A raw material mixing device for chemical copper plating solution preparation

A mixing device and raw material technology, applied in mixers, shaking/oscillating/vibrating mixers, dissolving, etc., can solve the problems of wasting electric energy, motor damage, high failure rate, etc., and achieve the goal of improving the mixing effect, improving the effect, and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

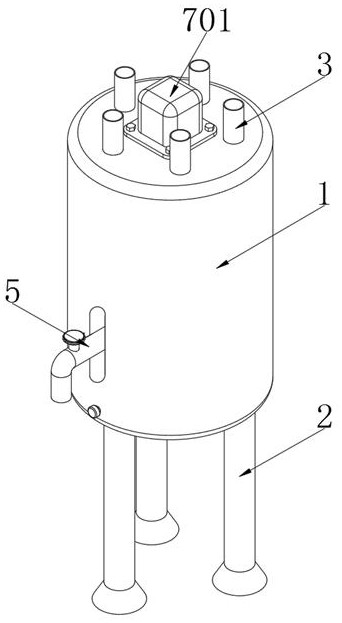

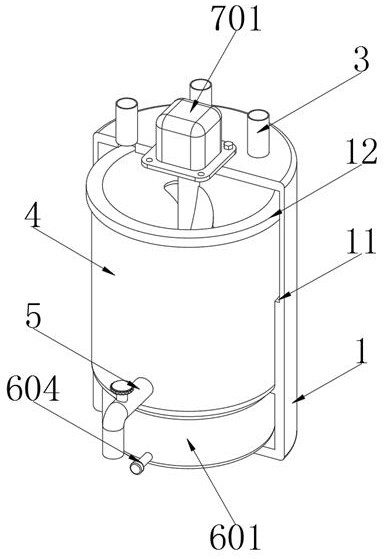

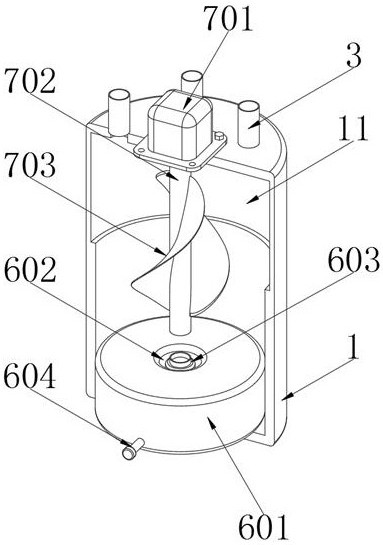

[0044] Example: Figure 1 ~ 9 As shown, the present invention provides the following technical solution, a chemical copper-plated solution to prepare a raw material mixing device, including an outer can body 1, a support leg 2, and a raw material inlet 3, and the outer can body 1 is supported by the support leg 2. The tank 1 is provided with a number of raw materials inlet 3 for adding a copper-plated solution to prepare a raw material. The outer can body is disposed inside a mixed inner tank 4 that can be moved, so that the mixed inner can 4 can move downward. The raw material is mixed, and the inner tank 4 is provided with a drain tube 5, and the discharge tube 5 and the outer can body are provided with a slide that is slid in the hydraulic tube 5 so that the inner can 4 is up and down. During the movement, it is not affected by the drain tube 5 of the extended outer can 1, and the inner bottom end of the mixed inner can 4 is provided with a pneumatic stirring mechanism for pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com