Rheoforming apparatus

A technology of rheological forming and forming cavity, which is applied in the direction of kneading massage equipment, auxiliary products for massage, equipment for feeding molten metal into casting molds, etc. Processing process, effect of shortening molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

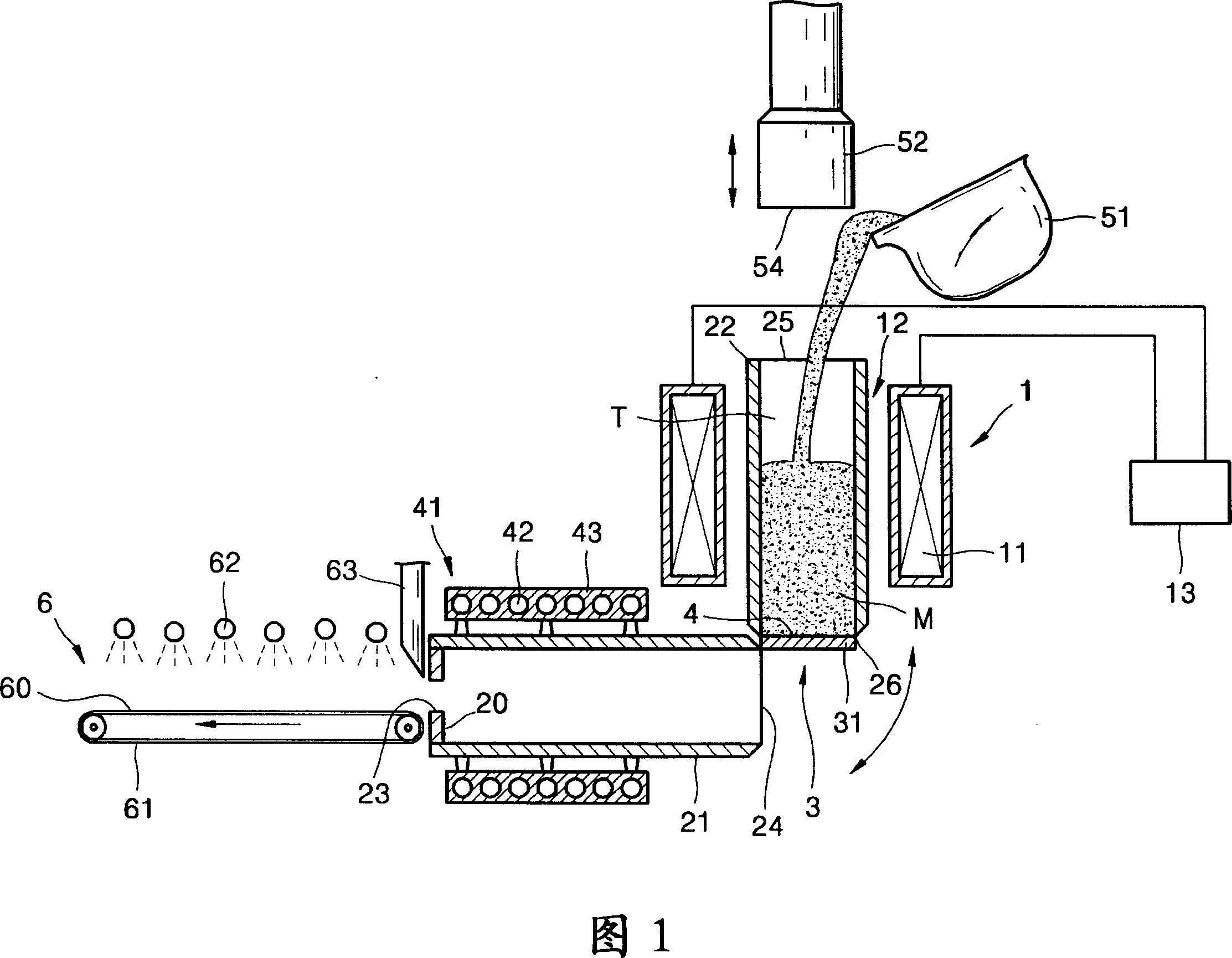

[0099] The specific implementation, structure, features and functions of the rheological shaping device according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0100] The rheological shaping device according to the present invention utilizes a semi-solid slurry to prepare a product having a predetermined shape.

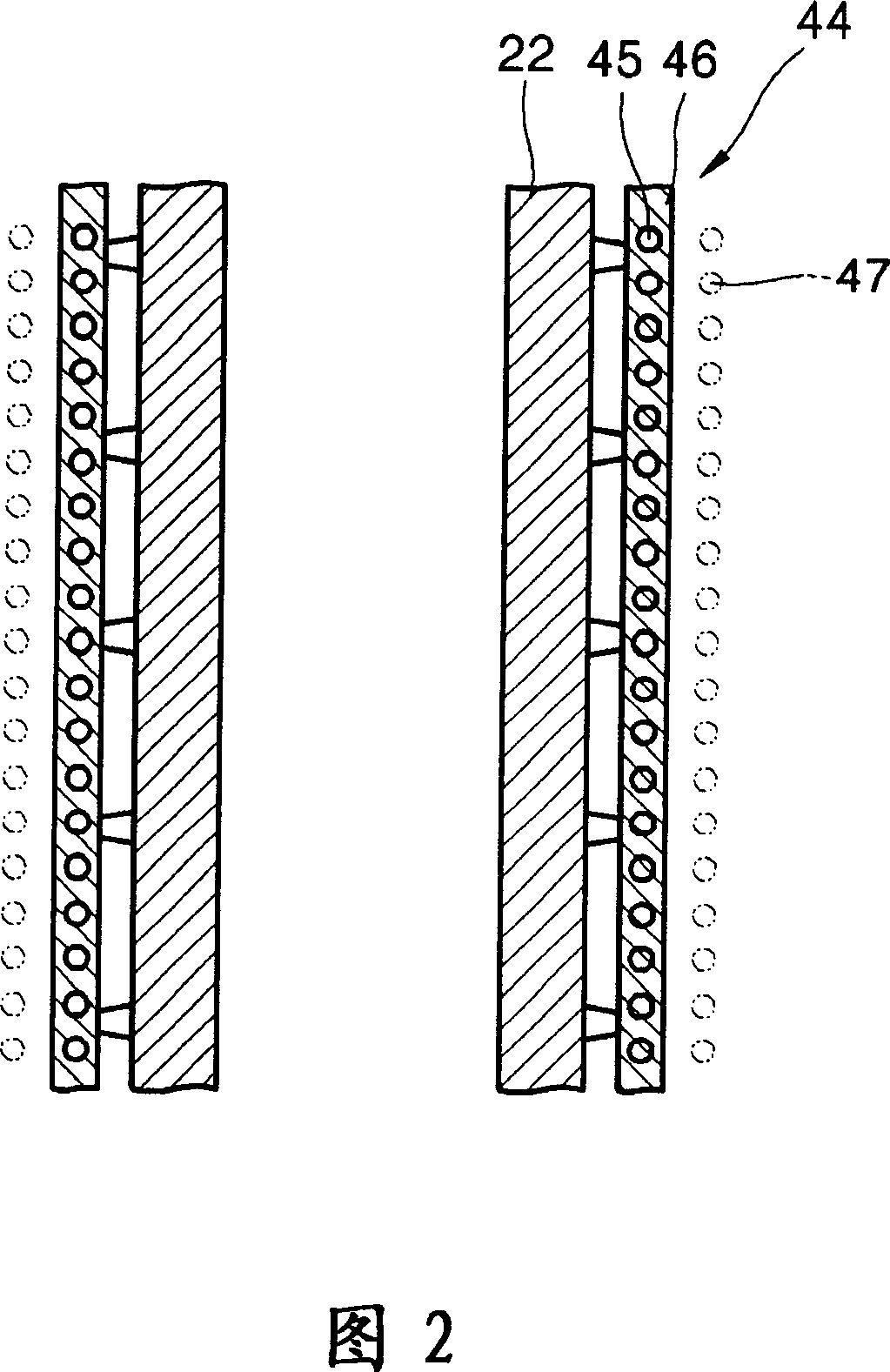

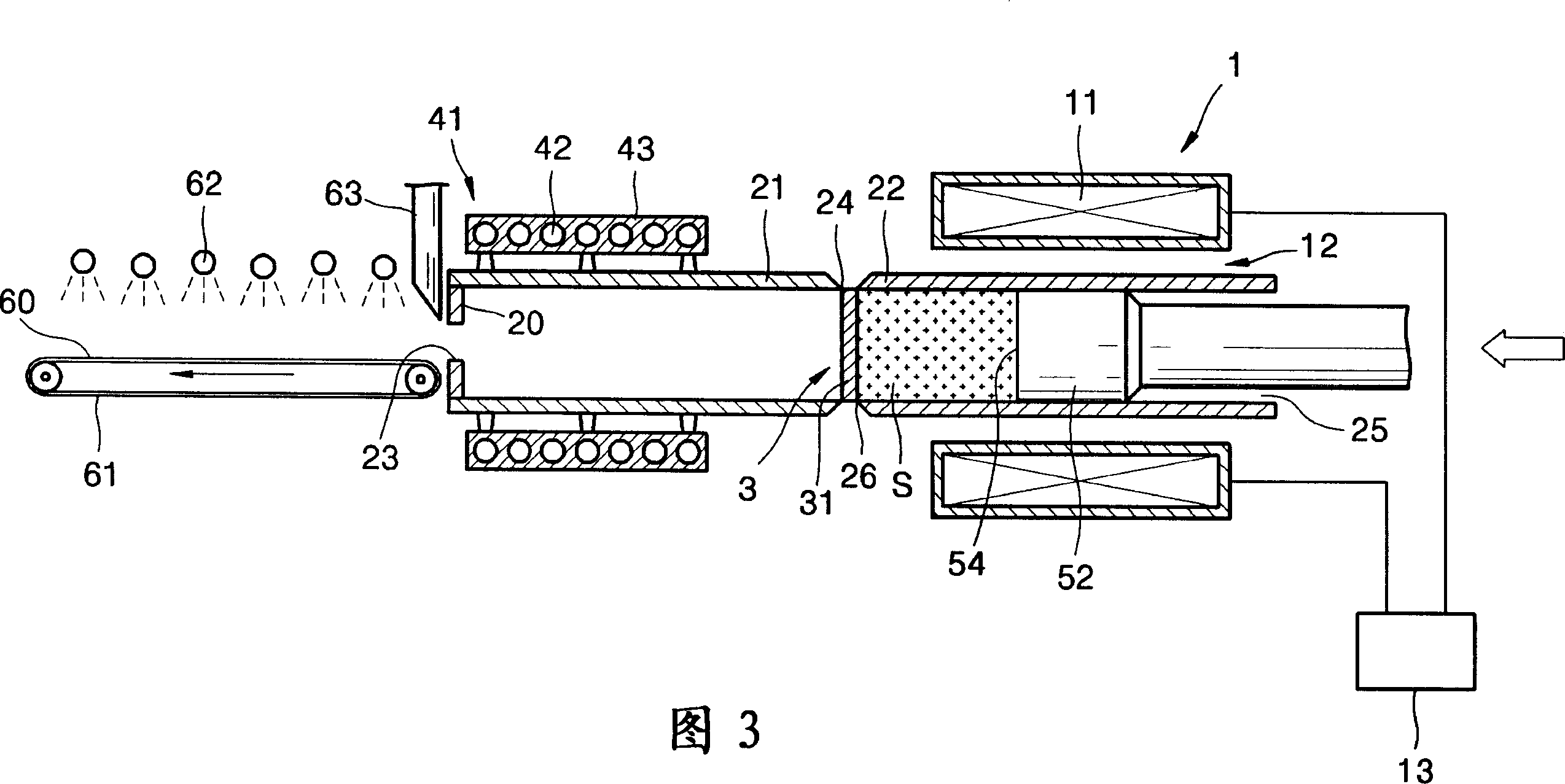

[0101] Referring to FIGS. 1 to 7 , the first embodiment of the present invention will be described in detail. Fig. 1 is a schematic diagram of the structure of the rheomorphic device according to the first embodiment of the present invention, Fig. 2 is a sectional view of the second casing used in the rheomorphic device shown in Fig. 1, Figs. 3-6 are A schematic diagram of the sequence of processes for preparing an extruded profile using the rheological deformation device according to the first embodiment of the present invention, and FIG. 7 is a temperature distribution curve for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com