Antibacterial TPE (Thermoplastic Elastomer) and preparation method thereof

A technology of antibacterial agent and flame retardant, which is applied in the field of antibacterial TPE and its preparation, can solve the problems of oxidative decomposition of antibacterial agent, decline of antibacterial effect, poor anti-oxidation effect, etc., and achieve the effect of slowing down the oxidation of antibacterial agent and preventing coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A1: Heat 50 parts of SBES and 40 parts of PP in a high mixer while premixing;

[0044] A2: After premixing for 2 hours, keep the heating temperature and add 80 parts of white oil and stir at 165r / min for 5 minutes;

[0045] A3: Stop stirring and observe the oil filling of the material in the high mixer.

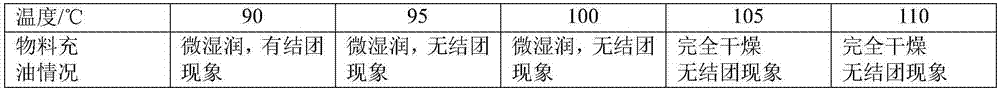

[0046] According to the heating temperature of 90°C, 95°C, 100°C and 105°C, the experiment results are as follows:

[0047]

[0048] It can be seen from the above table that there is a temperature range within the temperature range of 95-105°C so that the white oil is fully absorbed and the heating energy consumption is low, and the increase in the heating temperature in it is conducive to the absorption of the white oil.

Embodiment 2

[0050] temperature / ℃

Embodiment 3

[0052] B1: Heat 60 parts of SBES and 40 parts of PP in a high mixer while premixing;

[0053] B2: After premixing for 2 hours, add 60 parts of white oil while maintaining the heating temperature and stir at 165r / min for 5 minutes;

[0054] B3: Stop stirring and observe the oil filling of the material in the high mixer.

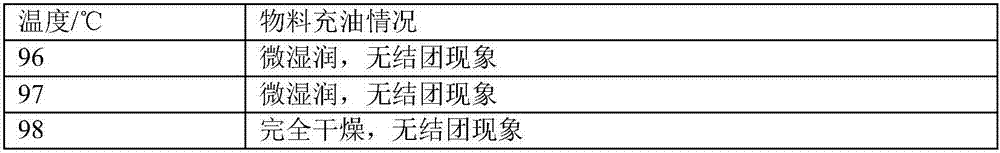

[0055] According to the heating temperature of 96°C, 97°C, 98°C, 99°C, 100°C, 101°C, 102°C, 103°C, the experiment results are as follows:

[0056]

[0057]

[0058] From the results of Examples 2 and 3, it can be seen that the ratio of SEBS and white oil in Example 2 reaches the minimum within the component requirements, and the white oil is completely absorbed when the heating temperature is 103°C; The white oil ratio reaches the maximum, and its absorption is complete when the heating temperature is 98°C, so when the heating temperature is preferably 98°C-103°C, the white oil is fully absorbed and the heating energy consumption is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com