Sea-island composite fiber filtering material and preparation method thereof

A composite fiber and composite fiber web technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., to achieve the effect of high filtration interception efficiency and small air surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

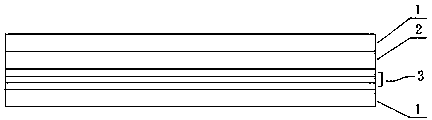

Method used

Image

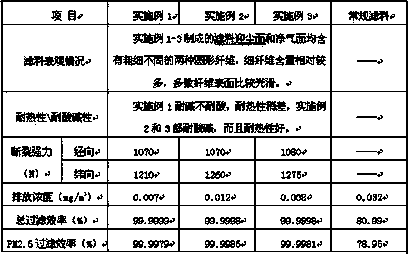

Examples

Embodiment 1

[0055] 1. Hybrid laying:

[0056] The COPET / PA 30 / 70 island-in-the-sea composite fiber, which accounts for 10% of the overall fiber web weight, is mixed with ordinary polyester fiber to lay the net, in which: the upper and lower sides are island-in-sea composite fiber web, and the middle is ordinary polyester fiber web and three layers of polyester base Cloth (0.5×0.5cm grid cloth).

[0057] 2. Acupuncture:

[0058] The acupuncture parameters are:

[0059] Acupuncture equipment 1 2 3、4 5、6 Acupuncture Upper stab Lower stab Upper stab, lower stab Upper stab, lower stab Acupuncture Depth (mm) 11 8 3 4 Acupuncture frequency (times / min) 750 950 670 670 Needle density: 4500 6000 8000 8000

[0060] 3. Fiber opening:

[0061] In this example, COPET / PA 30 / 70 sea-island composite fiber is used, which is composed of COPET and alkali-resistant components, and the COPET content is 3% (accounting for the weight of the whole fibe...

Embodiment 2

[0069] 1. Hybrid laying:

[0070] 20% COPET / PTFE 30 / 70 island-in-the-sea composite fibers accounting for 10% of the overall fiber web weight are mixed with ordinary polyester fibers to lay the web. The upper and lower sides are sea-island composite fiber nets, and the middle is ordinary polyester fiber net and three-layer polyester base cloth (0.5×0.5cm grid cloth).

[0071] 2. Acupuncture:

[0072] The acupuncture parameters are:

[0073] Acupuncture equipment 1 2 3、4 5、6 Acupuncture Upper stab Lower stab Upper stab, lower stab Upper stab, lower stab Acupuncture Depth (mm) 10 9 4 6 Acupuncture frequency (times / min) 770 980 650 650 Needle density: 4500 6000 8000 8000

[0074] 3. Fiber opening:

[0075] In this example, the island-in-the-sea composite fiber is composed of COPET and PTFE, and the COPET content is 6% (accounting for the weight of the whole fiber web), so the amount of caustic soda used for fiber openin...

Embodiment 3

[0082] 1. Hybrid laying:

[0083] The COPET / PPS 30 / 70 island-in-the-sea composite fiber, which accounts for 30% of the overall fiber web weight, is mixed with ordinary polyester fiber to lay the web. The upper and lower sides are sea-island composite fiber nets, and the middle is ordinary polyester fiber net and three-layer polyester base cloth (0.5×0.5cm grid cloth).

[0084] 2. Acupuncture:

[0085] The acupuncture parameters are:

[0086] Acupuncture equipment 1 2 3、4 5、6 Acupuncture Upper stab Lower stab Upper stab, lower stab Upper stab, lower stab Acupuncture Depth (mm) 10 9 4 6 Acupuncture frequency (times / min) 800 1000 700 700 Needle density: 4500 6000 8000 8000

[0087] 3. Fiber opening:

[0088] In this example, the island-in-the-sea composite fiber is composed of COPET and PPS, and the COPET content is 9% (accounting for the weight of the whole fiber web), so the amount of caustic soda used for fiber open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com