Wet material blending mobile trolley for small and medium-sized pig house

A mobile trolley, small and medium-sized technology, applied in the field of livestock breeding, can solve the problems of high labor intensity, long feeding time of weaned piglets, low blending efficiency, etc., and achieve the effect of reducing labor intensity, shortening feeding time, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

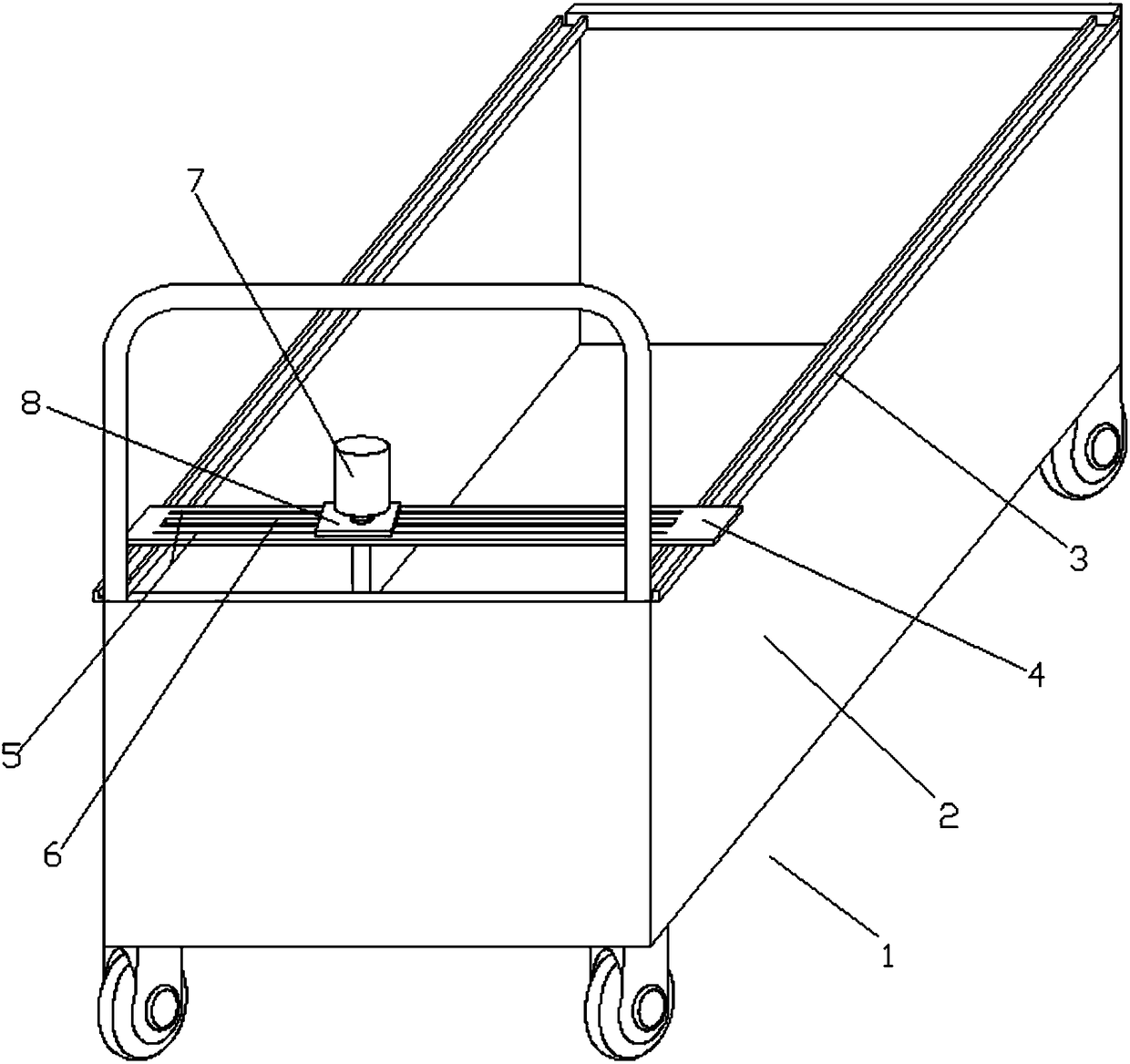

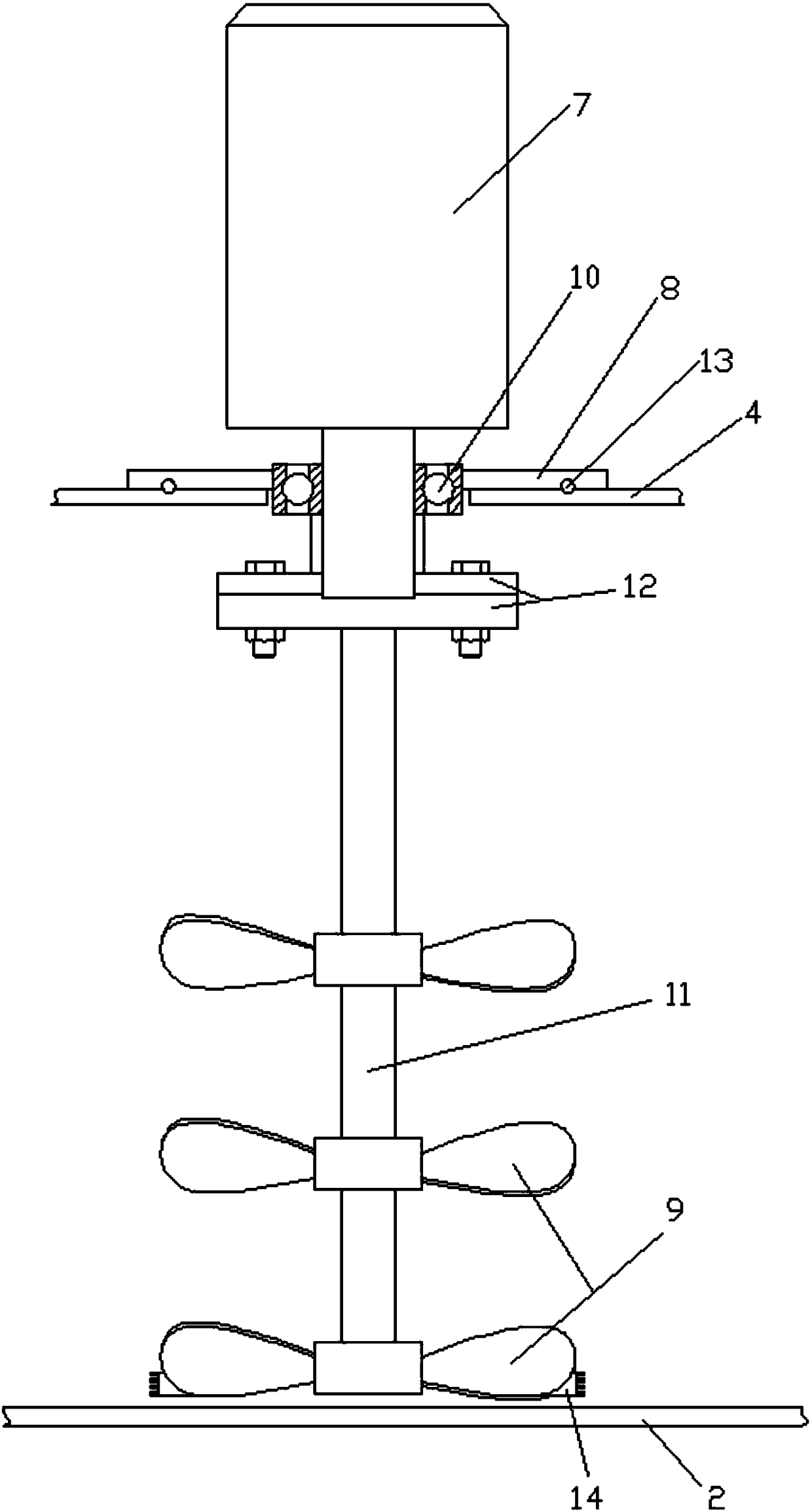

[0016] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0017] The wet material blending mobile trolley for small and medium-sized pig houses has a mobile trolley 1 and a food trough 2 mounted on the mobile trolley 1. The upper end of the mobile trolley 1 is equipped with a moving device and the mobile device is fixed on the upper edge of the food trough 2 And linearly slide along the length direction of the food tank 2, the moving device is provided with a stirring device for stirring the blended material in the food tank 2 and the stirring device is installed on the moving device and slides along the length direction of the moving device; , the moving device includes a guide rail 3 and a mounting plate 4, the notch of the guide rail 3 is set upwards and fixed on the upper edge of the trough 2, the upper end surface of the mounting plate 4 is shaped on an arc groove 5 and a long The bar holes 6 and the arc grooves 5 are distributed on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com