High performance backward bent stirring paddle with circular arc surface

An arc surface, high-performance technology, applied in the field of stirring paddles, can solve problems such as the reduction of stirring performance, and achieve the effect of reducing sedimentation, inhibiting the generation of sedimentation, and the ability to inhibit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

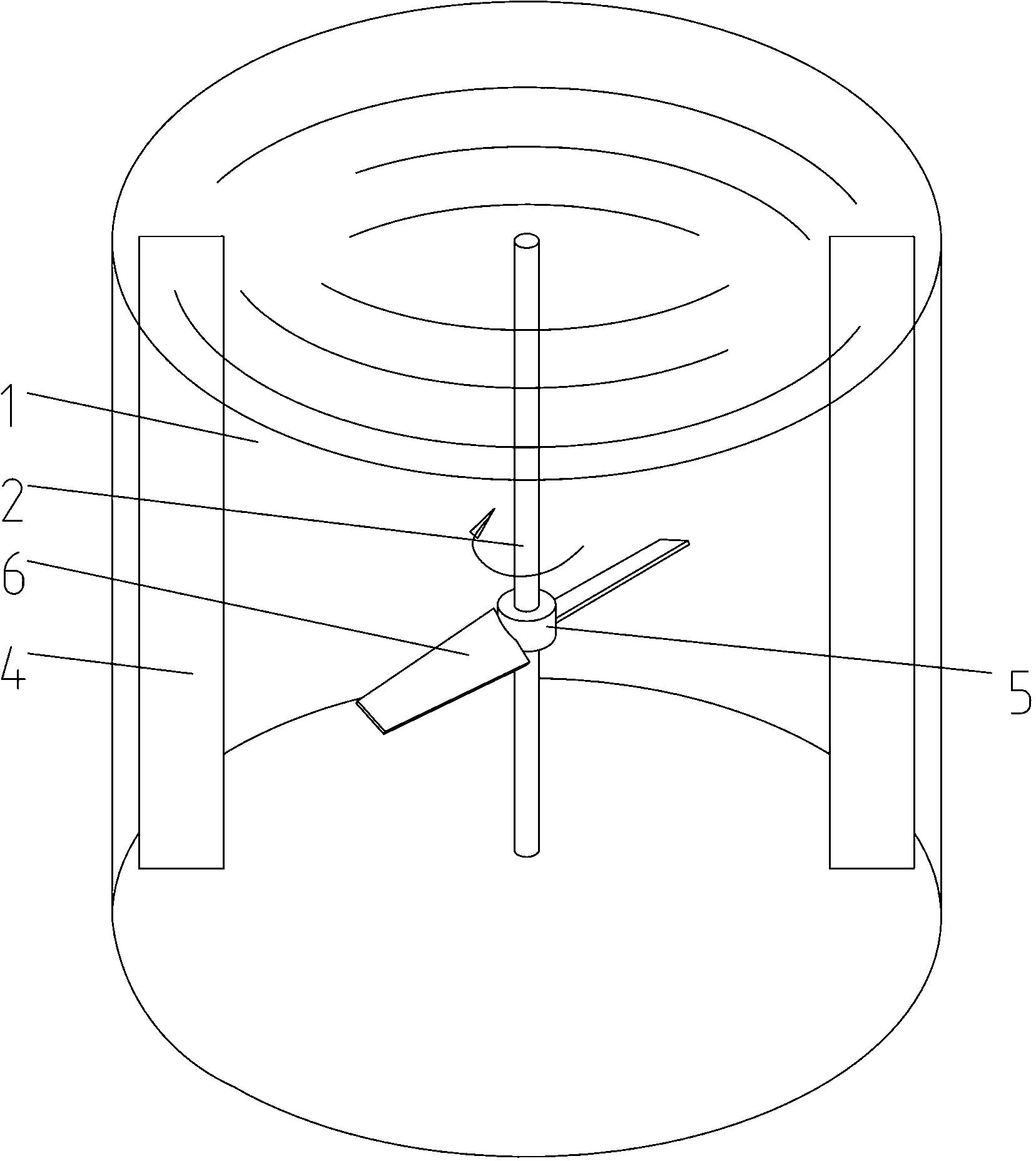

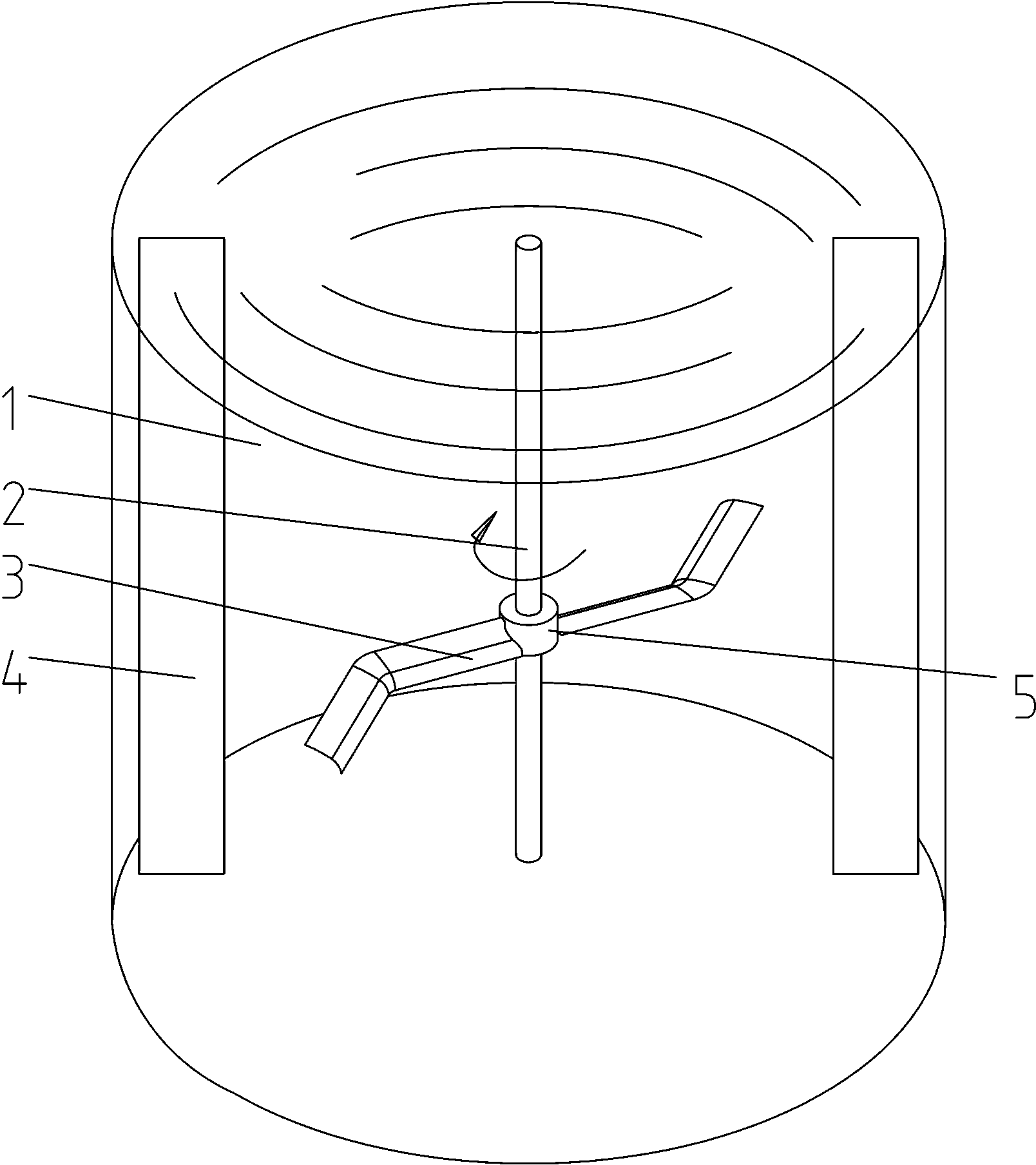

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] As shown in the figure, a high-performance circular-arc-surfaced backward-curved stirring paddle of the present invention includes a paddle 3, the cross section of the paddle 3 is arc-shaped or approximately circular-arc-shaped, and the tangential direction of the upstream side of the paddle 3 is in line with the paddle. The direction of rotation of the blades is parallel; the projection shape of the blade 3 in the vertical direction is the outer end back-bending type, the direction of the back-bending is opposite to the direction of rotation, and the angle is 0-90 degrees.

[0016] The blade width gradually narrows from the root to the outer end, and the outer end is chamfered.

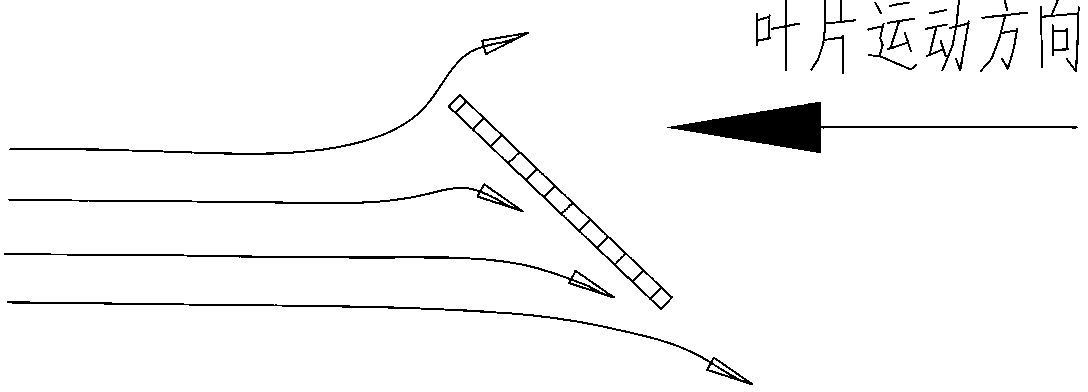

[0017] The outflow edge of the paddle is gradually curved, parallel to the direction of liquid flow.

[0018] The number of the paddles is 2-6.

[0019] The hub 5 is used to fix the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com