Reactive powder concrete as well as preparation and application thereof

A technology of active powder and concrete, applied in the field of concrete materials, can solve the problems of high cost, short life, poor texture, etc., achieve the effect of stable volume, solve high cracking risk, and reduce cracking risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0050] Examples 1-5: Active powder concrete under different component distribution ratios.

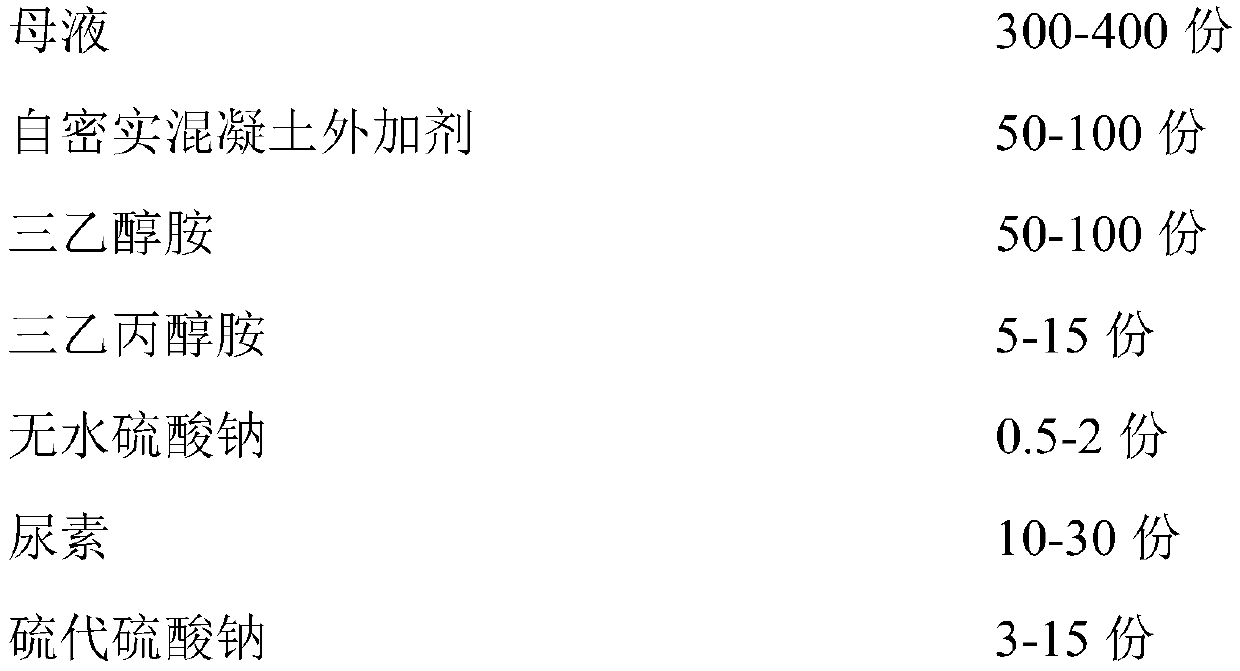

[0051] The used admixture of embodiment 1~5, by following weight portion proportioning:

[0052] Take 350 parts of mother liquor, 60 parts of self-compacting concrete admixture, 62 parts of triethanolamine, 6.5 parts of triethylenepropanolamine, 0.8 part of anhydrous sodium sulfate, 20 parts of urea, 8 parts of sodium thiosulfate, mix and stir evenly, and prepare Get additives.

[0053] Wherein, the preparation method of mother liquor is as follows:

[0054] First mix 400 parts of tpeg monomer, 300 parts of bottom water, 0.3 parts of ethylenetetramine and 5 parts of potassium persulfate, then add 36 parts of acrylic acid, 64 parts of water and 3.3 parts of potassium persulfate, and control the dropping time to 1.5 Add 0.3 parts of vitamin C, 1.2 parts of mercaptopropionic acid, and 97.5 parts of water, and control the dripping time for 2 hours; finally replenish 228 parts of water, r...

Embodiment 6~10

[0070] Examples 6-10: Active powder concrete under different component distribution ratios.

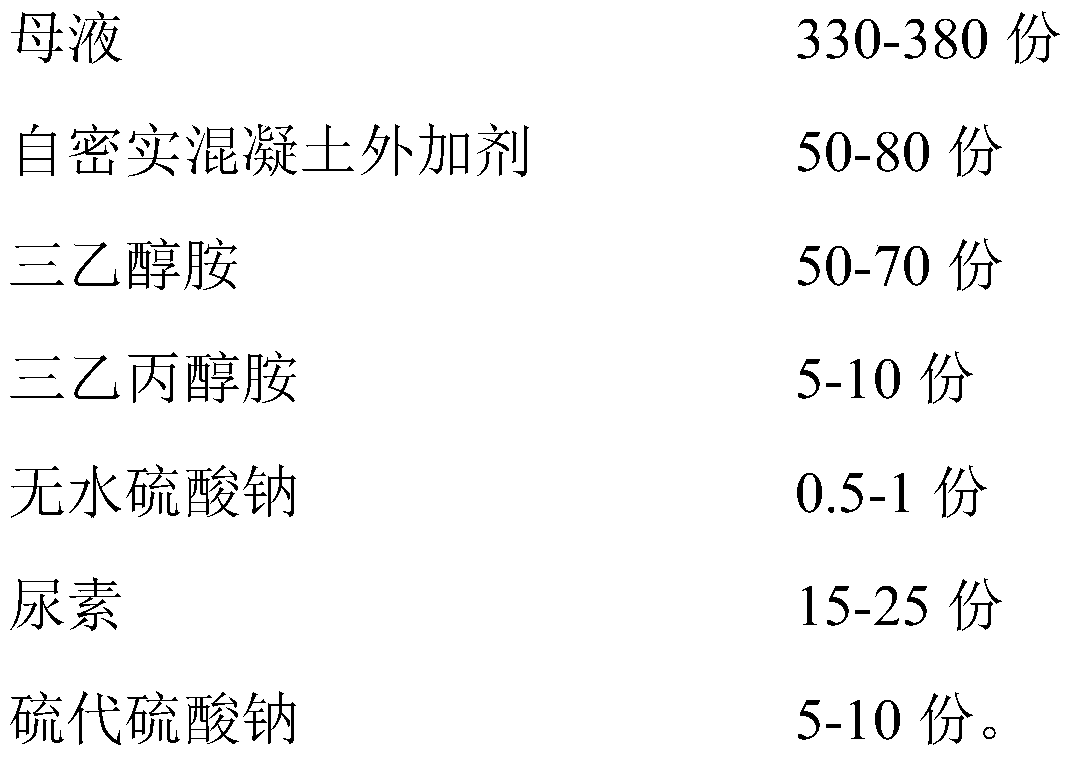

[0071] The used admixture of embodiment 6~10, by following weight portion proportioning:

[0072] Take 330 parts of mother liquor, 70 parts of self-compacting concrete admixture, 55 parts of triethanolamine, 8 parts of triethylenepropanolamine, 1 part of anhydrous sodium sulfate, 25 parts of urea, 10 parts of sodium thiosulfate, mix and stir evenly, and prepare admixture.

[0073] Wherein, the preparation method of mother liquor is identical with embodiment 1-5.

[0074] See Table 4 for raw material components, and see Table 5 for the properties of the prepared reactive powder concrete.

[0075] The active powder concrete of embodiment 6~10, preparation method is as follows:

[0076] 1) Mix water and admixture first to get mixed liquid;

[0077] 2) Then add cement, silica fume, and mineral powder in turn to mix evenly, then add sand and mix evenly;

[0078] 3) Finally, add steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com