Large fermentation tank stirring device and stirring method

A stirring device and fermenter technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc., can solve the problems of large-scale fermenter and energy saving. Solve problems such as failure to achieve ideal results and achieve wide range of design diameters, significant energy-saving effects, and lower tank heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

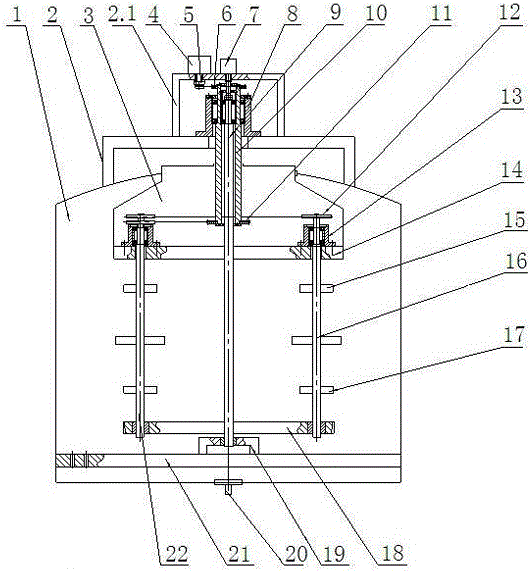

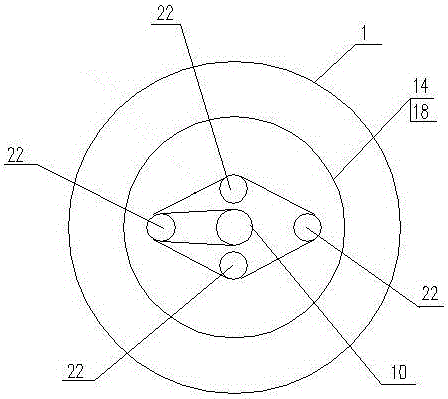

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] see figure 1 , figure 2, an embodiment of a stirring device for a large-scale fermentation tank of the present invention, comprising: a tank body 1 and a stirring device inside the tank body 1, the stirring device includes a central shaft 9 and a blade shaft 22, and the central shaft 9 is vertically arranged on the tank In the middle of the body 1 (the central axis 9 of this embodiment is set on the center line of the tank body 1), a rotary disk is arranged on the central axis 9, and the central axis 9 is driven by the central axis driving motor 7 and drives the rotary disk to rotate. At least two blade shafts 22 (four blade shafts 22 in this embodiment) are arranged on the rotary disk, stirring blades are arranged on the blade shafts 22, and the blade shafts 22 are driven by the blade shaft driving motor 4, so that the blade shafts 22 are Said turntable is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com