Desilting flexible sealing system of Baijiu fermenting tank

A closed system and fermentation tank technology, applied in the field of liquor fermentation tanks, can solve the problems of overall volume expansion, time-consuming and laborious, poor reusability of sealing materials, etc., achieve a scientific and simple system structure, solve environmental pollution problems, and seal the effect keep up the good work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

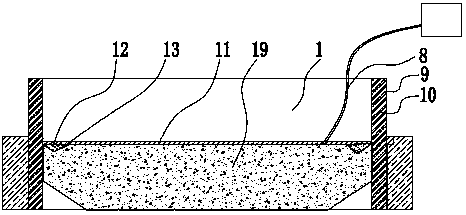

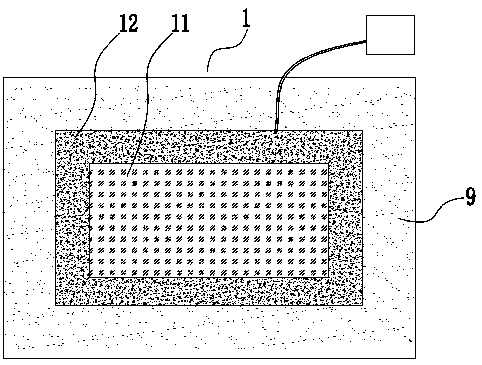

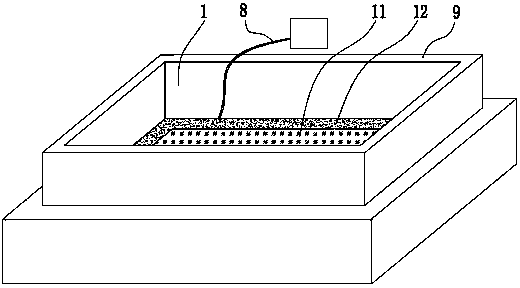

[0026] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0027] see Figure 1~Figure 3 , as a preferred embodiment of the present invention, the grit settling flexible closed system of the liquor fermentation tank includes the cellar 1 as the fermentation tank, the cellar cover for the fermentation raw materials in the cellar 1, and the wall of the cellar cover and the cellar 1 The sealing packing material for sealing is characterized in that: the cellar cover is a flexible sealing cover 11 that conforms to the wall of the cellar 1, and the sealing packing material is stacked and pressed on the edge of the flexible sealing cover 11 Fine sand12.

[0028] Preferably, the flexible sealing cover 11 is made of malleable transparent material.

[0029] Preferably, the fine sand 12 is Shenjiang sand with an average particle size of 0.35mm or less.

[0030] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com