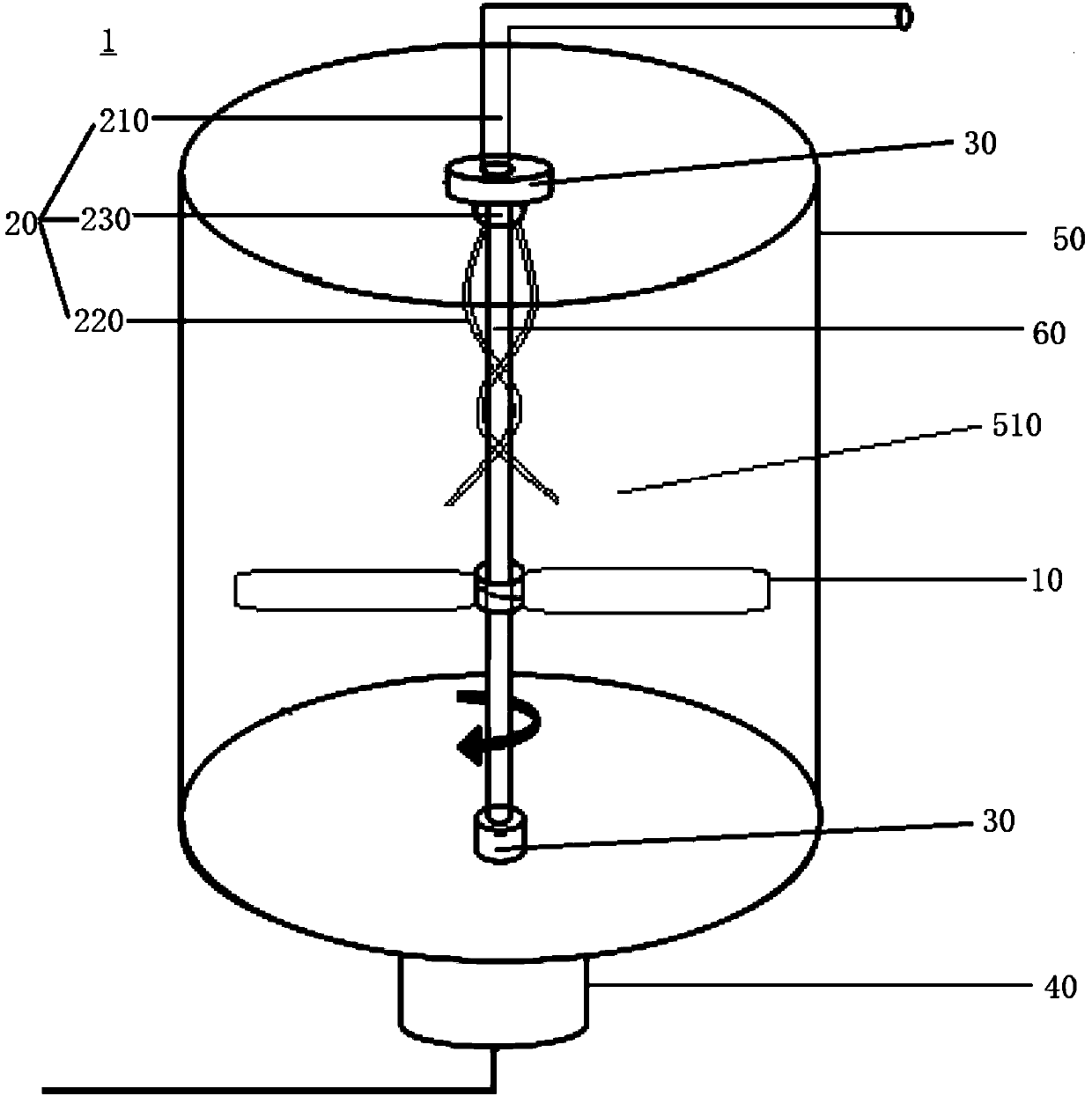

Gas-liquid mechanical coupled agitator

A stirring device and mechanical technology, which is applied to mixers, mixer accessories, mixers and other directions with a rotating stirring device, can solve the problems of low gas-liquid mixing efficiency, large electric energy demand, and many stirring dead zones, and reduce the stirring energy. consumption, improve the effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

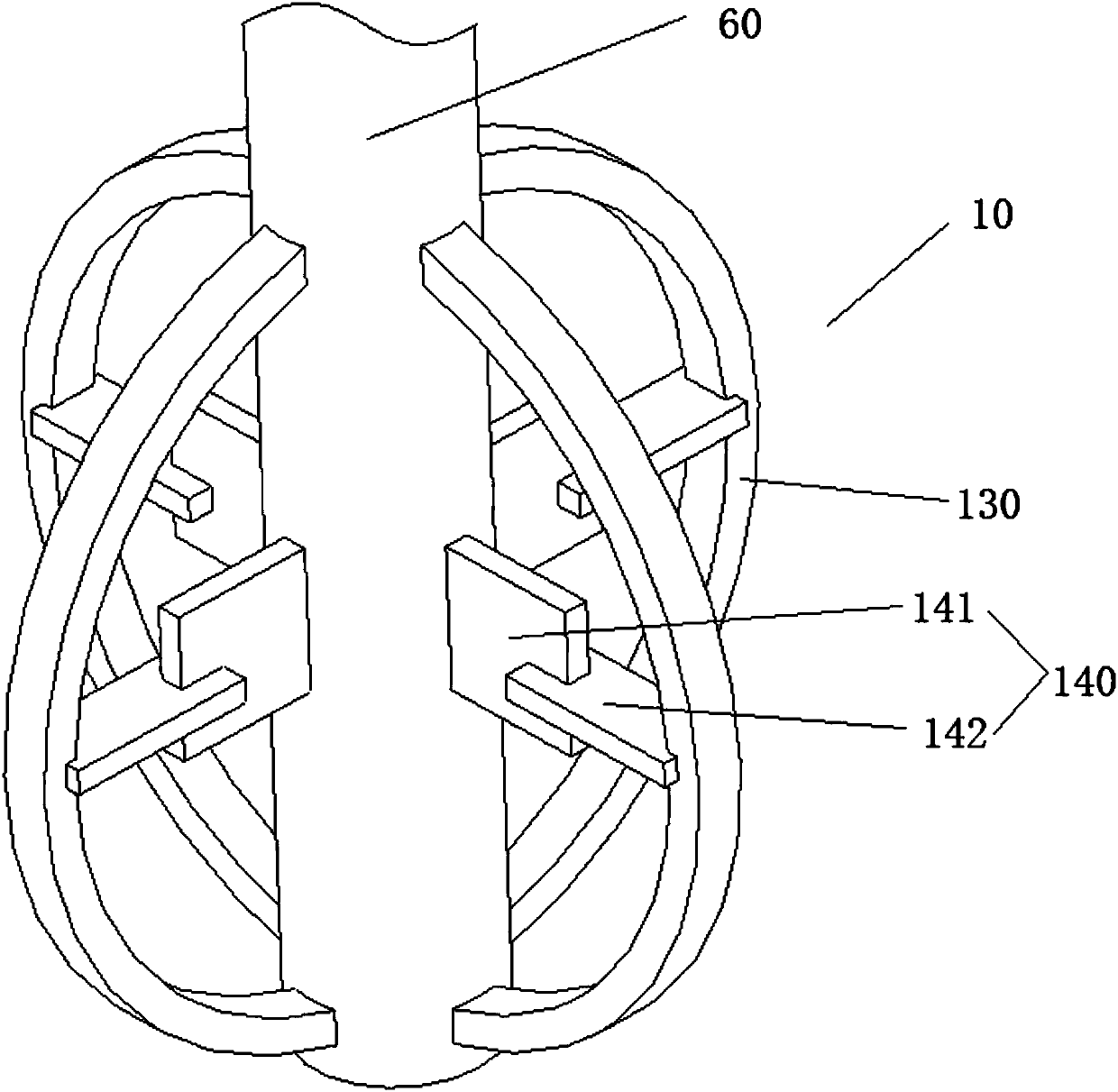

[0055] Such as figure 2 As shown, the stirring member 10 of this example includes a stirring rib 130 and a blade 140, the stirring rib 130 is arranged along the axial direction of the rotating shaft 60 and is arc-shaped, the two ends of the stirring rib 130 are connected on the rotating shaft 60, and the blade 140 includes a first One end of the first leaf 141 is connected with the rotating shaft 60 , one end of the second leaf 142 is connected with the first leaf 141 , and the other end of the second leaf 142 is connected with the stirring rib 130 . The thickness direction of the first leaf portion 141 is perpendicular to the thickness direction of the second leaf portion 142 .

example 2

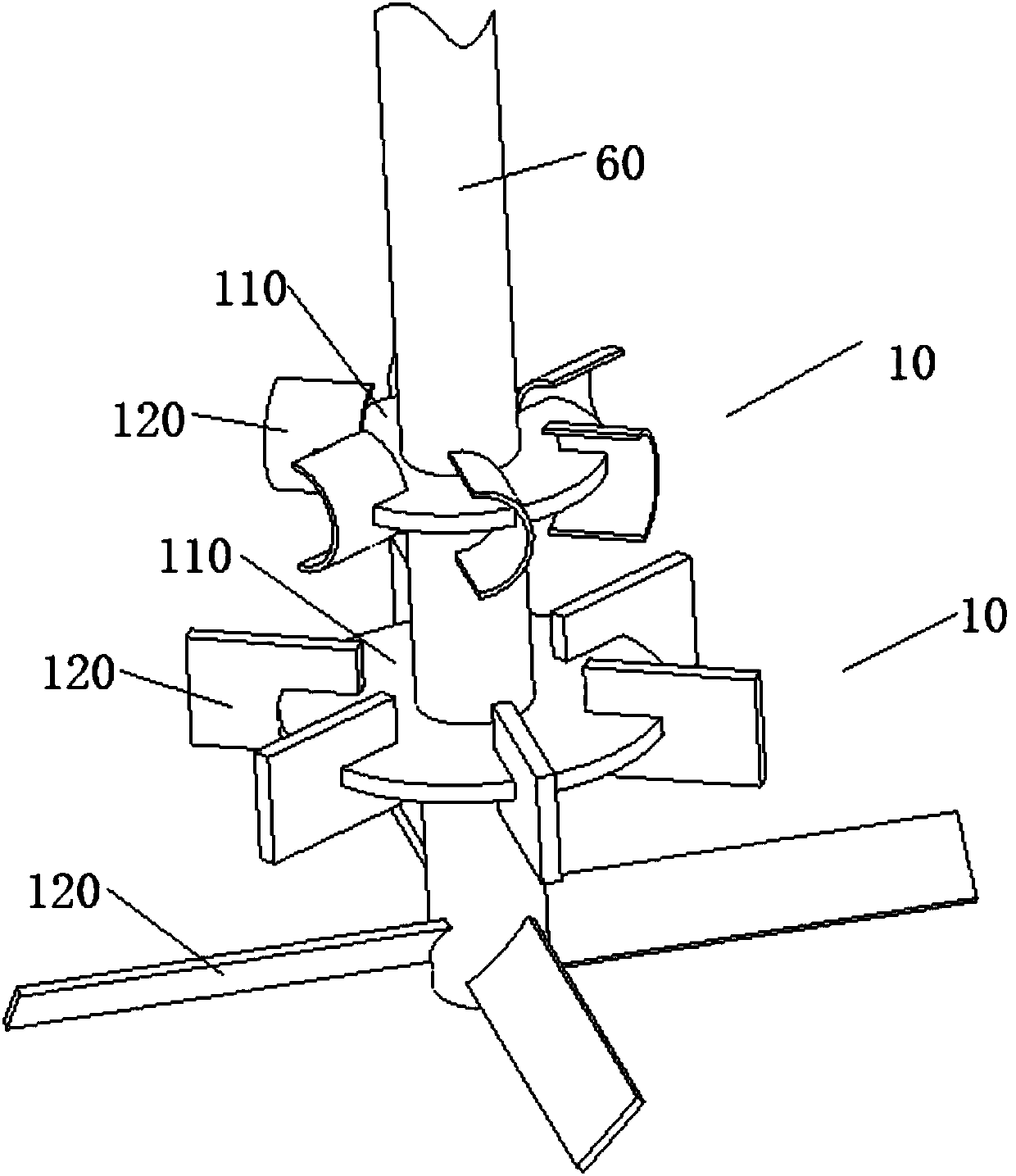

[0057] Such as image 3 As shown, there are a plurality of stirring elements 10 in this example, and the plurality of stirring elements 10 are arranged at intervals along the axial direction of the rotating shaft 60 . The stirring member 10 above includes a hub 110 and paddles 120 , the hub 110 is fixedly connected to the rotating shaft 60 , and the paddles 120 are connected to the hub 110 . The stirring member 10 at the bottom only includes the blade 140 , and the paddle 120 is directly connected to the rotating shaft 60 .

[0058] The application of the gas-liquid mechanical coupling stirring device 1 of this embodiment to achieve a uniform mixing effect is as follows:

[0059] Add 1000kg of mixing material fluid into the mixing tank 50, extend the nozzle of the air jet pipe 220 into the place 150mm below the liquid surface, the gas is sprayed into the mixing space 510 through the air guide pipe 210 and the air jet pipe 220, and at the same time, start the motor 40 to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com