Reaction kettle

A reaction kettle and reaction technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problem that stirring is not uniform and sufficient, and affects the reaction rate and quality. and other problems to achieve the effect of avoiding insufficient reaction and sufficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

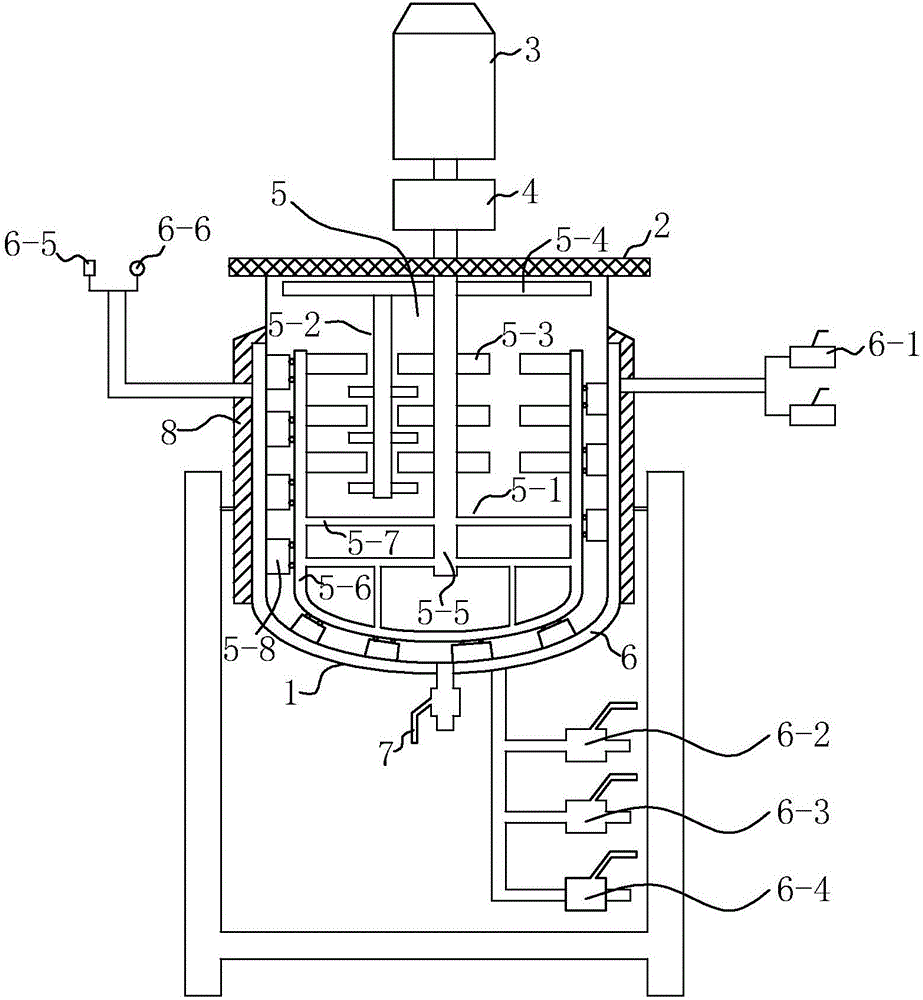

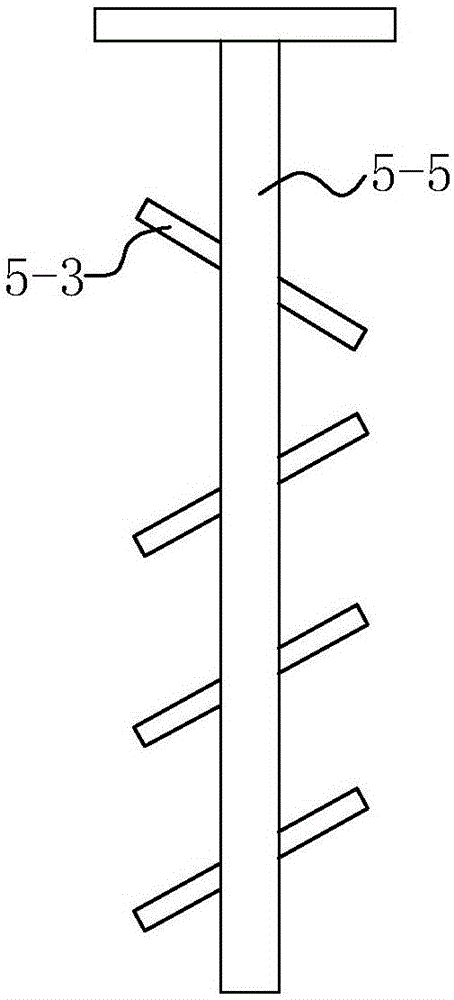

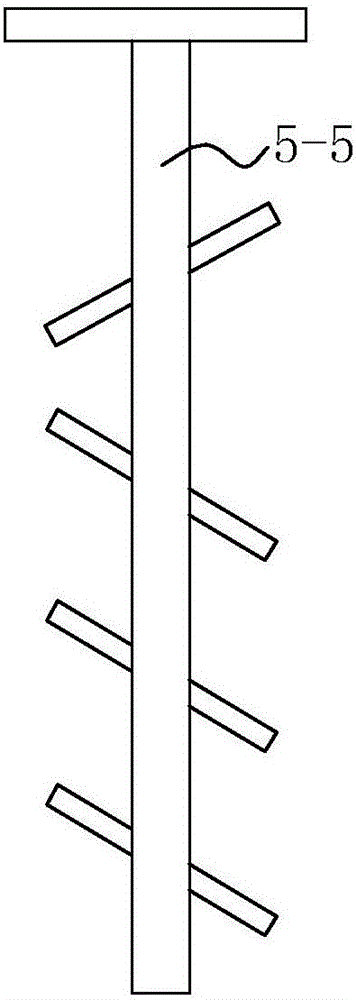

[0020] refer to Figure 1 to Figure 4 , a reaction kettle of the present invention, comprising a kettle body 1 and a kettle cover 2, a motor 3 is arranged on the kettle cover 2, a speed reducer 4 is connected under the motor 3, and the speed reducer 4 is provided with an output shaft , the motor 3 and the speed reducer 4 are all arranged on the top of the kettle cover 2, the motor 3 provides power for the rotation of the reaction paddle 5, but the speed of the motor 3 is too fast, the speed needs to be reduced to the required speed by the speed reducer 4, A reaction paddle 5 is connected under the output shaft of the speed reducer 4. The kettle body 1 includes a closed jacket 6 composed of an outer wall and an inner wall. The reaction paddle 5 includes a first reaction paddle 5-1 and a second reaction paddle 5-1. A second reaction paddle 5-2 with a reaction paddle 5-1 vertically arranged, the first reaction paddle 5-1 and the second reaction paddle 5-2 are all provided with ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com