Tail gas treatment device for cremation machine

A technology of tail gas treatment and cremation machine, which is applied in transportation and packaging, methods of incinerating corpses, combustion types, etc. It can solve the problems of low heat energy recovery efficiency of tail gas, environmental pollution, etc., to increase the contact time, ensure the filtering effect, and improve the exchange rate. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

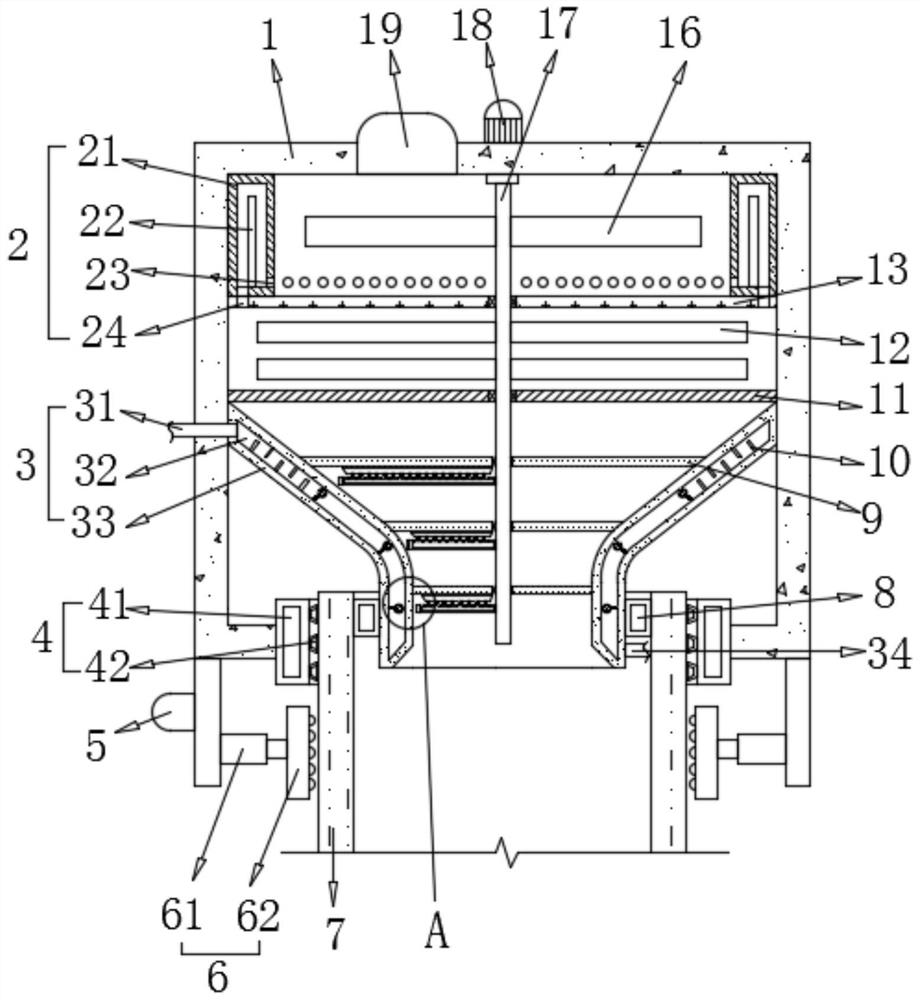

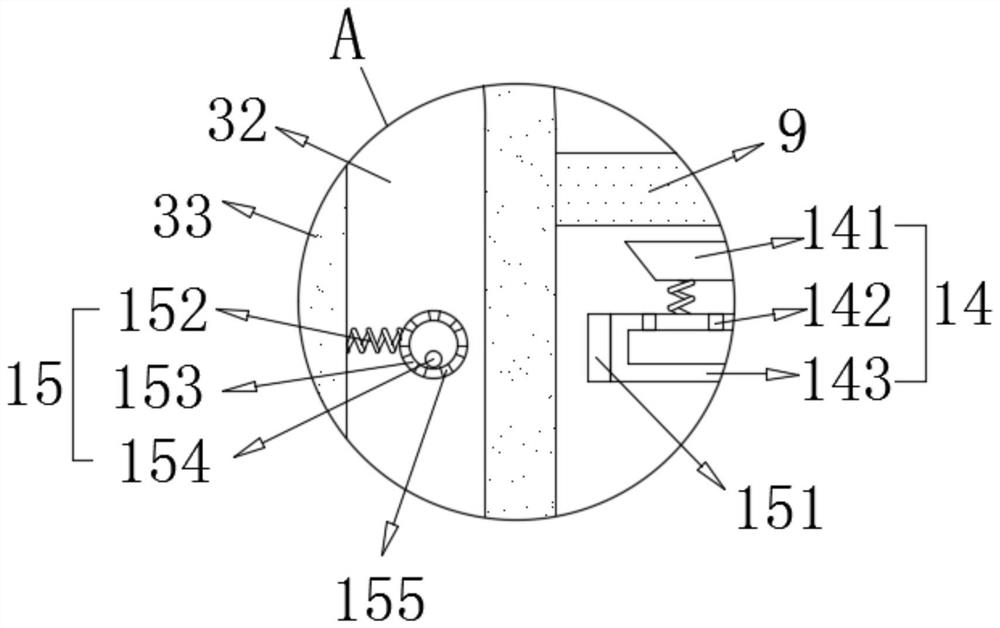

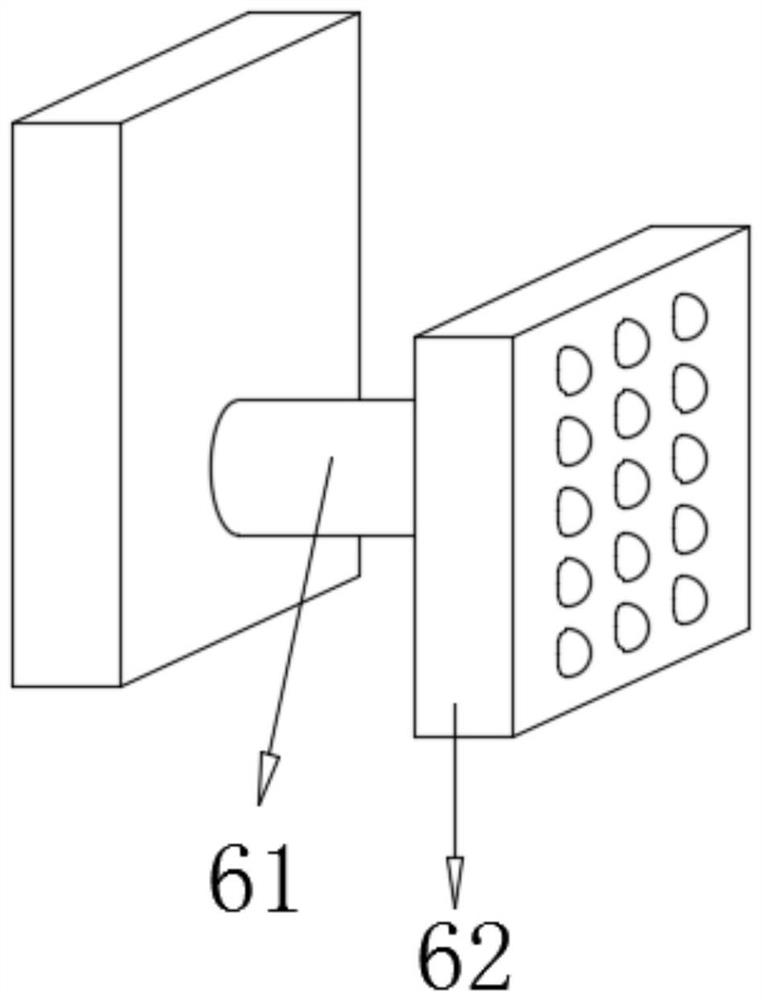

[0022] refer to Figure 1 to Figure 3 , an exhaust gas treatment device for a cremator, comprising a casing 1, a side of the casing 1 away from the smoke exhaust part 7 is provided with a suction part 19 for drawing the exhaust gas in the smoke exhaust part 7, and also comprising a fixing mechanism 6, It is used to fix the casing 1 at the opening of the smoke exhaust component 7; the heat exchange mechanism 3 is used to conduct contact heat exchange for the exhaust gas entering the casing 1; the heat exchange mechanism 3 includes a funnel-shaped heat exchange shell body 33, the bottom of the heat exchange shell 33 extends to the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com