Low-heat silicate cement clinker for maritime work and preparation method thereof

A Portland cement and cement clinker technology, applied in the field of Portland cement clinker, can solve the problems of high dry shrinkage rate and high hydration heat release, achieve low cement dry shrinkage rate, promote mineral nucleation and long-term Great, reduce the effect of intermediate transition phase products

Active Publication Date: 2017-01-04

CHINA BUILDING MATERIALS ACAD +1

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

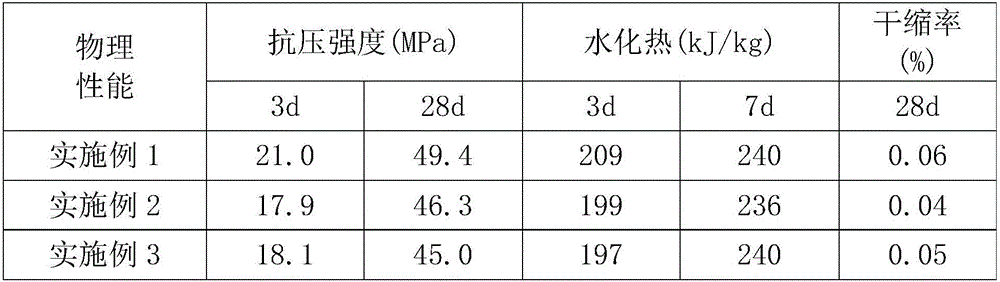

At present, ordinary Portland cement and a small amount of sulfate-resistant cement are mainly used in marine projects such as ports and docks in my country. This type of cement has high hydration heat release and high drying shrinkage rate. Its 7d is greater than 300kJ / kg, and 28d dry The shrinkage rate is greater than 0.1, which cannot fully meet the special requirements of marine engineering

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0023] A kind of preparation method of marine low-heat portland cement clinker that an embodiment of the present invention proposes, it comprises the following steps:

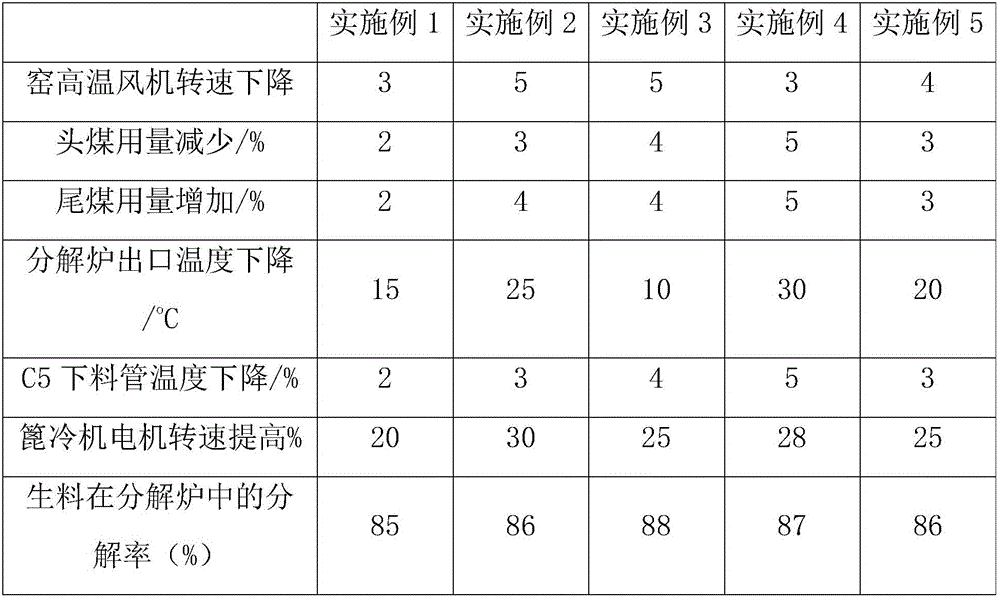

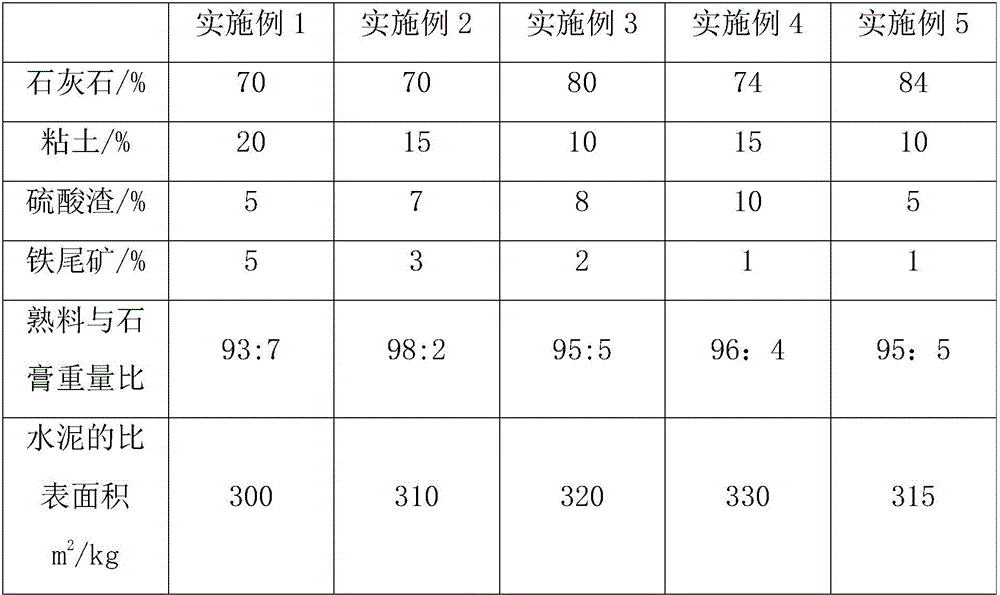

[0024] 1) Mix and grind 70%-84% limestone, 10%-20% clay, 5%-10% sulfuric acid slag and 1%-5% iron tailings into powder according to the mass percentage to obtain cement raw meal;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a preparation method of low-heat silicate cement clinker for maritime work. The preparation method comprises the following steps: (1) mixing and grinding the following components in percentage by mass into powder: 70 to 84 percent of limestone, 10 to 20 percent of clay, 5 to 10 percent of sulfate slag and 1 to 5 percent of iron tailings to obtain a cement raw material; (2) decomposing the cement raw material in a decomposing furnace, then calcining at the temperature of 1,350 to 1,400 DEG C for 30 to 45 min, and cooling to obtain the cement clinker, wherein on the basis of the parameters of the decomposing and calcining production processes of the existing cement raw material of the same yield, the following parameters of the calcining process of the cement raw material are adjusted respectively according to the yield of the cement clinker of 500 to 10,000 t / day: the rotating speed of a high-temperature fan of a kiln is reduced by 3 to 5 percent, the use amount of head coal is reduced by 2 to 5 percent, the use amount of tailings is increased by 2 to 5 percent, the outlet temperature of the decomposing furnace is reduced by 10 to 30 DEG C, the temperature of a C5 discharging pipe is reduced by 2 to 5 percent, and the rotating speed a motor of a grate cooler is increased by 20 to 30 percent. Cement prepared from the cement clinker disclosed by the invention is low in water heat and dry shrinkage rate.

Description

technical field [0001] The invention relates to a Portland cement clinker, in particular to a marine low-heat Portland cement clinker and a preparation method thereof. Background technique [0002] In recent years, countries all over the world have attached great importance to the development of marine resources. In foreign countries, the structural materials used in marine engineering mainly include steel structures and cement concrete structures. In terms of use effects, cement concrete materials are a better structural material. Foreign concrete projects mainly use medium-heat or low-heat Portland cement and add appropriate amount of chemical admixtures and mineral admixtures to make the performance of cement concrete meet the special requirements of marine engineering. Our country is rich in marine resources, and the development and utilization of marine resources has broad prospects. In the future, whether it is offshore, in the sea or under the sea, the structural ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B7/22

CPCC04B7/22

Inventor 王敏文寨军王晶张坤悦黄文

Owner CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com