Wine grains stacking fermentation device

A technology of stacking fermentation and fermented grains, applied in the preparation of alcoholic beverages and other directions, can solve the problems of poor temperature controllability of fermented grains, increase production costs, poor air permeability, etc., and achieve the effects of improving competitiveness, vigorous metabolism, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

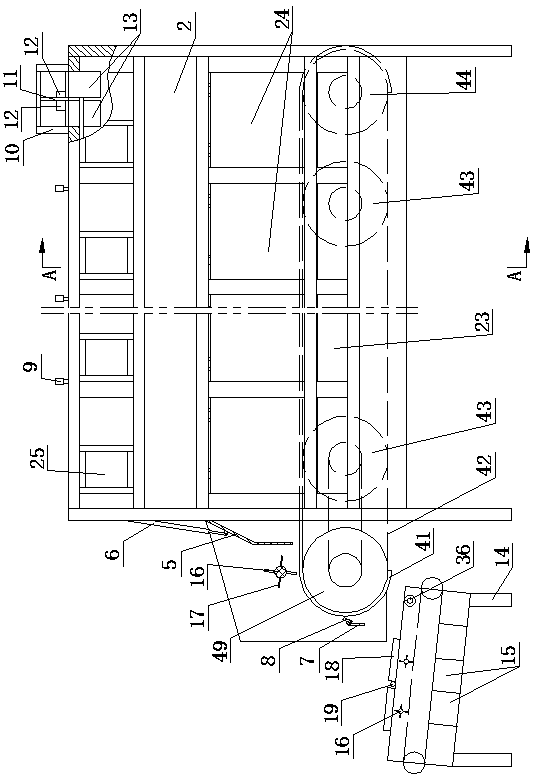

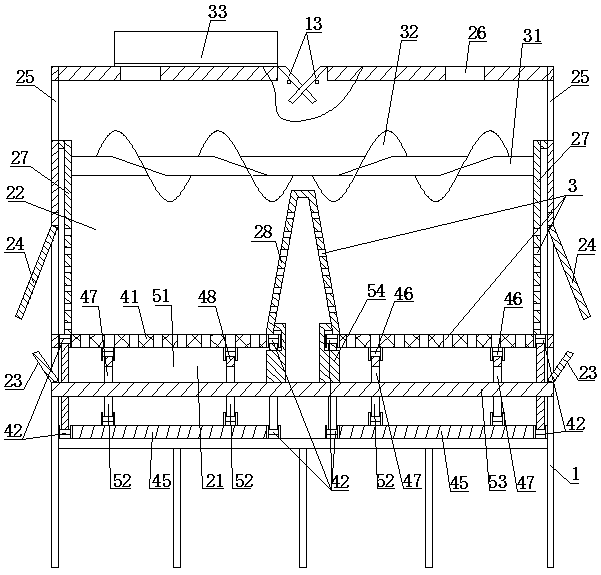

[0018] Such as figure 1 with figure 2 As shown, the fermented grains accumulating and fermenting device includes a frame 1 and a cuboid-shaped accumulation chamber 2 mounted on the frame 1, and the frame 1 is rotatably connected with a drive roller 49 driven by a power device and a set of rollers corresponding to the drive roller 49. The driven roller 44, the driving roller 49 and the driven roller 44 are respectively arranged at the two ends of the stacking chamber 2 in the lengthwise direction, and the driving roller 49 and the driven roller 44 are provided with conveyor belts, and a plurality of vent holes 3 are evenly distributed on the conveyor belt. , the conveyor belt separates the chamber cavity of the stacking chamber into an upper cloth chamber 22 and a lower ventilating chamber 21, and the bottom wall 53 of the stacking chamber is fixedly equipped with a plurality of partitions that divide the ventilating chamber 21 into multiple chambers in turn along the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com