Mechanical stirring desulfurization method for desulfurization pretreatment of molten iron

A technology of mechanical stirring and hot metal desulfurization, which is applied in the field of hot metal desulfurization before converter steelmaking, can solve the problem of improving the kinetic conditions of mechanical stirring desulfurization of hot metal, can not curb the formation of the forced vortex zone in the stirring center, and can not reduce the forced vortex zone Size and other issues, to reduce the short life of the agitator, save stirring energy consumption, and expand the mixing and dispersing area of the molten pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

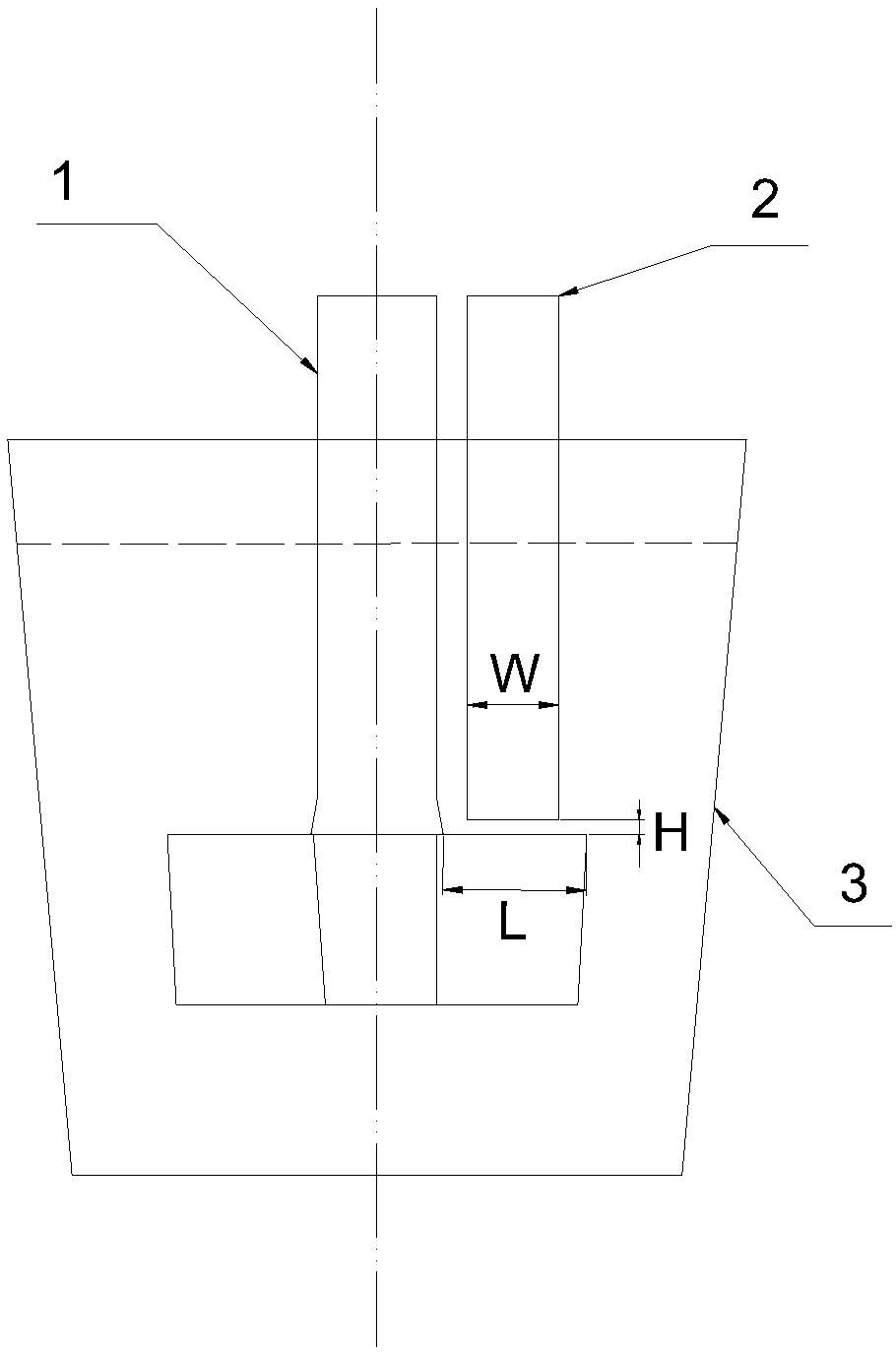

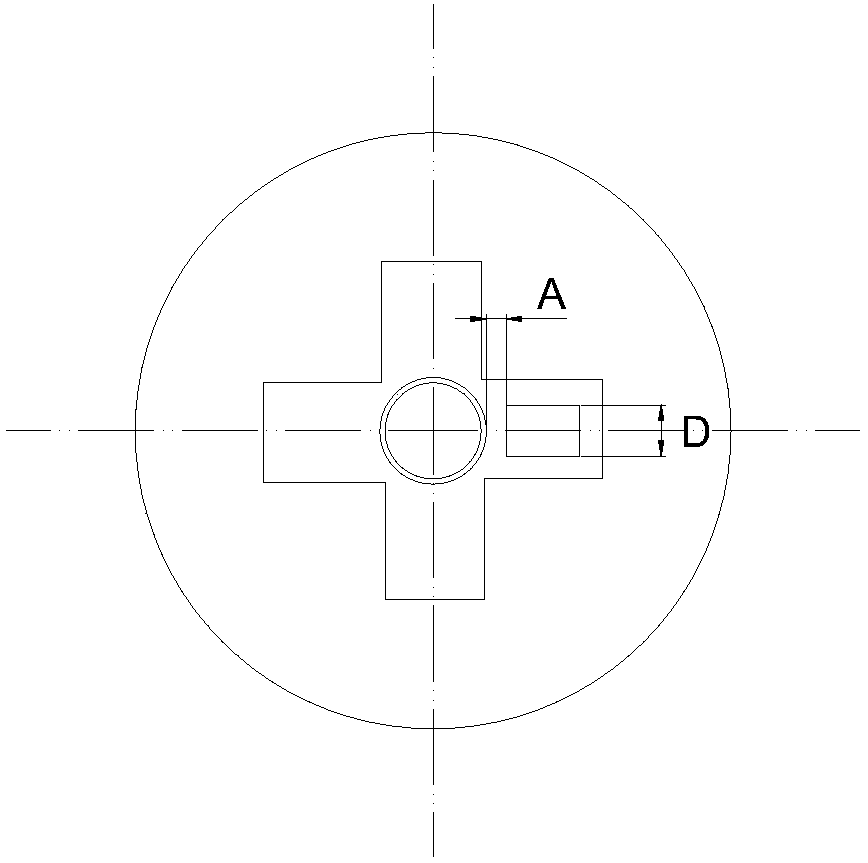

[0029] Such as Figure 1~2 A mechanical agitation desulfurization method for hot metal desulfurization pretreatment is shown. The desulfurization method is completed by several major steps. slag, sample temperature measurement after taking, wherein, in the stirring step of adding desulfurizer, the stirring device is inserted into the molten iron tank 3 equipped with molten iron, the stirring device is composed of a stirrer 1 and a deflector 2, and the deflector Both the plate 2 and the agitator 1 are vertically inserted into the molten iron, and the vertical distance H from the bottom of the deflector 2 to the top of the blade of the agitator 1 is 50 mm; the vertical distance A from the side of the deflector 2 near the stirring shaft to the stirring shaft is 100 mm;

[0030] The width W of the deflector 2 is 1 / 2 times of the length L of the agitator blade;

[0031] The thickness D of the deflector 2 is 1 / 2 times the thickness L of the agitator blade;

[0032] The depth at wh...

Embodiment 2

[0036] The method of this embodiment is basically the same as Embodiment 1, the difference is:

[0037] The vertical distance H between the bottom of the deflector and the top of the blade of the agitator is 100mm; the depth of insertion of the deflector 1 into the molten iron is 4 / 5 times the height h of the molten iron level. The vertical distance A from the side of the flow plate close to the stirring shaft to the stirring shaft is 50mm; the width W of the flow guide plate is 1 times the length L of the agitator blade; the speed of the agitator is 10% lower than that of the conventional KR method.

Embodiment 3

[0039] The method of this embodiment is basically the same as Embodiment 1, the difference is:

[0040] The vertical distance H between the bottom of the deflector and the top of the blade of the agitator is 75 mm; the depth of insertion of the deflector 1 into the molten iron is 3.5 / 5 times the height h of the molten iron level. . The vertical distance A from the side of the deflector close to the stirring shaft to the stirring shaft is 200mm; the width W of the deflector is 3 / 4 times the length L of the agitator blade; the speed of the agitator is 15% lower than that of the conventional KR method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com