Paper impregnation device used for processing film adhesive

A technology of impregnating device and film paper, which is applied in the process of adding paper and pulp raw materials, papermaking, etc. It can solve the problems of poor stirring stability, high labor intensity, and sedimentation at the bottom of the liquid, so as to ensure quality and temperature and improve product qualification. The effect of efficiency and structure is reasonable and simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

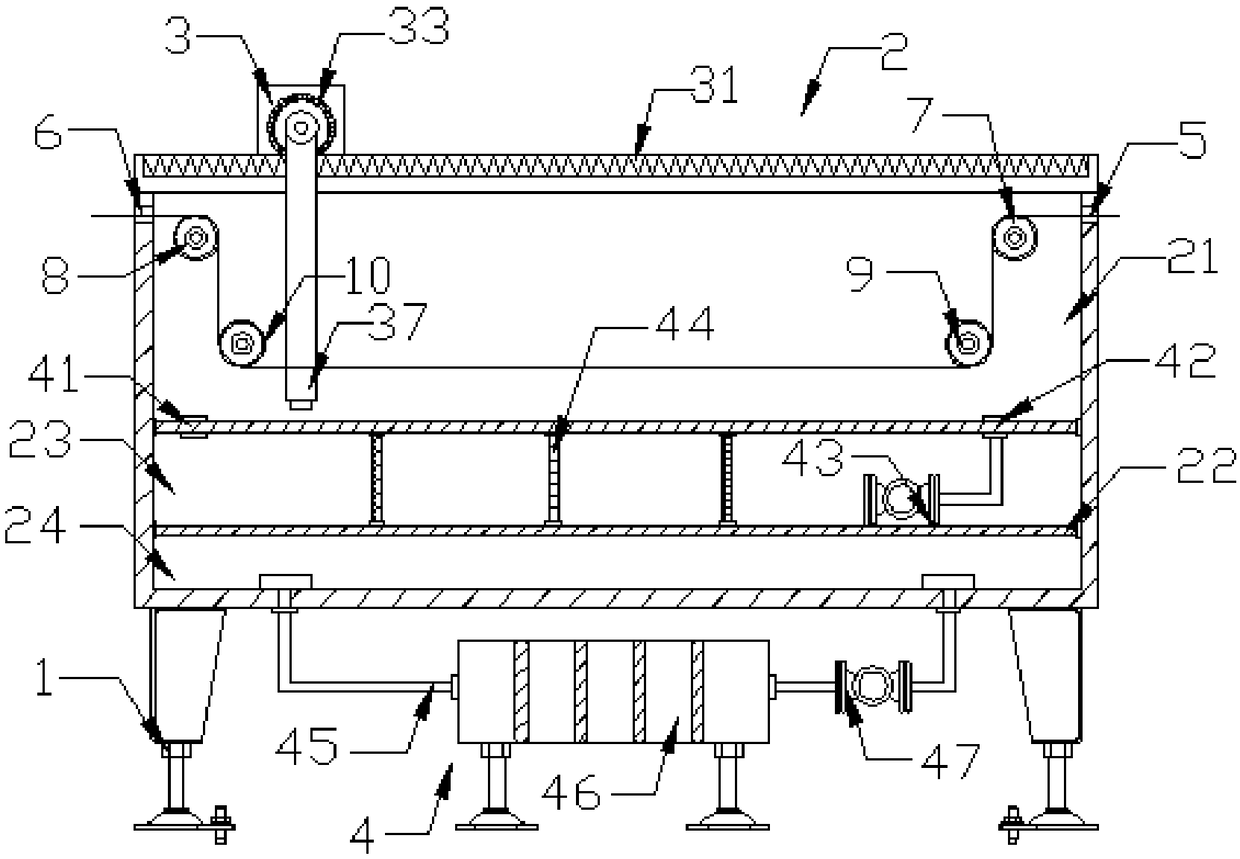

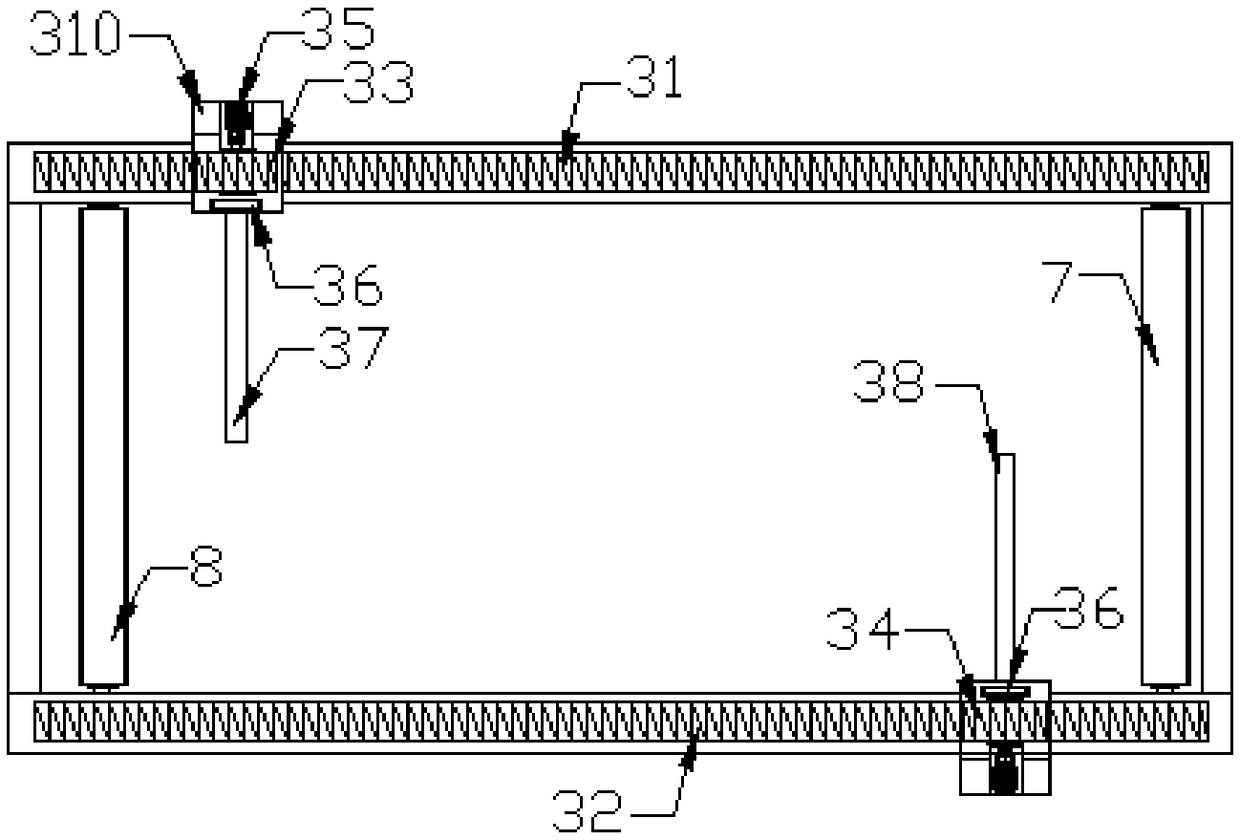

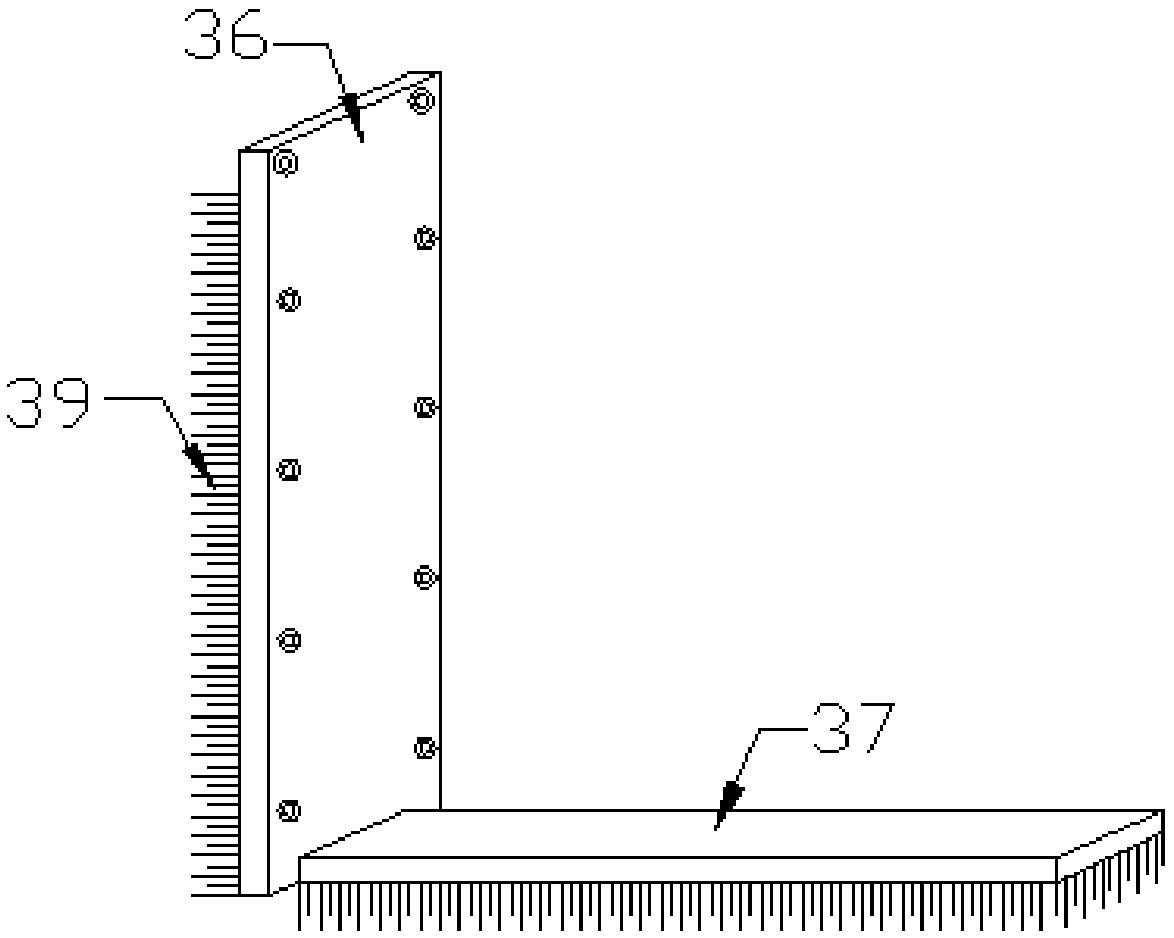

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a paper impregnation device for film paper processing, including a support frame 1, an impregnation tank body 2, a drive mechanism 3, a circulation mechanism 4, a feed roller shaft 7, an outlet The material roller shaft 8, the first material guide roller 9 and the second material guide roller 10, the support frame 1 is provided with four, and the tops of the four support frames 1 are fixedly equipped with a dipping tank body 2, and the dipping tank The body 2 includes an immersion liquid tank 21, a sealing partition 22, a circulation tank 23 and a heat preservation tank 24. There are two sealing partitions 22, and the two sealing partitions 22 separate the dipping tank body 2 from top to bottom. Dip tank 21, circulation tank 23 and heat preservation tank 24, drive mechanism 3 is installed on the top of the dip tank body 2, circulation mechanism 4 is installed on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com