Method and device of treating urban mud by using cement rotary kiln

A technology for cement rotary kiln and municipal sludge, which is applied in the oxidation treatment of sludge, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of reduced mechanical rigidity of conveyor, low thermal reaction effect of reaction cylinder, and inability to form continuous work. , to avoid the loss of heat, increase the stirring effect and overall strength, and improve the reaction speed and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

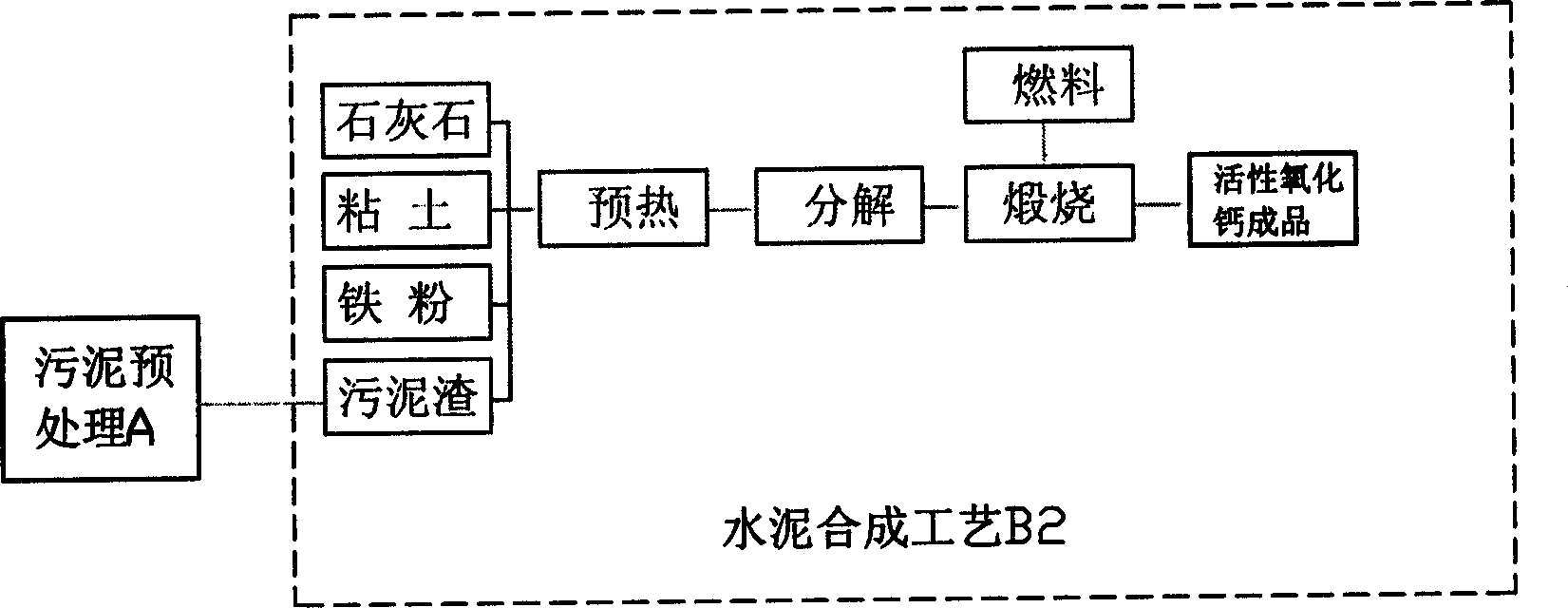

[0044] Concrete embodiment: the main raw material needed for producing one ton of activated calcium oxide is as follows:

[0045] Limestone 756Kg,

[0046] Clay 220Kg,

[0047] Silica 60Kg,

[0048] Iron oxide 30Kg,

[0049] Gypsum 35Kg,

[0050] Sludge residue 324Kg.

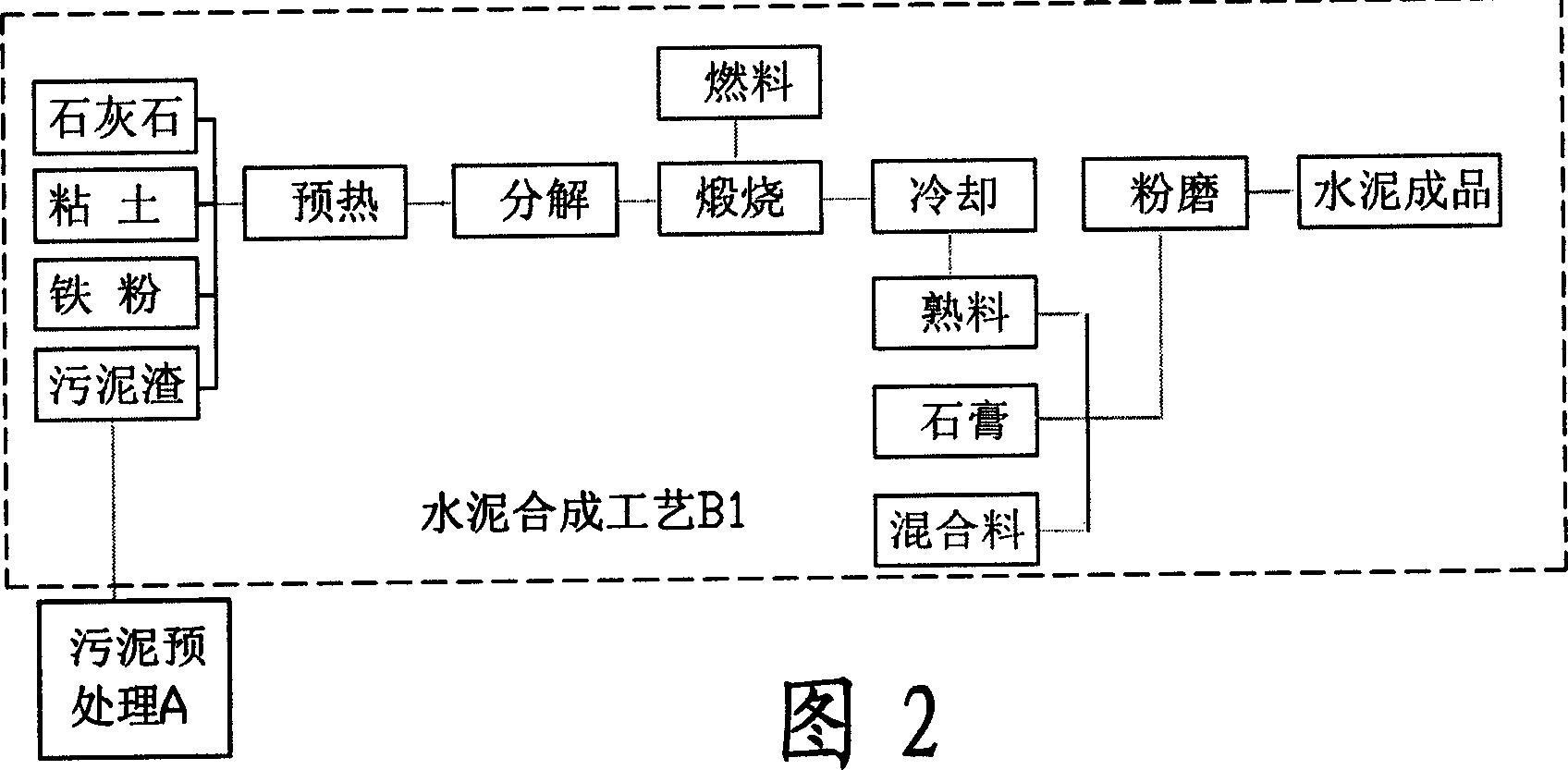

[0051] That is to say, 30% of the limestone is replaced by sludge slag, and after calcining at 1100℃≈1250℃, the finished cement can be produced by using the conventional cement production process, as shown in Figure 2.

[0052] Chemical analysis of the sludge treatment shows that its calcium oxide content is as high as 50%, which can be replaced by calcium oxide in limestone, a common cement raw material. The process of the present invention uses the sludge treatment instead of limestone for batching according to this test result. The chemical compositions of the raw materials used in the experiment are listed in Table 1.

[0053] In order to simulate the experimental situation as much as possible, this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com