Heat exchanger for industrial production

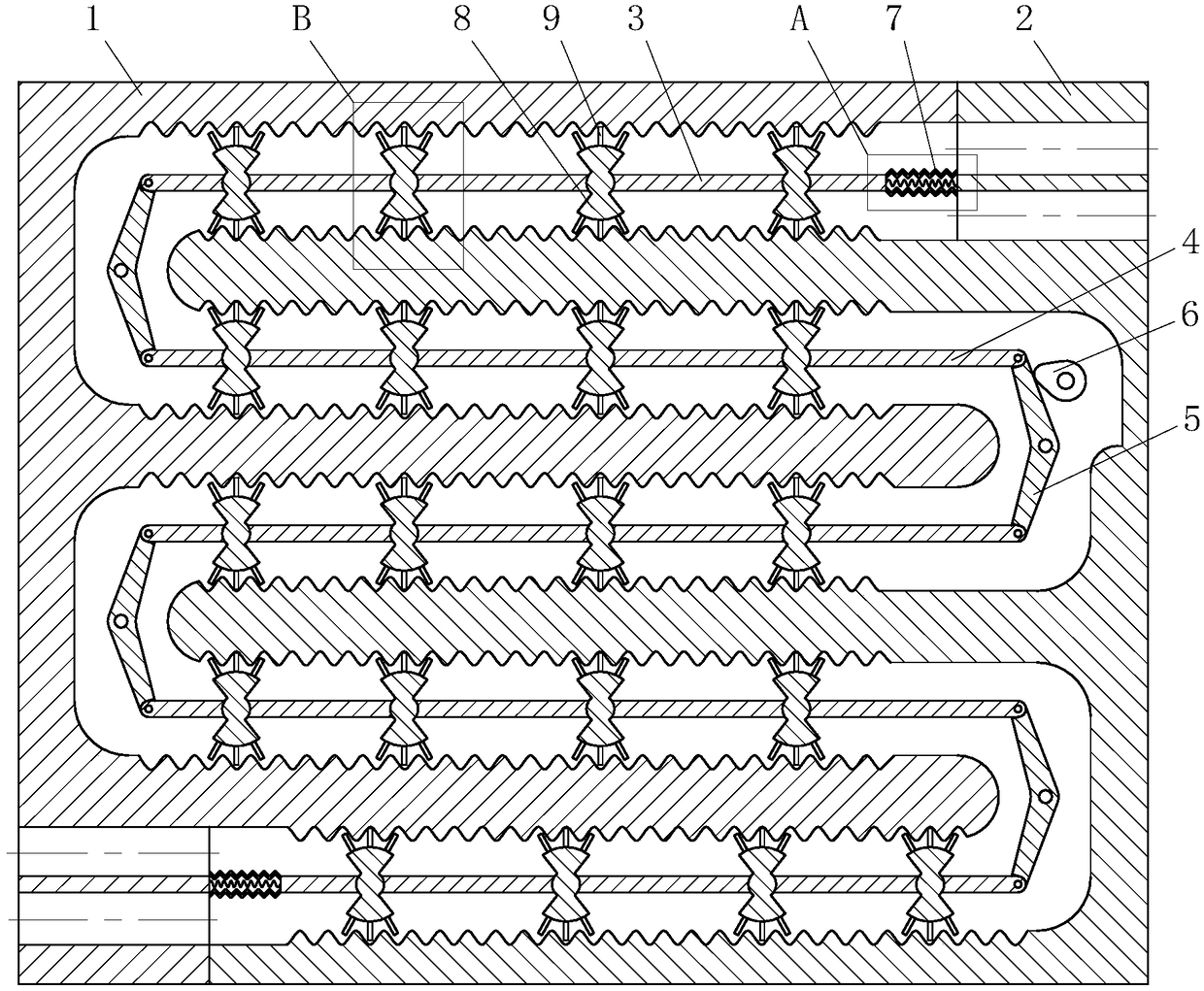

A heat exchanger, No. 1 technology, applied in heat exchange equipment, indirect heat exchangers, heat transfer modification, etc., can solve problems such as installation inconvenience, achieve the effect of increasing the degree of turbulence and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

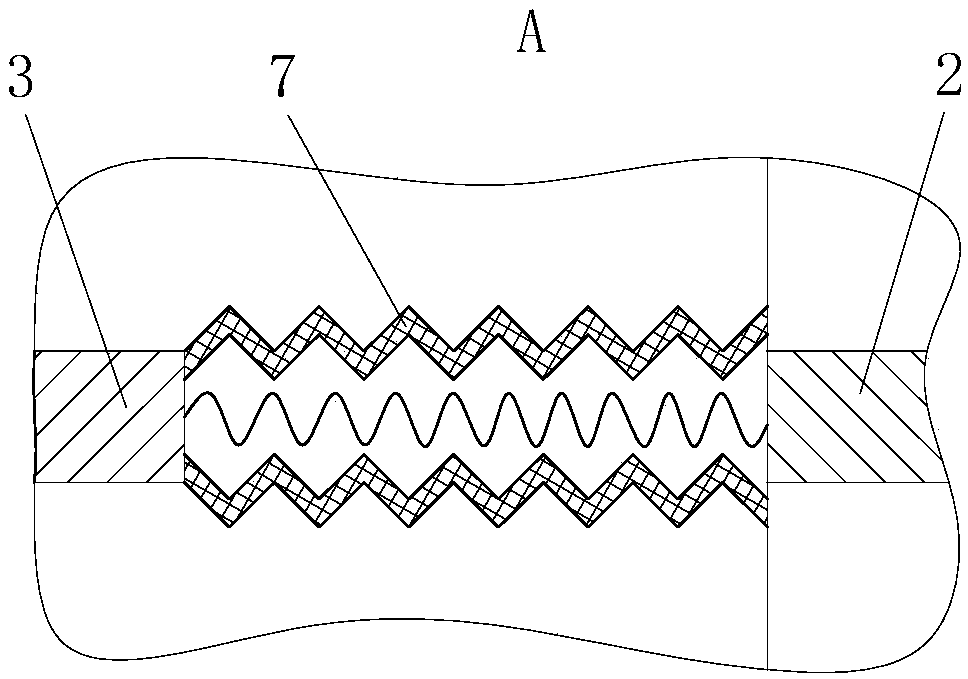

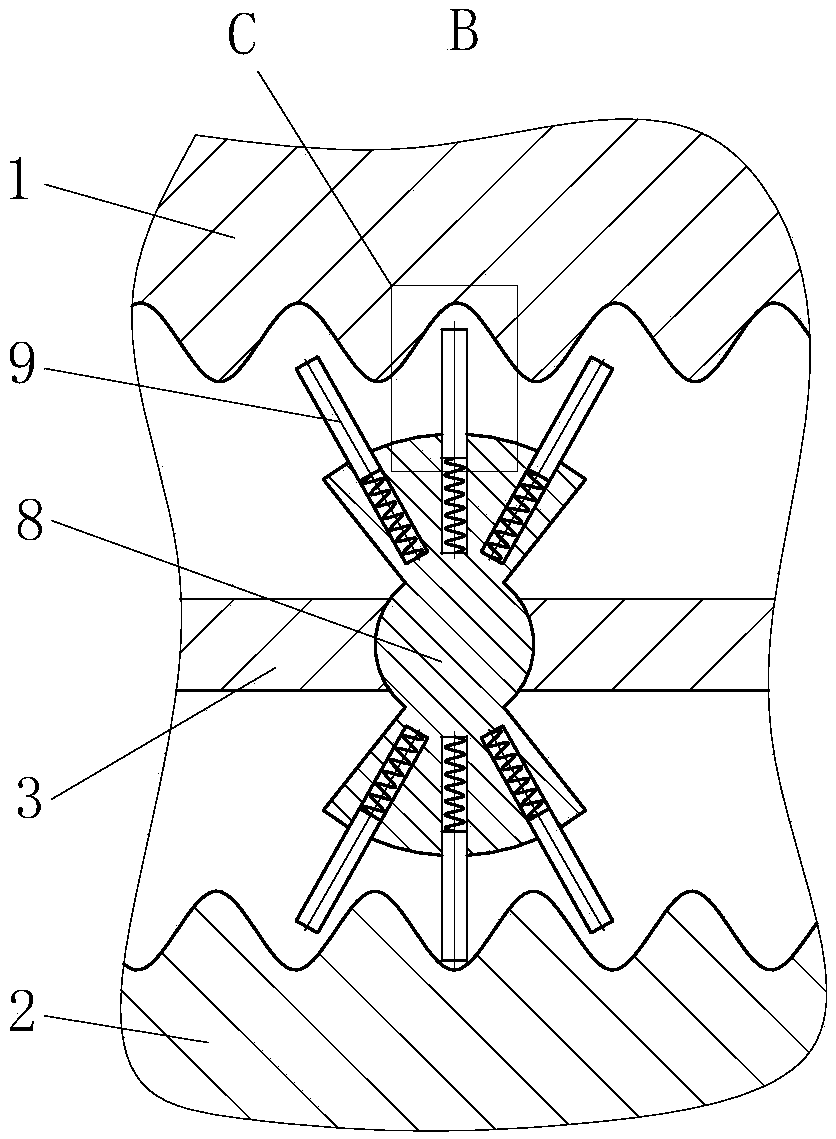

[0031] As an embodiment of the present invention, the sliding rod 9 is provided with a cylindrical blind hole 91 near one end of the swinging block 8, and a group of through holes are arranged on the cylindrical surface of the sliding rod 9; during operation, the sliding rod on the swinging block 8 9 slides through the arc-shaped grooves on the side walls of the rectangular grooves of the left housing 1 and the right housing 2, the sliding rod 9 is squeezed and slides along the blind hole on the swing block 8, and the liquid in the blind hole on the swing block 8 is After being extruded, it is ejected from the through hole on the cylindrical surface of the sliding rod 9, so turbulent flow is formed in the area around the sliding rod 9, and the heat exchange efficiency thereof is improved.

[0032] As an embodiment of the present invention, the middle part of the sliding rod 9 is provided with a shock absorbing plate 92; The surface and the swing block 8 are connected by a No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com