Sludge separation treatment method

It is a kind of quality separation treatment and sludge technology, which is applied in the direction of sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc. It can solve the problems of affecting gas production, high sludge viscosity, and difficult mixing, and achieves low cost, ease of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

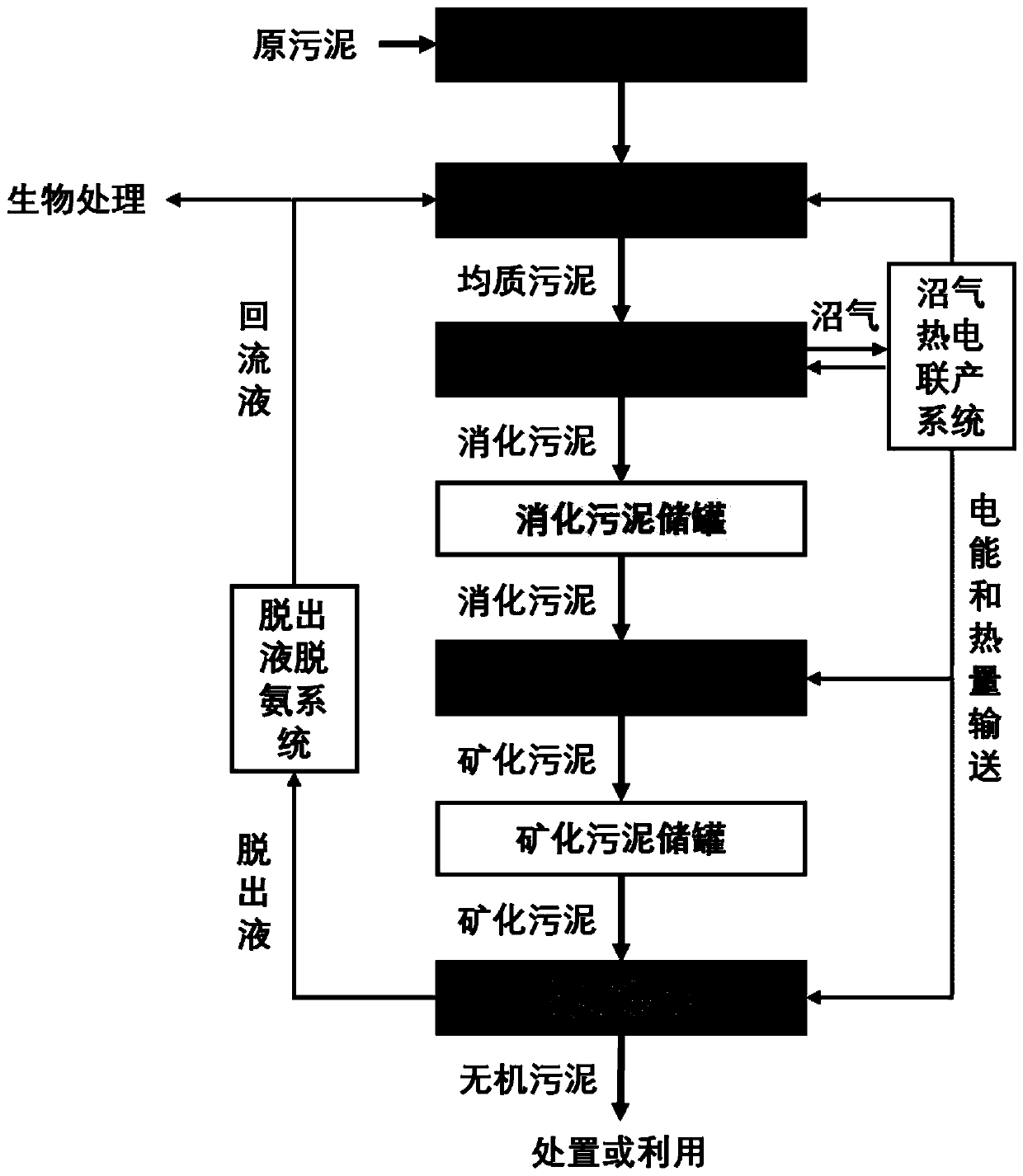

[0026] Such as figure 1 , a preferred embodiment of the present invention provides a method for sludge quality treatment and disposal, comprising the following steps:

[0027] S1: transport the raw sludge to the low-temperature thermal hydrolysis reactor, and pass the reflux liquid generated in step S5 into the low-temperature thermal hydrolysis reactor, and obtain the hydrolyzed homogeneous sludge after the low-temperature thermal hydrolysis reaction;

[0028] Specifically, the raw sludge (dewatered sludge with a solid content of about 20%) is transported from the feed storage bin to the low-temperature thermal hydrolysis reactor, and the reflux liquid generated in step S5 is added to it to make the solid content of the mixture The rate is controlled at 8-12%, the temperature is controlled at 60-90° C., and stirred for 15-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com