A spiral-type and paddle-type compound agitator with special-shaped dispersing discs and comb spoilers

A spoiler and dispersing disk technology, which is applied in the field of spiral and paddle compound agitators, can solve the problems of affecting product quality, unsatisfactory dispersing effect, and reducing stirring efficiency, so as to increase the coverage of streamlines and flow The field speed range, the stirring performance and the material dispersion effect are good, and the effect of improving the stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

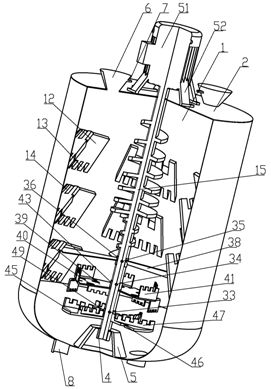

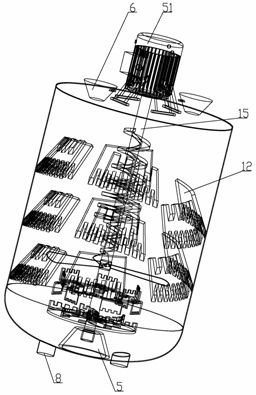

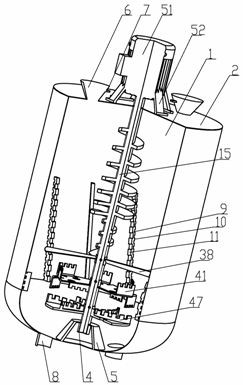

[0029] like Figure 1-Figure 14 As shown, a helical and paddle type composite agitator with a special-shaped dispersing disc and a comb spoiler is mainly composed of a mixing tank assembly, a helical agitator assembly, a paddle agitator assembly, a double-sided helical tooth dispersing Disk assembly, turbine blade type dispersion disk assembly and motor 51; the spiral agitator assembly is fixed inside the stirring tank assembly, the motor 51 is fixed above the stirring tank assembly through a bracket 52, and connected with the spiral agitator assembly, the turbine blade type The dispersing disc assembly is fixed on the lower end of the spiral agitator assembly by bolts, the double-sided helical-toothed dispersing disc assembly is fixed on the lower end of the spiral agitator assembly by bolts, and the double-sided helical-toothed dispersing disc assembly is installed above the turbine blade assembly , the paddle agitator assembly is fixed on the lower end of the helical agitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com