Method for preparing lithium ion battery electrode slurry by using vibration-mechanical stirring combination

A lithium-ion battery, mechanical stirring technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems that affect the self-discharge performance of lithium-ion batteries, affect the coating quality, material agglomeration, etc., and achieve good dispersion and fineness. , Improve the beating efficiency and improve the effect of dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

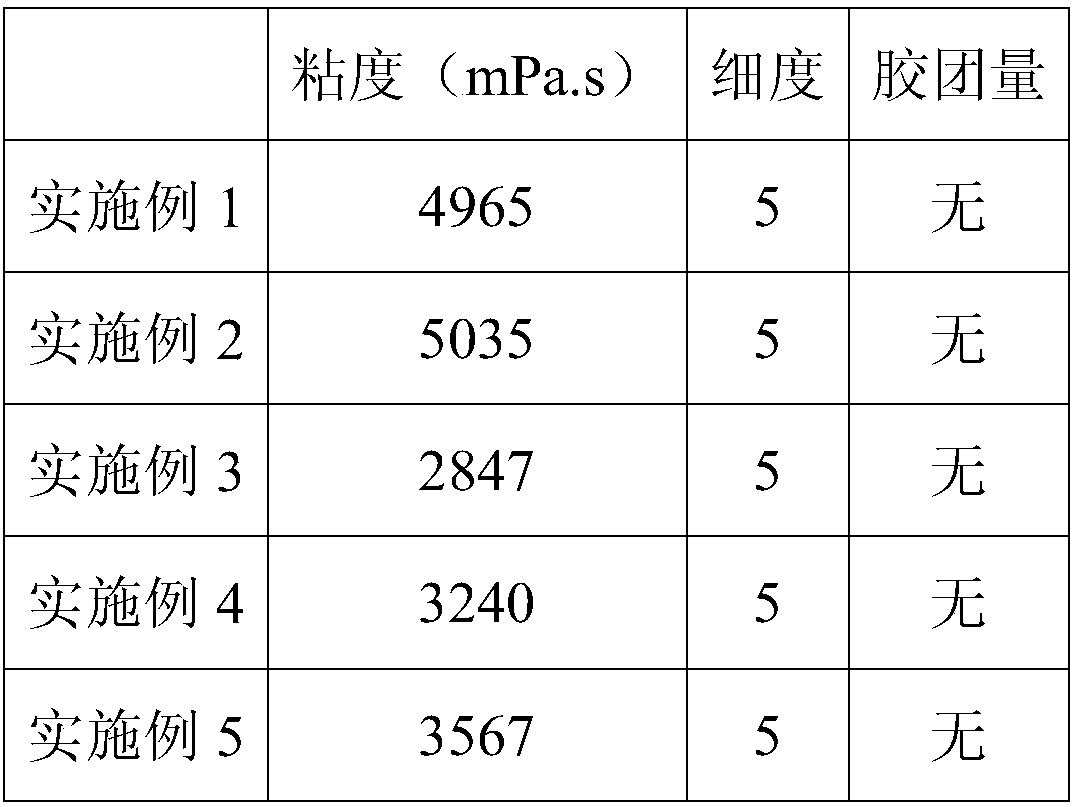

Examples

Embodiment 1

[0024] The method for preparing lithium-ion battery electrode slurry by means of vibration-mechanical stirring comprises the following steps:

[0025] S1: The active substance lithium manganate, the binder polyvinylidene fluoride, and the conductive agent SP are added together into a vibrating mixer for 1 hour of vibration stirring; the rate of vibration stirring is 30 rpm, the vibration frequency is 100 Hz, and in the process of vibration stirring The solvent N-methylpyrrolidone was continuously added in the form of spray, and the required solvent was added to the vibrating mixer within 1 h.

[0026] S2: After the addition of the solvent is completed, continue to vibrate and stir for 1 hour;

[0027] S3: Finally, the slurry is transferred to a stirring pot by a liquid pump and subjected to vacuum mechanical stirring for 2 hours to obtain the lithium-ion battery electrode slurry. The degree is -0.1MPa.

[0028] In the above steps, the weight ratio of lithium manganate, carbo...

Embodiment 2

[0030] The method for preparing lithium-ion battery electrode slurry by means of vibration-mechanical stirring comprises the following steps:

[0031] S1: Add the active material ternary cathode material (Ni:Co:Mn=4:2:4), the binder polyvinylidene fluoride, and the conductive agent SP into the vibrating mixer for 0.5h; the rate of vibrating stirring The vibration frequency is 50rpm, the vibration frequency is 150Hz, and the solvent N-methylpyrrolidone is continuously added in the form of spray during the vibration stirring process, and the required solvent is added to the vibration mixer within 0.5h.

[0032] S2: After the addition of the solvent is completed, continue to vibrate and stir for 1 hour;

[0033] S3: Finally, the slurry is transferred to a stirring pot by a liquid pump and subjected to vacuum mechanical stirring for 1.5 hours to obtain the lithium-ion battery electrode slurry. The degree is -0.1MPa.

[0034] In the above steps, the weight ratio of the ternary po...

Embodiment 3

[0036] The method for preparing lithium-ion battery electrode slurry by means of vibration-mechanical stirring comprises the following steps:

[0037] S1: Add the active material lithium iron phosphate, binder styrene-butadiene rubber, and conductive carbon nanotubes into a vibrating mixer for 1 hour of vibration stirring; the rate of vibration stirring is 40rpm, the vibration frequency is 180Hz, and Continuously add the solvent N-methylpyrrolidone in the form of spray, and add the required solvent to the vibrating mixer within 1h;

[0038] S2: After the addition of the solvent is completed, continue to vibrate and stir for 1 hour;

[0039] S3: Finally, the slurry is transferred to a stirring pot by a liquid pump and subjected to vacuum mechanical stirring for 2 hours to obtain the lithium-ion battery electrode slurry. The degree is -0.085MPa.

[0040] In the above steps, the weight ratio of lithium iron phosphate, carbon nanotubes, and styrene-butadiene rubber is 90:5:5; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com