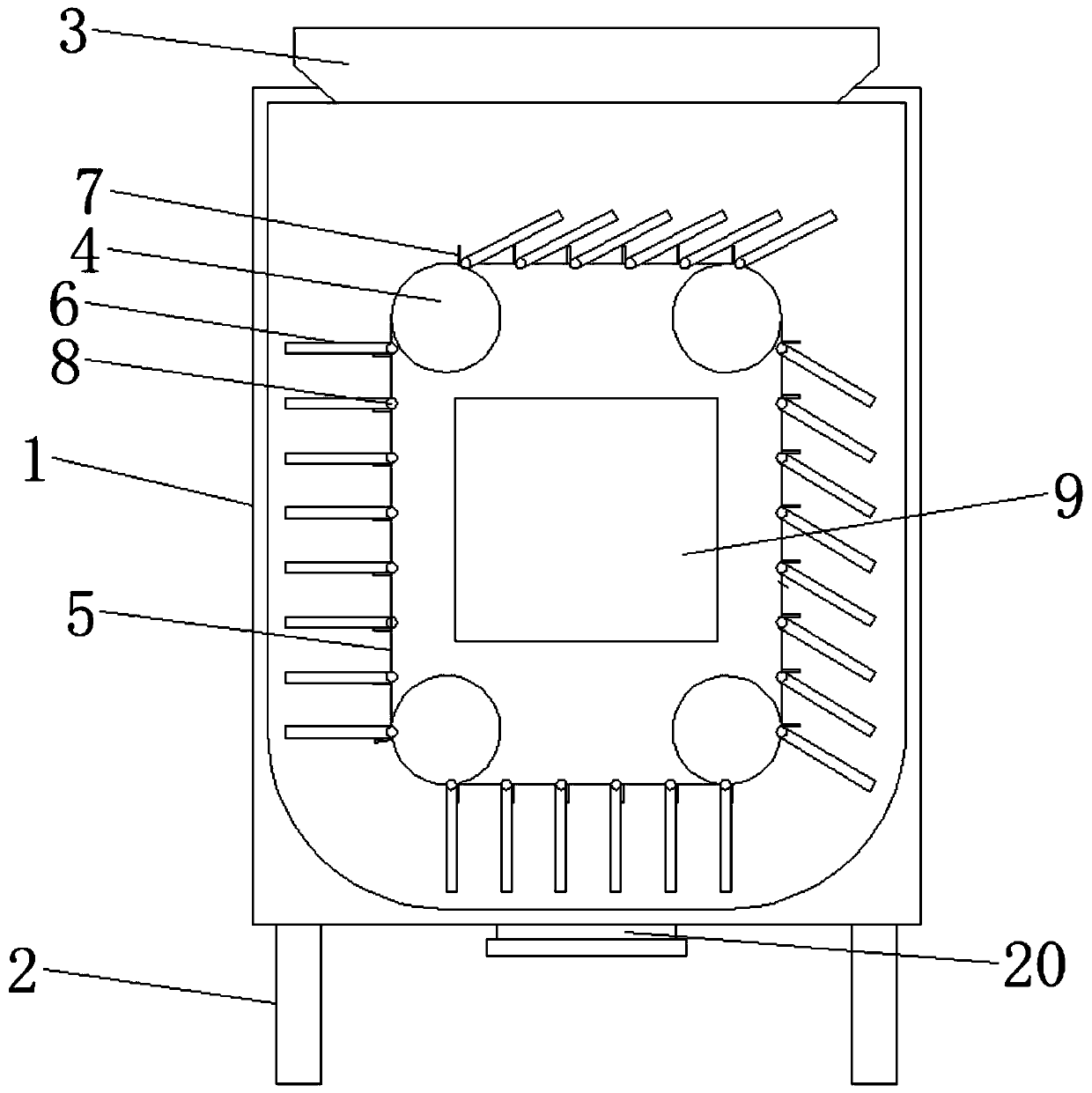

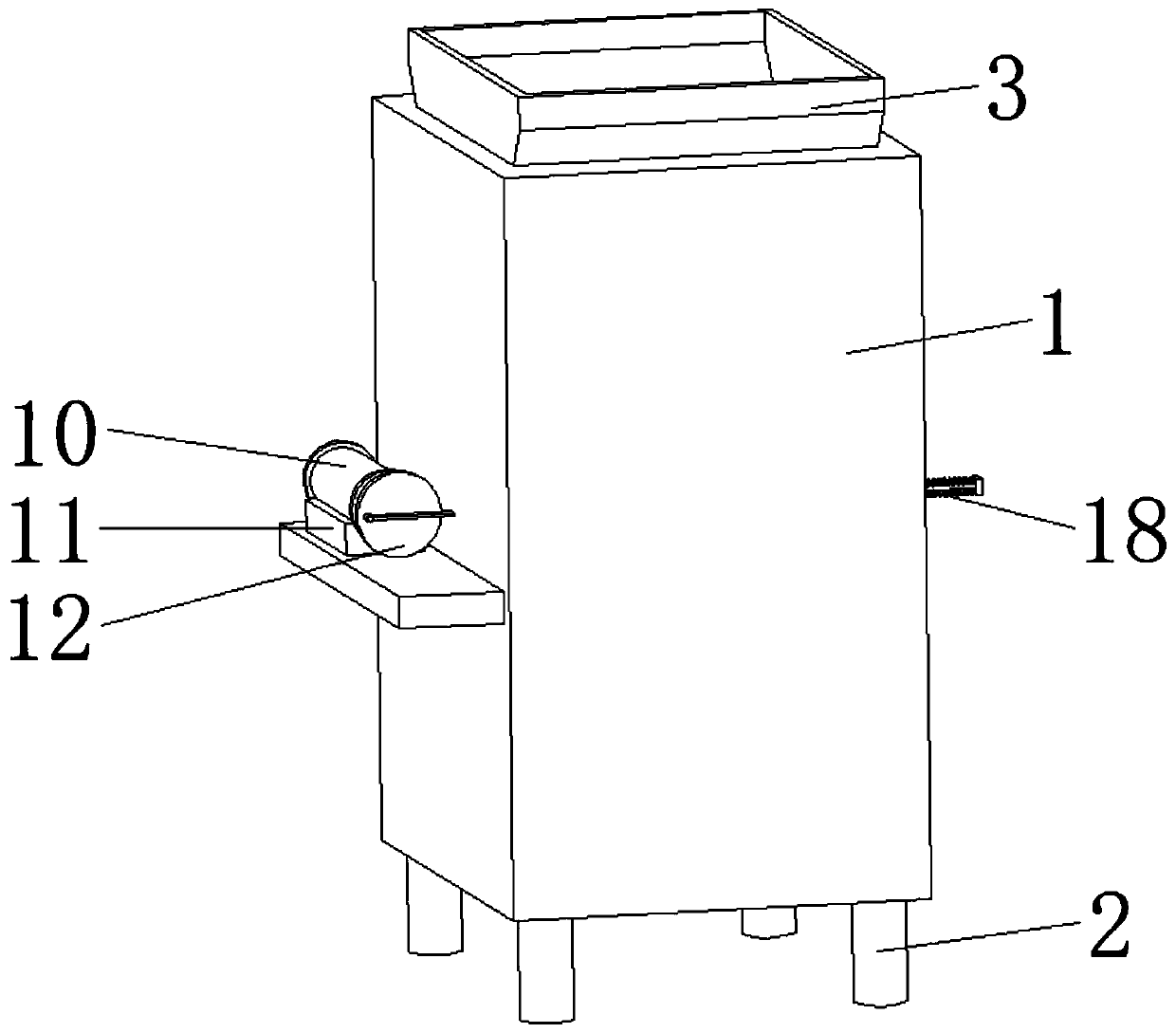

[0023] Please refer to the figure, in the embodiment of the present invention, a kind of annular stirring concrete processing equipment includes a mixing tank 1, a leg 2, a feed hopper 3 and a discharge port 20; the four corners of the bottom of the mixing tank 1 are fixed supports Leg 2 supports the mixing tank 1 through the supporting leg 2, and a shock-absorbing foot is fixedly installed on the lower end of the supporting leg 2, which plays a shock-absorbing role during mixing and reduces noise; the feeding hopper 3 is fixed on the top of the mixing tank 1 And it communicates with the inside, the raw materials are sent into the mixing tank 1 through the feed hopper 3, and the bottom of the mixing tank 1 is connected with a discharge port 20 with an end cover, and the mixed concrete is discharged from the discharge port 20.

[0024] The mixing tank 1 is provided with four driving rollers 4 in the water direction, and the four driving rollers 4 are respectively located on the ...

Embodiment 2

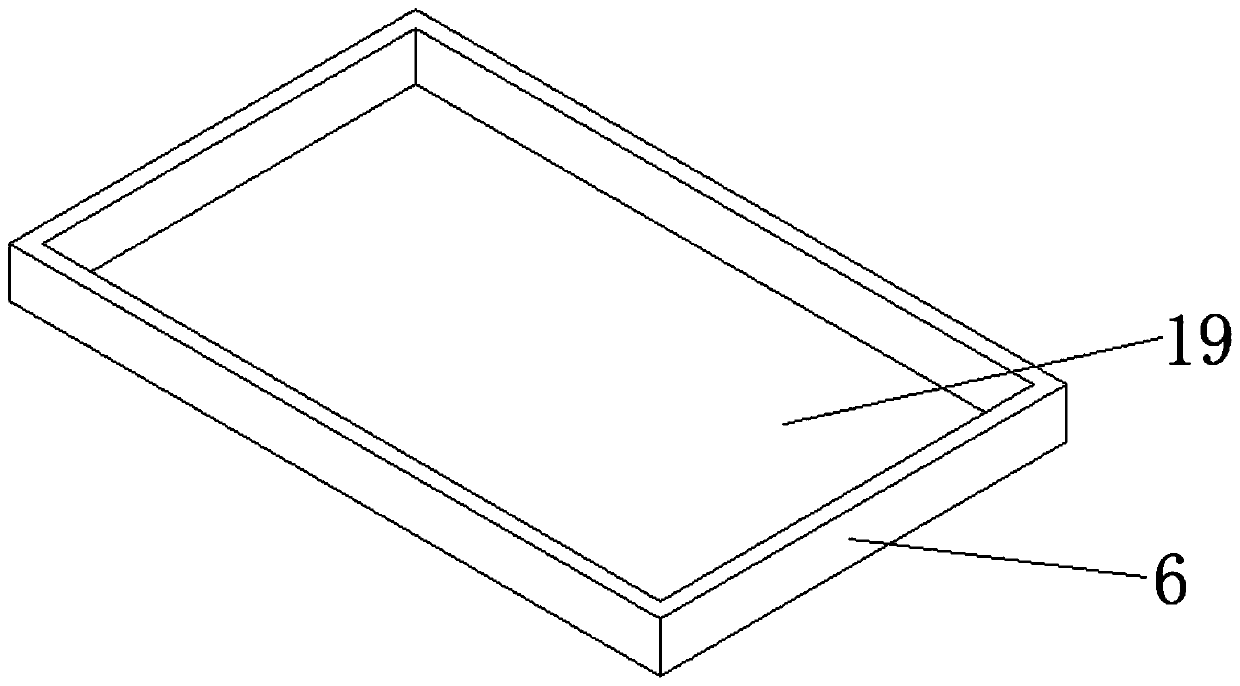

[0027] On the basis of embodiment 1, in order to avoid the dead angle of stirring, a reciprocating stirring piece 9 moving back and forth is arranged inside the rectangle surrounded by the driving belt 5, and the area of the reciprocating stirring piece 9 accounts for 2 / 3-3 of the inner area of the driving belt 5 / 4, occupies most of the space in the driving belt 5, and the concrete therein is moved by the reciprocating stirring piece 9 moving back and forth; Going out from the side wall of the mixing tank 1, one end is fixedly connected with several return springs 18, and the other end of the return spring 18 is fixedly connected on the outer wall of the mixing tank 1, and the push-pull rod 17 is supported by the return spring 18, so that the push-pull rod 17 is Can be reset after pulling, is convenient to the reciprocating movement of push-pull rod 17; On the other end of push-pull rod 17, is connected with connecting rod 15 by rotating shaft 16 rotations, pulls push-pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com