Papermaking sludge conditioning agent and application thereof

A technology of papermaking sludge and chemicals, which is applied in sludge treatment, water/sludge/sewage treatment, sludge oxidation treatment, etc. It can solve the problems of low calorific value of combustion and difficulty in dehydration of papermaking sludge, and achieve calorific value Improve, excellent oxidation bleaching, and accelerate the effect of filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

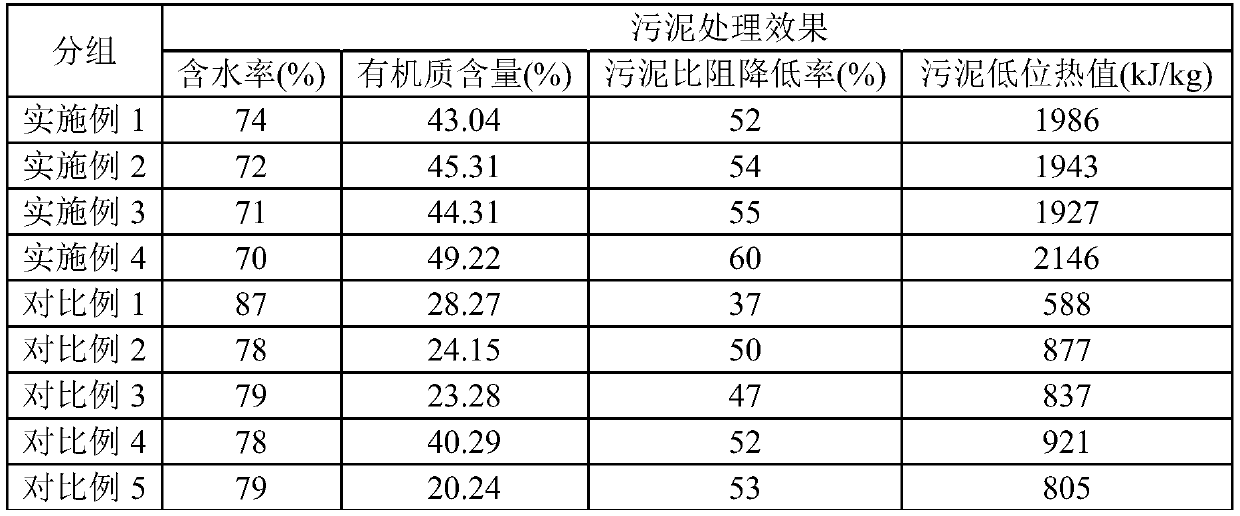

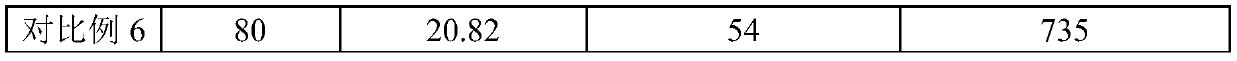

Examples

Embodiment 1

[0020] A paper-making sludge conditioning agent, which is composed of sodium ferrate and pine sawdust powder. The paper-making sludge can be dehydrated by using the conditioning agent. The specific process is as follows:

[0021] Under the action of stirring, 40 mg / g sodium ferrate was added to the sludge on a dry basis, and the reaction was mixed for 10 minutes, and the amount of sodium ferrate added was based on the mass of iron ions; Measuring, adding 400mg / g pine sawdust powder, mixing for 1min, and the resulting sludge mixture is left standing for treatment.

Embodiment 2

[0023] A paper-making sludge conditioning agent, which is composed of potassium ferrate and pine sawdust powder. The paper-making sludge can be dehydrated by using the conditioning agent. The specific process is as follows:

[0024] Under the action of stirring, 60 mg / g potassium ferrate was added to the sludge on a dry basis, and the reaction was mixed for 30 minutes, and the amount of potassium ferrate added was based on the mass of iron ions; Measuring, adding 500mg / g pine sawdust powder, mixing for 5min, and standing the sludge mixture for disposal.

Embodiment 3

[0026] A paper-making sludge conditioning agent, which is composed of sodium ferrate and poplar sawdust powder. The paper-making sludge can be dehydrated by using the conditioning agent. The specific process is as follows:

[0027] Under the action of stirring, 50 mg / g sodium ferrate was added to the sludge on a dry basis, and the reaction was mixed for 20 minutes, and the amount of sodium ferrate added was based on the mass of iron ions; Measuring, adding 450mg / g poplar sawdust powder, mixing for 3min, and the resulting sludge mixture is left standing for disposal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com