Jet type hydraulic blender

A mixer and jet-type technology, which is applied in the field of mixers or aerators, and jet-type hydraulic mixers, can solve the problems of low mixing efficiency, large mixing energy consumption, and single mixing method, and achieve simple structure, reduced mixing dead zone, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

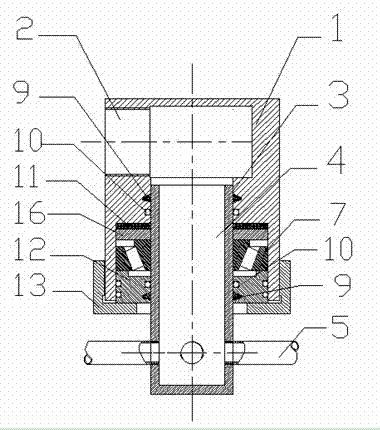

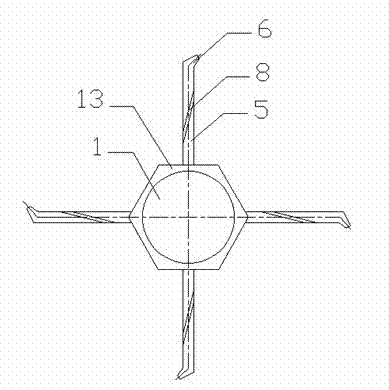

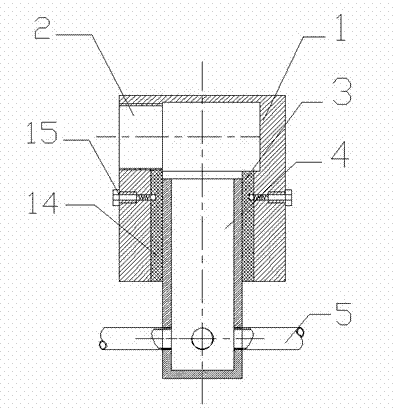

[0020] see figure 1 , figure 2 , the first structural schematic diagram of a jet hydraulic mixer, including a stirring body, and also includes a main joint 1, the main joint 1 has a connected liquid inlet hole 2 and a connecting hole 3, and the stirring body is composed of a hollow back The rotating shaft 4, the liquid spray pipe 5 and the nozzle 6 are composed of one end of the hollow rotating shaft 4 being a holed end with a shaft hole, and the other end being a non-porous end with a closed shaft hole. The connecting hole 3 is a moving fit and the shaft hole is connected with the liquid inlet hole 2. The non-porous end of the hollow rotary shaft 4 extends out of the main joint 1, and the shaft hole on the side of the non-porous end is radially connected with at least one liquid spray pipe 5 , the end of the liquid spray pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com