Rolling equipment for tea production and processing and rolling method of rolling equipment

A rolling equipment and tea technology, which is applied in the field of tea processing equipment, can solve the problems of low work efficiency and poor quality, and achieve the effects of improving work efficiency, improving fluidity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

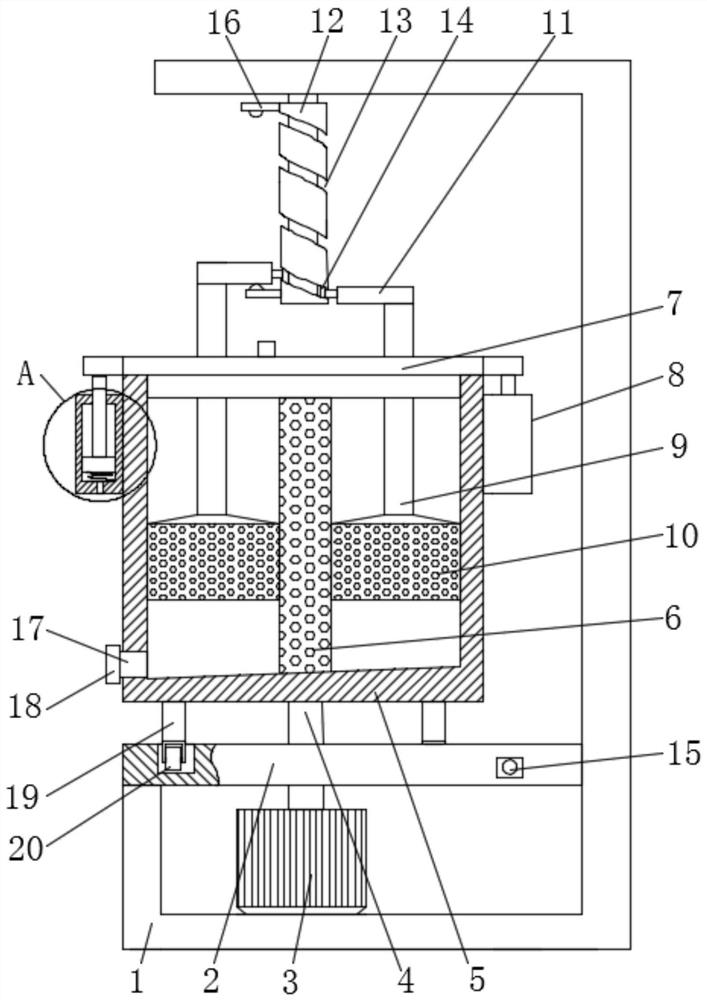

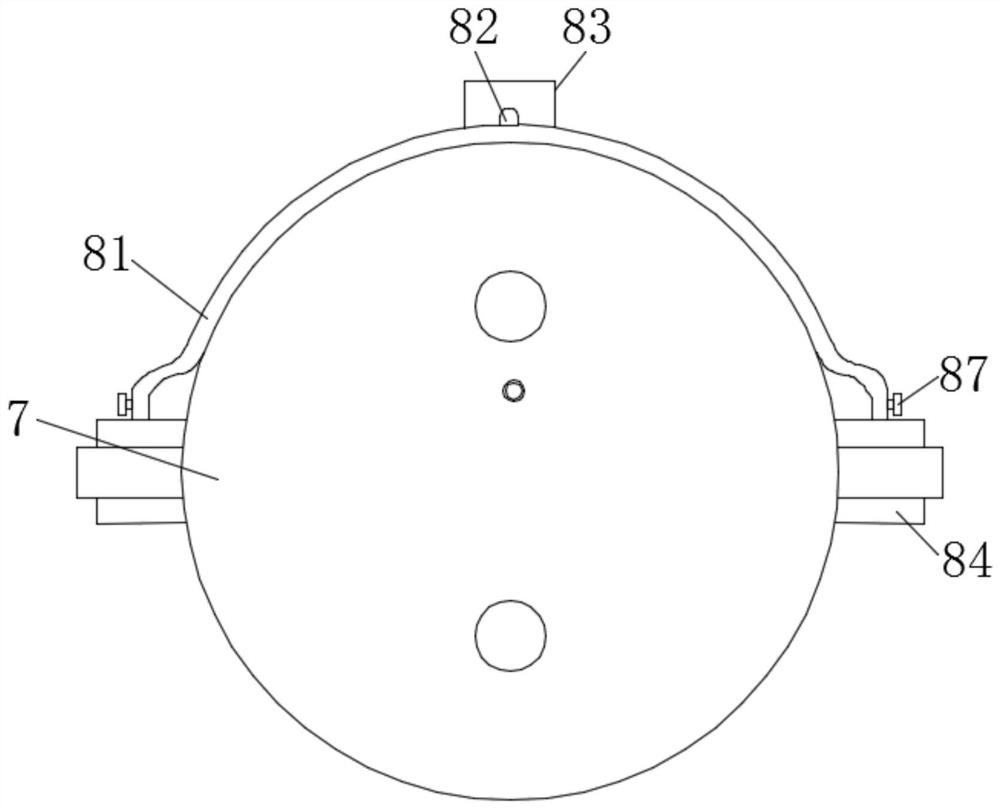

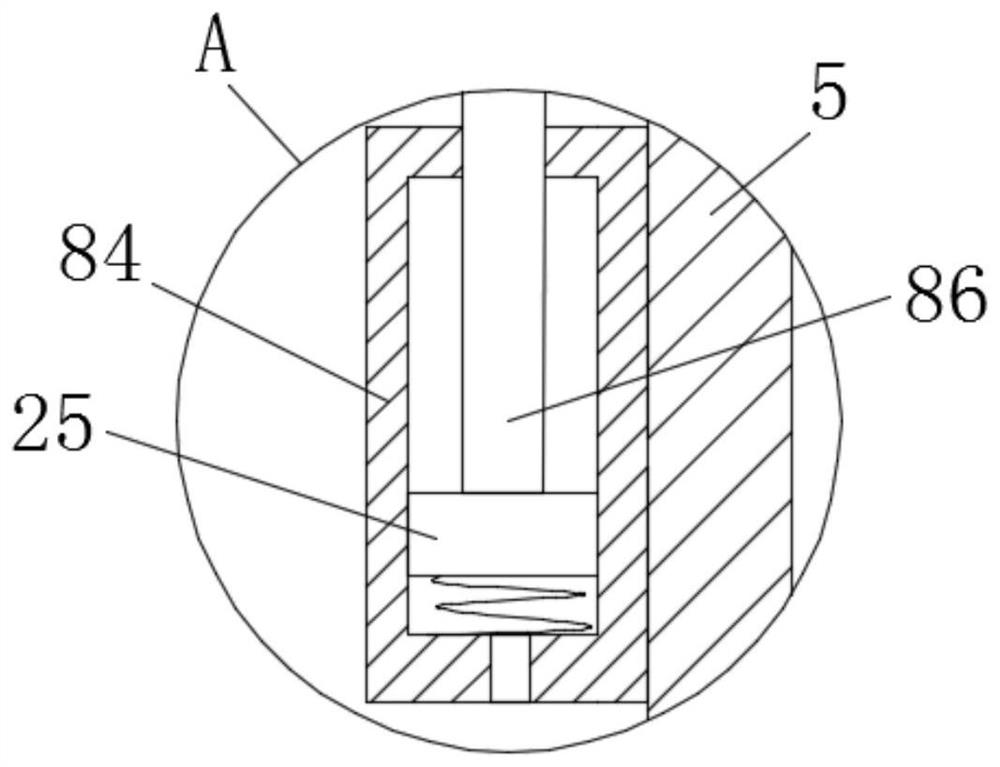

[0034] see Figure 1-3 , a rolling equipment and rolling method for tea production and processing, comprising a frame 1, a support platform 2 arranged horizontally is installed on the frame 1, and a motor 3 installed on the frame 1 is arranged on the lower side of the support platform 2, The output shaft of the motor 3 is fixed with a central shaft 4 through a shaft connector, the top of the central shaft 4 passes through the support table 2, and is fixed with a kneading barrel 5, the inner bottom of the kneading barrel 5 is equipped with a first kneading barrel 6, and the kneading barrel 5 The top of the cover plate 7 is clamped with a cover plate 7, and mounting ears are fixed on both sides of the cover plate 7, and a limit mechanism 8 is installed between the cover plate 7 and the kneading barrel 5, and two through holes are provided on the cover plate 7, and the limit The mechanism 8 includes a first air pipe 81 fixed on the kneading barrel 5, the middle part of the first ...

Embodiment 2

[0037] refer to figure 1 , 3 and 5, suspenders 9 are movably connected in the two through holes, and the bottom ends of the two suspenders 9 pass through the cover plate 7, and are rotatably connected with the second kneading cylinder 10, and the two second kneading cylinders 10 are located at On both sides of the first kneading cylinder 6, the axis of the first kneading cylinder 6 is collinear with the axis of the kneading cylinder 5, the axes of the two second kneading cylinders 10 are parallel to the axis of the first kneading cylinder 6, and the first kneading cylinder 6 And the outer walls of the two second kneading cylinders 10 are all provided with evenly distributed kneading convex grains, the tops of the two suspenders 9 are fixed with a cross bar 11, and a guide rod 12 is arranged in the middle of the two cross rods 11, and the guide rod 12 The top of the top is fixed on the frame 1, and the guide rod 12 is provided with a spiral guide groove 13, and two connecting ...

Embodiment 3

[0040] refer to Figure 1-5 , a rolling method of rolling equipment for tea production and processing, comprising the following steps:

[0041] S1. Put the tea leaves to be kneaded into the kneading barrel 5, then squeeze the manual air pump 832, and send air to the box body 84 through the first air pipe 81 and the second air pipe 82, so that the cover plate 7 is pressed down until the cover plate 7 is closed On the kneading barrel 5, stop pressing and kneading the manual air pump 832 to complete feeding and cover tightly;

[0042] S2. Start the motor 3, and the kneading barrel 5 rotates. During the rotation, the first kneading cylinder 6 cooperates with the second kneading cylinder 10 and the inner wall of the kneading bucket 5 to realize stirring, squeezing and kneading the tea leaves up and down. The kneading time During the kneading process, the two suspenders 9 on the cover plate 7 realize the reciprocating lifting of the two suspenders 9 through the cooperation of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com