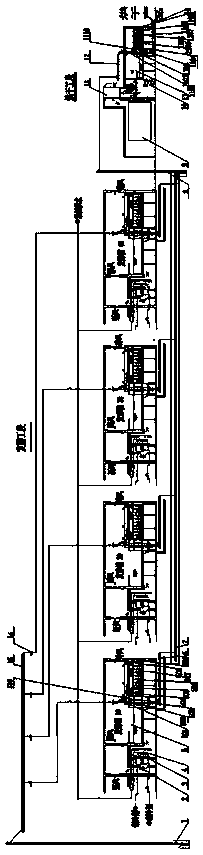

Industrial and agricultural production waste residue biological fermentation, drying method and special integrated system

A biological fermentation and fermentation system technology, applied in the field of integrated systems, can solve problems such as the influence of the surrounding environment, easy-to-contaminate bacteria, and incomplete fermentation, and achieve the effects of moderately controllable fermentation temperature, increased protein content, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

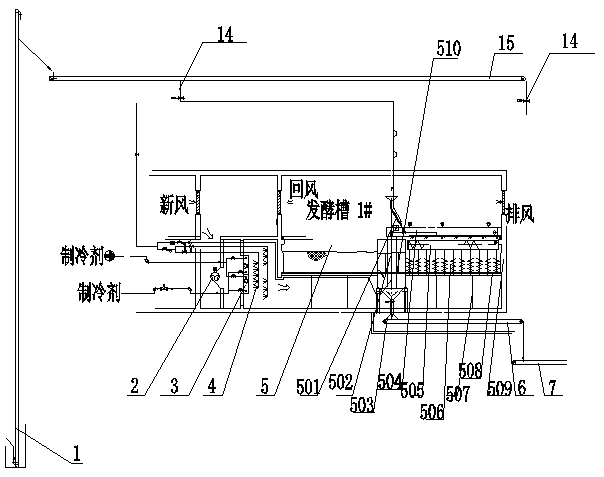

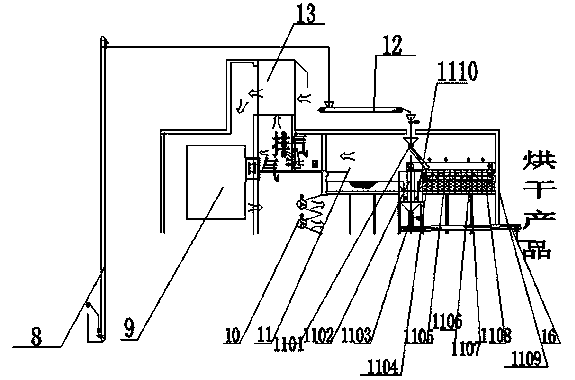

[0049] A method for biological fermentation and drying of industrial and agricultural production waste residues, the method comprising the following steps:

[0050] Fermentation and drying of materials;

[0051] (1) The mixed material is lifted by the bucket elevator 1 and conveyed by the buried scraper conveyor 15 into the feed chute I501 of the fermentation tank, and the material is evenly distributed on the sieve plate of the fermentation tank 5 under the push of the leveling machine I505. Carry out fermentation production; the mixed material is liquor distiller's grains;

[0052] (2) Test the temperature and humidity of the fermentation materials; when the temperature and humidity of the materials do not match the process conditions, adjust the temperature and humidity of the materials, start the fermentation fan 2, the fermentation refrigeration system 3, the humidification system 4, and start the turning machine Ⅰ506 Stirring, the temperature and humidity in the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com