Patents

Literature

45results about How to "Reduce stirring energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of long carbon chain dibasic acid

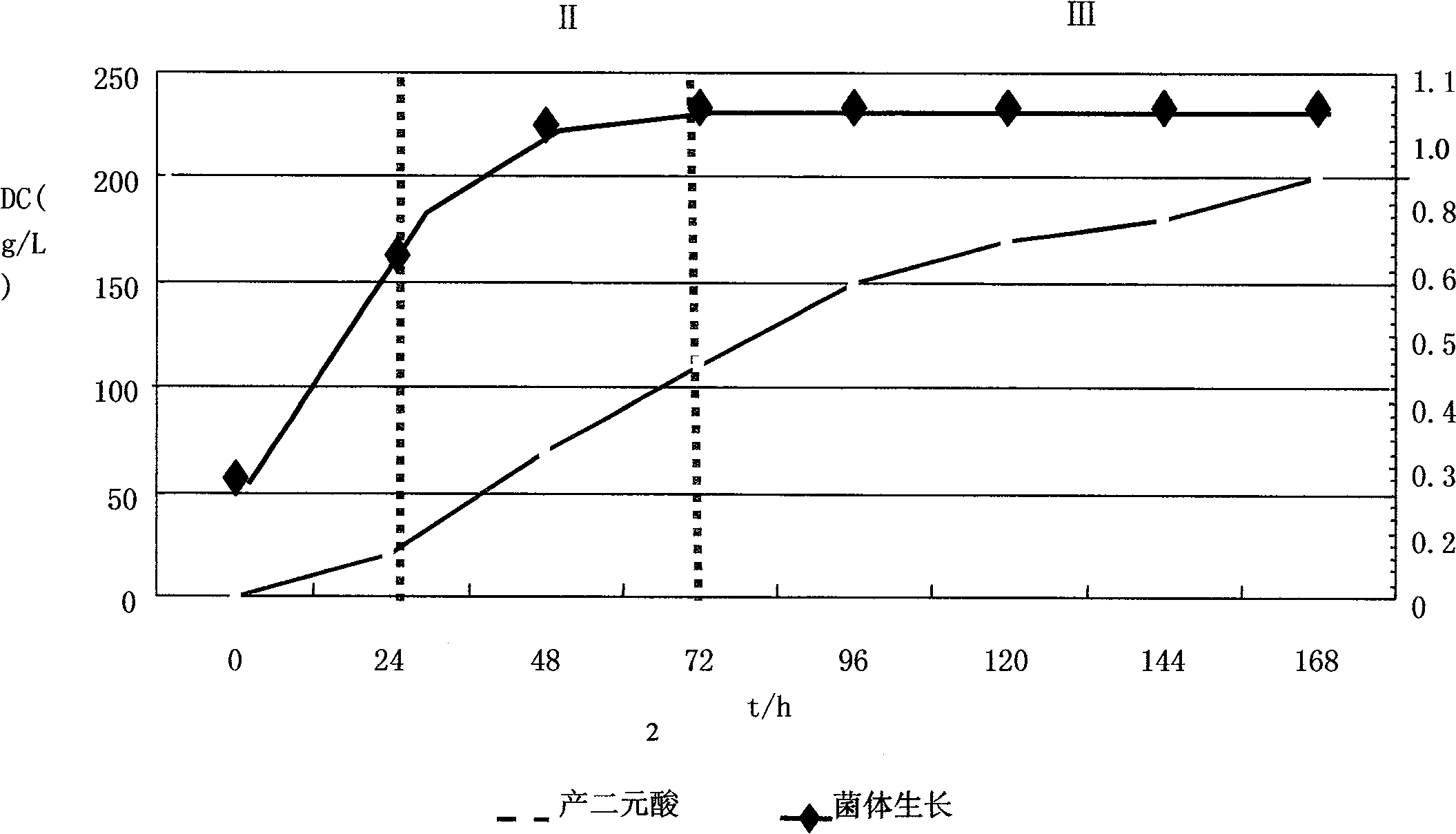

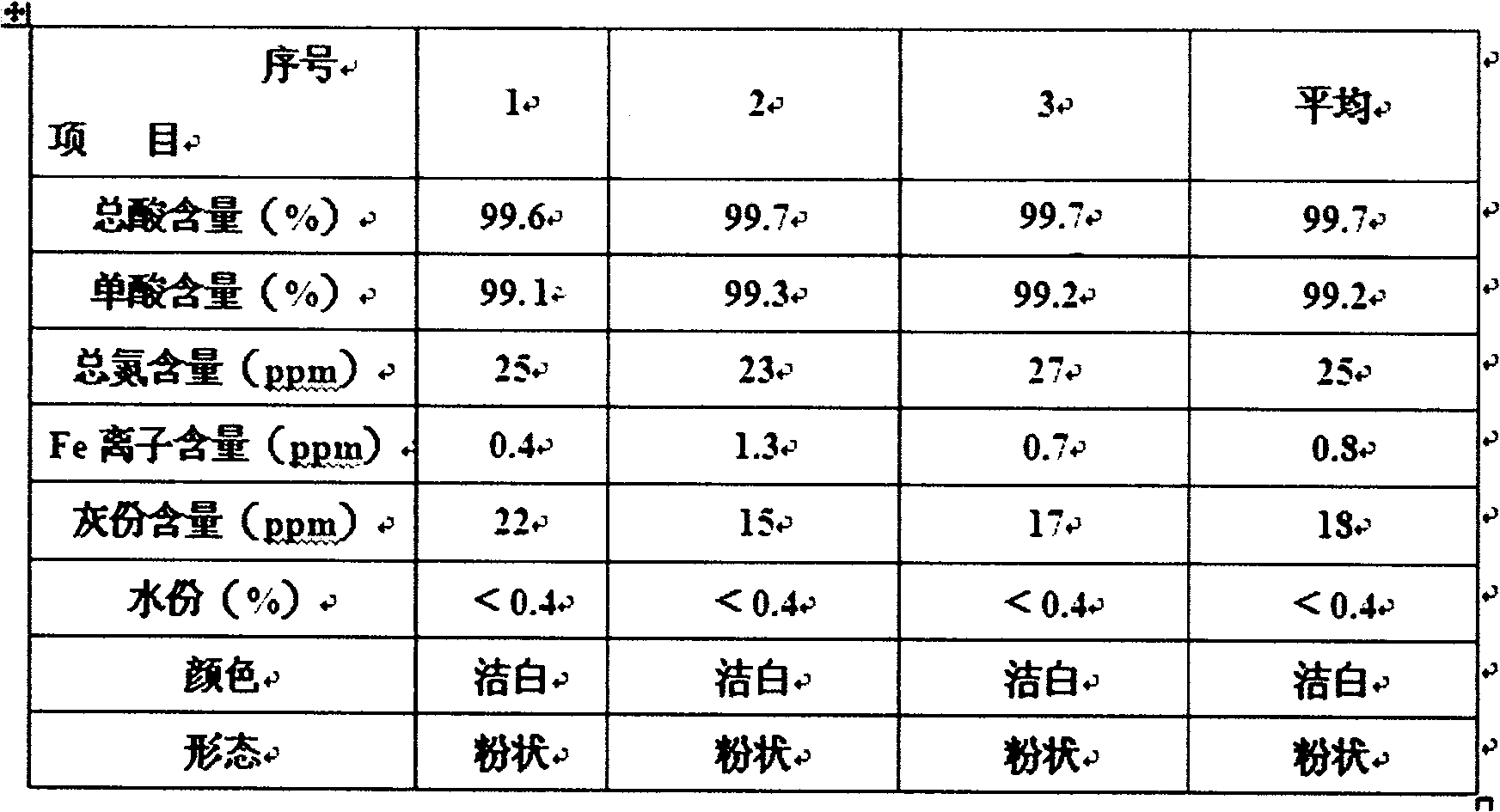

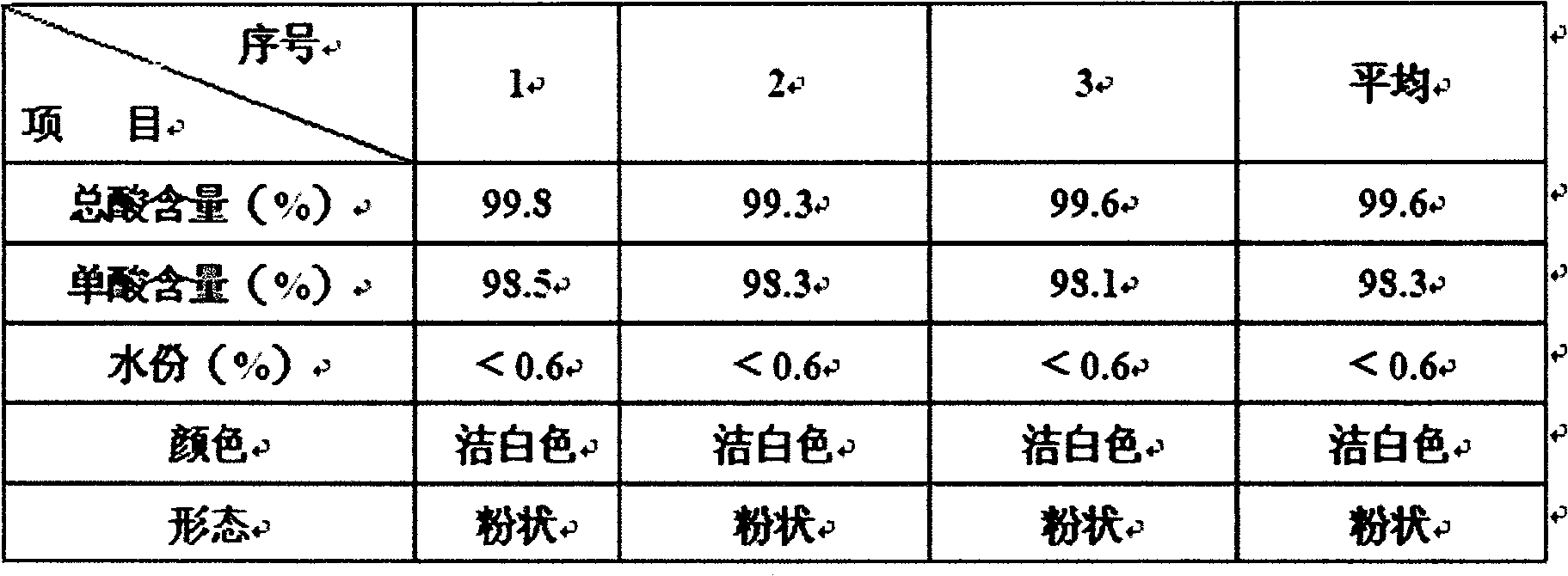

The invention relates to a preparation method of a long carbon chain dibasic acid. C11 and upper alkane is used as a substrate to produce a corresponding long carbon chain dibasic acid product through the conversion of the substrate into the long carbon chain dibasic acid by using a microbial fermentation method as well as the extraction and the separation of fermentation liquid and the refining processes of a crude product of dibasic acid. Through technological innovation and process innovation, the invention researches a new preparation method of the long carbon chain dibasic acid, greatly decreases the production cost of the long carbon chain dibasic acid, improves the yield and the product quality of the long carbon chain dibasic acid, can produce C11 and upper long carbon chain dibasic acid, finally solve the bottleneck problem restricting the rapid development of the long carbon chain dibasic acid, and form the industrialized scale and the technological predominance. The long carbon chain dibasic acid produced by using the bioanalysis provided by the invention has the advantages of high acid generation level, low production cost, good product quality, complete variety, and the like, the prepared long carbon chain dibasic acid product has high single acid content, good light transmission and high thermal stability, can meet the requirements of different clients, and can be used for producing high-grade spices, high-performance engineering plastics, high-temperature dielectric medium, high-grade hot-melt adhesive, coldness-resistant plasticizer, high-grade lubricating oil, high-grade paint, coating, and the like. The invention greatly widens the development space of the downstream products of the long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD +2

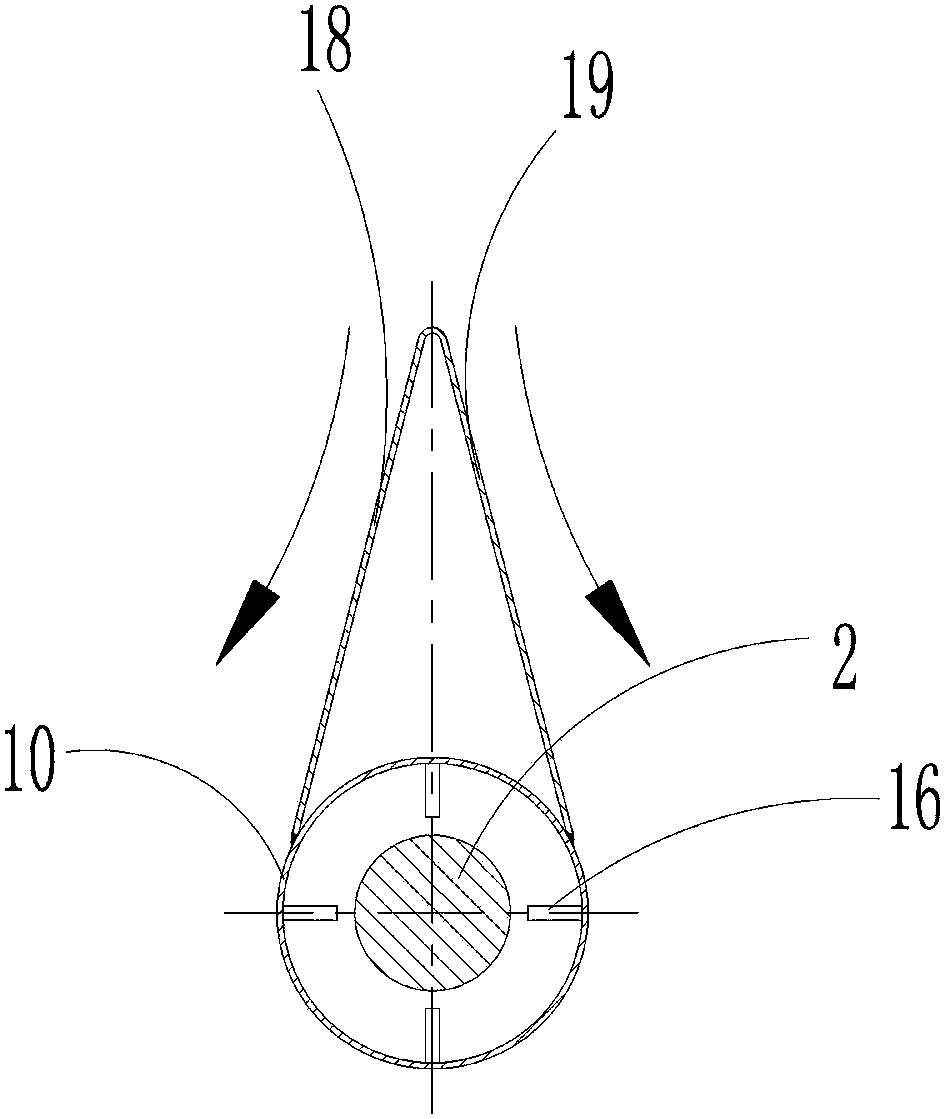

Photobioreactor

ActiveCN102296022AChange shapeDegree of changeBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorCulture fluid

Owner:ENN SCI & TECH DEV

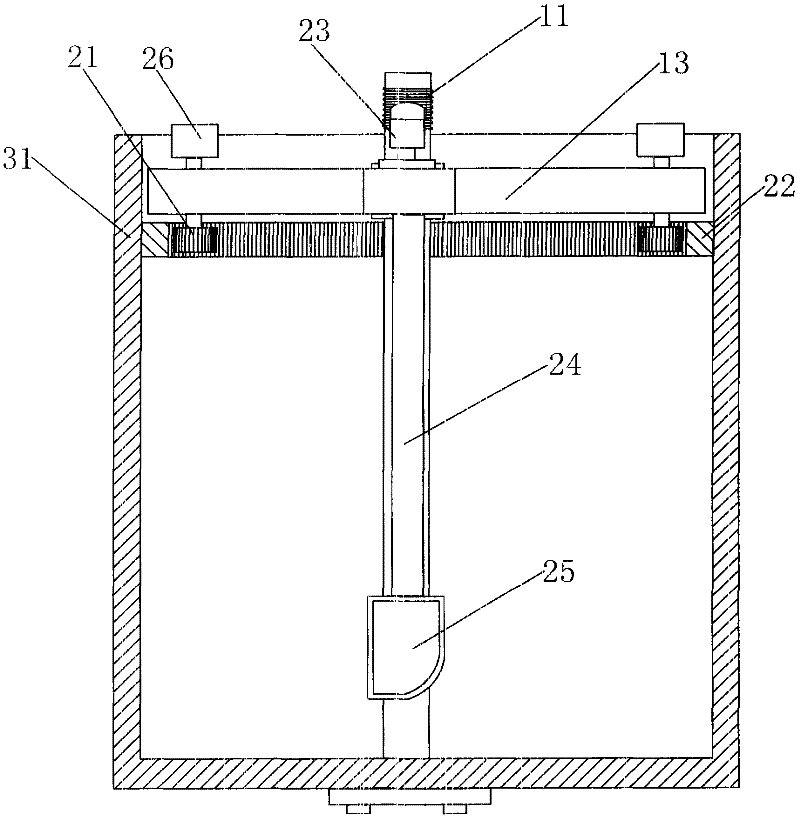

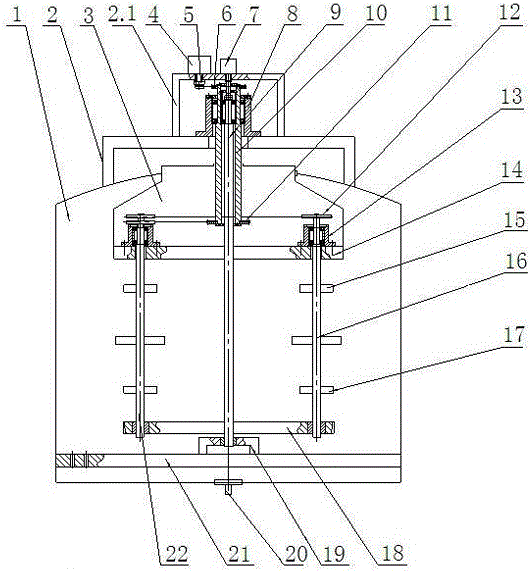

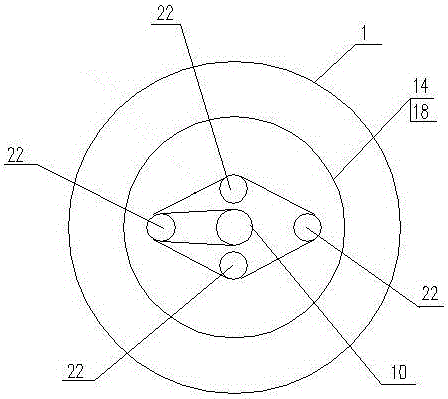

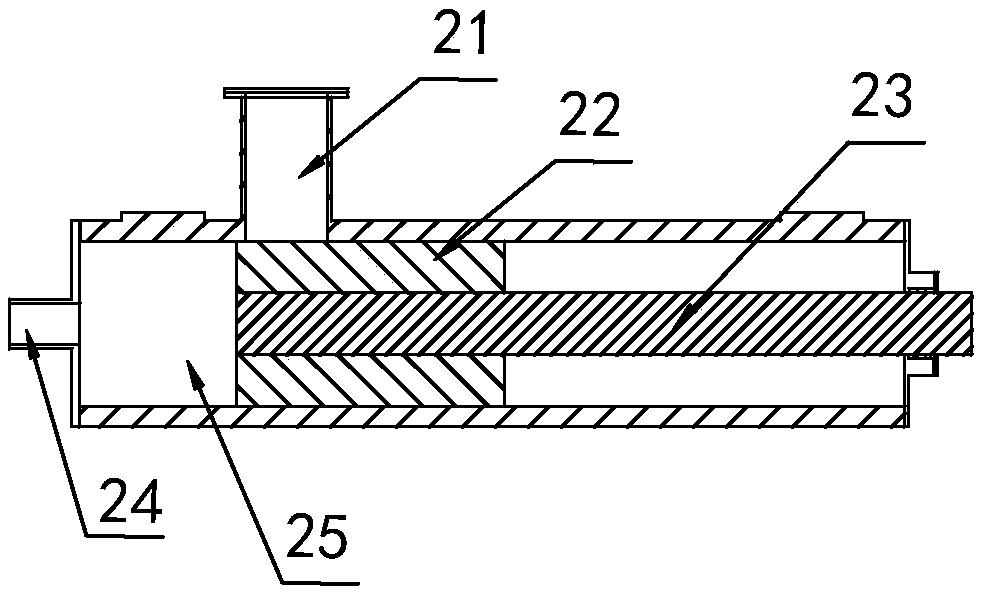

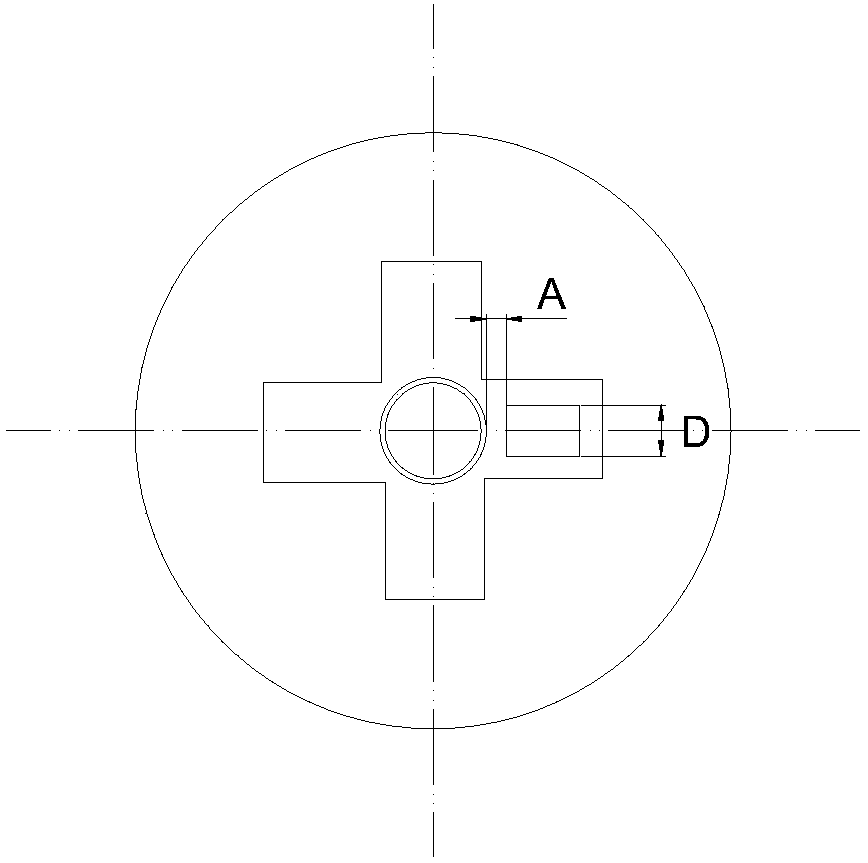

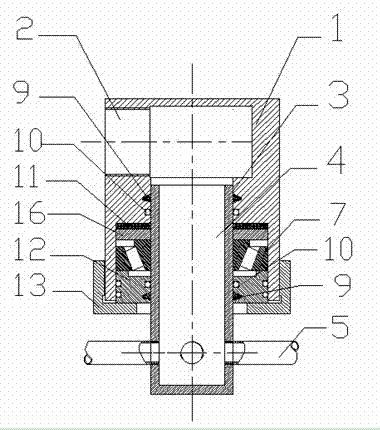

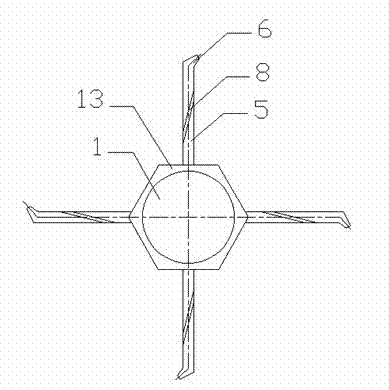

Stirring method and stirring apparatus thereof

InactiveCN102350252AImprove fit stabilityImprove kinetic energy transfer efficiencyRotary stirring mixersEngineeringDrive motor

The invention relates to a stirring method and a stirring apparatus thereof. The stirring method is characterized in that: a main shaft is employed; a revolutional support is arranged on the main shaft; a driving gear is arranged on the revolutional support; and the revolutional support is driven by the driving gear to generate revolution; besides, two secondary driving shafts are arranged on the revolutional support; secondary drive motors are arranged at and are connected with the two secondary driving shafts; and the secondary drive motors are driven by the secondary driving shafts to carry out autoroatation. According to the invention, the stirring method is rapid and is highly effective; and the stability is high and the energy consumption is low; besides, autoroatation and revolution of secondary driving shafts can be effectively realized; meanwhile, independent stirring and driving of a single secondary driving shaft are also supported, so that a demand on mixing and stirring of fluid with different viscosities and non fluid can be met. Moreover, the stirring apparatus has advantages of reasonable structure and design as well as uniform and highly efficient stirring performance; on the basis of combination of autoroatation and revolution of the secondary driving shafts, uniform and highly efficient stirring as well as rapid tank cleaning operation can be realized; and time saving and power saving purposes can be achieved; meanwhile, control on autoroatation and revolution of the secondary driving shafts can be adjusted independently; therefore, stirring work that is suitable for different fluid and materials can be realized.

Owner:吴振军

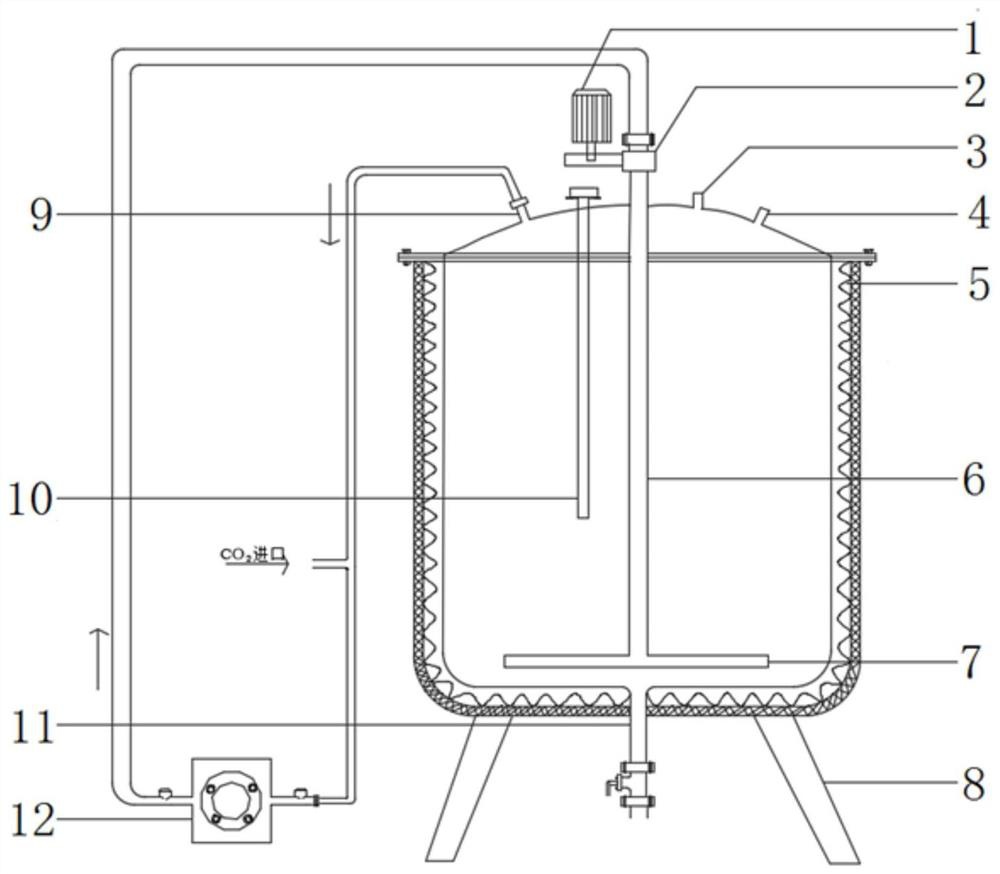

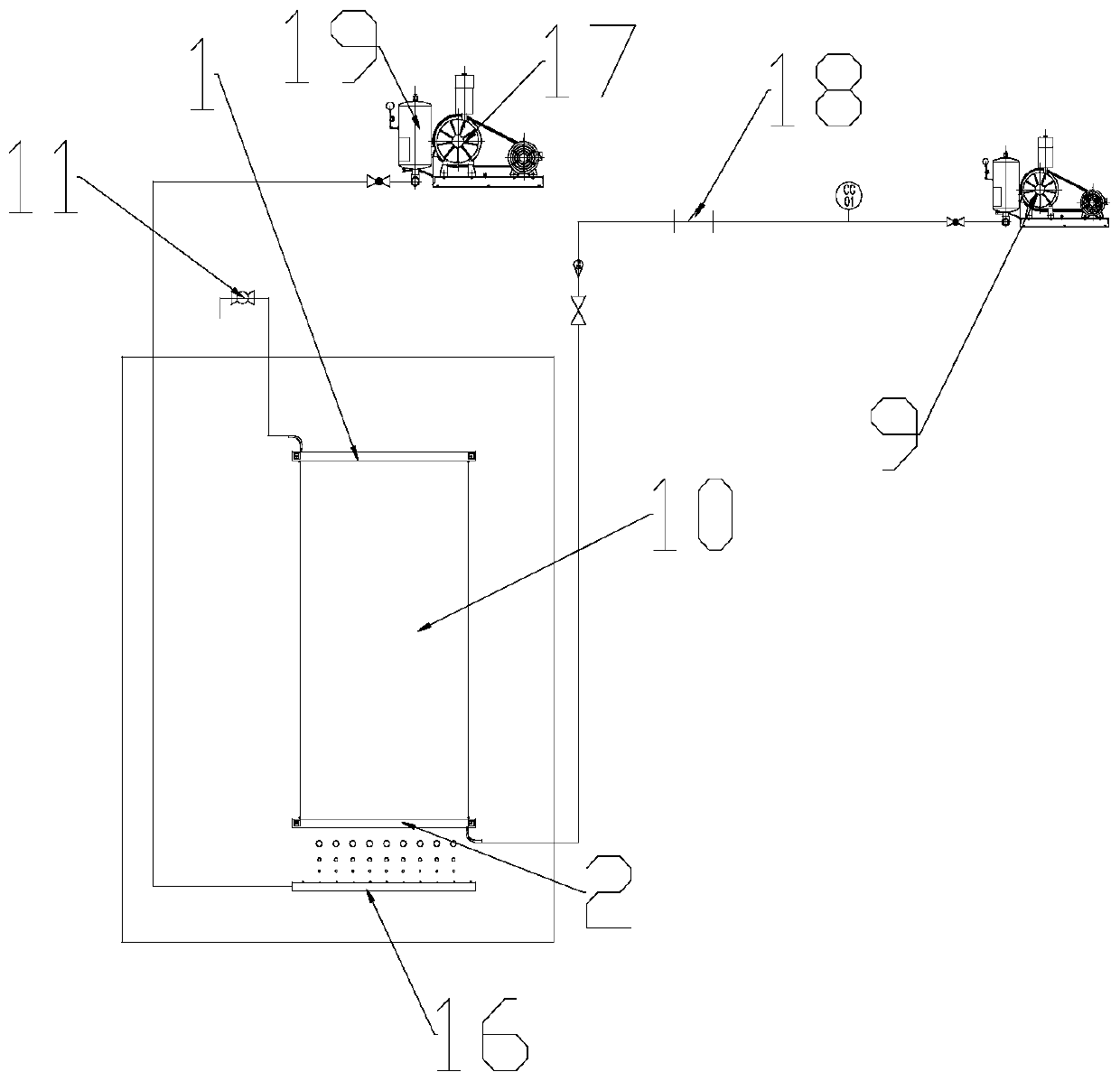

Fly ash washing device based on carbon dioxide hardening and tempering, and method

PendingCN112275782ALower pHPromote dissolutionSolid waste disposalTransportation and packagingTemperingFly ash

The invention discloses a fly ash washing device based on carbon dioxide hardening and tempering, and a method. The device comprises a stirring tank body and a stirring device arranged in the stirringtank body, wherein the stirring device comprises a hollow stirring rod and hollow stirring blades; the hollow stirring rod is a hollow shaft body; the bottom end of the hollow stirring rod is communicated with the hollow stirring blades; the multiple hollow stirring blades are evenly arranged around the bottom end of the hollow stirring rod in the circumferential direction of the hollow stirringrod; air holes, water drainage pipes and injection pipes are arranged on blades of the hollow stirring blades; and a carbon dioxide circulating pipeline is also arranged outside the stirring tank body. According to the fly ash washing device based on carbon dioxide hardening and tempering, and the method, the pH of water is reduced through carbon dioxide, so that dissolution of chlorine salt withlow water solubility is promoted, meanwhile, dissolution of heavy metal and calcium is reduced, and the effects of saving energy consumption and strengthening component separation are achieved.

Owner:NANJING NORMAL UNIVERSITY +1

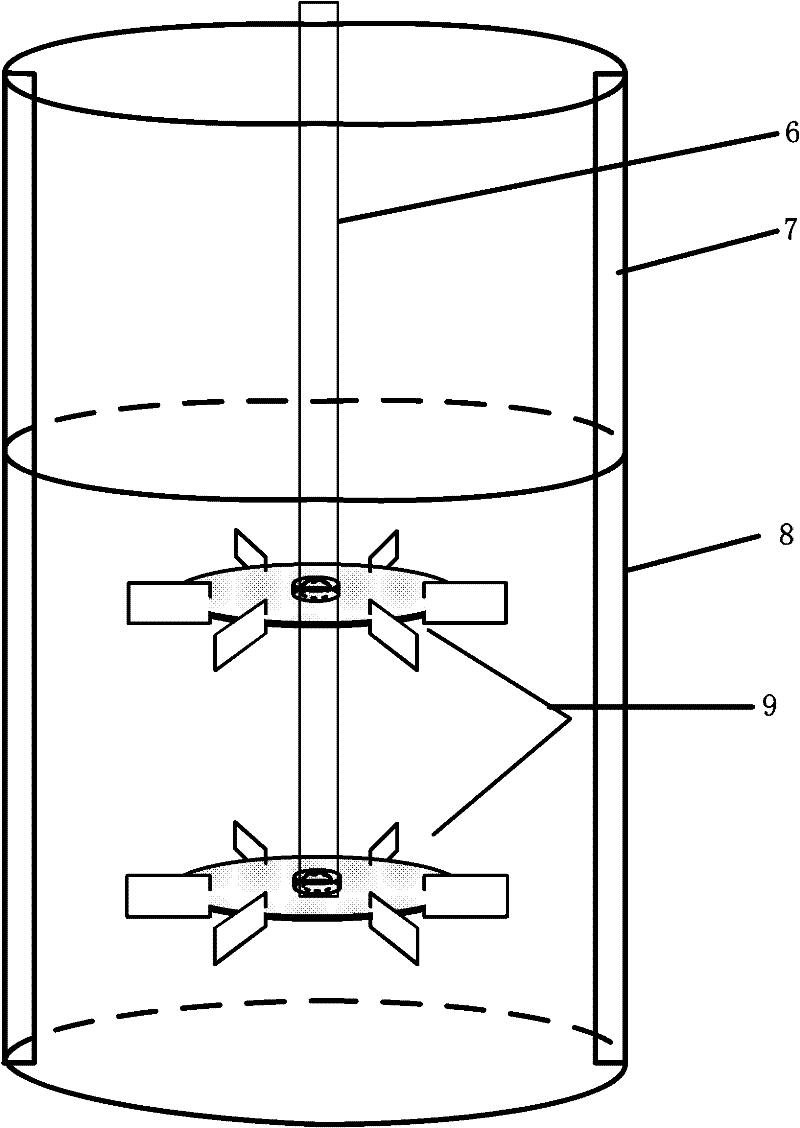

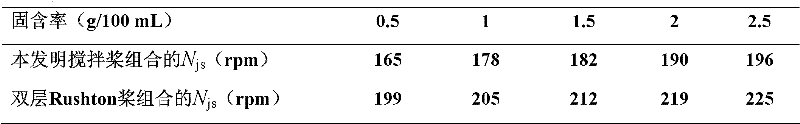

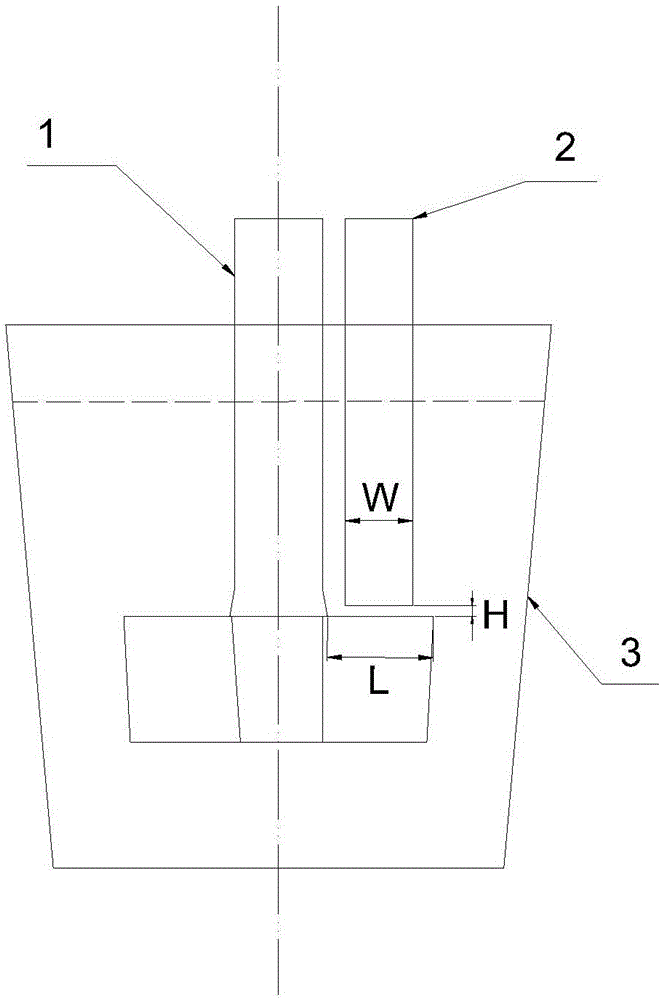

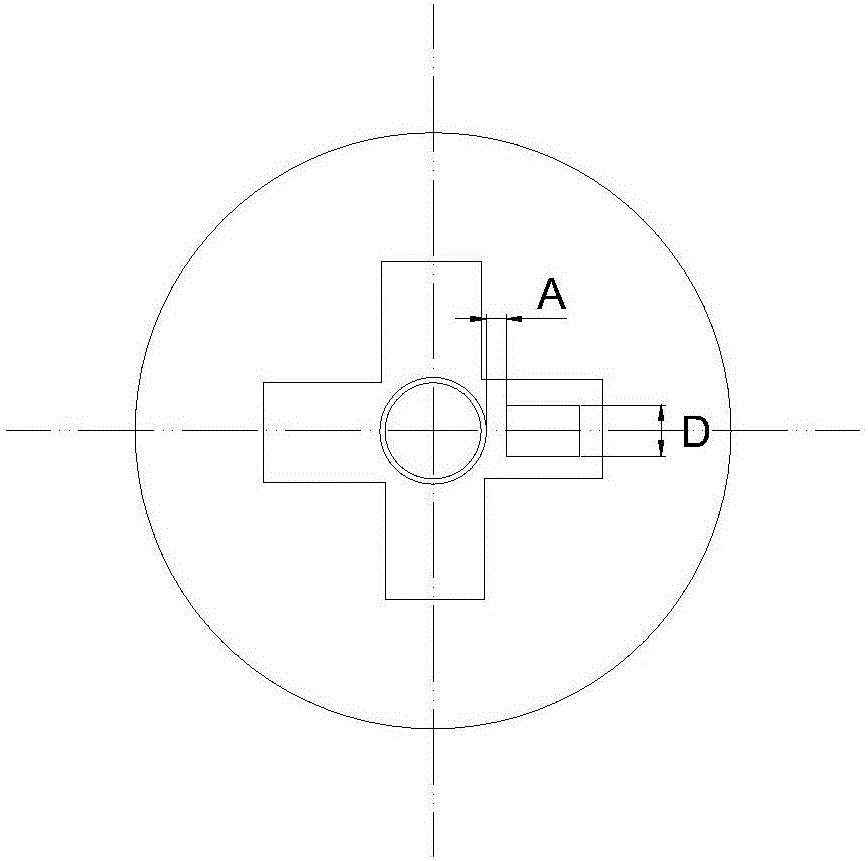

Double-layer stirring paddle combination device

InactiveCN102350250AGood suspensionImprove cycle performanceRotary stirring mixersTransportation and packagingCircular discEngineering

The invention relates to a double-layer stirring paddle combination device comprising a stirring shaft, wherein an offset paddle and a centripetal paddle are sequentially installed at the stirring shaft from top to bottom. Compared with a traditional combined stirring paddle, the double-layer stirring paddle combination device is characterized in that the upper part of the stirring shaft is provided with the offset paddle, paddle blades are vertically and evenly distributed above and below a disk in a staggered way, and vanes are installed on the disk along a radial direction; and the lower part of the stirring shaft is provided with the centripetal paddle, and paddle blades are pitched at 20 to 70 degrees towards a rotating direction in comparison with the radial direction of the disk. The combined paddle is beneficial to lowering the stirring energy consumption, reducing the mixing time and increasing the axial circulation capability, thereby improving liquid-solid suspension.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

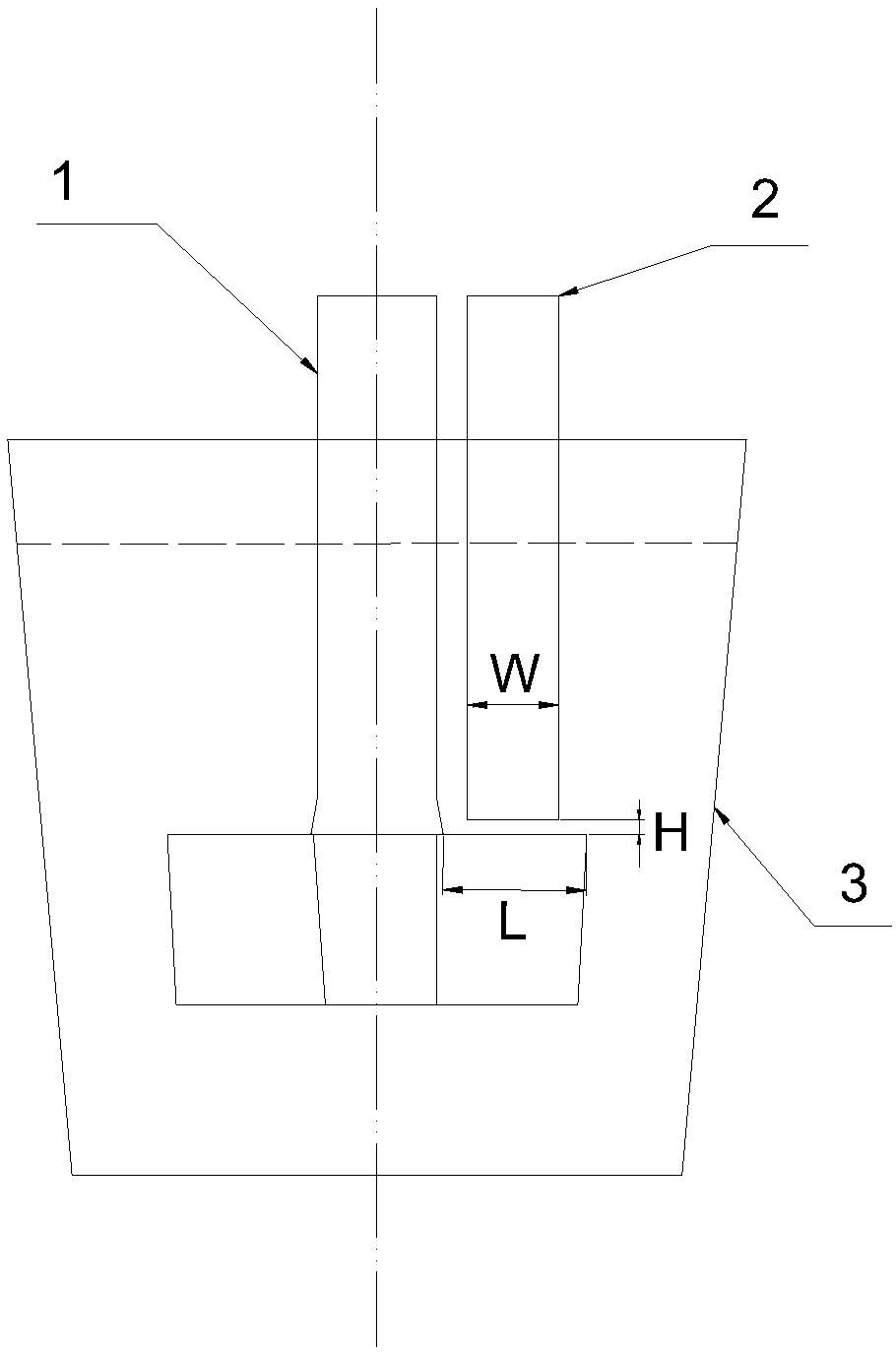

Mechanical agitation desulphurization method for molten iron desulphurization pretreatment

The invention discloses a mechanical agitation desulphurization method for molten iron desulphurization pretreatment. The desulphurization method includes five steps including prior sample taking for temperature measurement, prior slag scrabbling, desulfurizing agent adding and agitation, later slag scrabbling and later sample taking for temperature measurement. In the steps of desulfurizing agent adding and agitation, an agitation device is inserted into a molten iron tank containing molten iron, and is composed of an agitator and a guide plate, and the guide plate and the agitator are both vertically instead into the molten iron; and the vertical distance between the bottom of the guide plate and the top of a blade of the agitator is H. Compared with the rotating speed of a conversional KR method, the rotating speed of the agitator is decreased by 10% to 20%; and the insertion depth of the agitator is increased by 10% to 30% compared with the insertion depth of the conversional KR method.

Owner:武汉钢铁有限公司

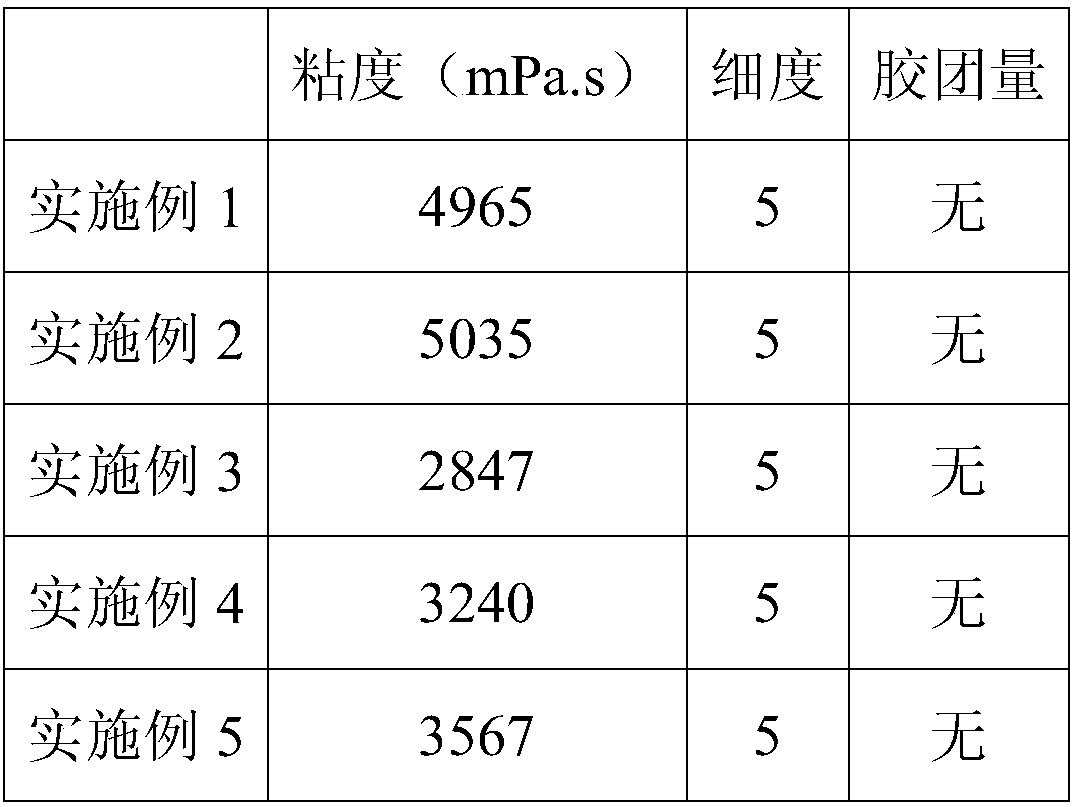

Method for preparing lithium ion battery electrode slurry by using vibration-mechanical stirring combination

InactiveCN108400287AImprove dispersion uniformityEvenly dispersedElectrode manufacturing processesSlurrySolvent

The invention discloses a method for preparing lithium ion battery electrode slurry by using vibration-mechanical stirring combination, comprising the following steps of: S1: mixing active materials,binders and conductive agents for vibration stirring for 0.5 to 1h, and continuously adding the solvent by spraying during the vibration stirring process; S2: continuing the vibration stirring for 0.5to 1hour after the solvent is added; and S3: finally performing the vacuum mechanical stirring for 0.5 to 2 hours to obtain the lithium ion battery electrode slurry. The method has simple operation steps, improves production efficiency and reduces energy consumption. The obtained lithium ion battery electrode slurry has suitable viscosity, good dispersibility and fineness, and the prepared lithium ion battery has excellent performance.

Owner:安徽益佳通电池有限公司

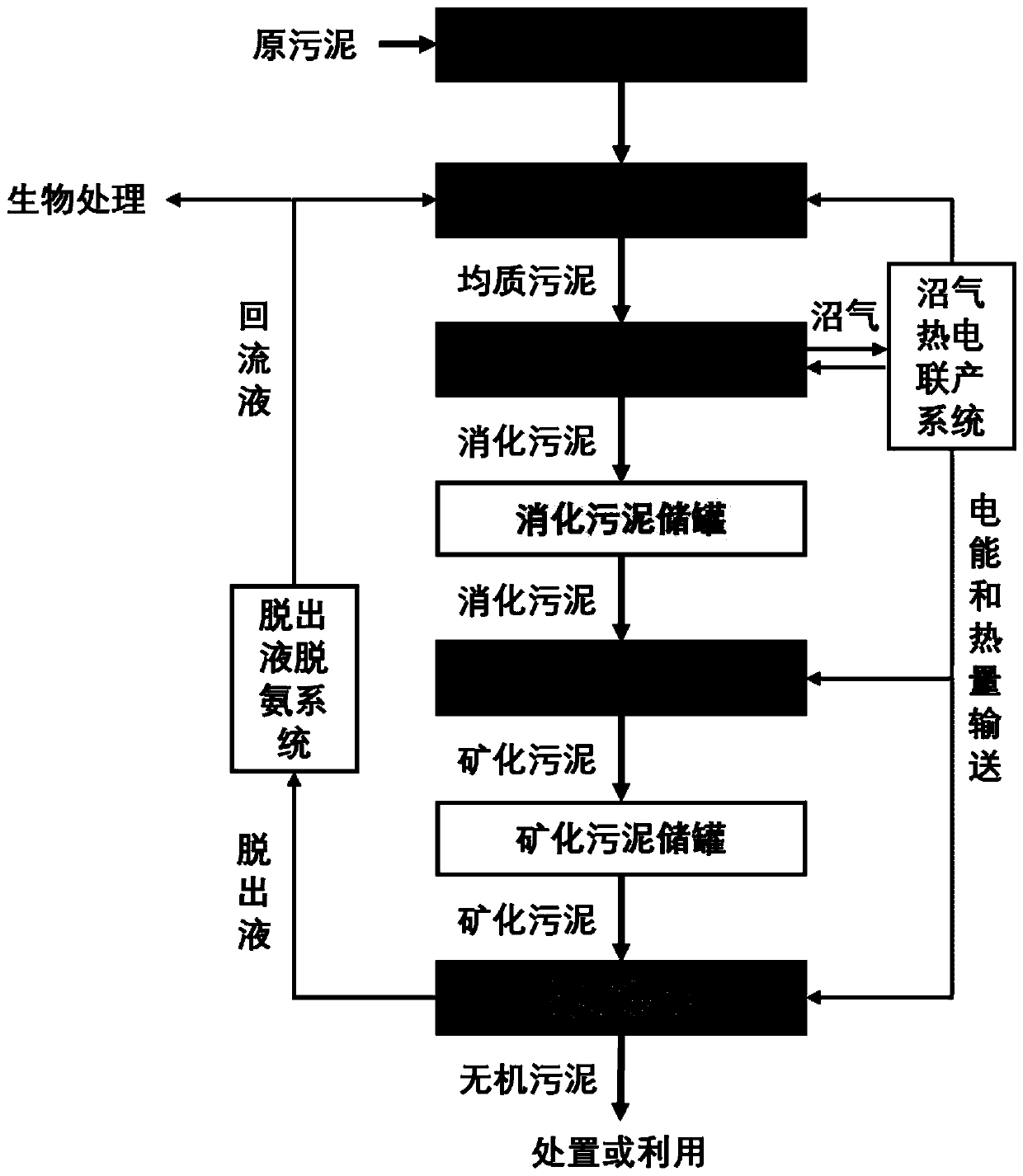

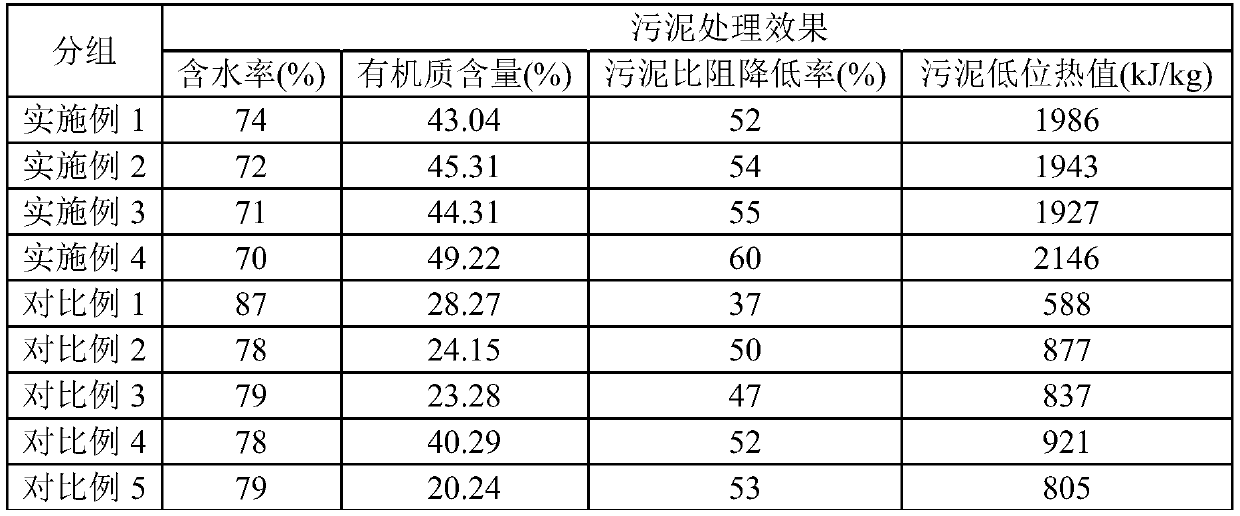

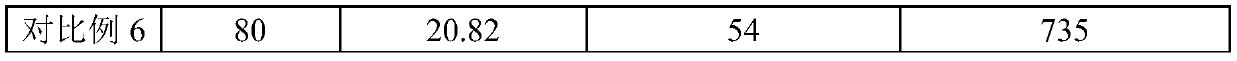

Sludge separation treatment method

ActiveCN109867428ASolve viscositySolve the difficulty of stirringSludge treatment by oxidationSludge treatment by pyrolysisMoistureSolid phases

The invention discloses a sludge separation treatment method. The method comprises the following steps: S1: conveying raw sludge into a low-temperature pyrohydrolysis reactor, introducing a backflow liquid generated in a step S5 into the low-temperature pyrohydrolysis reactor, carrying out a low-temperature pyrohydrolysis reaction to obtain hydrolyzed homogenized sludge; S2, conveying the homogenized sludge to a high-solid anaerobic digestion reactor to carry out a high-solid anaerobic digestion reaction, and discharging digested sludge; S3, conveying the digested sludge to a wet-type catalytic air oxidation reactor, adding a catalyst, and carrying out a wet-type catalytic air oxidation reaction to obtain mineralized sludge; S4, conveying the mineralized sludge to a dewatering device, andseparating the solid phase and moisture to separately obtain inorganic sludge and a separated liquid; and S5, carrying out deamination treatment on the separated liquid to obtain the backflow liquid,and conveying the backflow liquid to the low-temperature pyrohydrolysis reactor in the step S1. According to the method, coordinated distribution of substances and energy is realized, great reductionof the sludge can be realized at relatively low cost, and inorganic residues are convenient to dispose.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

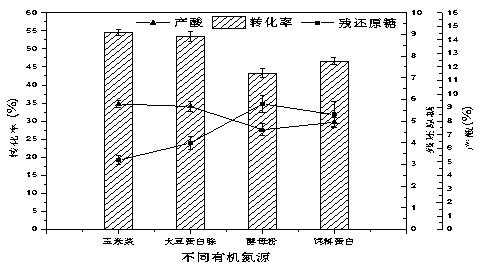

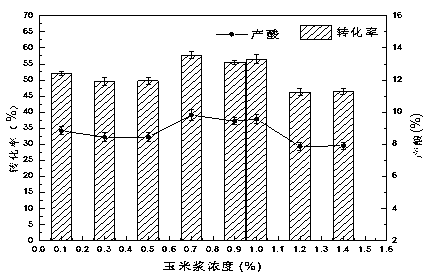

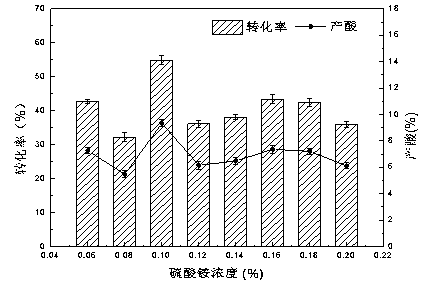

A citric acid-producing microorganism strain and a method for producing citric acid by fermenting starch sugar thereof

ActiveCN109207373AIncrease productionSimple production processFungiMicroorganism based processesMicroorganismSugar

The invention discloses a citric acid-producing microorganism strain and a method for producing citric acid by fermenting starch sugar thereof. The strain is Aspergillus niger 101-HAC11 with an accession number of No. CGMCC No. 12480. At that same time, a culture medium formula and a fermentation process control process for producing citric acid by using starch sugar as carbon source are also disclosed. The yield of citric acid produced by the strain is 166.8 g / L. Compared with the prior art, the citric acid yield of the recombinant Aspergillus niger strain is 220.34 g / L, and the yield is increased by 32.10%. The method has the characteristics of high speed, simple production process, non-toxic residue and high safety.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

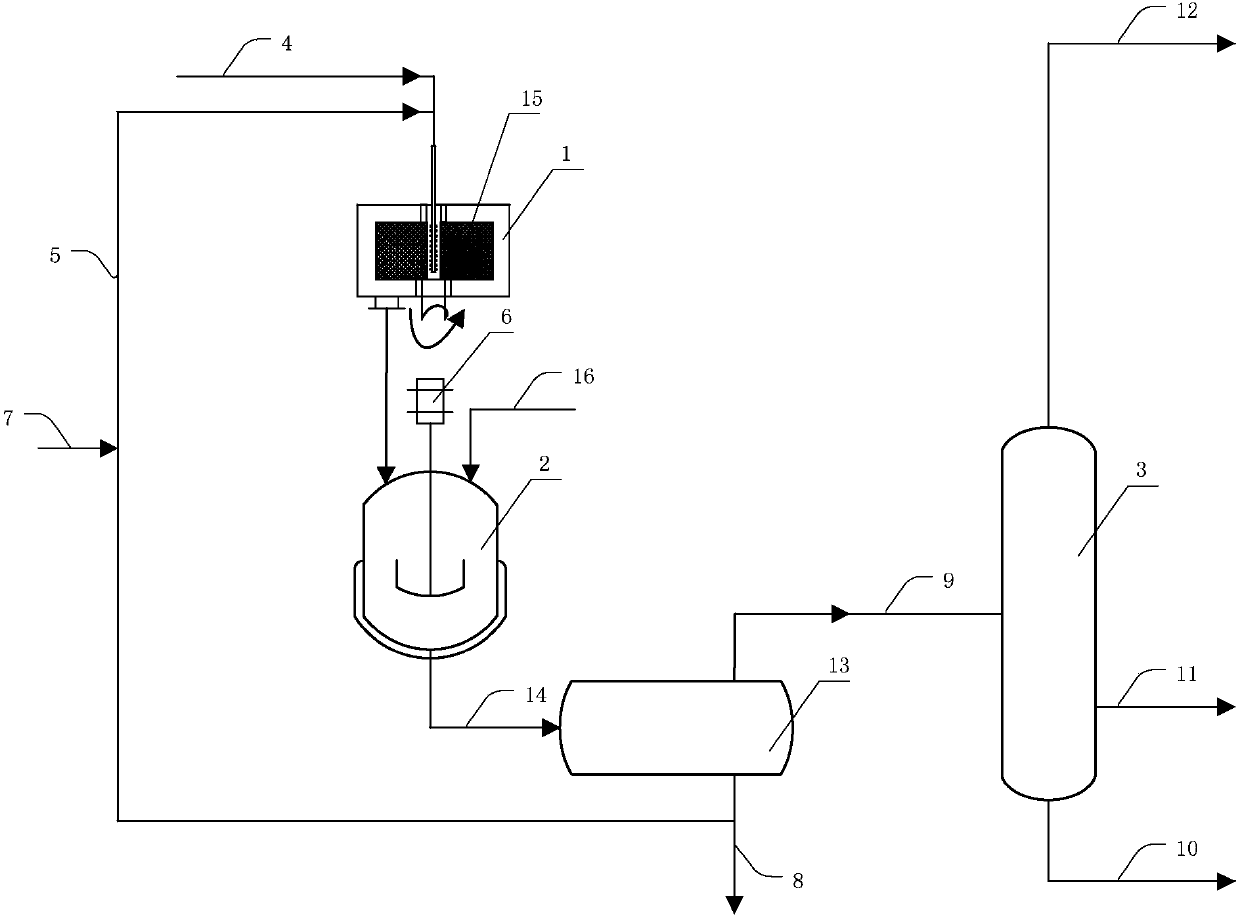

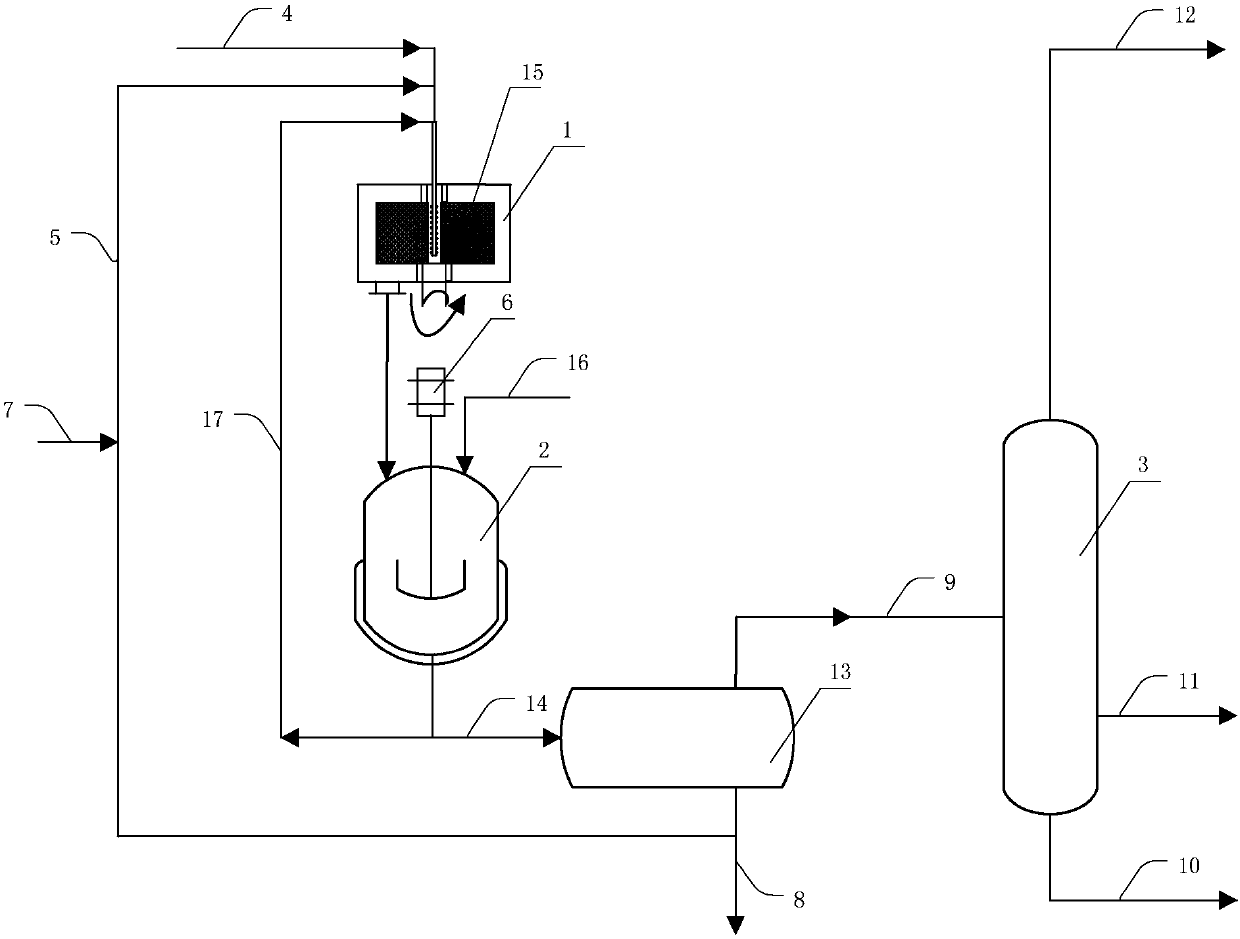

Alkylation method for isobutane and C3-C5 olefins

ActiveCN107867966AExtension of timeBoost octaneCatalystsHydrocarbon preparation catalystsReaction temperatureAlkylation

The invention discloses an alkylation method for isobutane and C3-C5 olefins. The method comprises the following steps: S1, raw hydrocarbon containing isobutane and C3-C5 olefins as well as a catalystsulfuric acid are added to a liquid-liquid separation device, acid hydrocarbon emulsion with average diameter of dispersed-phase droplets smaller than 20 mu m is formed, dispersed isobutane, C3-C5 olefins and the catalyst sulfuric acid are subjected to a contact reaction at the temperature of subzero 5 DEG C-4 DEG C, and a mixed reaction material containing unreacted raw hydrocarbon, a reaction product and sulfuric acid is formed at an outlet of the liquid-liquid separation device; S2, the reaction material in S1 enters a stirring reactor for continuous reaction at the temperature of 5-20 DEGC; S3, alkylated oil is separated from a reaction product in S2. Alkylation reaction time when acid hydrocarbon is highly dispersed can be prolonged, adverse impact of incomplete reaction on octane value of the alkylation product is reduced, and the octane value of the alkylation product is increased.

Owner:PETROCHINA CO LTD

Aquatic plant recycling method

InactiveCN105418175AReduced fertilityAlleviate ecological problems such as deterioration of soil physical and chemical propertiesBio-organic fraction processingClimate change adaptationEnvironmental engineeringBiology

The invention discloses an aquatic plant recycling method. The method comprises the following steps: 1, producing a botanical feed: 1-1) preprocessing a raw material; 1-2) producing a feed; and 1-3) nursing livestock and poultry; 2, producing biomass energy: 2-1) carrying out retting pretreatment; 2-2) mixing raw materials; 2-3) carrying out dry anaerobic fermentation; and 2-4) carrying out biogas comprehensive utilization; and 3, producing a high-efficiency multi-bacterial composite ecologic fertilizer: 3-1) preparing raw materials; 3-2) mixing and proportioning the raw materials; 3-3) carrying out high-temperature aerobic composting; 3-4) carrying out medium-temperature aerobic composting; and 3-5) mechanically granulating the obtained product, and packaging the granulated product. Aquatic plant wastes are adopted as the raw material, so the environment problems brought by landfill, onsite stacking or burning and other common aquatic plant waste disposing means are solved, the aquatic plant recycling mode is enriched, and values of aquatic plants are fully shown.

Owner:广东景泽生态环境股份有限公司

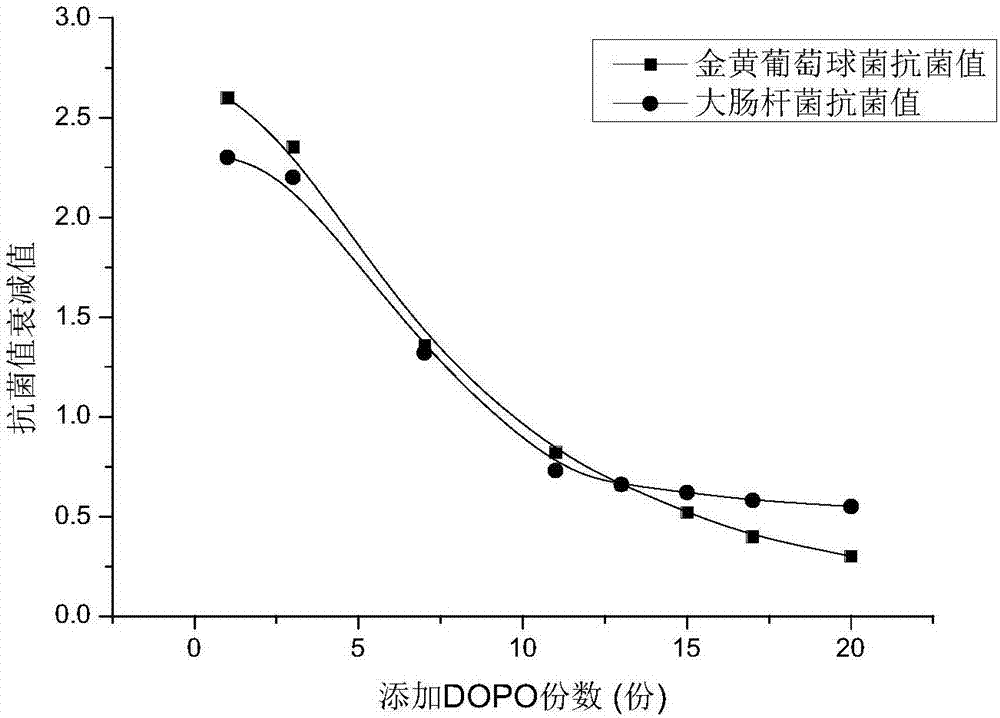

Antibacterial TPE (Thermoplastic Elastomer) and preparation method thereof

InactiveCN107987538AStrong reductionSlow down the antibacterial effectThermoplastic elastomerFire retardant

The invention relates to antibacterial plastics and discloses an antibacterial TPE (Thermoplastic Elastomer) and a preparation method thereof. The antibacterial TPE comprises the following componentsin parts by weight: 50-60 parts of SBES, 20-60 parts of PP, 60-80 parts of white oil, 5-15 parts of an antibacterial agent, 0.1-20 parts of a flame retardant DOPO and 2-4 parts of a UV-resistant agent, wherein the antibacterial agent is composed of one or more than one of quaternary ammonium salt, chitosan and sorbic acid. The antibacterial TPE has an effect of retarding reduction of the antibacterial effect of the antibacterial TPE along with oxidation time.

Owner:余姚优信塑业有限公司

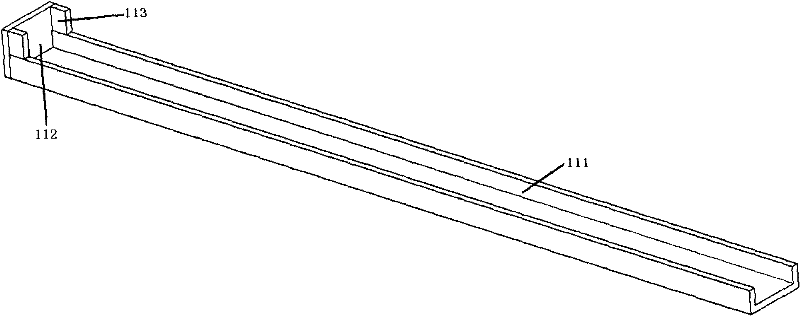

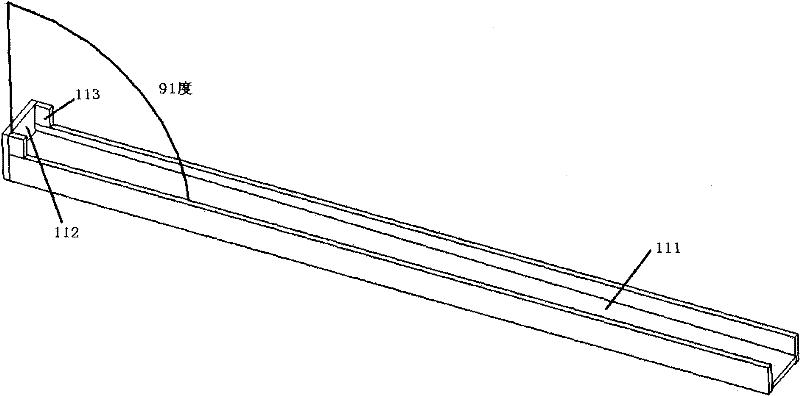

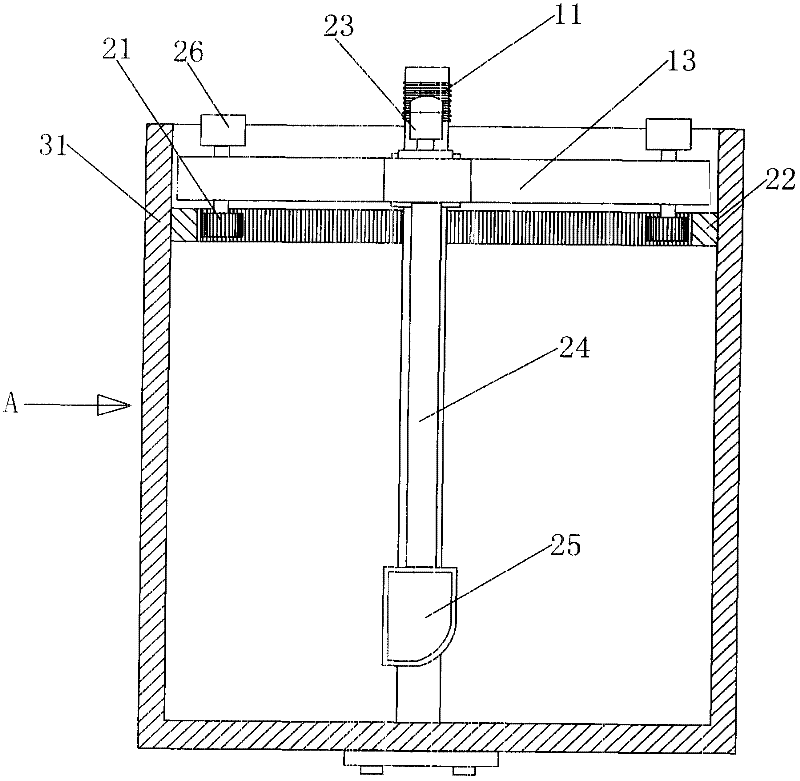

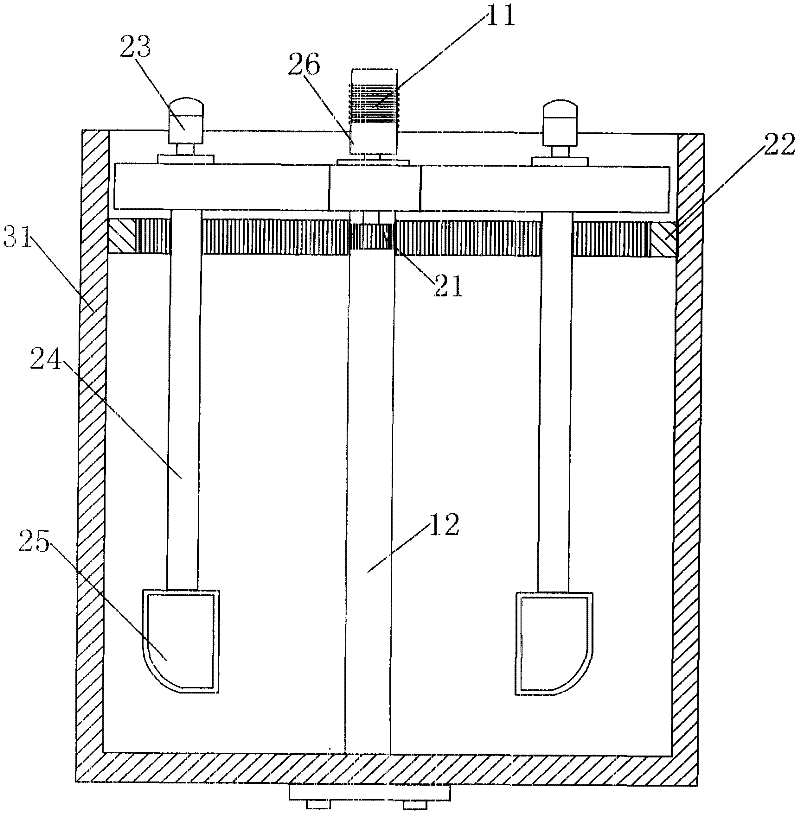

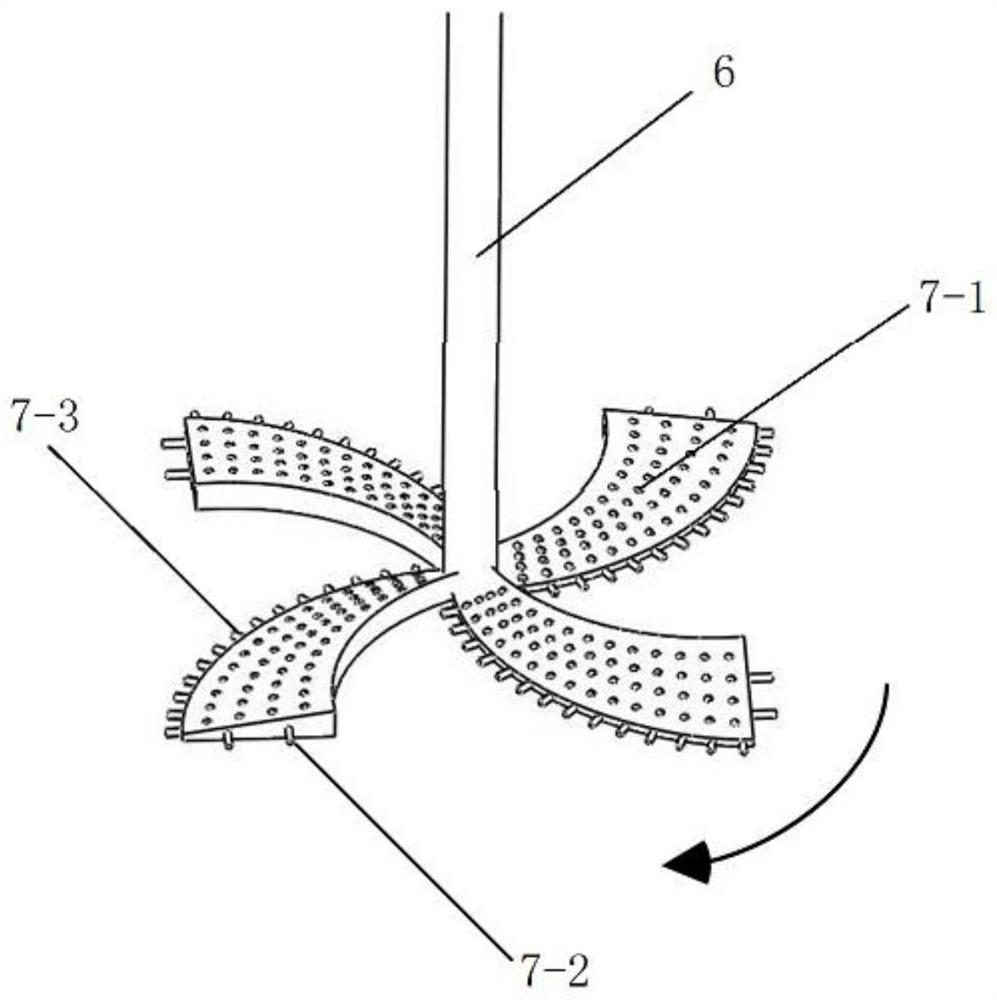

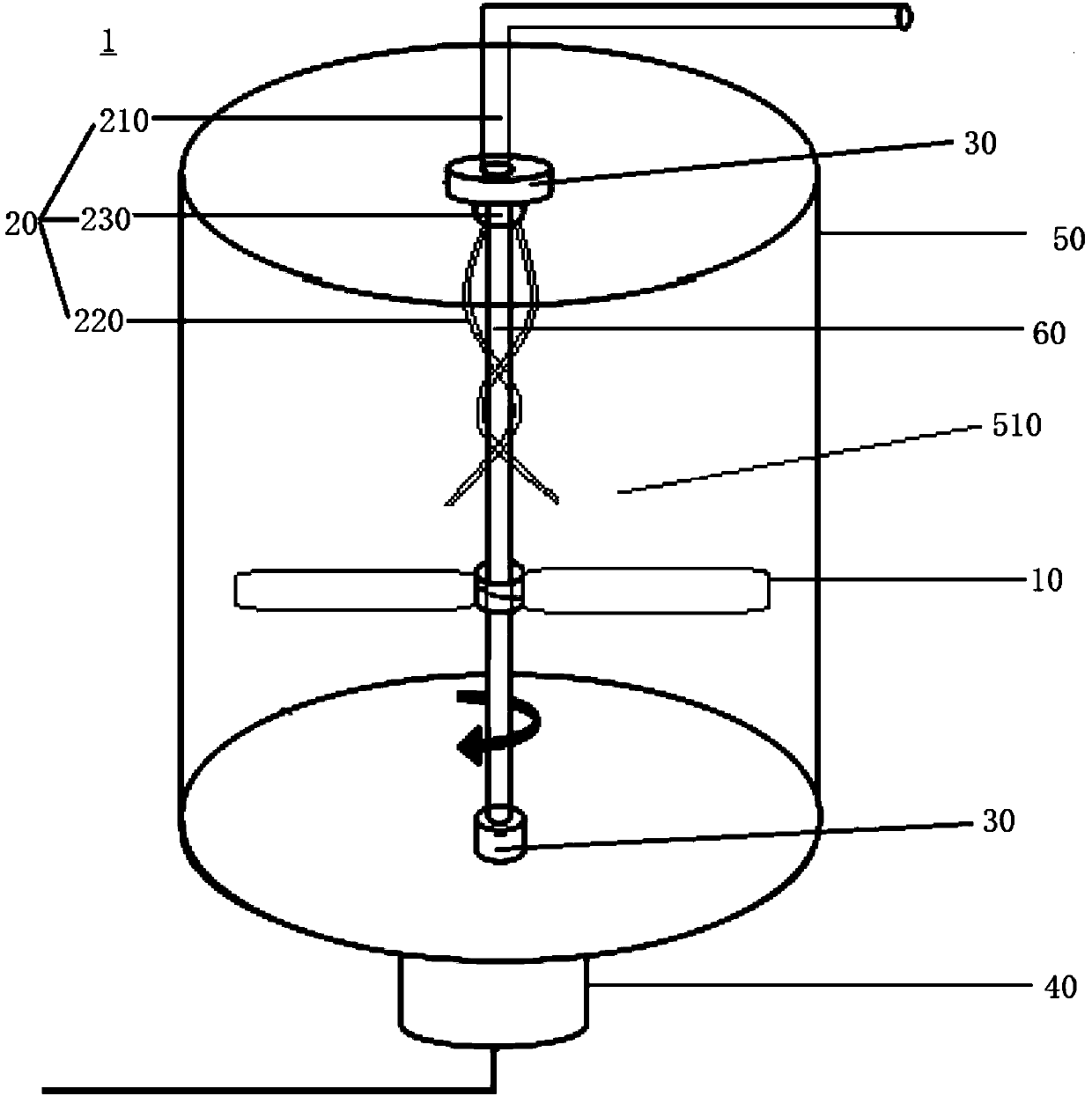

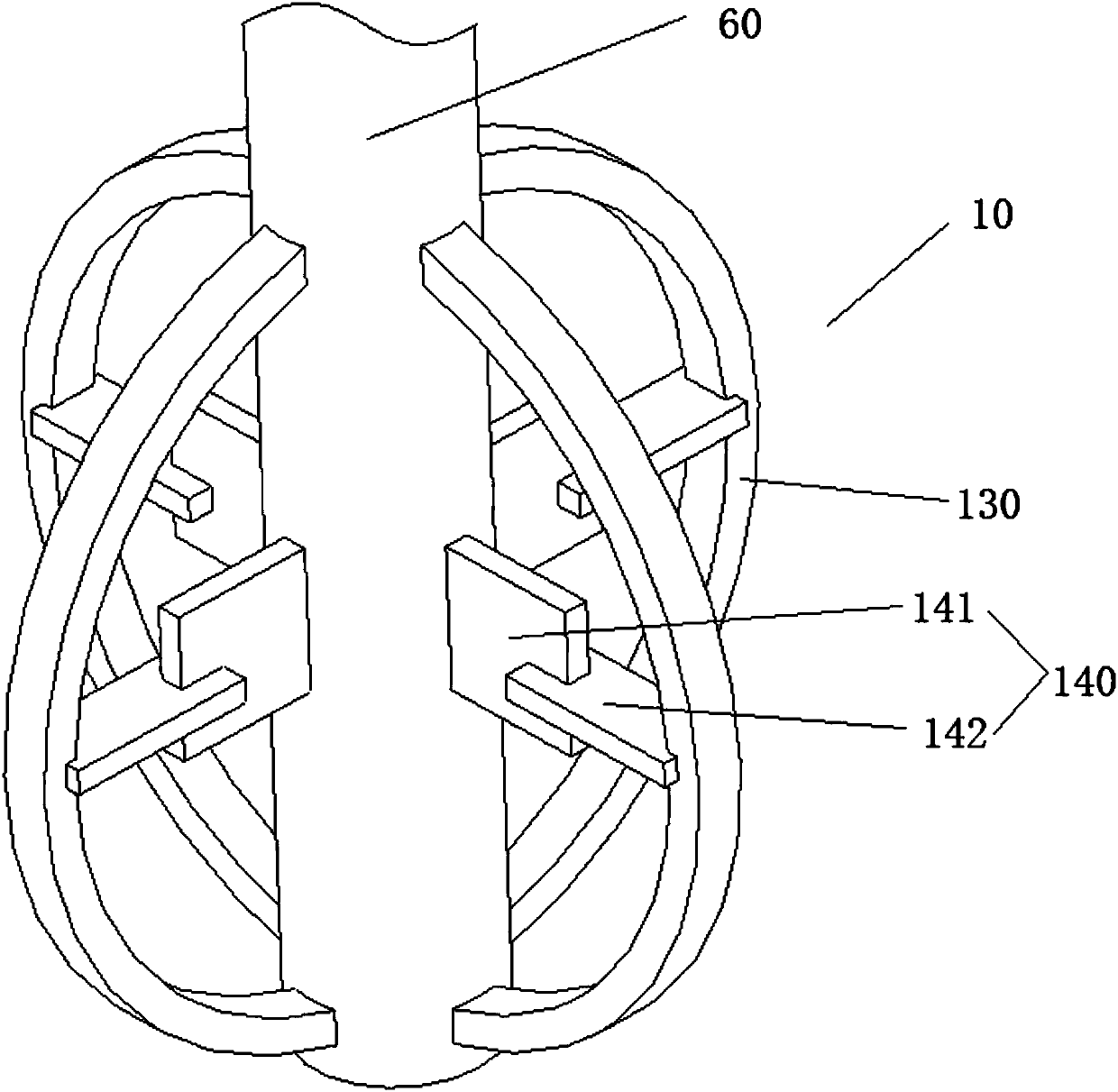

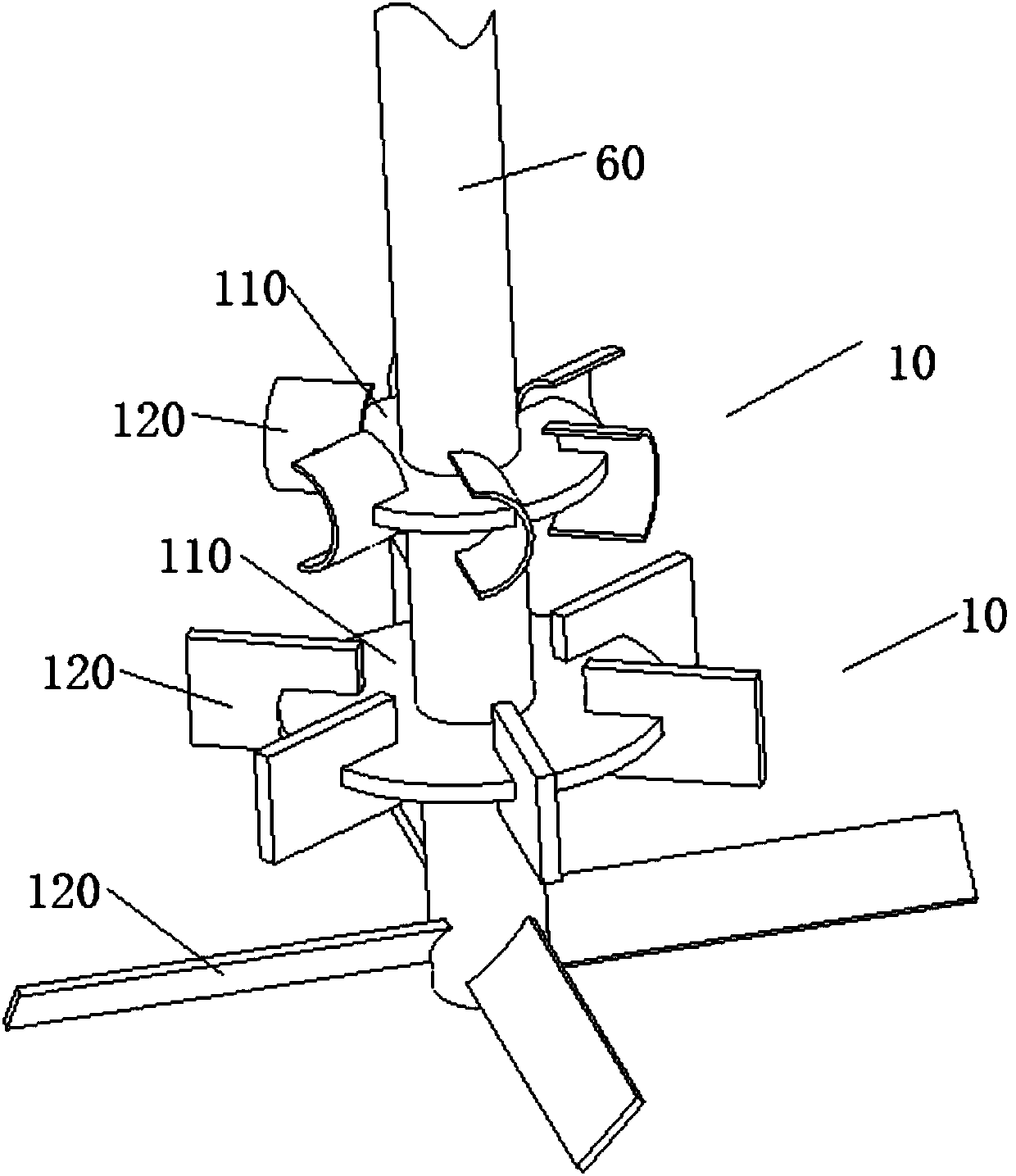

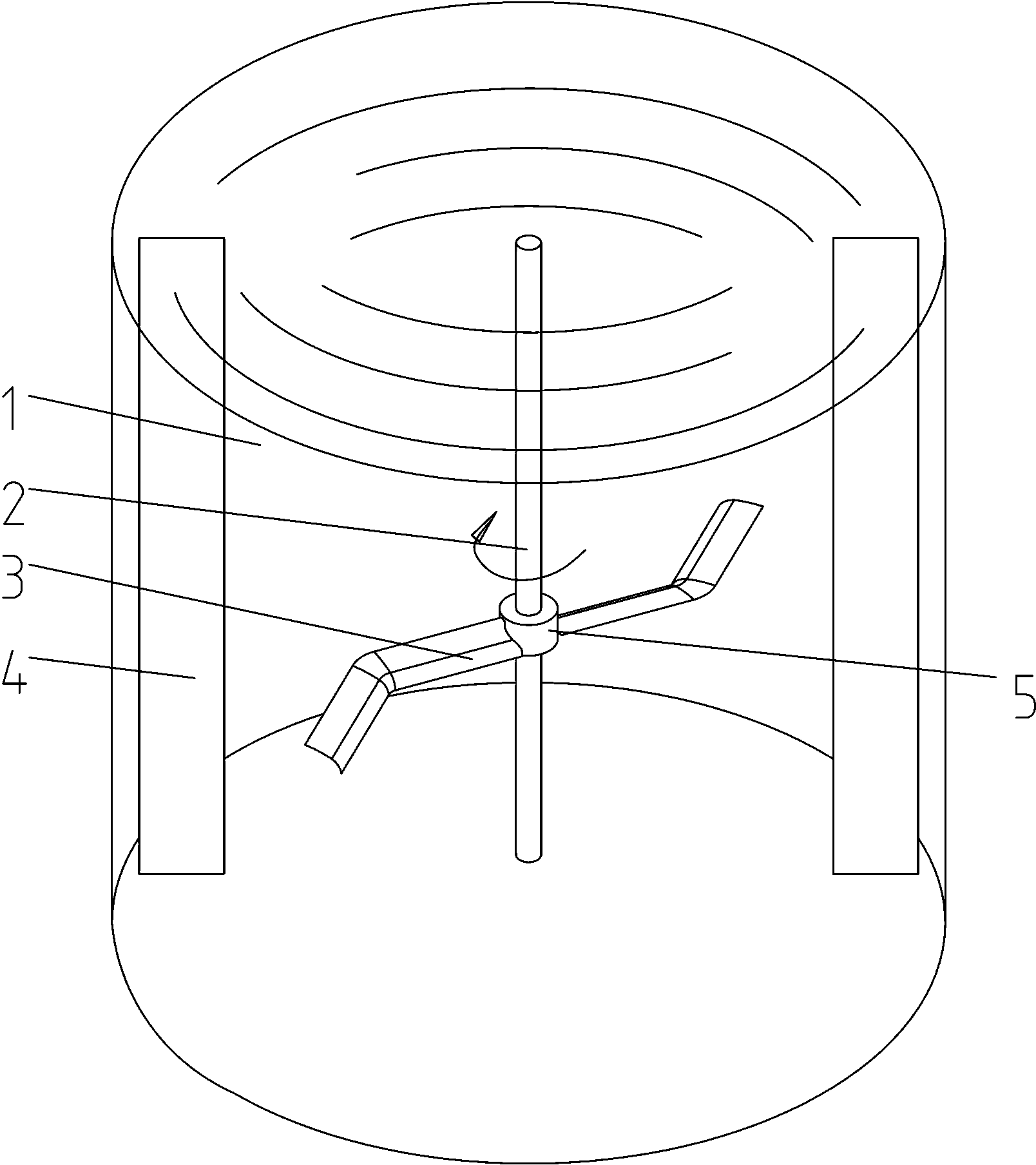

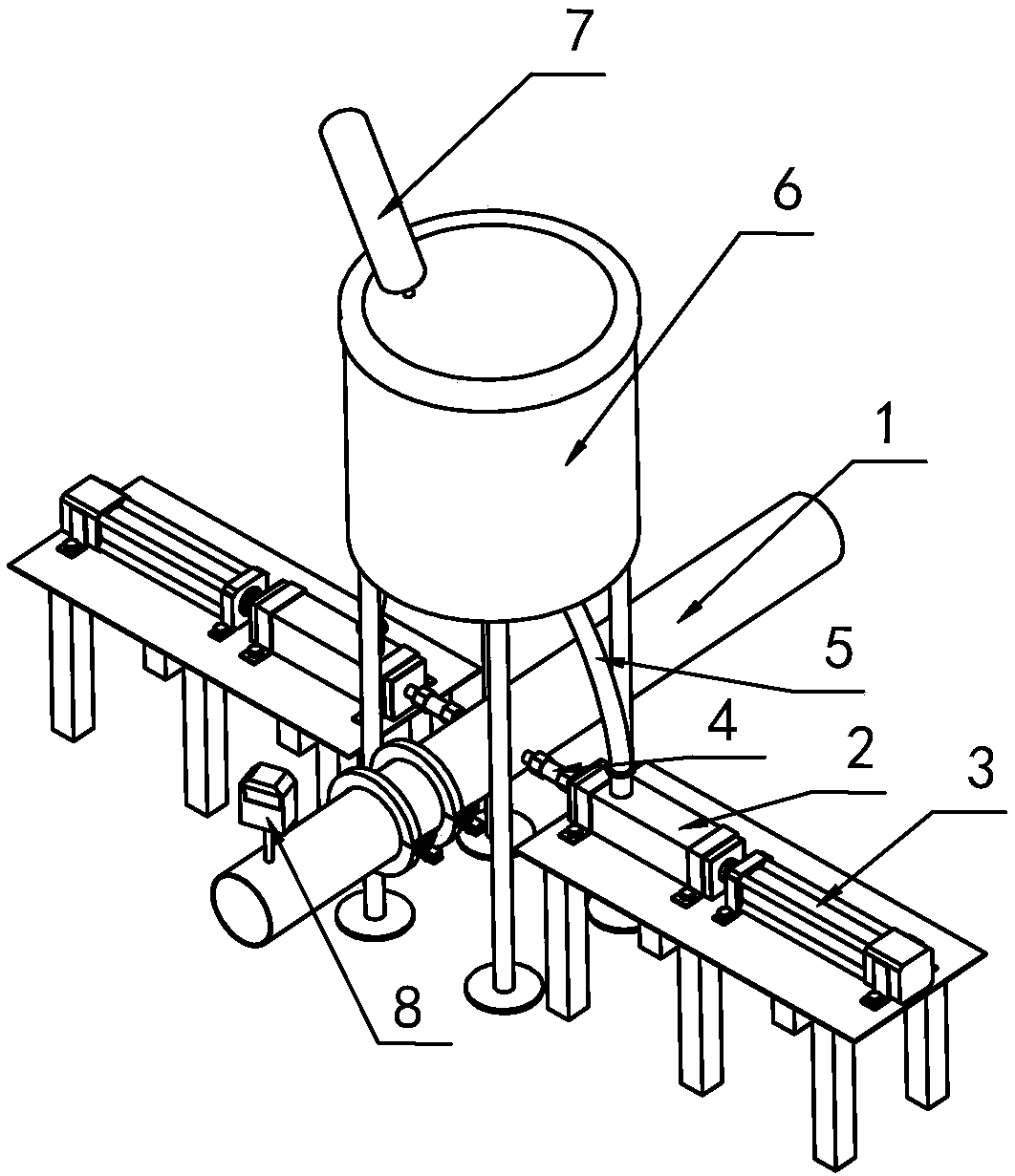

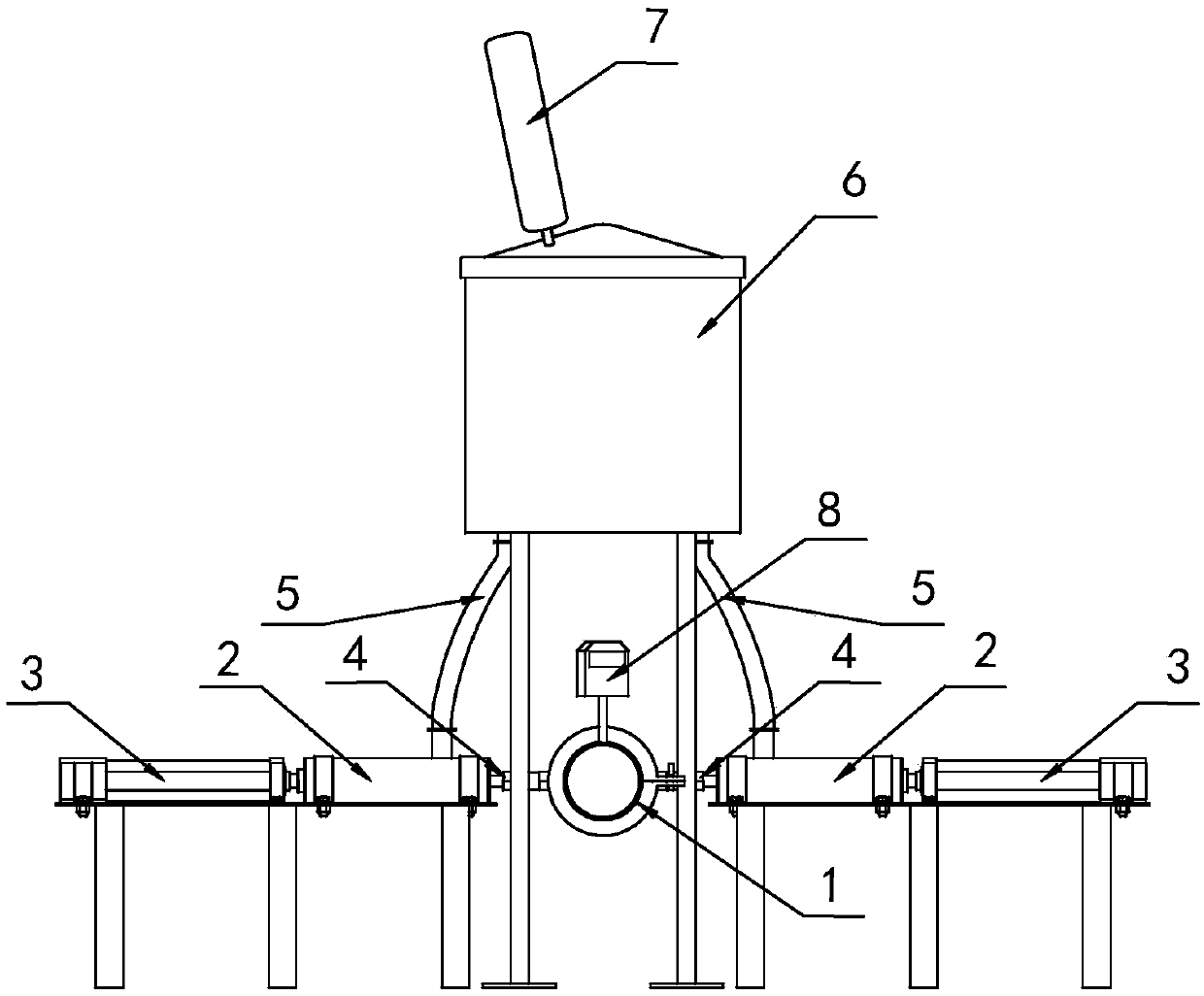

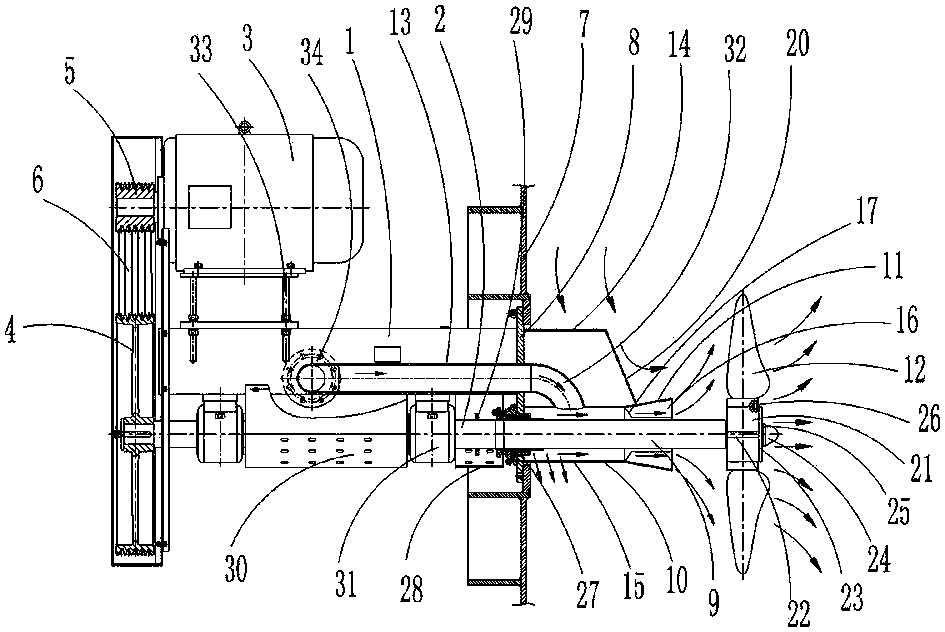

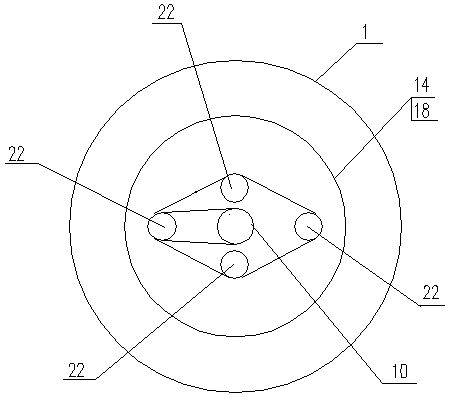

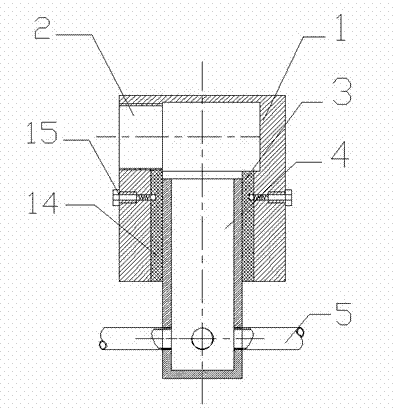

Large fermentation tank stirring device and stirring method

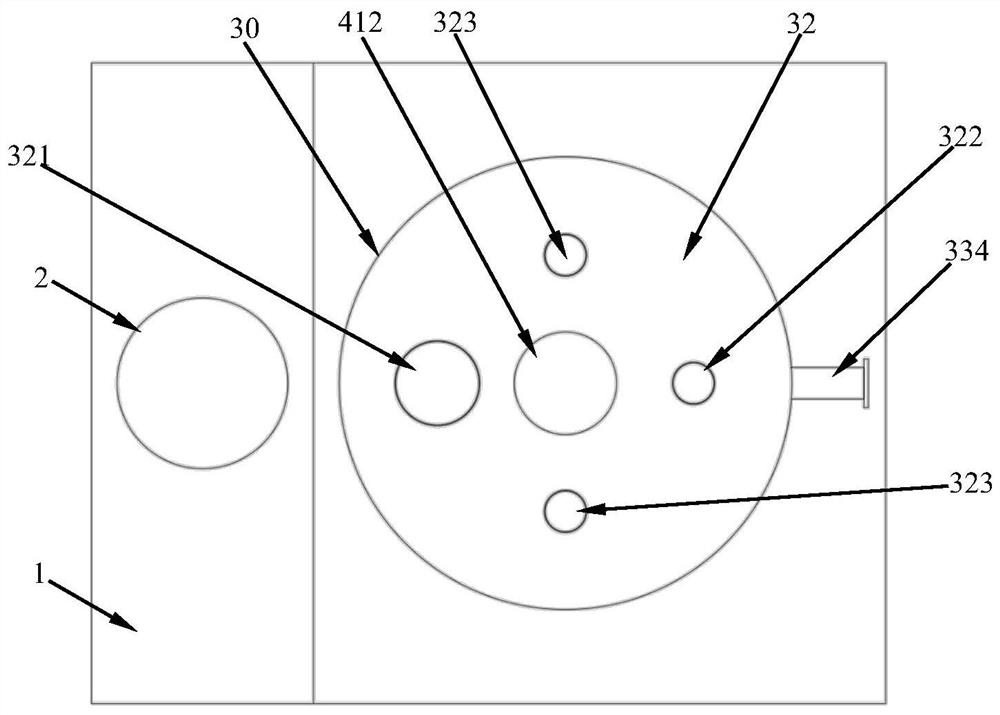

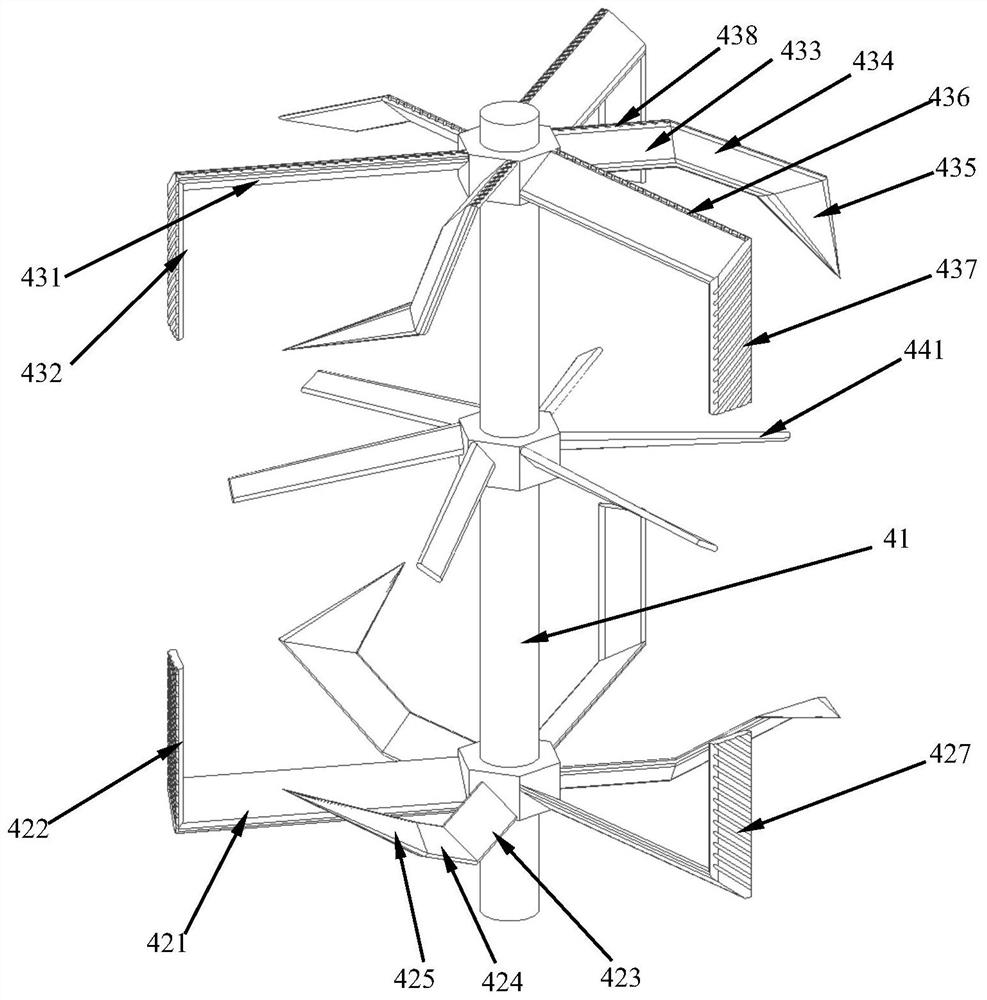

ActiveCN105695305AWide range of design diametersLower the altitudeBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemDrive motor

The invention provides a large fermentation tank stirring device and a stirring method. The large fermentation tank stirring device comprises a tank body, a stirring device body in the tank body and a control system. The large fermentation tank stirring device is characterized in that the stirring device body comprises a central shaft and at least two blade shafts, the central shaft is vertically arranged in the middle of the tank body, a rotary disc is arranged on the central shaft, the central shaft is driven by a central shaft movement driving motor and drives the rotary disc to rotate, the blade shafts are arranged on the rotary disc, stirring blades are arranged on each blade shaft, and each blade shaft is driven by a blade shaft driving motor to be in autorotation while being along with revolution of the rotary disc. The control system controls linkage and rotating speed of the central shaft movement driving motor and the blade shaft driving motor and rotating direction of the blade shafts to realize autorotation and revolution of the blade shafts, and materials in the tank body are stirred by the blades on the blade shafts. By using the large fermentation tank stirring device, fermentation liquid can be fully stirred, fermentation quality can be improved, and stirring energy consumption and power consumption in delivering filtered air into the bottom of the tank body can be lowered.

Owner:吴文宇 +1

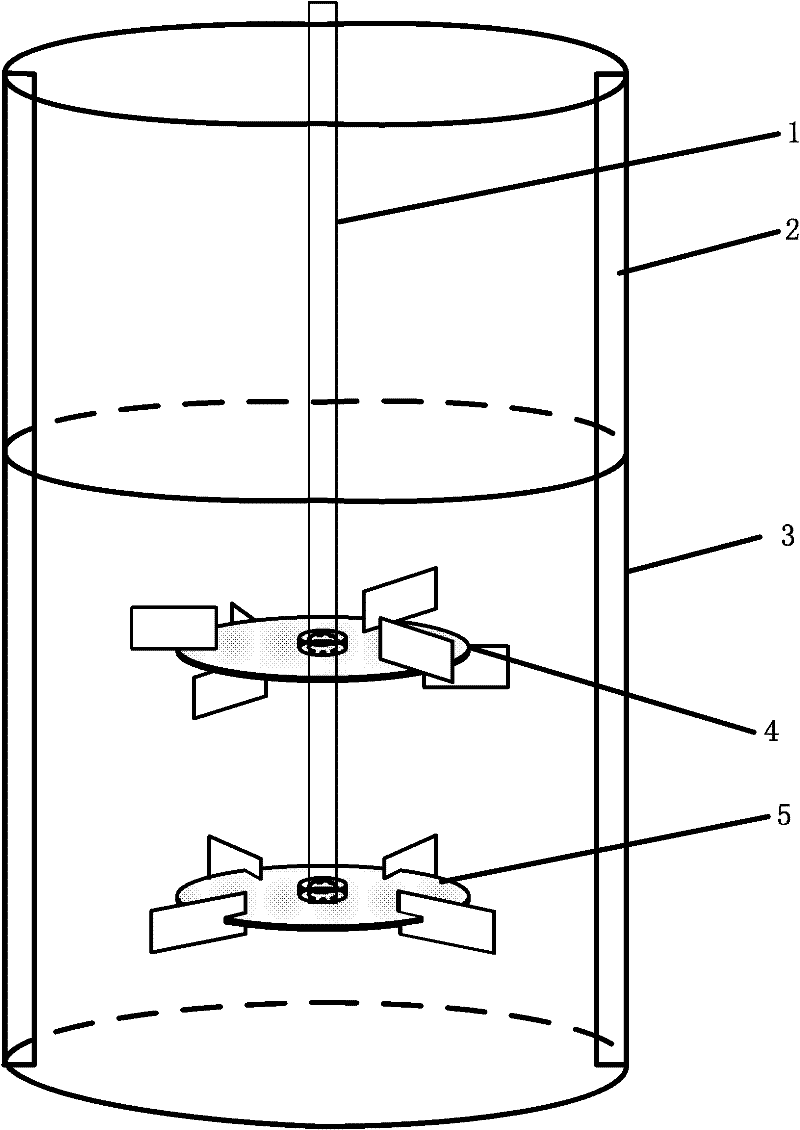

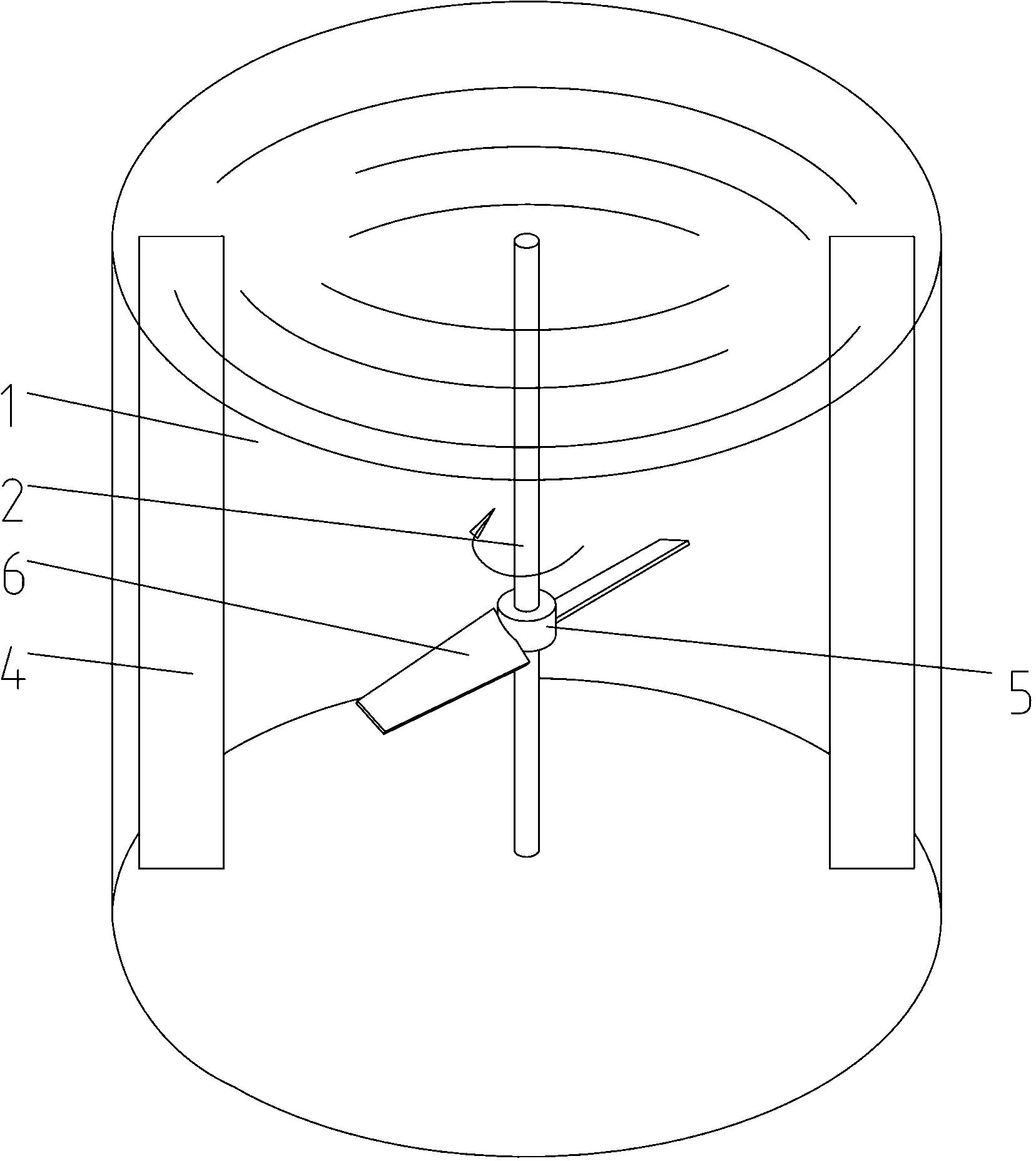

Gas-liquid mechanical coupled agitator

PendingCN108014711AReduce stirring dead zoneReduce stirring energy consumptionTransportation and packagingRotary stirring mixersEngineeringInjection air

The invention discloses a gas-liquid mechanical coupled agitator. The gas-liquid mechanical coupled agitator comprises an agitating cylinder, a rotating shaft, an agitating part and an air injection assembly; the agitating cylinder defines a stirring space, the rotating shaft is arranged in the stirring space, the agitating part is connected to the rotating shaft, the agitating part is used for stirring a fluid material put in the stirring space, and the air injection assembly is used for passing gas into the stirring space to stir the fluid material. According to the gas-liquid mechanical coupled agitator, by arranging the agitating part to stir the fluid material and the air injection assembly to pass gas into the stirring space to stir the fluid material, the effective combination of gas stirring and mechanical stirring can achieve the effect of chaotic stirring. In this way, it can solve the problem of excessive energy input in the process of mechanical stirring, and solve the problem of stirring blind areas in gas stirring, thus, the mixing efficiency in the stirring space is greatly improved, at the same time, the energy consumption of agitation is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

High performance backward bent stirring paddle with circular arc surface

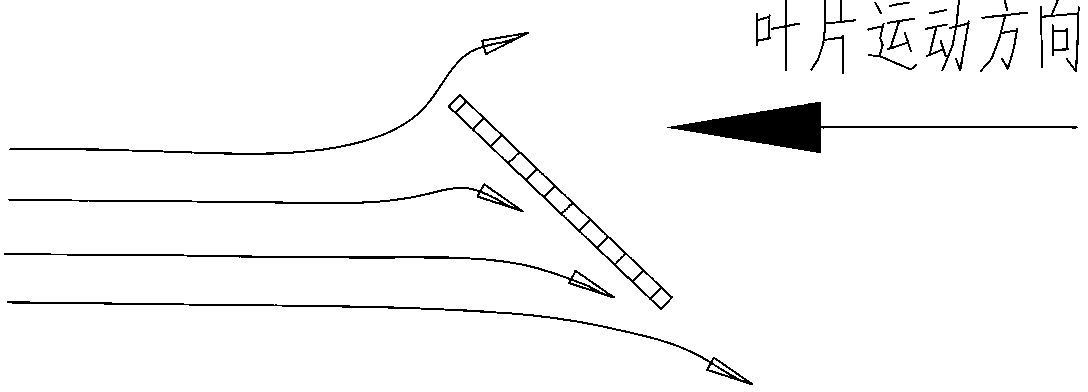

ActiveCN103143287AImprove the mixing effectIncrease flow rateRotary stirring mixersEngineeringEnergy consumption

The invention relates to a stirring paddle, and especially relates to a high uniformity-required high performance backward bent stirring paddle with a circular arc surface. The stirring paddle includes a blade, wherein the cross section of the blade is circular arc-shaped or approximately circular arc-shaped, the tangential direction of the incident flow edge of the blade is parallel to the rotation direction of the blade; the projected shape of the blade in the vertical direction is outer end backward bent, the bent direction is opposite to the rotation direction, and the angle is 0-90 degrees. The stirring paddle has the following advantages that 1, low stirring energy consumption, wherein the projected shape of the blade in the vertical direction is backward bent, further reducing the resistance and reducing the energy consumption. 2, good stirring effect, wherein the stirring performance of the blade is improved; 3, capability of significantly reducing sedimentation at the bottom of the tank, wherein the backward bent blade can enhance the radial flow velocity, and enhance the wash force to edge of the tank, thereby controlling sedimentation; and 4, a gradually bent outflux edge of the blade of the stirring paddle, wherein the outflux edge is in parallel with the direction of flow movement, so the resistance to flow can be reduced, thereby further reducing energy consumption. Compared with folding blade paddles with the same specifications, the stirring paddle provided by the invention has 40% reduced energy consumption and has a stronger sedimentation controlling ability.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for improving semi-dry fermentation stability of municipal sludge by adding cassava vinasse

InactiveCN102643000ASmall volumeReduce occupancyWaste based fuelBiological sludge treatmentAnaerobic reactorWaste recycling

The invention belongs to the field of solid waste recycling and relates to a method for improving semi-dry fermentation stability of municipal sludge by adding cassava vinasse. The method comprises the following steps: (1) starting fermentation; (2) domesticating strains; and (3) operating an anaerobic reactor. In the invention, a semi-dry process is adopted for treating municipal sludge, the solid containing rate of fermentation materials is enabled to be more than or equal to 12% and less than or equal to 18%, compared with the process for treating municipal sludge by wet type fermentation, the volume of the reactor is reduced by 60-70%, energy consumption, equipment and land occupation are saved; compared with the process for treating municipal sludge by dry type fermentation, the cassava vinasse is added, so the viscosity of the fermentation materials is reduced, the energy consumption of stirring is reduced, and meanwhile, the mass transfer is improved, the carbon nitrogen ratio of materials is balanced, and the gas production rate is improved. According to the method, fermentation sludge is used as inoculation material, after the mixture of dehydrated sludge and cassava vinasse is added, alkaline substance is not needed to be added for adjusting the pH value of the reactor.

Owner:TONGJI UNIV

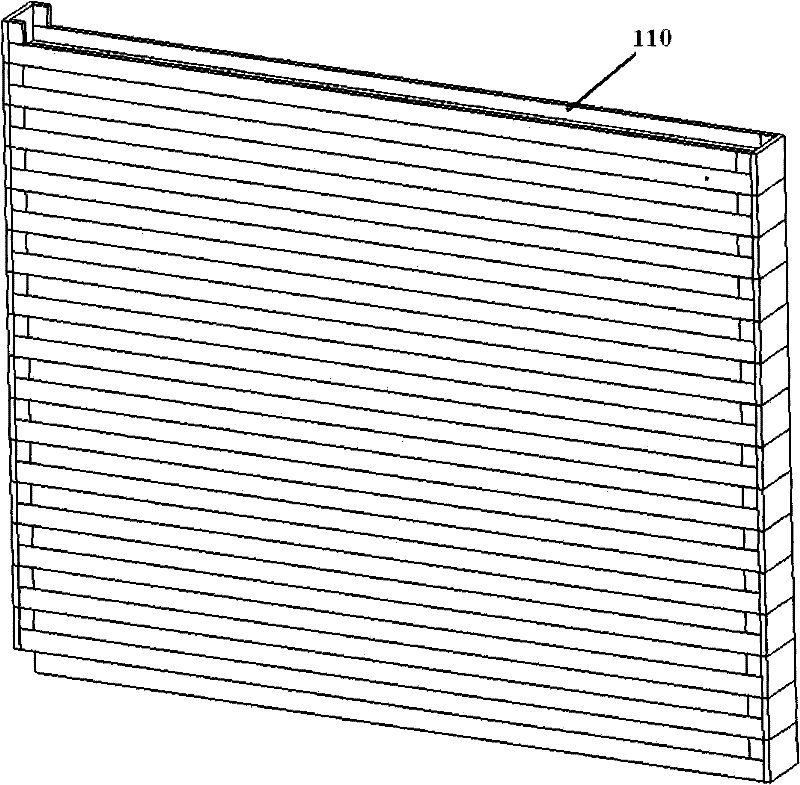

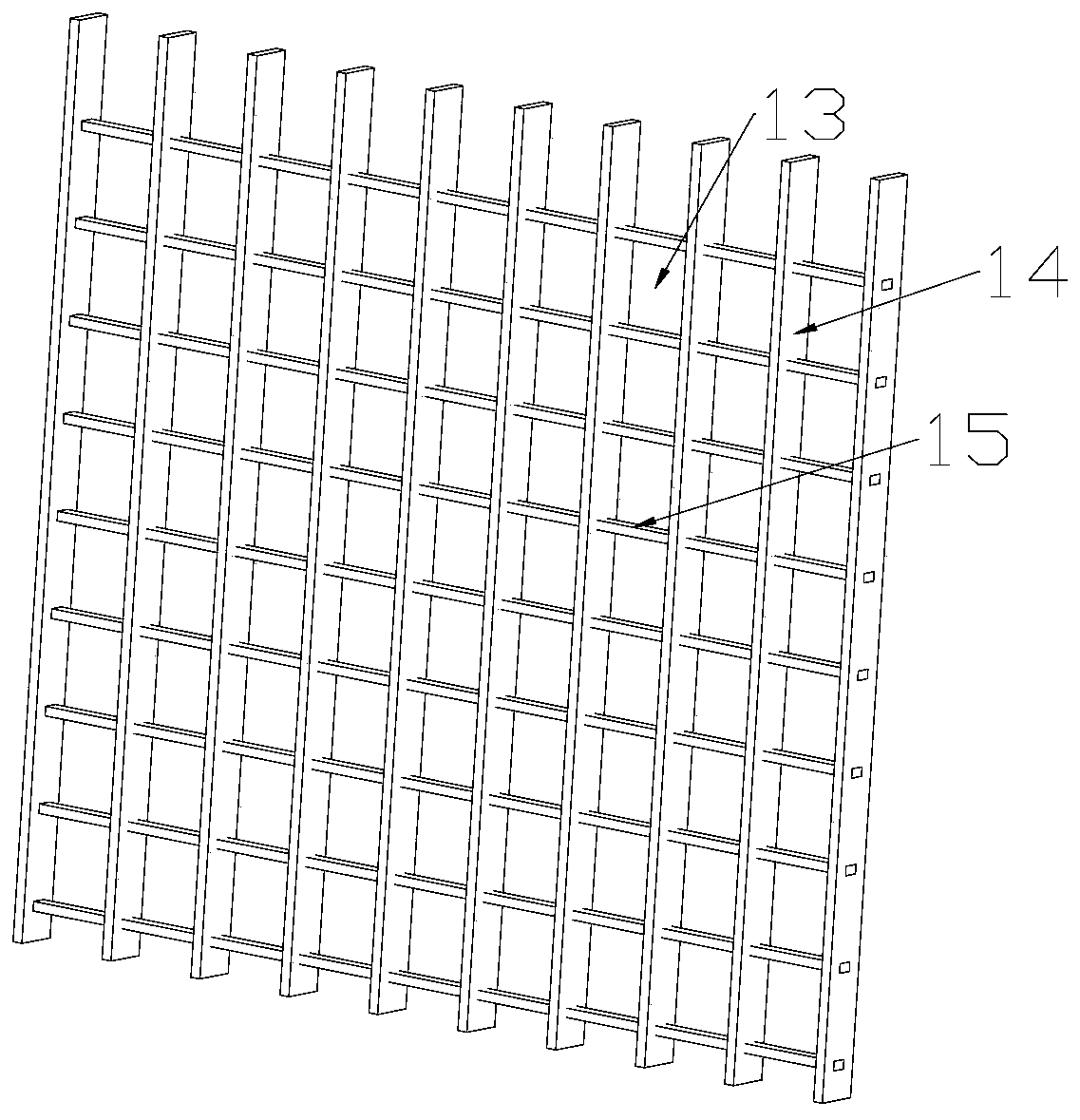

Flatbed MABR (membrane aeration bioreactor) oxygen permeation membrane

PendingCN110054298AEnhance coordinationImprove abilitiesWater contaminantsTreatment with aerobic and anaerobic processesOxygen supplyBioreactor

The invention discloses a flatbed MABR (membrane aeration bioreactor) oxygen permeation membrane component which comprises an MABR diaphragm unit. An air output pipeline is fixed on the upper portionof the MABR diaphragm unit, an air inlet pipeline is arranged on the lower portion of the MABR diaphragm unit, the MABR diaphragm unit comprises two symmetrically arranged MABR diaphragms, a sealing air cavity is formed between the MABR diaphragms, each MABR diaphragm sequentially comprises a breathable membrane layer, an aerobiotic biological membrane layer, a facultative biological membrane layer and an anaerobic biological membrane layer from inside to outside, the air output pipeline is communicated with the upper portion of the sealing air cavity, the air inlet pipeline is communicated with the lower portion of the sealing air cavity and connected with an oxygen supply fan, and the air outlet pipeline is provided with an emptying valve. According to the flatbed MABR oxygen permeationmembrane, overall operating energy consumption is low, nitrification and denitrification are simultaneously implemented, a coordination function is enhanced, ammonia nitrogen and total nitrogen removing capacity is high, the occupied space of a system is less, bubbles are omitted when aeration operation is implemented, odor is low, noise is low, the MABR diaphragms cannot be blocked, maintenance is almost omitted, the problem of the excessive aeration is avoided, the system is simple in process, and automation is easily achieved.

Owner:JIAXING LIREN ENVIRONMENTAL PROTECTION TECHCO LTD

Device for online adding materials

InactiveCN109529711ALow efficiencyEasy to produceFlow mixersTransportation and packagingPolymer scienceTransfer procedure

The invention discloses a device for online adding materials. The device comprises a material pipe, a material storage tank, a material injection device and a material stirring device; the material stirring device is located in the material pipe; the material injection device is respectively connected with the material storage tank and the material pipe. Such a device for online adding materials utilizes the material storage tank, the material injection device and the material stirring device to finish adding and stirring of additives during the conveying process of the materials in the material pipe; low operation efficiency of the traditional stirring tank can be effectively avoided; stirring energy consumption can be reduced; production process of beverages can be simplified; demands onproduction requirement can be reduced; the device is compact, can be conveniently maintained and debugged, can be easily cleaned and is convenient for production of other products; the device provided by the invention is applied to the field of material adding.

Owner:广州风行乳业股份有限公司

Fermentation method for fermenting liquid fodder

ActiveCN104938768AImprove liquiditySolve the problem of large increase in viscosityAnimal feeding stuffBiotechnologyAmylase

The invention discloses a fermentation method for fermenting liquid fodder. The method comprises the following steps that water is added into cereal raw materials, even mixing is carried out, mixture liquid is prepared, and the pH value of the mixture liquid is regulated to range from 5.5 to 6.5; amylase is added into the mixture liquid, thermal insulating processing is carried out; high-temperature sterilizing is carried out on the thermal insulated mixture liquid in advance, cooling is carried out, and fermenting bacteria are inoculated into the mixture liquid to be subjected to fermenting. According to the fermenting method, the problem that the product viscosity is greatly improved after sterilizing is carried out is solved, the material viscosity can be reduced for 20 times to 7000 times or more, the energy consumption of fermenting and stirring can be greatly lowered, and the fermenting cost is lowered. In addition, due to the fact that the viscosity is lowered, the material fluidity is obviously improved, and the fermenting mass and oxygen transferring processed can be obviously enhanced, so that the fermenting process is accelerated, and the product quality is evener and more stable.

Owner:北京英惠尔生物技术有限公司

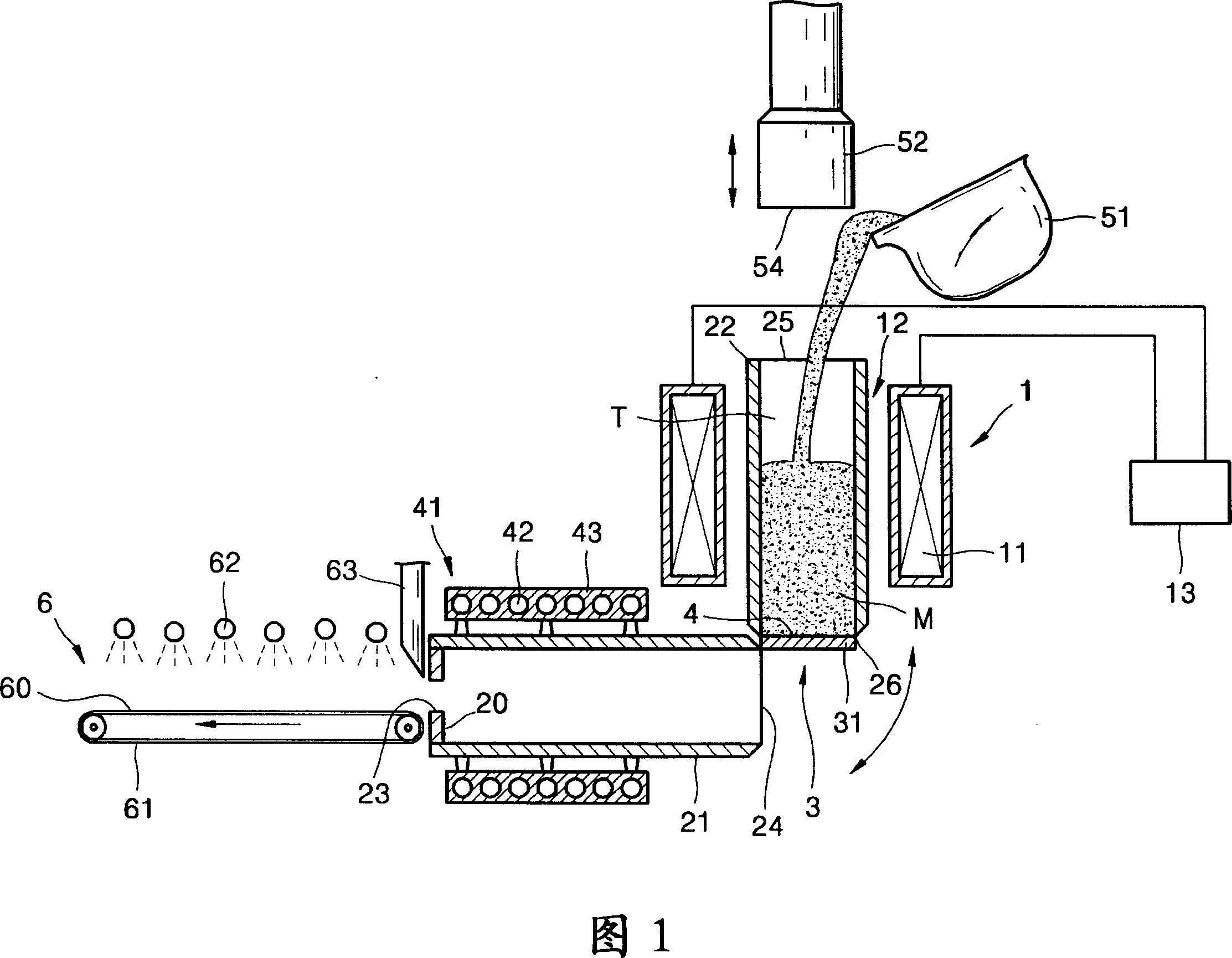

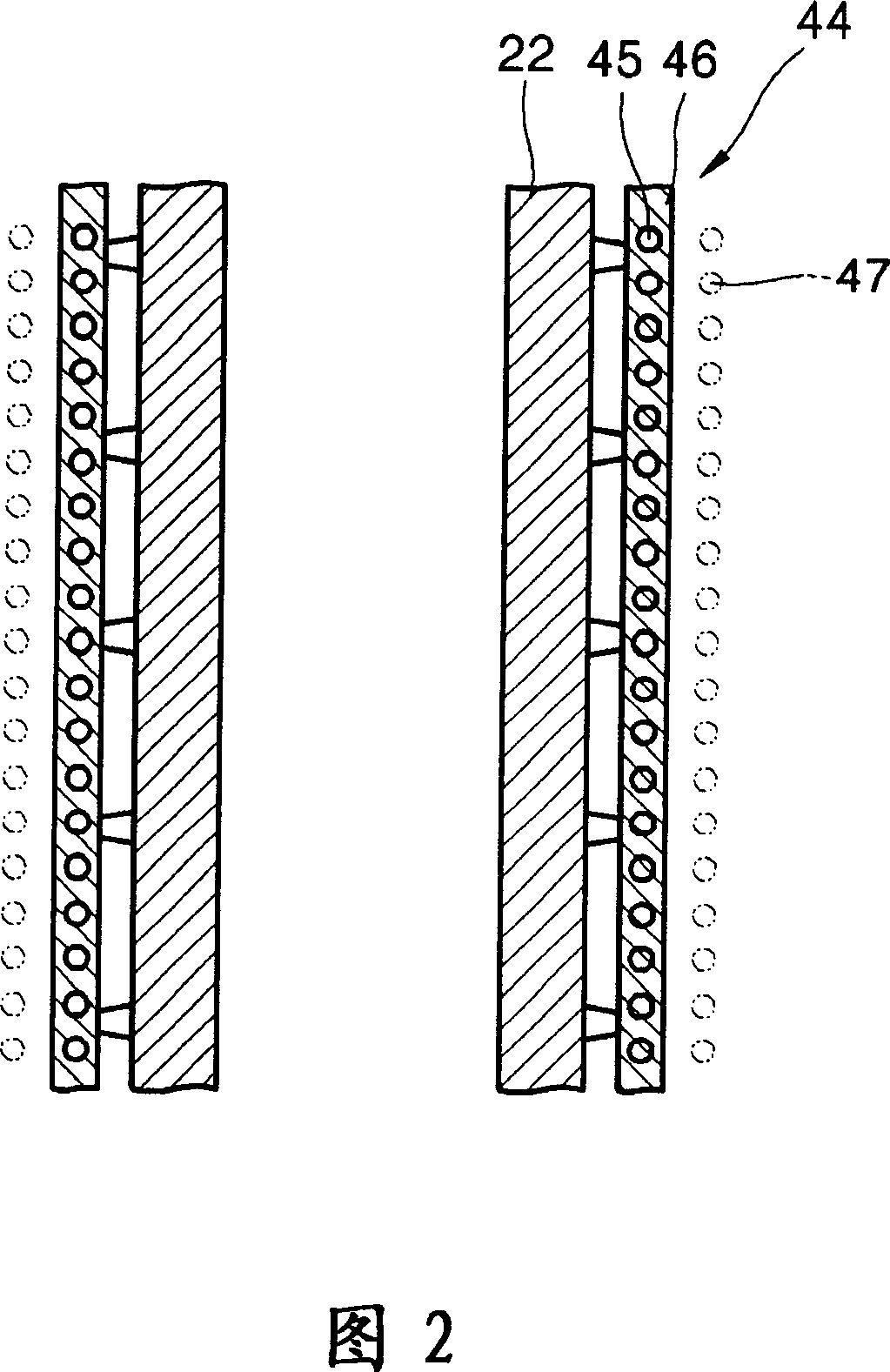

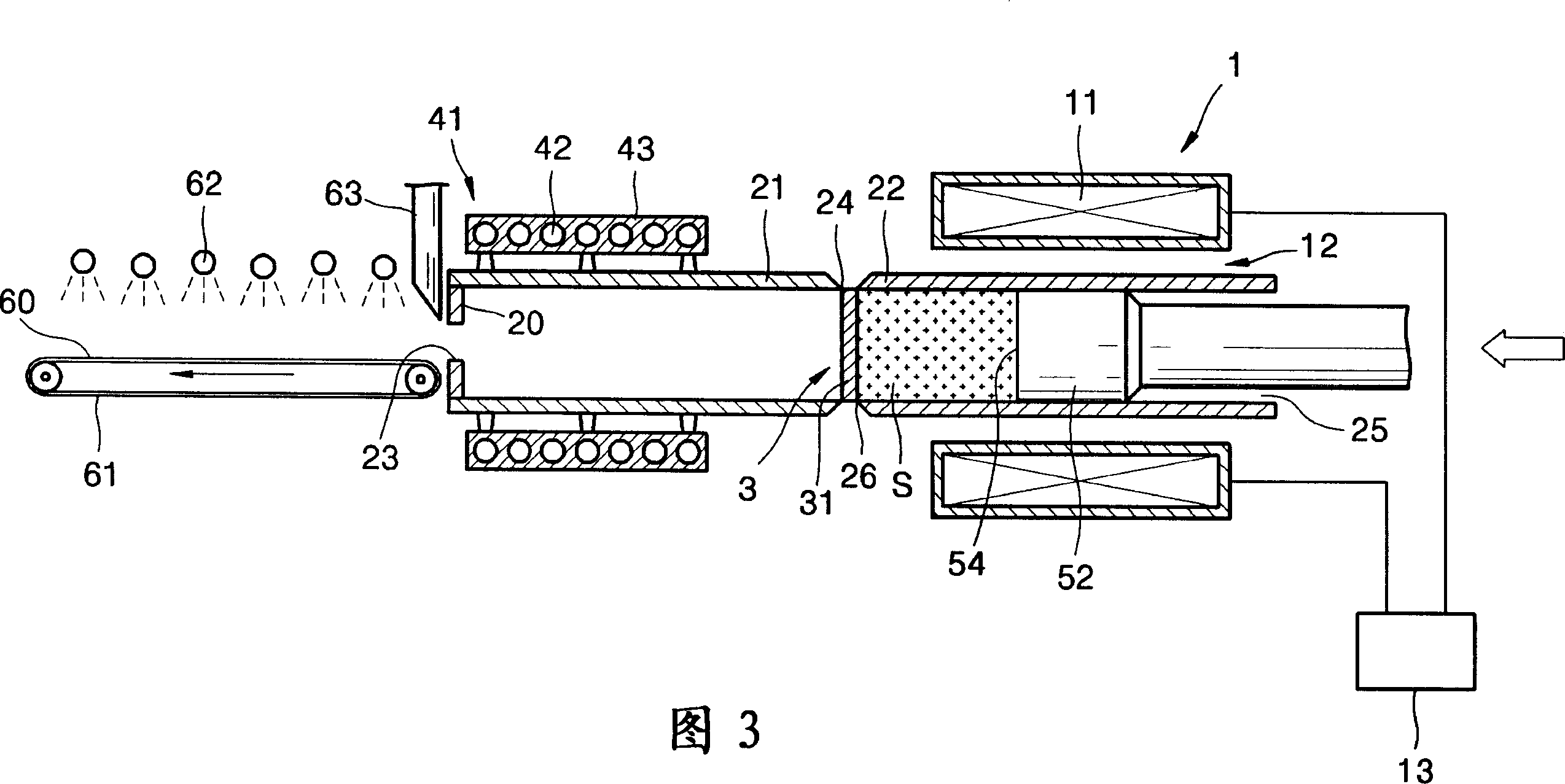

Rheoforming apparatus

InactiveCN1310724CUniform structureImprove mechanical propertiesMelt-holding vesselsSuction-kneading massageEngineeringSlurry

Provided is a rheoforming apparatus that ensures the manufacture of products with fine, uniform, spherical particles, with improvements in energy efficiency and mechanical properties of the products, cost reduction, convenience of forming, and shorter process duration. The apparatus includes a first sleeve, an end of which is formed with a slurry outlet port for releasing a slurry, a second sleeve for retaining a molten metal, an end of which communicates with the first sleeve, a sealing member for opening or closing the end of the second sleeve, a stirring unit for applying an electromagnetic field to the second sleeve, and a plunger, which is slidably inserted into the other end of the second sleeve to press the slurry manufactured in the second sleeve.

Owner:洪 俊杓 +1

Mechanical stirring desulfurization method for desulfurization pretreatment of molten iron

The invention discloses a mechanical agitation desulphurization method for molten iron desulphurization pretreatment. The desulphurization method includes five steps including prior sample taking for temperature measurement, prior slag scrabbling, desulfurizing agent adding and agitation, later slag scrabbling and later sample taking for temperature measurement. In the steps of desulfurizing agent adding and agitation, an agitation device is inserted into a molten iron tank containing molten iron, and is composed of an agitator and a guide plate, and the guide plate and the agitator are both vertically instead into the molten iron; and the vertical distance between the bottom of the guide plate and the top of a blade of the agitator is H. Compared with the rotating speed of a conversional KR method, the rotating speed of the agitator is decreased by 10% to 20%; and the insertion depth of the agitator is increased by 10% to 30% compared with the insertion depth of the conversional KR method.

Owner:武汉钢铁有限公司

A kind of fermentation method of fermented liquid feed

ActiveCN104938768BImprove liquiditySolve the problem of large increase in viscosityAnimal feeding stuffOxygenViscosity

Owner:北京英惠尔生物技术有限公司

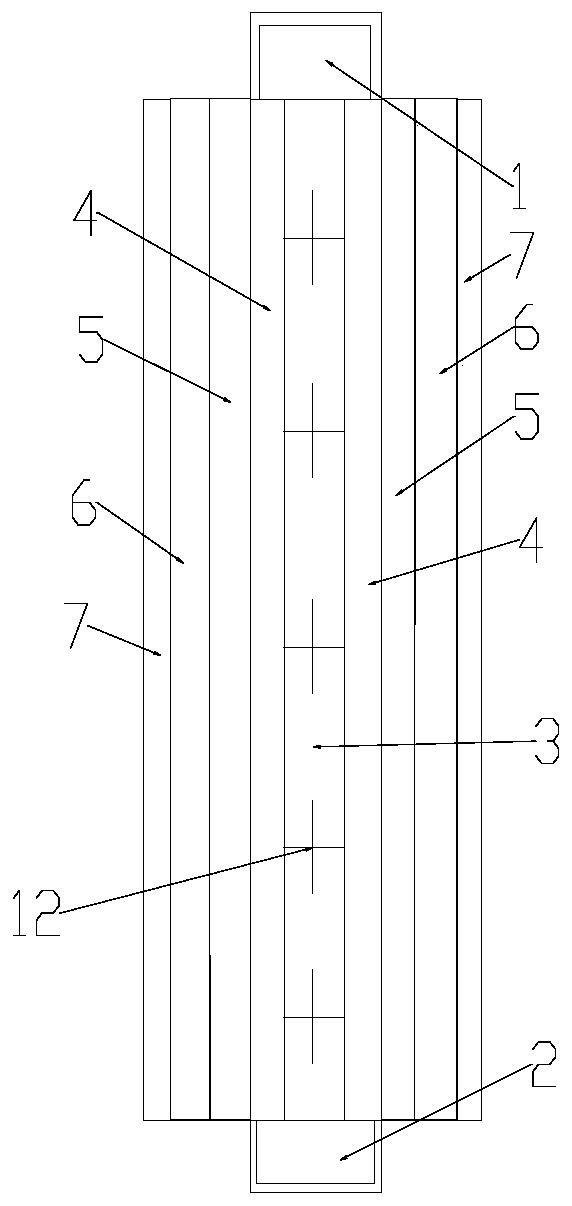

Diluting type slurry tank and slurry tower stirrer

ActiveCN102698628BSimple structureImprove the dilution effectMixing methodsRotary stirring mixersHigh concentrationStraight tube

The invention relates to a stirrer, in particular to a diluting type slurry tank and slurry tower stirrer which is mainly used for diluting, mixing, circulating and stirring of slurry with medium and high concentration of 8-20% in the field of papermaking of light industries. A slurry tower is fixedly connected with a machine base through a connection flange, a stirring section on the head portion of a spindle in the machine base extends in the slurry tower, a core part diluting straight tube fixed with the inner wall of the slurry tower is sleeved outside the stirring section, a core part liquid outlet reducer is arranged on the head portion of the core part diluting straight tube, a slurry blade is sleeved on the head portion of the spindle, an upper diluting straight tube is arranged in the machine base and penetrates through the connection flange to extend into the core part diluting straight tube, a flow guiding cover is arranged above the core part diluting straight tube, and the upper diluting straight tube is communicated with the inside the slurry tower through the core part diluting straight tube and the core part liquid outlet reducer. The diluting type slurry tank and slurry tower stirrer is simple in structure, high in diluting performance, convenient and safe, reduces stirring energy consumption and improves circulating efficiency and operation stability.

Owner:杭州萧山美特轻工机械有限公司

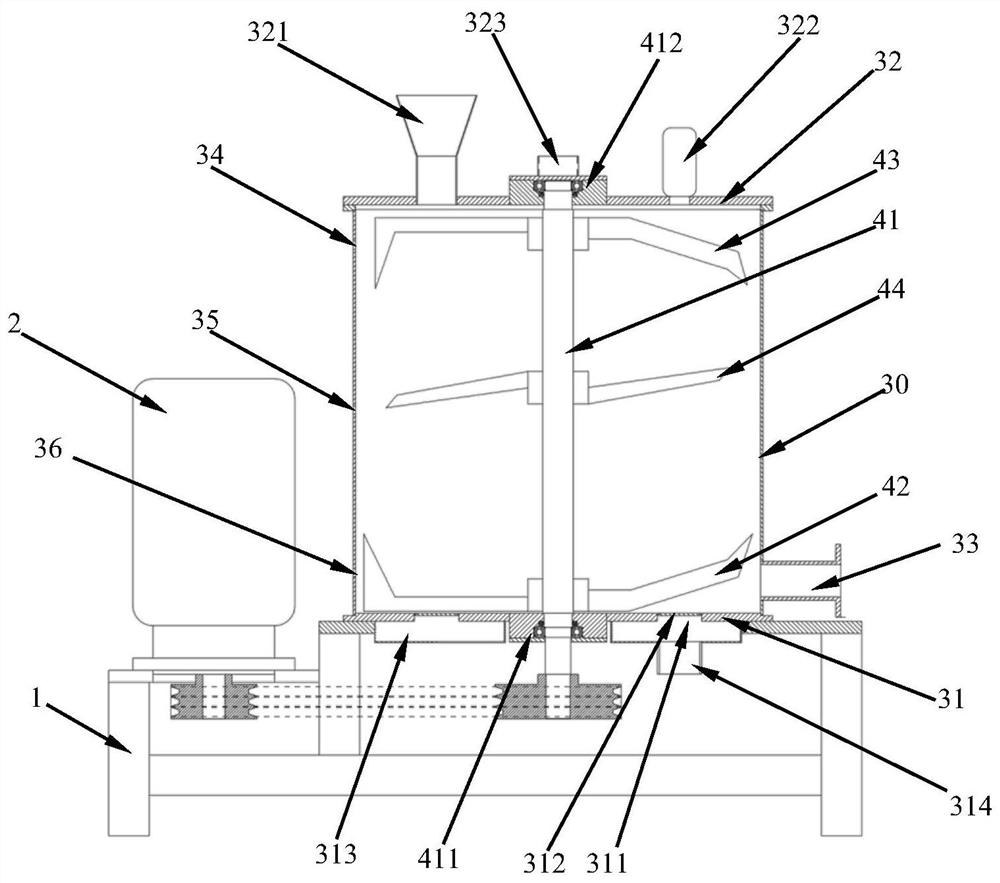

Powder surface modification device and method

ActiveCN112892446AFast temperature controlUniform and precise temperature controlChemical/physical/physico-chemical stationary reactorsSurface modificationPowder

The invention discloses a powder surface modification device which comprises a charging barrel composed of a barrel body, a barrel bottom and a barrel top and a stirrer arranged in the charging barrel, wherein the barrel top is provided with a gas outlet used for discharging gas, the barrel bottom is provided with a gas inlet, a permeable plate is arranged in the gas inlet, the permeable plate allows gas to enter the charging barrel and does not allow powder to flow out of the charging barrel, the gas inlet is communicated with an air source and is used for guiding inlet air into the charging barrel, and the stirrer comprises a first group of blades arranged in the bottom of the charging barrel and a second group of blades arranged in the top of the charging barrel. The invention also provides a method for conducting power surface modification by using the device. The powder surface modification device and method have the advantages of being uniform in modification temperature, rapid in temperature rising and cooling, small in powder breakage rate, high in modified powder yield, small in comprehensive energy consumption, small in equipment abrasion, free of particle attachment to the inner wall of equipment and the like.

Owner:常州驰励粉体材料有限公司

Papermaking sludge conditioning agent and application thereof

PendingCN110981158AFacilitate deep prolapsePromote formationSludge treatment by oxidationWaste water treatment from plant processingForest industryProcess engineering

The invention relates to the technical field of papermaking sludge treatment, and more specifically relates to a papermaking sludge conditioning agent and application thereof. The papermaking sludge conditioning agent is composed of a ferrate and sawdust powder, can improve the sludge dewatering effect, and is low in raw material cost; resource utilization of forestry waste sawdust can be achieved; the production cost of the papermaking sludge conditioning agent is reduced, and the papermaking sludge conditioning agent can be widely applied to sludge pre-conditioning and has good application prospects.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

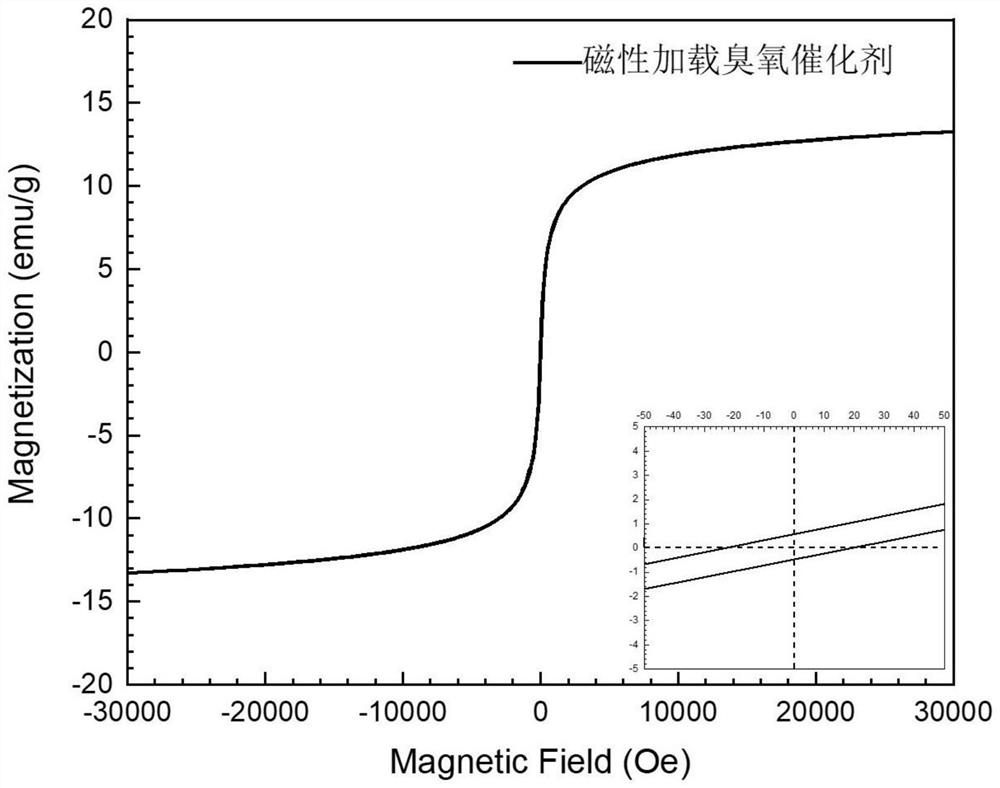

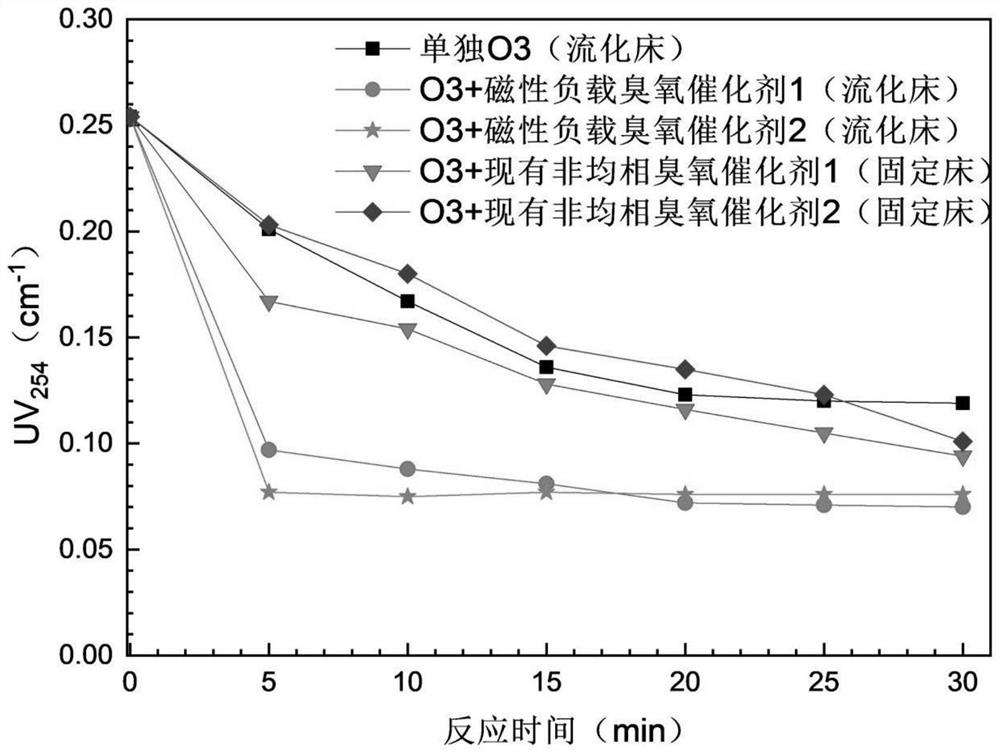

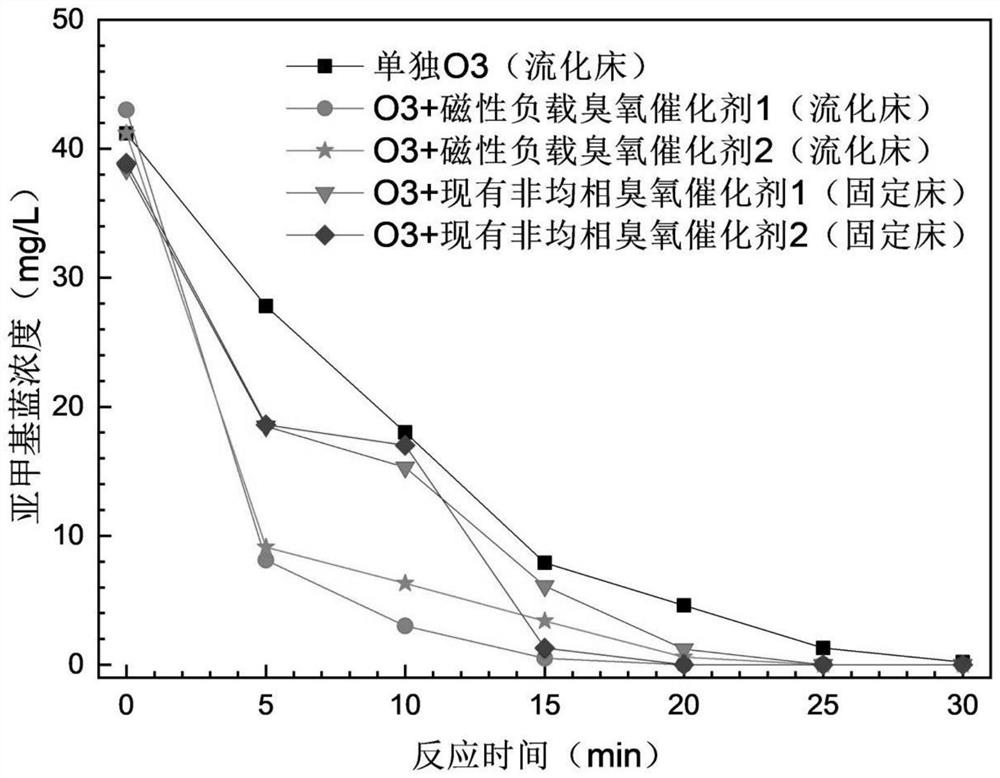

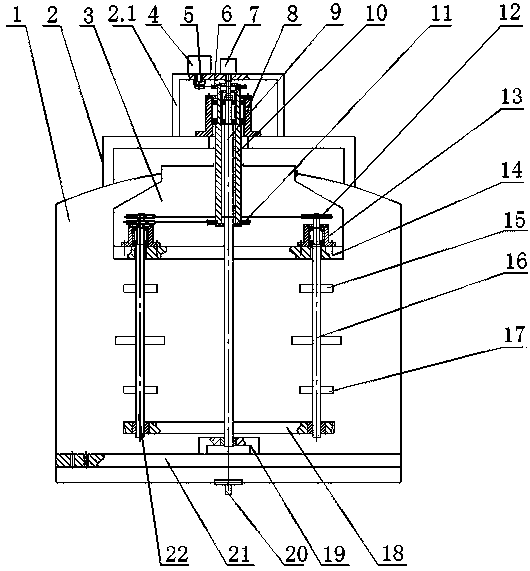

Magnetic supported ozone catalyst and preparation method and use method thereof

PendingCN114849727ALarge specific surface areaSmall particle sizeWater contaminantsHeterogenous catalyst chemical elementsActivated carbonPtru catalyst

The invention provides a magnetic loaded ozone catalyst and a preparation method and a use method thereof, and the preparation method comprises the following steps: dissolving a trivalent iron salt and a divalent iron salt in water, and stirring and dissolving in the absence of air; adding a metal salt M, and stirring and dissolving while isolating air; adding powdered activated carbon, uniformly stirring to form a black suspension, and standing and impregnating for 6-24 hours in an air-isolated manner; dropwise adding the soaked turbid liquid into a container filled with a 1-10mol / L alkaline solution, and stirring for 20-60 minutes while isolating air to form a black turbid liquid; filtering the turbid liquid, and drying the solid at 60-100 DEG C for 2-4 hours; and under the protection of N2, calcining at 200-500 DEG C for 1-3 hours to obtain the magnetic loaded ozone catalyst which can be used for catalytic ozonation treatment of industrial wastewater and the like. The magnetic loaded ozone catalyst is micron-sized particles, is large in specific surface area, has catalytic active sites distributed on the outer surface, is easy to contact with pollutants and an oxidizing agent for catalysis, is high in reaction speed, does not have the problems of pore blockage and hardening, and is high in catalytic activity; and the material has magnetism and is convenient to recycle.

Owner:SCIMEE TECH & SCI CO LTD

Large-scale fermentation tank stirring device and stirring method

ActiveCN105695305BStir wellAchieve the purpose of stirringBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemDrive motor

The invention provides a large fermentation tank stirring device and a stirring method. The large fermentation tank stirring device comprises a tank body, a stirring device body in the tank body and a control system. The large fermentation tank stirring device is characterized in that the stirring device body comprises a central shaft and at least two blade shafts, the central shaft is vertically arranged in the middle of the tank body, a rotary disc is arranged on the central shaft, the central shaft is driven by a central shaft movement driving motor and drives the rotary disc to rotate, the blade shafts are arranged on the rotary disc, stirring blades are arranged on each blade shaft, and each blade shaft is driven by a blade shaft driving motor to be in autorotation while being along with revolution of the rotary disc. The control system controls linkage and rotating speed of the central shaft movement driving motor and the blade shaft driving motor and rotating direction of the blade shafts to realize autorotation and revolution of the blade shafts, and materials in the tank body are stirred by the blades on the blade shafts. By using the large fermentation tank stirring device, fermentation liquid can be fully stirred, fermentation quality can be improved, and stirring energy consumption and power consumption in delivering filtered air into the bottom of the tank body can be lowered.

Owner:吴文宇 +1

Jet type hydraulic blender

ActiveCN102000519BAchieve mechanical stirringIngenious designFlow mixersRotary stirring mixersRadial planeSpray nozzle

This invention relates to a jet type hydraulic blender. The jet type hydraulic blender comprises a blending body consisting of a hollow rotating shaft, a jet pipe and a nozzle, a main joint with a liquid inlet hole and a connecting hole which are communicated with each other. One end of the hollow rotating shaft is a perforated end, arranged in the connecting hole and communicated with the liquidinlet hole and the other end of the hollow rotating shaft is an unperforated end and is radially communicated with more than one jet pipe; a nozzle which forms an included angle of -45 to 45 degrees with a radial plane of the hollow rotating shaft and an included angle of 30 to 90 degrees with the jet pipe is fixed at the end of the jet pipe; and an axial position device is further arranged between the hollow rotating shaft and the main joint. When the hydraulic blender is used, the high-pressure liquid is ejected from the nozzle and the liquid is blended; the jet pipe is driven to rotate so as to blend the liquid by a reacting force generated by the ejected liquid; and the mechanical and hydraulic double blending function is realized on the premise of no increase of power equipment and energy consumption; the jet type hydraulic blender improves blending effect and efficiency, reduces energy consumption, has ingenious design, a simple structure and low cost, and is suitable to be usedas a blender in a methane-generating pit or a sewage treatment pond.

Owner:武汉蓝颖新能源有限公司

A microbial strain with high yield of citric acid and method for producing citric acid by fermenting starch sugar

ActiveCN109207373BLow viscosityIncrease initial sugar concentrationFungiMicroorganism based processesMicroorganismMicrobiology

Owner:TIANJIN UNIV OF SCI & TECH

Concrete compound step-by-step stirring process

PendingCN114227915AHigh strengthAvoid enrichmentCement mixing apparatusProcess engineeringCement mortar

The invention discloses a concrete compound step-by-step stirring process which comprises the following steps: according to raw materials required by the mixing ratio of concrete, putting fine aggregate and cement into a stirring machine A, stirring for t1, then adding a certain mass of water, and stirring for t2 to prepare cement mortar; when the cement mortar is prepared, coarse aggregate is put into a stirring machine B, then a certain mass of water is added, and stirring is conducted for the time t3; adding the rest mass of cement into the stirrer B, and stirring for t4; adding the cement mortar into the stirrer B, and stirring for t5; and finally, adding the additive and the rest water into the stirrer B, stirring for t6, and discharging to finish the whole stirring process. In general, the invention has the advantages of improving the interfacial strength of coarse aggregate and fine aggregate, enhancing the mechanical properties of concrete and reducing the cement consumption.

Owner:德通智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com