Convenient-to-maintain energy-saving broken black tea production line

A technology that is convenient for maintenance and broken black tea, applied in the direction of tea processing before extraction, can solve the problems of time-consuming and laborious, low drying efficiency, uneven drying degree, etc., to prevent environmental pollution, improve screening efficiency, and improve screening efficiency. sub-effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

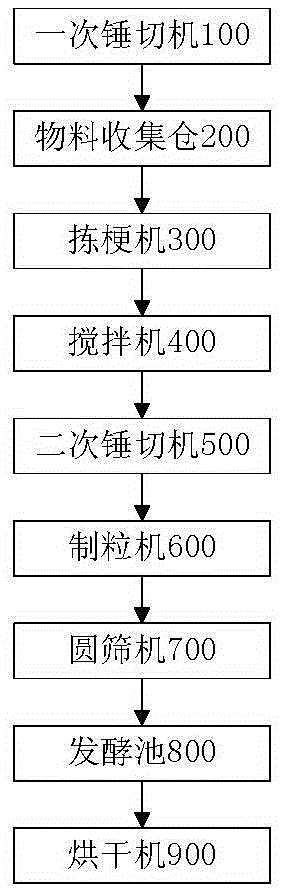

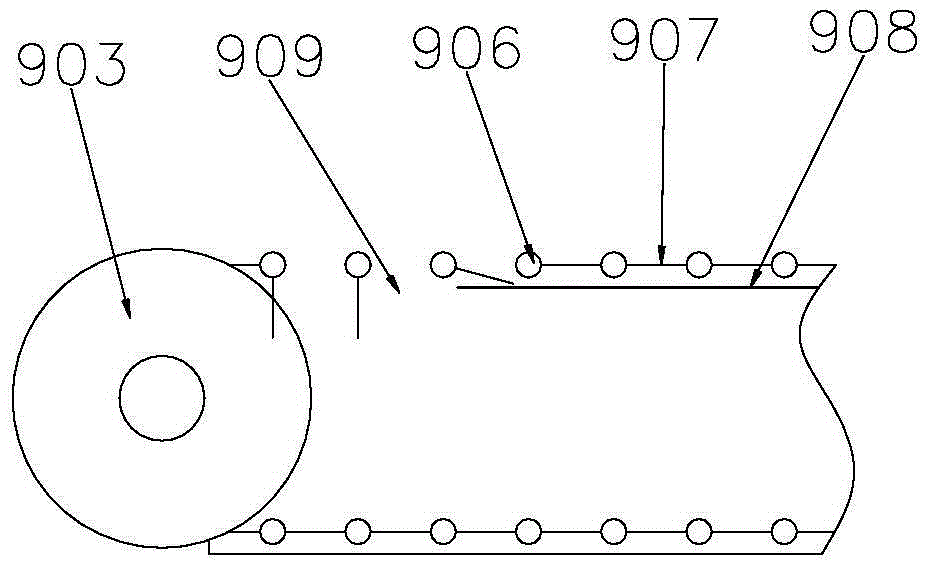

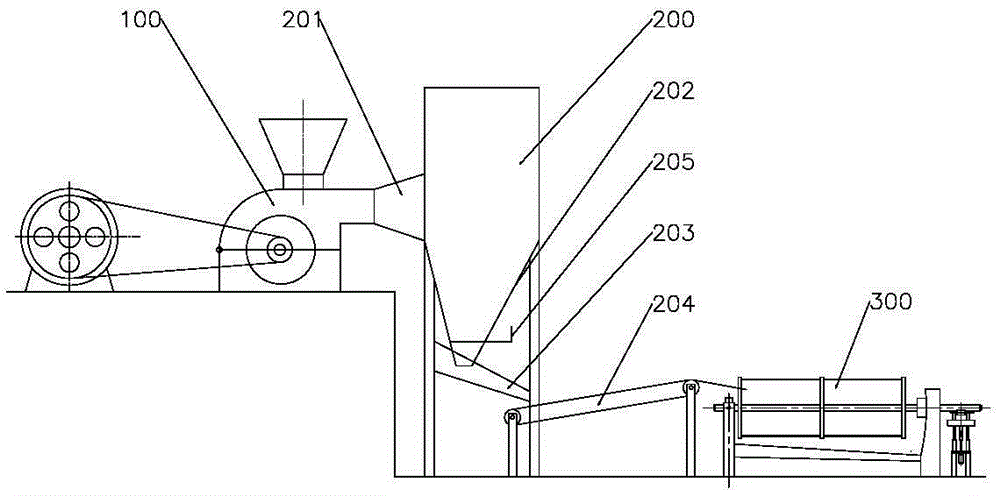

[0041] Such as figure 1 As shown, it is a block diagram of the equipment layout of the embodiment of the energy-saving crushed black tea production line embodiment of the present invention. The energy-saving crushed black tea production line that is convenient for maintenance in this embodiment includes a hammer cutter 100, a stem sorter 300, a mixer 400 for mixing the chopped tea leaves with water, and a mixer 400 for mixing the stirred tea leaves. The secondary hammer cutting machine 500 for hammer cutting again, the granulator 600 for making the hammered tea leaves into granules, the round sieve machine 700 for screening tea granules, the fermentation tank 800 for tea fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com