Sour milk machine and operating method thereof

An operation method and technology of a yogurt machine, which can be applied to milk preparations, beverage preparation devices, household appliances, etc., can solve problems such as unsatisfactory, and achieve the effect of good fermentation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

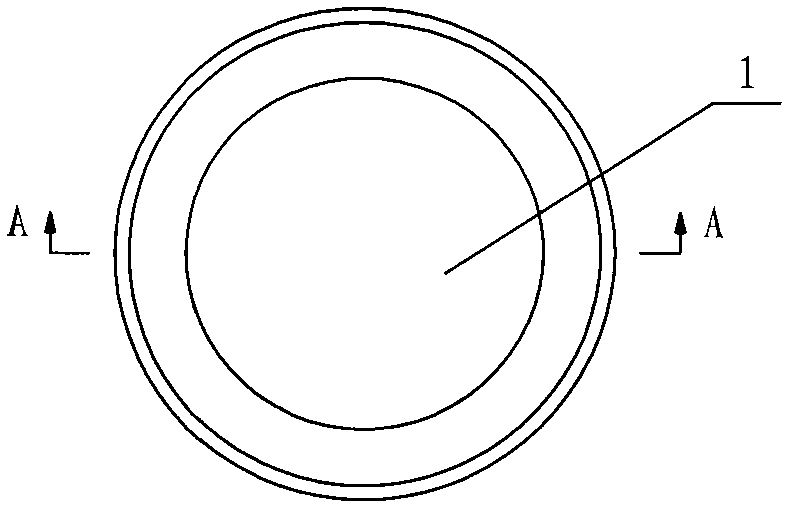

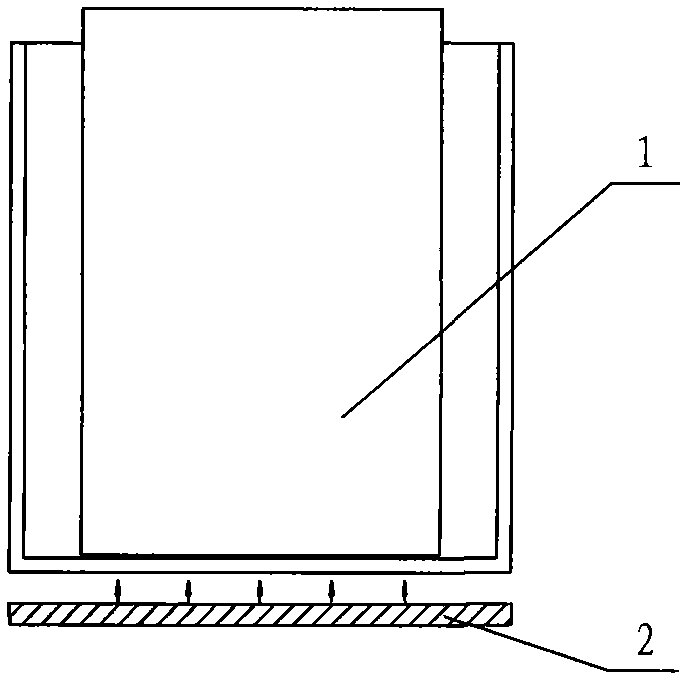

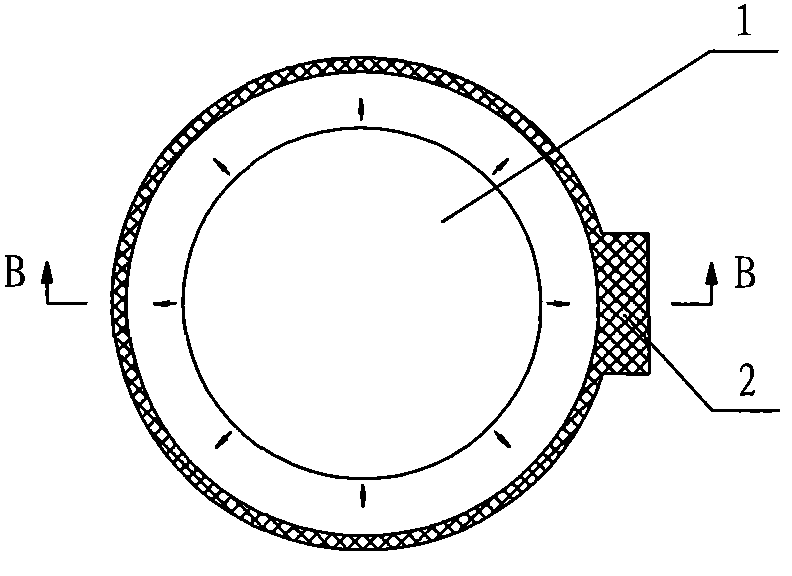

[0067] see Figure 3-Figure 5 , The yogurt machine includes a fermentation cup 1 arranged in a heat conduction barrel 2, a semiconductor chip and a heat conduction barrel temperature sensor are arranged on the heat conduction barrel 2, and a fermentation cup temperature sensor 3 is arranged at the bottom center of the fermentation cup 1. The semiconductor chip surrounds the sides of the fermenter 1 . The heat conduction bucket temperature sensor is a high and low temperature protection sensor 4.

[0068] The operation of the yogurt machine includes the following steps:

[0069] The first step is to select the working mode of the yogurt machine. When it is fresh, enter the second step; when it is fermentation, enter the seventeenth step;

[0070] The second step is to start the power supply, input the reverse voltage U=-11.5±1V to the semiconductor ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com