A steamed bun machine

A steamed bread machine and steamed bread technology, which is applied to plug-ins, cooking utensils, household utensils, etc., can solve the problems of inconvenient operation, large area, and inability to make steamed bread, etc., and achieve the effects of reducing labor, compact structure, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

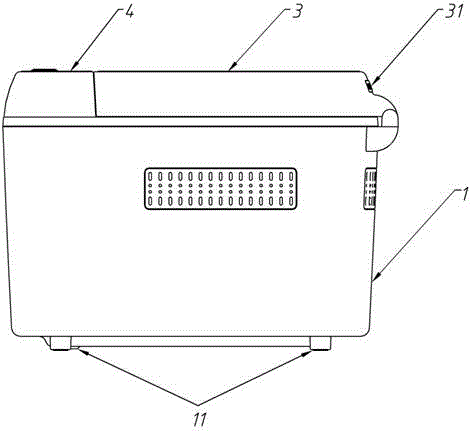

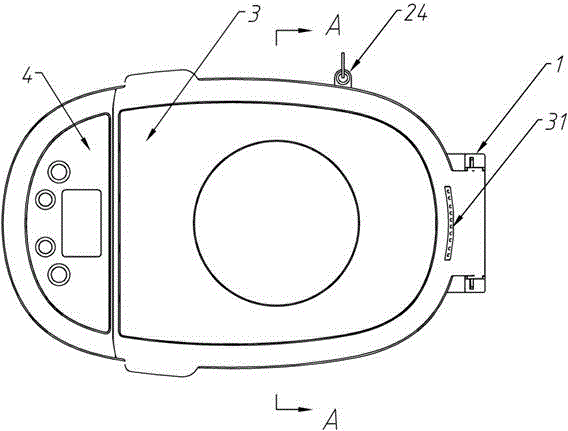

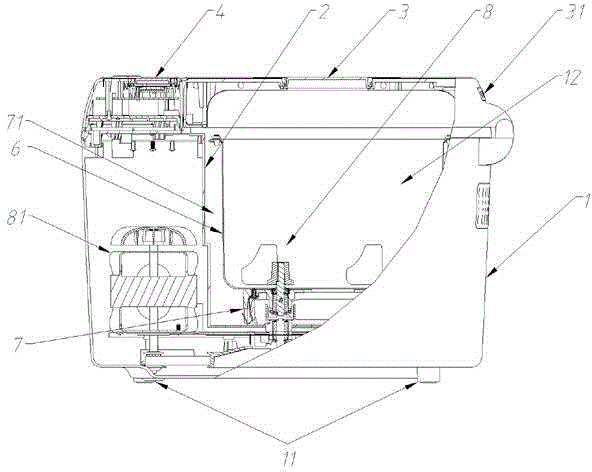

[0037] Such as Figure 1 to Figure 8 , Figure 15 and Figure 16 As shown, in this embodiment, the present invention includes a housing 1, a cavity 2 disposed in the housing 1, an upper cover structure 3 disposed on the upper end of the housing 1, and a control panel disposed on the housing 1 4. The lower part of the cavity 2 is provided with a heating element 5, and the cavity 2 and the upper cover structure 3 are surrounded to form a closed space 12, and the upper cover structure 3 can rotate around the rotating shaft 10 without the aid of tools , the upper cover structure 3 is disassembled from the whole machine, the opening of the cavity 2 is upward, and the cavity 2 has good sealing properties, and can hold a certain amount of water. The cavity 2 is provided with at least A steamed bun bucket 6 with an opening upward, a support frame 7 is arranged between the steamed bun bucket 6 and the cavity 2, there is an interval 71 between the periphery of the steamed bun bucket 6...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is: as Figure 9 to Figure 11 As shown, the upper end of the cavity 2 is provided with a steamer assembly 9 matching the opening of the cavity 2 , and the steamer assembly 9 and the cavity 2 form a closed space 12 .

[0051] The steamer assembly 9 includes at least one steamer 91 and a steamer cover 92 adapted to the steamer 91 . In this embodiment, the steamer assembly 9 includes one steamer 91 .

[0052] When using the semi-automatic function of the present invention, after the user puts raw materials such as flour into the steamed bun bucket 6, when the dough fermentation is completed, the alarm device sends out a warning signal, and the steamed bun bucket 6 needs to be manually taken out, and at the same time The upper cover structure 3, the shaped steamed buns are placed on the steaming tray 22 and the steamer 91, the steamer cover 92 is covered, and the control panel 4 is adjusted to continue the next step un...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is: as Figure 12 to Figure 14 As shown, at least one steaming rack 23 is also provided in the cavity 2. In this embodiment, two steaming racks 23 are provided. The steaming racks 23 can be stacked for use. When using the semi-automatic function of the present invention, use After the flour and other raw materials are put into the steamed bun bucket 6, when the fermentation of the dough is completed, the alarm device sends out a warning signal, and the steamed bun bucket 6 needs to be manually taken out, and then the steamed bun bucket 6 is put into the cavity 2. Steaming rack 23, the formed steamed bun base is placed on the steaming rack 23, the upper cover structure 3 or the steamer cover 92 is covered, and the control panel 4 is adjusted to continue the next step until the steamed buns are made.

[0055] The invention has a reservation function, and this function is suitable for use at night, and is also suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com